The connection of wires in the junction box requires special care in execution. Not only the reliable operation of electrical appliances, but also the safety of the premises depends on how correctly the work is done.

Wires from the electrical panel are distributed to separate rooms of the apartment or house. Moreover, in each room there is usually not one, but several connection points (sockets and switches). To standardize the joining of conductors and concentrate them in one place, junction boxes are used (their other names are: "junction" or "branching"). The boxes contain cables from all consumer devices.

The wires in the box are not laid randomly, but in accordance with clear rules prescribed in the Electrical Installation Rules (PUE). According to the requirements of the PUE, all wire connections in the box, as well as branches, are carried out only inside the junction box. Conductors are guided along the top of the wall, but no closer than 15 centimeters from the ceiling. When the cable reaches the branch, it descends strictly vertically. At the site of the branch is a junction box. The connections in it are made according to the existing scheme.

Junction boxes are classified according to the type of installation. There are internal junction boxes and external ones. A niche is provided for flush-mounted boxes in the wall. Only the cover remains on the surface, which is installed flush with the finishing material. It is allowed to cover the cover with decorative panels. If the thickness of the walls or other circumstances do not allow the installation of an internal junction box, it is mounted directly on the wall.

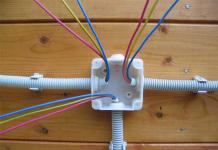

The junction box can be rectangular or round. The number of pins is usually four, but in some cases there are additional pins. Each outlet is equipped with a fitting or thread to secure the corrugated hose. The presence of such a hose or plastic pipe greatly facilitates the process of laying and replacing wires. To replace the wires, it will be enough to disconnect the hose or pipe from the junction box and the consumer, and then pull it out. After replacing the conductors, the hose is returned to its place. If the wires are located in the strobe, you will need to break the layer of plaster, which is much more laborious.

The use of junction boxes entails the following positive results:

- The maintainability of the power supply system is increased. Since all connections are easily accessible, it is much easier to find the damaged area.

- The vast majority of faults are found at the joints. Since all connections are concentrated in one place, it is easier to carry out routine inspections.

- Thanks to junction boxes, the degree of fire safety increases.

- Using junction boxes saves money and reduces labor costs when laying cables.

Ways of connecting conductors

There are many options for connecting wires in a junction box. The choice of a particular method depends on the following factors:

- the material from which the cores are made (steel, copper, aluminum);

- environmental conditions (street / indoor, work in the ground or water, etc.);

- number of wires;

- matches or mismatches of the cross section of the cores.

Based on these parameters, the most appropriate method is selected.

The following methods of connecting wires in the junction box are used:

- terminal blocks;

- Wago spring terminals;

- self-insulating clamps (PPE, or plastic caps);

- twist;

- crimping with sleeves;

- soldering;

- "nuts";

- bolted connections.

Below we consider the features of each of these methods.

Terminal blocks

Terminals are devices made of plastic, the inside of which contains a brass sleeve. There are screws on both sides of the bushing.

To connect the wires to each other, you need to insert a conductor on each side of the terminal block and fix them tightly with screws. This method of docking is most common in distribution boxes, as well as when installing lighting fixtures, sockets and switches.

Note! The inlet holes of the terminal blocks differ in diameter depending on the cross section of the conductors intended for them.

Advantages of the method:

- low cost of terminal blocks;

- simplicity and convenience of installation work;

- reliability of conductor fixation;

- the ability to connect incompatible materials such as copper and aluminum.

Disadvantages of the method:

- The pads offered for sale are often of low quality, which is detected during docking and forces the products to be rejected.

- Only two wires are allowed.

- Terminal blocks are not suitable for aluminum or stranded wires, as aluminum is brittle and stranded conductor strands are too thin.

- Although the method is reliable, a better connection can be obtained, for example, by soldering.

Terminals Wago

Wago spring terminal blocks are one of the most popular devices used when connecting wires.

Unlike standard terminal blocks, in Wago docking is carried out not with screws, but with the help of a special mechanism. The device is equipped with a lever that allows you to fix the conductor, while maintaining its integrity. Before using Wago, you need to remove the insulating layer. Next, the wires are sent to the shoe hole.

Note! There are both disposable and reusable pads on the market. Disposable mounts mean that they can only be used once, and if the wire is replaced, the pads become unusable. Reusable terminals are more expensive, but they can be easily removed and then reused for their intended purpose.

Advantages of Wago spring pads:

- It is possible to connect both conductors from one metal, and dissimilar materials.

- There is the possibility of joining multiple cores (three or more).

- When fixing stranded conductors, thin conductors do not break.

- The pads are small in size.

- Working with pads does not take too much time, the process is not labor-intensive.

- The fastening is of high quality.

- The block has a hole for an indicator screwdriver to control the functioning of the electrical network.

Wago has one drawback - the high cost of products.

Self-Isolating Clamps (PPE)

A self-insulating clamp (or a connecting insulating clamp) is a plastic cap, inside of which there is a special spring for fixing the wire.

The advantages of PPE include the following characteristics:

- Low cost.

- Products are made of non-combustible plastic, therefore, there is no danger of spontaneous combustion of electrical wiring at the docking point.

- Easy installation.

- A wide variety of color shades, which allows you to mark the phase, zero and ground with colors.

The disadvantages of PPE include:

- low fixing and insulating qualities;

- impossibility of application for connection of aluminum and copper conductors.

Crimping with sleeves

Connecting wires in a junction box using sleeves is considered a method that ensures high quality splicing. The essence of the technique is to place the stripped cores in a special tube (sleeve), which is then subjected to crimping by compression. Next, the sleeve is processed with an insulating material, for which a heat shrink tube or ordinary electrical tape is used. Wires can be inserted both from both ends of the tube, and from only one end. In the first case, the joint will be located in the middle part of the sleeve, in the second case, it is necessary that the total cross section of the cores be no more than the section of the sleeve.

Benefits of pressing:

- The connection is of high quality and reliable insulation.

- Affordable prices for sleeves.

Disadvantages of pressing:

- The sleeve cannot be replaced after it has been removed - this is a one-time mount.

- The connection will require the use of a specialized tool (crimping tongs, pipe cutter).

- Crimping of aluminum and copper wires is possible only with the help of a sleeve specially designed for this purpose.

- The work is labor intensive.

Soldering

The connection by soldering is considered the highest quality of all possible. Before docking, it is necessary to clean the conductors well. Next, the bare ends are processed with molten solder, after which the cores are immersed in the bath. When the cores have cooled, insulating material (cambric or electrical tape) is applied to them.

