There is an opinion that soon the whole world will switch exclusively to Chinese-made goods: they do not differ in durability, but in the event of a breakdown, it is not a pity to throw them away, since the cost can be an order of magnitude lower than the European counterpart. For a real man, even such arguments cannot be an argument: any malfunction must be tried to be eliminated. It makes sense to talk about malfunctions in electrical circuits separately.

An electric soldering iron will help to firmly connect the parts, taking into account all the subtleties of the technology.

The fact is that in 60% of cases of malfunction of electrical appliances, the contacts in the circuits are to blame. The usual ability to read electrical circuits and the ability to work with a soldering iron will allow you to return a huge number of electrical appliances to working condition.

At present, the previously familiar soldering iron is a little forgotten and is used less and less in everyday life. Consider the rules for using a soldering iron and the basic techniques for working with it.

What does the structure consist of?

The soldering iron belongs to the category of heating devices. It consists of a heating element (nichrome coil) placed in a metal case, a tip, a handle and an electric cord with a plug.

The tip of the soldering iron is made of copper, as this metal has excellent thermal conductivity and a very high melting point. For different types of soldering, replaceable stings of various shapes and diameters are used.

Back to index

How to prepare the tool for work and why you need a flux

Preparing the soldering iron for work is almost the main part of the whole process. The fact is that on the metal, under the influence of air and water molecules dissolved in the air, a layer of oxides is formed, which interfere with successful soldering. Before starting work, the soldering iron tip is carefully cleaned with a file or sandpaper.

The soldering iron is plugged in and allowed to warm up for a while. When the temperature reaches about 70 ° (at the tip), the sting must be tinned. It is simply immersed in any available flux. Rosin is most often used as a flux (soldering additive). Currently, many radio amateurs use other fluxes designed for certain types of solder. It's no secret that you often have to solder not only copper parts.

Ordinary solder and ordinary fluxes will definitely not work here. Therefore, other consumables are used. A special role here is given to fluxes with various additives. But such additives are rather harmful for a novice master, since their use requires serious experience in soldering issues. The flux spreads over the tip of the soldering iron and creates a protective layer on it.

Back to index

What is solder and how to prepare a place for soldering

The solder is an alloy of lead and tin. This is the optimal combination of metals: a low melting point and a high level of heat transfer. This means that the solder melts easily and hardens at the soldering point very quickly. This is where the first rule of the shareholder comes from: everything is done quickly and accurately.

Soldering is never done spontaneously. Soldering points also need to be cleaned of oxides and apply a thin layer of rosin on them. The reasons for the need for this procedure are the same as for the soldering iron itself.

Then we bring a small piece of solder to the place of soldering and press it with a hot soldering iron. The solder should form a ball of molten metal. We remove the soldering iron, after a few seconds the ball will harden. Contact will be strong and reliable. In order not to burn your hand when applying solder, use any holder with heat-resistant handles for this action. You can also use ordinary medical tweezers with a long holder. But it is better to use solder, which is made in the form of a wire.

The edge of such a wire is brought to the place of soldering, and the soldering iron is also directed there. In this case, it is necessary to monitor the angle of inclination of the tip to the solder: it is important that during soldering an excess amount of molten metal is not formed. Firstly, it looks very sloppy, and secondly, there is a chance that you will touch the track in the electrical circuit, which will cause a short circuit.

Back to index

How to learn to solder well

Learn to solder should be on the connection of stranded wires. There are several reasons for this:

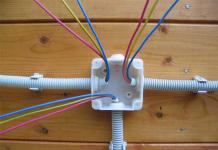

The soldering iron stand is used to ensure that the heated soldering iron does not touch the table or other objects.

- it does not incur special costs for consumables;

- not an easy task;

- places of poor quality connections become a frequent cause of a short circuit.

As for the latter: the current moves along the surface of the metal (wire). With a small load, even a thin wire (one core) is enough for the incoming current to be enough to operate a certain electrical appliance. Simply put, even one thin core in a wire can work properly for a long time and not create problems for the user.

With an increase in the load, the number of transferred charges will increase sharply and the current will look for ways to move, respectively, the charges will slip in places of poor contact. Such minimal short circuits heat up the wiring and its insulation very much - and not far from a fire. Therefore, it is worth training to solder at the junctions of the wires.