Note! The cooling process should not take place in cold weather, because as a result of too rapid cooling, the material will be covered with microcracks, which will greatly impair the quality of fixing the conductors.

As already mentioned, the main advantage of soldering is the unsurpassed quality of the connection.

Disadvantages of the technique:

- A specialized tool is required, as well as skills in handling it.

- The job requires a lot of work.

- The connection is one-piece, that is, one-time.

- There are restrictions on the use of soldering, which are detailed in the PUE.

- Over time, soldering resistance increases, which affects the form of voltage losses and electrical conductivity.

Thus, despite the reliability of the docking, specialists rarely turn to soldering.

Welding is sometimes used instead of soldering. The essence of this method is the same as in the case of soldering. The only difference is the need for different skills, namely the ability to work with a welding machine.

Twisting

Connecting wires in a junction box using the most primitive method - twisting - is not used so often due to significant limitations: poor bonding quality and the impossibility of joining aluminum and copper conductors. However, twisting is still sometimes found, since it is attractive for its ease of implementation, as well as the absence of financial costs. Most often, twisting is used when laying temporary electrical wiring. It is recommended to use cambric as an insulating material.

Note! Twisting is unacceptable in rooms with high humidity, as well as in wooden buildings.

Clamp type "nut"

"Nutlet" is a cable clamp with two plates and four bolts in the corners. Before connecting, the insulation is removed from the wires. Further, the conductors are fixed in the plate and covered with a carbolite sheath.

Nut Benefits:

- Low costs.

- Installing the "nut" is not very difficult.

- Connection of dissimilar materials (aluminum and copper) is possible.

- Quality insulation.

The disadvantages of the method:

- Fasteners loosen over time and need to be tightened regularly.

- "Nut" is not the best way to mount in the junction box due to the excessive dimensions of the connection.

Bolted connection

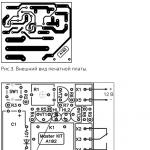

Bolting is a very simple but effective way of joining conductors to each other. To do the job, you only need a bolt, three washers and a nut. The wiring diagram in the junction box with a bolt is shown in the picture below.

A washer is threaded onto the bolt thread. Next, the core is wound (previously, the insulation should be removed). After that, the thread is laid with a second washer and another core. At the end, a third washer is placed, which is pressed with a nut. The connection must be covered with insulating material.

Bolted connection has the following advantages:

- low cost;

- ease of implementation;

- the possibility of joining copper and aluminum products.

Disadvantages of joining conductors with bolts:

- Poor fixation quality.

- You will need a lot of insulating material.

- The bolt is too large and may not fit in the junction box.

Solving other problems

The connection of stranded wires has a number of features.

Connecting multiple wires

Above, the options for connecting two contacts were considered. If we are talking about docking many contacts, it is recommended to choose among the following options (in order of priority - from the best method to the worst):

- Wago terminal blocks;

- sleeve crimping;

- soldering;

- twists;

- insulating tape.

The rules for docking in the indicated ways, as well as their advantages and disadvantages, are discussed above.

Docking lived with different sections

To combine conductors of unequal cross-section in a junction box, you will need Wago terminal blocks, although you can get by with standard terminal blocks - the latter option will be cheaper. In this case, it is necessary to firmly fix the cores with a screw or lever.

Note! If the wires have not only different cross-sections, but are also made of different metals, special pads will be needed, inside of which there is a special composition to prevent oxidative processes. Similar pads are available in the Wago range.

Cores with different cross-sections can also be fixed by soldering.

Splicing of stranded and solid conductors

The combination of conductors with one and many cores is carried out in the same way as all the others. In this regard, you can choose any of the above methods, but the highest priority is soldering or terminals (preferably Wago).

The procedure for carrying out work in land and water

It is not uncommon that there is a need to lay electrical wiring underground or under water. Let us briefly dwell on the features of performing electrical work in these conditions.

Wires can be laid in water, for example, when installing a submersible pump. In this case, you need to solder the ends of the wires. Next, the connection is processed with insulating material (hot-melt adhesive), and heat shrink is put on top. If the technology is followed, the joint will turn out to be very reliable and safe. However, carelessness should be allowed, and the matter will end in a short circuit.

Ground wiring is protected in the same way as described above, however a more advanced technique can be used to obtain a secure connection. The ends of the cable should be pressed with a terminal block, and the sealed junction box should be filled with silicone. It is recommended to place an underground highway in a durable box or pipe to prevent acts of sabotage by rodents. Damaged cable ends are best spliced with sleeves.

Basic wiring diagrams

Above, we talked in sufficient detail about how to connect the wires in the junction box. However, the work is not limited to connecting wires in the junction box. You also need to connect the wires to sockets and switches.

Connecting sockets

A group of outlets is usually separated into an independent line. There are three wires in the box, each of which has a color inherent in its purpose. Brown is usually phase, blue is zero, and green/yellow is ground. In some cases other colors are used. For example, phase is red, zero is blue, ground is green.

The wires before laying are laid out in full length and cut so that they have the same length. It is necessary to have 10-12 centimeters of stock - just in case. The connection of conductors is carried out by one of the methods described above.

If only a pair of wires is involved (where ground is not used), then we are talking about a neutral and a phase. If the conductors are of the same color, you first need to find the phase using a multimeter. For convenience, it is better to mark the phase wire with electrical tape or a marker.

Connecting a one-button switch

In the case of the switch, there are also three groups, but the connection is made a little differently. There are three inputs: from the junction box or electrical panel, from the lighting fixture, from the switch. The phase wire is connected to the switch button. From the output of the switch, the wire is directed to the lamp. In this case, the lighting device will work only when the contacts of the switch are closed.

Connecting a two-button switch

In two-gang switches, the circuit is somewhat more complicated. A three-wire cable must go to the switch that serves two groups of lighting fixtures (if earth is not used). One conductor is intended for the common contact of the switch, the remaining two are directed to the exit of the buttons. The phase is combined with the common contact of the switch. Zero wires from the input and two groups of lighting fixtures are connected. Phase wires from lighting devices and two conductors from the switch are combined in pairs: one - from the switch to the phase of one of the lamps, the second - from the switch to another lamp.

When repairing electrical wiring on your own, special attention should be paid to connecting wires in junction boxes, because electrical engineering, as electricians say, is the science of contacts, both desirable, providing an uninterrupted supply of electricity, and unacceptable, due to which many accidents and accidents happen.

In this article, with the help of links to other materials of this resource, all the baggage of the minimum knowledge and skills necessary for a home master for a successful electrical installation will be presented, and the entire process of connecting wires in a junction box will be described step by step, starting from the preparatory stages, ending with the introduction of a mounted home network into operation.

The scheme is the most important step

For an experienced electrician, it will not be difficult to connect a switch and a light bulb without a drawing, by making a wire connection in a junction box, guided by the color coding of the cable cores or by the results of the dialing of the already laid wiring.

But for experienced craftsmen, such work is obtained only because connection diagram clearly imprinted in the mind through many years of practice.

A simple wiring diagram in a junction box when connecting a switch and a light bulb

A simple wiring diagram in a junction box when connecting a switch and a light bulb If the master needs to conduct electrical wiring at any object, then he will begin first of all with the design of the circuit, if other specialists have not done this before him. Of course, there are standards, GOST and SNiP, according to which all electrical wiring drawings are made, but for an apartment or a private house, a diagram drawn by hand is suitable, the main thing is that it subsequently works properly and safely.

This approach not only insures against errors, but also saves time by dividing labor - by carrying out electrical wiring in a junction box, the electrician will not be distracted by drawing up a wiring plan, while trying to keep the planned lines and connections in his head.

A more complex wiring diagram for a two-gang switch

A more complex wiring diagram for a two-gang switch Examples of schemes for and apartments can be viewed by clicking on the links. You will also need to familiarize yourself with the graphic symbols of the network elements so that you can consult a familiar master by showing him a diagram, or in the future carry out electrical wiring repairs by referring to the saved drawing.

The importance of planning electrical wiring is also determined by rationality and economy. When drawing up a wiring diagram, you need to plan in such a way that there are as few junction boxes in the apartment as possible, because each connection of wires increases the risk of losing contact.

An example of a hand-drawn wiring diagram (blue circles represent junction boxes)

An example of a hand-drawn wiring diagram (blue circles represent junction boxes) When connecting one outlet or switch, many electricians advise to do without a junction box altogether and connect the wires in the socket. This decision is due to the unwillingness of the apartment owners to provide access to the junction box, as required by the PUE (in their opinion, the interior of the dwelling is deteriorating). The socket or switch is easily disassembled, which provides access to the connection of wires in the socket.

Quote from PUEA detailed story about the various wiring diagrams in junction boxes is shown in the video:

Correct pin marking

In order to connect the wires in the junction box according to the diagram without undue doubt, it is necessary that the conclusions of the laid electrical wiring be marked. Very often, disconnection (separation of the main wiring line into several branches) is done when all the wires are already laid and hidden under plaster, and there will be no way to visually trace the purpose of the cables.

It is easy to get confused without being sure about the purpose of the same cables.

It is easy to get confused without being sure about the purpose of the same cables. In order not to waste time on cables, which is also described on this site, you need to mark their ends at the stage of laying the cables. In some cases, if there are few wires in the junction box, you can navigate by the color of the insulation of the current-carrying cores. But with a large accumulation of cables, the colors of the wire insulation will be repeated, so the likelihood of an error increases.

To exclude the possibility of incorrect connection, it is necessary mark termination of the laid cables in any available way. The industry produces many different tags designed for marking pins. Very often, electricians use transparent heat shrink tubing, inserting a strip of paper with a terminal symbol inside.

Samples of industrially produced cable marking tags

Samples of industrially produced cable marking tags You can also use transparent tape, wrapping labels with inscriptions around them. In extreme cases, use a marker or felt-tip pen to write the designations directly on the insulation of the wires or on the wall - but there is a risk that the inscriptions will be erased during the installation process.

Marking of electrical wiring conclusions is made on the wall

Marking of electrical wiring conclusions is made on the wall You should also strictly adhere to the color marking of the cables (brown, red, black - phase, blue - working zero, green with yellow stripes - protective conductor PE).

Generally accepted color marking of cable core insulation

Generally accepted color marking of cable core insulation Junction box installation

Before starting wiring, make sure that the junction box is securely fixed. , which depend on the type of wiring, are also described on this site. The importance of fixing is due to the possibility of damage to already connected wires when manipulating the junction box and cables.

When working with single-core wires, frequent bending of current-carrying wires should be avoided. Stranded wires, although they allow frequent bends, but mechanical loads and the weight of a loose cable of hanging electrical wiring can damage an already finished connection, so it is important not to violate the wiring technology.

PUE requirement for fixing cables and boxesIf hidden wiring is installed in a brick or concrete wall, then the wires are laid in a groove made manually or with the help of tools (chasing), and the sockets and junction boxes are mounted in holes that are drilled in the wall using a special crown. Fixation is carried out with plaster or alabaster.

Drill bit for junction boxes

Drill bit for junction boxes Each type of wire connection requires a specific lead length. For example, when using very bulky connector blocks that have bolted connection terminals, the craftsmen try to leave as little free length of wires as possible so that all connections fit in the box.

But, if wire welding is used, then the length of the bare conductors should be about seven centimeters in order to prevent the insulation from melting during strong heating, plus the length of the insulated cores for convenient and safe installation. Long, bare, connected wires are insulated and placed in a junction box.

Wire connections are made by welding

Wire connections are made by welding The above examples mean that regardless of the chosen method of connecting the wires, the length of the leads protruding from the junction box must be at least ten centimeters, because excess conductors can always be cut off, but it will be extremely difficult to build them up, and the reliability of the entire wiring line will deteriorate. .

Conductor preparation

At this stage, the master must finally decide how to connect the wires in the junction box, and accordingly prepare guides- remove the insulation and bend the cable cores. The list of existing types of wire connections is given below, and now, regardless of the method chosen, special attention should be paid to the quality of stripping and preparation of conductors for electrical installation.

Stripped wires ready for connection in the junction box

Stripped wires ready for connection in the junction box To carry out any electrical installation, the master must have, which you can familiarize yourself with by clicking on the link. At this stage, the wires are prepared for connection - stripping from insulation. This process should be taken with special care, since when using improvised means (knife, pliers, wire cutters), imperceptible damage to current-carrying wires is possible.

Professional electrician's tool kit

Professional electrician's tool kit When wires are bent and reassembled, subtle cracks in the metal can grow larger, impairing electrical conductivity and can lead to breakage and loss of contact. At high currents in the thinnest section of the circuit (in the place of the crack), a large amount of heat will be released, which can heat the insulation and even the conductor metal itself to a melting point.

With a high current in a broken conductor, an avalanche-like process occurs - when heated, the resistance of the material increases, which further increases heat generation. This process ends with the melting of the metal of the conductor and the occurrence of an electric arc, which, by burning other wire connections in the junction box, renders them completely unusable.