Back to index

How to solder wire and more complex elements

To do this, the ends of the wires are cleaned, a thin layer of rosin is immediately applied to them. Now we grab a small amount of solder with a soldering iron and apply it to the junction of the wires. Reciprocating movements of the soldering iron along the joint will create a thin layer of solder in the marked place. Then everything will be easier: add solder to the place of soldering to the required amount.

Having trained on the wires, you can begin to solder more complex parts of electrical circuits. This usually requires a soldering iron with a thin tip. It will also be very problematic to bring a piece of solder to the place of soldering. A small ball of molten solder is easily transferred directly to the tip of the soldering iron. This is facilitated by surface tension forces, which are enhanced by rosin.

Soldering: basics for beginners, technology, types and materials, subtleties

The ability to solder in modern life, saturated with electrical appliances and electronics, is as necessary as the ability to use a screwdriver and a plunger. There are many methods for soldering metals, but first of all you need to know how to solder with a soldering iron, although other methods are feasible and may also be needed in domestic conditions. This article is intended to help those who wish to master the technology of manual adhesive work.

Note: soldering of propylene and other plastics is not covered here. This, in fact, is not soldering - the technical process lacks the mandatory components of soldering, solder and flux. Technologically, plastic soldering is closer to low-temperature contact welding. The same applies to cold soldering - connecting parts with conductive glue.

Soldering metals with solder is a rather complex physical and chemical process, but in work it comes down to fairly simple techniques and operations. In order to solder correctly, without wandering in the jungle of theory, the rules for the production of soldering work must be followed exactly. This is especially true for the choice of soldering method, solder and flux, depending on the type of parts to be joined and the requirements for the solder joint. The main part of the presented material is devoted to the description of these and other details, without which a strong junction will not work.

Note: If you want to quickly solder something, you can watch a detailed video tutorial on the basics of soldering for beginners below. But keep in mind that it will not replace the rest of the text. In adhesive work, the rule “do it this way, it will turn out like this” does not always work. And in a well-established production, it happens that you have to rack your brains - what to do if it doesn’t work out that way? Or, what needs to be done to make it all the same, if there is nothing that is supposed to do so.

Video: how to learn to solder - a lesson for beginners

What is soldering?

Do-it-yourself soldering at home comes down to the following technological operations:

- Soldered surfaces are cleaned of dirt, corrosion crusts, etc.

- Cleaned to a shine, i.e. until there are no visible traces of oxides;

- Coated with flux - a substance that removes oxide residues and prevents surface oxidation in the further process. For fluxing under tinning, it is preferable to use not liquid or solid fluxes, but flux pastes;

- Then the surfaces are tinned - molten solder is applied to them (an alloy specially designed for soldering), while it spreads with a thin film and chemically combines with the base metal;

- The parts are pre-connected mechanically: by twisting, compressing with tweezers, pliers, in a vice, clamp, etc.

- Another flux is applied to prevent the solder from oxidizing under heat;

- Another solder is applied with heating (possibly a different one) until a solder of a given quality is obtained;

- If the soldering was carried out with a soldering iron with a tinned tip (see below), at the end of it, it is cleaned and covered with an inactive flux. In order for the soldering to be of high quality, an ordinary soldering iron must be stored with a fluxed tip!

Necessary Retreat

Note: in the northern dialects of Russian there are also luds - underwater stone ridges - and even the whitefish fish that is found there. But in canonical Russian, luds are extremely rare, so they can be ignored.

Cleanup

Stripping after cleaning is the first tricky soldering operation. The use of abrasives for it is unacceptable! Their smallest particles, ingrained in the metal, cannot be completely removed. Subsequently, they become centers of processes that destroy the junction.

They clean the surfaces for soldering with a needle file, file, scraper tool (different types of scrapers) or just a knife. But it is best, especially if current-carrying wires are being prepared for soldering, immediately cover them with activated flux (see below), and carefully remove its remnants after soldering. It is convenient to do this with a toothbrush moistened with alcohol.

What and how to tin / solder?