Photo of burning an electric arc in a junction box

Photo of burning an electric arc in a junction box Without a doubt, a real master, even with the help of a kitchen knife, will be able to carefully and quickly remove the insulation without damaging the current-carrying core. But it will be very difficult for people without experience to avoid subtle damage to the material of the conductors, therefore, in order for the connection of wires in the junction box to be of high quality, it is necessary to use special ones (strippers).

Variety of stripping tools

Variety of stripping tools Many have seen the picture that some masters remove the insulation with the help of teeth. It is absolutely not worth following this example, in which case the purchase of a professional stripping tool will cost less than the services of a dentist.

An overview of the various stripping tools is shown in the video:

Wire connection methods

As already mentioned, for various methods of connecting wires to a junction box, there is its own wiring technology, which consists in the length of the stripped conductors, their bending and the use of appropriate tools.

Since each of the possible methods has many specific nuances and requires the use of special tools and skills, below, in the form of a list with links, are the types of wire connections:

- Terminal blocks;

- PPE caps;

- Connecting sleeves;

- Conductor welding.

Wiring in the junction box using terminal blocks

Wiring in the junction box using terminal blocks Each of the above methods has its own advantages and disadvantages, which you must familiarize yourself with by studying the materials by clicking on the links provided. Choosing the type of connections for do-it-yourself wiring should be based on the availability of tools, skills, the possibility of acquiring materials and the expected quality of contacts.

Most reliable wire welding is considered, but it requires a special welding machine and specific skills. Soldering conductors, which also has good characteristics, requires soldering iron skills. Wago terminal blocks are quite easy to install, reliable with properly selected products according to the load, they allow the connection of stranded wires without the use of special lugs, but you should beware of fakes.

Connections in the junction box are made using Wago terminal blocks

Connections in the junction box are made using Wago terminal blocks The use of sleeves is reliable, with the use of special products it is possible to connect copper and aluminum, but the connection itself requires special tongs and is non-separable, which does not give a chance for an easy correction of wiring errors. PPE caps are reliable if the technology is followed and the diameter is correctly selected. Terminal blocks require bolted connections to be securely tightened.

PPE caps in the junction box

PPE caps in the junction box It should be remembered that according to the PUE, twisting of wires is not allowed in its pure form.

Twisting in its pure form is not included in the list of connections allowed by PUE

Twisting in its pure form is not included in the list of connections allowed by PUE Testing wire connections in junction boxes

After all connections are made, the exposed sections of the conductors are insulated with heat shrink tubing, and the wires are laid in junction boxes. The boxes themselves are left open until testing of the installed wiring. First, the connected lines are energized by turning on the appropriate circuit breakers.

Insulation of connections in the junction box with heat shrink tubing

Insulation of connections in the junction box with heat shrink tubing If, after switching on, nothing sparked anywhere and the machine did not knock out from a short circuit due to an erroneous connection of wires or poor-quality insulation of connections, they carry out tests electrical wiring with load current (loading), which is carried out by connecting various electrical appliances to the mounted lines. It is recommended to load each line with the maximum allowable current.

The download should take some time (preferably several hours). During this period, possible defects in electrical installation will have time to manifest themselves. A visual inspection of the connections in the junction boxes should be made - signs of high temperature will be visible by melting the insulation or terminal blocks. It is also important that there is no characteristic smell of overheated or burnt insulation.

Melted insulation of one of the connections in the junction box

Melted insulation of one of the connections in the junction box After removing the voltage, check all connections by touch - they should not be hot. If, when loading the wiring with the maximum rated current for several hours, no remarks were found regarding the operation of the connections, then the wiring is considered normal, the junction boxes can be closed and the wiring put into operation.

The correct connection of the wires in the junction box is in many ways the key to the reliability of your electrical network. Indeed, unlike the connections in the switchboard, distribution boxes, or as they are also called, junction boxes are more closed for maintenance and contact connections are much more difficult to check here. That is why, even at the stage of installation, their quality and correctness should be given maximum attention.

Before connecting the wires in the junction box, we advise you to study the rules for their installation. After all, it is important not only to qualitatively connect the wires to each other, but also to correctly bring them into the junction box, and also conveniently position them for possible inspection or repair.

Rules for installing wires in a junction box

First of all, let's look at the rules for arranging and installing wiring in a distribution network. After all, it is with this factor that any installation begins.

So:

- First of all, it should be remembered that no more than eight groups of wires are allowed in one strobe, box or pipe.

- All connections must be made in accordance with paragraph 2.1.17 - 2.1.30 of the PUE. These paragraphs provide for a range of restrictions. First of all, remember that the wire in front of any contact must have a margin sufficient for at least one reconnection.

- Before connecting the wires in the junction box, make sure that they are not under tension.. Or that this tension will not occur during temperature changes.

- Any wire connection points must be accessible for repair and inspection.. At the same time, these places should be organized in such a way that inspection is not hindered by structural elements.

- Any connection must be insulated. However, this insulation must correspond to the level of basic insulation. To achieve these parameters, it is better to use electrical tape or heat shrink.

- The junction boxes themselves must be made of non-combustible or slow-burning materials. like in the video. This is especially true for the installation of wiring on combustible structures, which are subject to additional requirements.

Options for connecting wires in a junction box

First of all, let's look at how to connect wires in a junction box. After all, it is contact connections that are often the most vulnerable point of any electrical network, and any flaws appear very quickly.

According to clause 2.1.21 of the PUE, all connections of wires and cables must be made by welding, soldering, crimping, screw or bolt clamping. Other connection methods, especially twisting, are not allowed. Based on this, let's consider each of the possible connection methods separately.

So:

- The most reliable is the connection of wires by welding.. It has the lowest transient resistance, as a result of which there is practically no increased heating. In addition, over time, such a connection does not lose its properties.

Welding of wires in the junction box is carried out using a special welding transformer and a carbon electrode. The cost of such products is high enough for a simple replacement of wiring in an apartment, so you can often find home-made devices. Usually these are transformers up to 600 W and voltage 9 - 36V.

- In second place in terms of reliability is the connection by soldering. This method is more affordable for home use because it does not require special equipment other than a conventional soldering iron.

Soldering wires in the junction box is carried out according to the usual technology and does not impose special requirements. The only thing worth paying attention to is the quality of such connections. Indeed, in the case of heating, the tin heats up quickly enough and the contact will disappear. In order to prevent this, soldering is often combined with a twist connection.

- Crimping wires has become increasingly popular in recent years. Indeed, a large number of fairly cheap tools for crimping wires have appeared on the market, and the price of consumables for this method is quite low.

- But the most common is still the method of screw or spring clamp cores. A huge number of tires and terminals on the market now allow for a fairly reliable connection of wires.

All cables coming from electrical panels in walls or boxes in the floor or in the attic come to junction boxes, where they are twisted, soldered or welded or connected with clamps. In this article I want to show how to connect the most common connections, this is a one-gang, two-gang, through switch.

And so, after laying the cables at the junction, hidden or overhead junction boxes are mounted, bringing the ends of the cables into them, the secret ones are coated with gypsum or glue, overhead on 2 nail dowels, then the top insulation of the ends is removed, the excess length of the wire is cut off, about 3-4 cm is cleaned for twisting wires, and at the end they are twisted, insulated with PPE, we settle the connections by spreading them in different corners of the box.

Wiring diagrams, cable terminations in the junction box

It is easiest to connect the wires in the junction box that feed only the sockets, just twist all the cables by color, but if at least one switch is connected, the circuit becomes more complicated.

Distribution connection example boxes with one single-gang switch

Single switch connections

double switch and socket

- should get 4 solderings

Junction box installation: Video

How to connect a switch from an outlet with your own hands

Connect the switch to the outlet

Connecting the switch from the outlet is a procedure, although not very complicated, but often helps to solve a lot of problems.

First of all, this concerns the issues of additional connection of lighting systems.

Indeed, thanks to such a connection, we can significantly save not only on wires, but also on the number of additional works, such as wall chasing.

Therefore, if you are faced with the problem of connecting additional lighting and do not want to renovate the room in a new way, this option will be the ideal solution.

Preparatory work

Before proceeding directly to the connection process, you should perform a number of preparatory work and determine the location of the future switch.

To the preparatory work, we include work related to the choice of wire, the switch itself and the circuit that it will power.

Wire selection

Before you connect the switch from the outlet, we should choose the right wire that will be connected.

After all, the correct choice of wire will significantly reduce the likelihood of a fire or other breakdowns.

- To select a wire, we should know the rated power of the switched electrical appliances, from which it is then not difficult to derive the rated current. This is done with a formula.

Detailed socket connection diagram

where I is the rated current, P is the rated power, and U is the rated voltage, which for a single-phase network is 220V.

- Having calculated the rated current, we can use Table 1.3.4 of the PUE for copper conductors or Table. 1.3.5 for aluminum wires, to select their nominal cross section (see Calculating the wire cross section by power).

Summary table for selecting the cross-section of conductors by rated current

Note!

In most cases, when the switch is connected from the outlet, it switches one or two light bulbs. Because of this, the rated current is small and, according to Table. 1.3.4 and 1.3.5 you can use a wire of small cross section. But according to Table 7.1.1 PUE, the cross section of this wire in any case cannot be less than 1 mm 2 for copper wire or 2.5 mm 2 for aluminum.

- Another aspect to consider when choosing a wire is the way it is routed.

Indeed, in the case of its laying indoors in an open way on insulators, according to Table 2.1.1 of the Electrical Installation Code, its minimum cross section should be 1.5 and 4 mm 2, respectively, for copper and aluminum wires.

- If the wire will be used for outdoor laying in an open way on rollers or insulators, then its cross section should generally be at least 2.5 and 4 mm 2, respectively, for copper and aluminum wires.

Switch selection

Before you power the switch from the outlet, it is important to choose the switch itself correctly.

This aspect is often neglected, which is why circuit breakers often fail. This aspect is especially important if the switch will switch large loads.

- First of all, we select the switch according to the rated current.

When choosing a wire, we have already calculated the rated current of our network, therefore, using the same numbers, we select the rated current of the switch. At the moment, models in 6, 10 and 16A are presented on the market.

You can find more powerful switches, but they are rare.

- The next important selection factor is the way the circuit breaker is mounted. For hidden wiring, a recessed version of the switch is used, and for open wiring, respectively, with an outer box.

Here the choice depends entirely on the method of laying your electrical wiring. The only exceptions are bathrooms and showers, in which clause 12.22 of VSN 59 - 88 recommends using only concealed wiring. But given that it is forbidden to place switches in these rooms, the method of mounting the switch can be any at your discretion.

The photo shows different types of switches.

- Also, our instructions advise taking into account the installation location of the switch.

For outdoor installation, switches with IP not lower than 44 should be used. Of course, it is better to use switches with a higher degree of dust and moisture protection, but the price of such models increases in proportion to the level of protection.

We connect the switch from the socket

There are two options for how to power the switch from the outlet.

These methods do not differ fundamentally, and by and large the choice of each of them is carried out based on the location of the fixtures themselves.

If the lamp is located next to a switch or socket, then it is advisable to connect the "zero" directly from the latter.

If the luminaire is far enough away, then in order to save wires and make it more aesthetically pleasing, it is better to connect the neutral wire in the junction box.

Connecting the phase and neutral wires from the socket

The easiest way to make a switch from an outlet is to power both the phase and neutral wires directly from the contacts of the latter.

This method will be very convenient when the lamp is located in the immediate vicinity of the switch.

- In order to do it yourself, you first need to mount the lamp and switch. Only then should you proceed directly to the connection.

- At the first stage, we remove the voltage from the outlet. This can be done with a group circuit breaker for a specific group.

If you do not have a division into groups, then you will have to relieve tension from the whole apartment.

- At the next stage, we open the outlet to which the connection is to be made. and check the absence of voltage.

- If the wiring in your apartment or house is made in accordance with paragraph 1.1.29 of the PUE, then the blue wire is the neutral wire, the yellow-green wire is the protective wire, and the third wire is the phase wire.

If you have not completed the color designation, then briefly apply voltage to determine the wires.

- Now we connect a wire to the phase contact of the socket, which we attach with the second end to the input of the switch. We connect a wire to the switch output, which is connected directly to the lamp.

Connection diagram of the phase and neutral wires from the outlet

Note!

If a two- or three-gang switch is used, then the wires from the switch terminals are connected to the corresponding fixtures. The rest of the wiring diagram is identical.

- We attach a wire to the zero contact of the socket, which is attached to the output of the lamp with the second end. We also connect the protective wire to the corresponding contact of the lamp.

- This completes our connection.

Now you can lay the wires, insulate the live parts and apply voltage to test our circuit.

Connection from the socket only phase wire

Since only the phase wire opens in the switch, it is sometimes much easier to take only the phase wire from the socket.

The neutral wire is easier to connect directly to the junction box closest to the lamp.

Thanks to this, you will not only save wires, but also greatly facilitate your task of laying wires.

- Before you hold the switch from the outlet, as in the first option, you should remove the voltage from the outlet.

In addition, we should remove the voltage from all the wires passing in the junction box, in which the neutral wire is to be connected.

- Now we open the outlet and check the absence of voltage. We attach a wire to the phase output of the socket, which is also connected to the input of the switch. And the wire from the output of the switch is connected directly to the lamp.

- Now open the junction box.

Determine the neutral wire. Perhaps it will even be a whole tavern with neutral wires. We connect a wire to it, which we then connect to the lamp. In the same way, we connect the protective wire to the corresponding contacts in the lamp and in the junction box.

- After laying and insulating the wires, you can apply voltage and test the performance of our circuit.

Scheme for connecting the switch from the socket only with a phase wire

Note!

Due to the fact that only one phase wire is needed for the normal operation of the switch, the question: how to remove the socket from the switch has an unambiguous answer - no way. Unfortunately, the socket cannot be connected from the switch.

It is only possible to connect the phase wire, and the zero lead from the junction box. But this option is not the best. After all, often the current at the outlet is much higher than at the lighting network, and the wire of a small section of the lighting network, when connected to it, will also simply burn out the socket.

Hello dear visitors.

On our website sesaga.ru information will be collected on solving hopeless, at first glance, situations that arise in you, or may arise, in your home daily life.

All information consists of practical advice and examples on possible solutions to a particular issue at home with your own hands.

We will develop gradually, so new sections or headings will appear as the materials are written.

Good luck!

About sections:

Home radio- Dedicated to amateur radio.

Advice 1: How to connect another one from one outlet

Here will be collected the most interesting and practical schemes for devices for the home. A series of articles on the basics of electronics for beginner radio amateurs is planned.

Electrician- Detailed installation and circuit diagrams relating to electrical engineering are given.

You will understand that there are times when it is not necessary to call an electrician. You can solve most of the questions yourself.

Satellite- describes the principle of operation and configuration of satellite television and the Internet

Computer“You will learn that this is not such a terrible beast, and that it can always be mastered.

We repair ourselves- illustrative examples are given for the repair of household items: remote control, mouse, iron, chair, etc.

Miscellaneous- a large section covering a wide range of topics.

These are hobbies, hobbies, useful tips, etc.

Useful little things- in this section you will find useful tips that can help you solve everyday problems.

For the home gamer- the section is entirely devoted to computer games, and everything connected with them.

Reader's work- the section will publish articles, works, recipes, games, readers' advice related to the subject of home life.

Dear visitors!

The site has posted my first book on electrical capacitors, dedicated to novice radio amateurs.

By purchasing this book, you will answer almost all questions related to capacitors that arise at the first stage of amateur radio training.

Dear visitors!

My second book on magnetic starters is posted on the site.

By purchasing this book, you will no longer have to look for information about magnetic starters.

Everything that is required for their maintenance and operation, you will find in this book.

Dear visitors!

The third video for the article How to solve Sudoku has been released.

The video shows how to solve a difficult Sudoku.

Dear visitors!

A video has been released for the article Device, circuit and connection of an intermediate relay. The video complements both parts of the article.

Parallel and serial connection of sockets and switches: how to connect a socket with ground

Do-it-yourself installation and connection of sockets and switches is a simple process that can be performed with certain knowledge.

When installing electrical wiring in an apartment, you need to know what a socket connection diagram is. In addition to the installation of simple single-phase electrical outlets with or without grounding, three-phase electrical outlets are required for individual electrical appliances operating on a 380-volt network.

Currently, the most common socket blocks of several units or a block of sockets and a switch. All units of the socket group are connected only using a parallel connection, it is impossible to connect in series in the block.

Of the parallel connections, the most popular is the connection of the outlet with a loop.

Socket and switch connection diagram: loop, series, parallel

Let's look at how to connect an outlet or a block of several units.

You can connect electrical outlets in parallel through a junction box or using terminals, this method is also called a daisy chain connection. When connecting electrical outlets with a loop, the cable is connected to the first unit of the block, and the cable for the next block is powered from the last one. Daisy-chaining requires mandatory independent socket outlet disconnects. To do this, the conductors are connected to neutral conductors through terminals or soldering.

Zero and phase are connected to the first electrical outlet. A clamp is placed on the ground wire, from which a ground wire is connected to each of the units.

How to connect wires in a junction box

To connect the second socket block, you need to connect the phase and working zero from the last unit of the first block, and the ground wire to the compression.

Now consider connecting a conventional single-gang switch.

To do this, we connect the phase wire to the switch using the clamp marked with the English "L" or the arrow "out", connect the zero to the clamp with the arrow "in" or the letter "N". Both wires are securely fastened. Since grounding is not used in the switches, we cut off the excess wire and isolate it.

Another topical question: "How to connect the switch from the outlet"?

To do this, it is better to use a block consisting of an electrical outlet and one or more switches. A new cable is laid from the junction box. On one core of the cable, the phase is directed to the switch, and on the other, the working "zero" to the outlet. The rest of the wires pass to the lamps through the switches. From the junction box to the fixtures, 3-core wires are laid (zero, ground and phase).

How to connect a double socket and a triple, three-phase and three-wire (ground)

When connecting a double or triple socket block, the supply wires are connected to different conductive plates.

If these are separate electrical outlets, we connect them using a parallel connection, for example, a loop, as described above.

Now let's look at how to connect a grounded socket (three-phase). All three-phase electrical outlets are distinguished by the presence of four contacts for a three-phase plug (the fourth is ground or zero).

The socket with grounding is connected using a separate four-wire wiring (three phases, ground and zero), stretched from the electrical panel. The wires are connected to the same contacts on the electrical outlet.

Find out more about connecting outlets

Why is serial connection so rarely used?

If you are thinking about how to connect sockets in series, then you should remember that such a scheme has two unpleasant features:

- The voltage in the assembled circuit rises from the first socket to the next.

And an increase in voltage, in turn, leads to increased heating of sockets and plugs, as well as to an extra load on electrical appliances.

- Since the scheme involves powering each outlet from the previous one, damage to one of them will lead to the failure of all those following it.

It makes sense to use the series connection of sockets in cases where these power points will be used for low-power electrical appliances - small lamps, phone and laptop chargers, hair dryers, etc.

e. For power three-phase sockets in the kitchen, such a scheme can be simply dangerous.

What is the best parallel connection?

Parallel connection of outlets, unlike serial connection, ensures the independence of each power point. The voltage will always be uniform - no matter how many sockets in the circuit participate. And the performance of each individual power point does not affect all the others at all. Such a scheme is the most stable and safe for household appliances, and it has one minus - more wire consumption.

Parallel connection is used not only on free-standing sockets, but also in blocks of two or more pieces.

All the advantages of such a scheme in this case are preserved. True, the connection process itself will be more laborious and long.

How to connect the switch and socket?

The wiring diagram for the switch and socket may be different. For example, this is how it will look for a block of sockets and a switch:

- From distribution

boxes to the block we pull a three- or, if there is no grounding, a two-core cable. We connect the phase, zero, and ground, if any, to the outlet.

- Further from the socket, we clamp the phase into the switch terminals.

- From the switch, we pull the phase to the lamp and so we connect them.

- From distribution boxes to the lamps we lay zero and earth.

And one more scheme. It is not complicated, and is suitable for a switch located separately from the outlet:

- From the outlet, the phase is conducted through the switch and connected to the fixtures.

- Zero and earth for lamps also stretch from the outlet.

As you can see, the circuits are different, but they have one general rule: the phase must be broken by a switch.

Grounded outlet: what to do if the wiring is two-wire?

Connecting a grounded outlet is not difficult if the wiring in the apartment or house is three-core.

But in buildings where the network was divorced many years ago, the wiring, as a rule, is in two cores: phase and zero. In this case, the problem can be solved in two ways:

- There is always a switchboard on the landing, with grounding.

It is necessary to extend the contact from it to the apartment, and distribute grounding through the bus already throughout the apartment. It is better to use a wire with a copper core.

- Performing the so-called "zeroing".

Here, zero is connected to the terminals of the ground contact. This method should be used only as a last resort, as there may be problems in the operation of sockets with grounding.

How to connect the socket to the wires?

There is nothing difficult in how to connect the wires to the outlet. First, we prepare the wire: we remove the outer insulation by about 10 cm, and we clean the wires by 1.5 cm.

This is done with a special tool or any convenient knife. We remove the protective plastic cover from the socket, and then unscrew the clamping screws - so that between their caps and the base of the clamp there is a space of approx. 5 mm. We also unscrew the screw on the ground terminal. The electrical outlet is now ready to be connected. Stripped wires - phase, zero and ground, put one at a time into their nest and tighten them tightly with screws.

There is another option for attaching wires to an outlet.

We clean each core by 2 cm and turn the bare horses into rings with such a diameter that the legs of the screws enter them. We unscrew each screw in turn and put the ends of the wires twisted into rings under it. Insert the screw back and tighten tightly. This assembly is more reliable, but takes more time.

How to connect a triple switch?

A triple socket is connected in parallel or in series, they are described above.

The triple switch can also be connected in two ways:

- From an outlet. Zero and earth on the lamps at the same time come from the socket or from the junction box.

- from the junction box. The phase goes to the switch and is connected to the key terminals.

Then the cores are returned to the junction box and from there they are bred to the lamps. Zero and earth go from the box to the fixtures directly.

The second method is preferable, since in the first case, if the outlet fails, the switch will also stop working.

How to connect a double outlet if the wiring is done for a single one?

To work, you will need a double socket with a double socket, a piece of a three-core cable (approx.

25 cm) and tools for cutting and stripping wires. The connection is made like this:

- We pull the wires into the left socket of the socket.

- We cut off a piece of cable, we clean the cores from both ends.

- We put the cable into the socket so that its ends come out of both sockets.

- In the left nest, we twist the wires of the wiring with the wires of the cable in pairs - phase with phase, zero with zero, etc.

Next, we make the connection of wires with sockets, in the usual manner.

Electricity is an area in which everything must be done correctly and thoroughly. In this regard, many prefer to figure it out on their own, rather than trust strangers. One of the key points is the connection of wires in the junction box. Firstly, the correct operation of the system depends on the quality of work, and secondly, safety - electrical and fire.

What is a junction box

From the electrical panel, the wires diverge through the premises in the house or apartment. In each room, as a rule, there is more than one connection point: there are several sockets and a switch for sure. To standardize the methods of connecting wires and assemble them in one place, junction boxes are used (they are also sometimes called branching or junction boxes). Cables from all connected devices are brought into them, the connection of which takes place inside the hollow body.

In order not to look for wiring during the next repair, it is laid according to certain rules that are prescribed in the PUE - Rules for the Installation of Electrical Installations.

One of the recommendations is to conduct all connections and branches of wires in the junction box. Therefore, the wires are allowed along the top of the wall, at a distance of 15 cm from the ceiling level. Having reached the branch point, the cable is lowered vertically down. A junction box is installed at the branch point. In it, all the wires are connected according to the required scheme.

According to the type of installation, junction boxes are internal (for flush mounting) and external. A hole is made under the internal ones in the wall, into which the box is built. With this installation, the cover is flush with the finishing material. Sometimes during the repair process it is covered with finishing materials. However, such installation is not always possible: the thickness of the walls or finishes does not allow. Then a box for outdoor mounting is used, which is attached directly to the wall surface.

The shape of the junction box can be round or rectangular. There are usually four conclusions, but there may be more. Conclusions have a thread or fitting, to which it is convenient to attach a corrugated hose. After all, it is more convenient to lay wires in a corrugated hose or a plastic pipe. In this case, it will be very easy to replace the damaged cable. First, disconnect it in the junction box, then from the consumer (socket or switch), pull and pull it out. Tighten a new one in its place. If you lay it in the old fashioned way - in a strobe, which is then covered with plaster - you will have to hollow out the wall to replace the cable. So this is the recommendation of the PUE, which is definitely worth listening to.

What do junction boxes generally give:

- Increased maintainability of the power supply system. Since all connections are accessible, it is easy to identify the area of damage. If the conductors are laid in cable channels (corrugated hoses or pipes), it will also be easy to replace the damaged section.

- Most electrical problems occur in the connections, and in this installation option, they can be inspected periodically.

- Installing junction boxes increases the level of fire safety: all potentially dangerous places are in certain places.

- Requires less money and labor than laying a cable to each of the outlets.

Wire connection methods

In the box, the conductors can be connected in different ways. Some of them are more difficult, they are implemented, others are easier, but if executed correctly, they all provide the required reliability.

Twisting

The most popular method among craftsmen, but the most unreliable. It is not recommended by the PUE for use, as it does not provide proper contact, which can lead to overheating and a fire. This method can be used as a temporary one, for example, to check the operability of the assembled circuit, with a mandatory subsequent replacement with a more reliable one.

Even if the connection is temporary, everything must be done according to the rules. The methods of twisting stranded and solid conductors are similar, but have some differences.

When twisting stranded wires, the procedure is as follows:

- the insulation is stripped 4 cm;

- conductors unwind by 2 cm (pos. 1 in the photo);

- are connected to the junction of non-untwisted conductors (pos. 2);

- the veins are twisted with fingers (pos 3);

- the twist is tightened with pliers or pliers (pos. 4 in the photo);

- insulated (duct tape or heat shrink tubing put on before the connection).

Connecting wires in a junction box with one core using twisting is easier. The conductors, cleared of insulation, are crossed and twisted with fingers along the entire length. Then they take a tool (pliers and pliers, for example). In one, the conductors are clamped near the insulation, the second is strenuously twisted the conductors, increasing the number of turns. The junction is isolated.

Twist with pliers or pliers

Twisting with mounting caps

Twisting is even easier using special caps. With their use, the connection is more reliably insulated, the contact is better. The outer part of such a cap is molded from flame retardant plastic, a metal conical part with a thread is inserted inside. This insert provides a large contact surface, improving the electrical performance of the connection. This is a great way to connect two (or more) wires without soldering.

Twisting wires with the help of caps is even easier: the insulation is removed by 2 cm, the wires are slightly twisted. A cap is put on them, it is turned with effort several times until the metal is inside the cap. Everything, the connection is ready.

Caps are selected depending on the cross section and the number of conductors to be connected. This method is more convenient: it takes up less space than conventional twisting, everything fits more compactly.

Soldering

If there is a soldering iron in the house, and you know how to handle it at least a little, it is better to use soldering. Before twisting, the wires are tinned: a layer of rosin or soldering flux is applied. A heated soldering iron is dipped in rosin, and carried out several times over the part stripped of insulation. A characteristic reddish coating appears on it.

After that, the wires are twisted as described above (twisting), then the tin is taken to the soldering iron, the twist is heated until the molten tin begins to flow between the turns, enveloping the connection and ensuring good contact.

Installers do not like this method: it takes a lot of time, but if you do the connection of the wires in the junction box for yourself, take the time and effort, but you will sleep peacefully.

wire welding

If available, you can use a welding connection. This is done on top of the twist. Set the welding current on the machine:

- for a section of 1.5 mm 2 of the order of 30 A,

- for a section of 2.5 mm 2 - 50 A.

The electrode is used graphite (this is for welding copper). With grounding pliers, we carefully cling to the upper part of the twist, we bring the electrode to it from below, briefly touch it, achieving the ignition of the arc, and remove it. Welding takes place in a fraction of a second. After cooling, the junction is isolated. The process of welding wires in the junction box, see the video.

Terminal blocks

Another connection of wires in the junction box is using terminal blocks - terminal blocks, as they are also called. There are different types of pads: with clamps and screw, but, in general, the principle of their device is the same. There is a copper sleeve / plate and a wire attachment system. They are designed so that by inserting two / three / four conductors into the right place, you connect them securely. In installation, everything is very simple.

Screw terminal blocks have a plastic housing in which the contact plate is fixed. They are of two types: with hidden contacts (new) and with open ones - the old model. In any of them, a conductor stripped of insulation (length up to 1 cm) is inserted into the socket and clamped with a screw and a screwdriver.

Their disadvantage is that it is not very convenient to connect a large number of wires in them. The contacts are arranged in pairs, and if you need to connect three or more wires, you have to squeeze two wires into one socket, which is difficult. But they can be used in branches with significant current consumption.

Another type of blocks is Vago terminal blocks. These are fast mounting pads. Two types are mainly used:

The peculiarity of these terminal blocks is that they can only be operated at low currents: up to 24 A with a copper wire cross section of 1.5 mm, and up to 32 A with a cross section of 2.5 mm. When connecting loads with high current consumption, the wiring in the junction box must be connected in a different way.

Crimping

This method is possible with special pliers and a metal sleeve. A sleeve is put on the twist, it is inserted into the pliers and clamped - it is pressed. This method is just right for lines with a large ampere load (like welding or soldering). See the video for details. It even has a junction box model assembled so it will be useful.

Basic wiring diagrams

Knowing how to connect the wires in the junction box is not all. It is necessary to figure out which conductors to connect.

How to connect sockets

As a rule, the socket group is a separate line. In this case, everything is clear: you have three cables with three (or two) conductors in your box. Coloring can be the same as in the photo. In this case, usually brown is the phase wire, blue is zero (neutral), and yellow-green is ground.

In another standard, the colors may be red, black and blue. In this case, the phase is red, blue is neutral, green is ground. In any case, the wires are assembled by color: all of the same color in one group.

Then they are folded, stretched, cut to be the same length. Do not cut short, leave a margin of at least 10 cm so that you can remake the connection if necessary. Then the conductors are connected by the chosen method.

If only two wires are used (there is no grounding in the houses of the old building), everything is exactly the same, only there are two connections: phase and neutral. By the way, if the wires are of the same color, first find the phase (with a probe or multimeter) and mark it, at least by winding a piece of electrical tape around the insulation.

Connecting a single-gang switch

With a switch, the matter is more complicated. There are also three groups, but their connection is different. Eat

- input - from another junction box or from the shield;

- from a chandelier;

- from the switch.

How should the circuit work? Power - "phase" - goes to the switch key. From its exit is fed to the chandelier. In this case, the chandelier will only light when the switch contacts are closed (position "on"). This type of connection is shown in the photo below.

If you look carefully, this is how it turns out: the phase with a light wire enters the switch. It leaves from another contact, but already blue (do not mix it up) and connects to the phase wire that goes to the chandelier. Neutral (blue) and ground (if mains) are twisted directly.

Connecting a two-gang switch

Connecting the wires in the junction box with a two-gang switch is a little more complicated. The peculiarity of this circuit is that a three-core cable must be laid to the switch for two groups of lamps (in the circuit without grounding). One wire is connected to the common contact of the switch, the other two are connected to the key outputs. In this case, it is necessary to remember what color the conductor is connected to the common contact.

In this case, the phase that has arrived is connected to the common contact of the switch. The blue wires (Neutral) from the input and the two bulbs are simply twisted all three together. There are wires left - phase from the lamps and two wires from the switch. So we connect them in pairs: one wire from the switch to the phase of one lamp, the second output to another lamp.

Once again about connecting wires in a junction box with a two-gang switch in video format.