For the following operations, you will need a special electric heating tool: a soldering iron, a soldering iron or a soldering torch. Soldering at home most often has to be done with an electric soldering iron with a tinned copper tip. Its device is shown in pos. 1 fig. “For complete happiness”, an amateur solderer needs 16-20 W soldering rods for microcircuits and printed circuit boards, pos. 2a, 40-50 W (pos. 2b), for electrical wires and surface mounting of radio electronics components, and 80-150 W (pos. 2c), for assembling small metal structures by soldering.

The device and types of electric soldering irons with a tinned copper tip

If you do not intend to work with microchips (phones, tablets, computers) and solder steel with a thickness of more than 0.5-0.6 mm, you can get by with a set of soldering irons for 25 W (pos. 3a) and 60-65 W, pos. 3 b. Suddenly, it becomes necessary to solder metal profiles with a wall thickness of up to 3-4 mm and / or a thick steel sheet, you will need a radiator soldering iron “ax” for 300-400 W, pos. 4.

The tips of low-power soldering irons (pos. 2a, 2b, 3a, 3b) are not initially forged and therefore oxidize (burn out) rather quickly. In order to increase their durability, and at the same time to mold them in the right way, the rod taken out of the soldering iron is forged with a bench hammer on the anvil of a desktop vise. After that, there is no need to “shirkat” it with a needle file, and it is not necessary, so as not to erase the outer compacted layer of copper. After forging, the sting is immediately covered with an activated flux.

Now you need hard rosin and soft, fairly refractory solder (see below): POS-10, POS-30 or POS-40. The soldering iron rod is inserted into place, fixed if there is a fixing screw, and the soldering iron is connected to the network. As the flux boils away during heating, the sting is immersed in rosin so that it does not become bare. When the rosin around the sting begins to bubble, it is rubbed with a solder stick until an even, dense half is obtained on the entire surface of the sting. The thread-like solder on the coil in this case is not very good, it is for soldering small parts.

While we were preparing the soldering iron, the flux on the soldering surfaces did its job: under its layer they are clean, you can tin. Here the critical point will be the thickness of the parts:

- Less than 1/8 of the soldering iron rod diameter - will warm up to solder melting temperature in less than 7 seconds. The flux will not boil away.

- More than 1/6 of the same value - they will warm up in more than 10 s, the flux will boil away, the parts will be exposed and oxidized.

- 1/8-1/6 rod diameter - you need, most often based on your own experience, to tin with low-melting solder under high-boiling flux. Or use a soldering iron more powerful.

In the first case, a drop of solder is collected on the tip, transferred to the soldered surface, and, if:

- The wire is thin - easily, without pressure, move along the bare end with a sting from one and then from the opposite side until the solder spreads. The wire is held with the tip down. A drop of excess solder that has flowed down is removed with a soldering iron.

- The wire is thick - the sting is moved in a spiral back and forth.

- A flat thin long part - solder is applied to the end and the tip is moved along. When the untinned edges of the part appear behind the sting, apply more flux to the under-tinned area, pick up another drop of solder and continue tinning.

- Long wider detail - the same as in the previous. case, but the sting is carried by a snake.

- Wide detail - the sting is moved in a spiral from the center to the edges.

For tinning thick parts, they take thread solder with flux, the so-called. Harpius: This is a thin flexible tube of solder foil, in the lumen of which is powdered rosin. Tinning starts from the edge of long or from the middle of wide parts. The end of the harpius is applied to the place of the beginning of tinning, heated with a soldering iron until it spreads. Sting movements are the same as in the previous. cases. Solder is served under the sting as it is spent. Give it to the sting - it will stick to it until a large drop forms, which drains where it is not necessary.

Features of soldering wires

In the preliminary connection of soldered parts, the most problems arise with wires: for this you have to touch them with your hands, which makes the metal surface dirty, and wire junctions, more often than other solder joints, have to withstand mechanical loads.

Wire twists

Before soldering the wires, they must be twisted correctly. The main types of wire twists for soldering are shown in fig. Each of them has its own purpose:

- Rigid (thick single-core) current-carrying wires are connected with bandage twists, i.e. through which electrical power is transmitted. Especially the outer wires. The bandage connection provides sufficient electrical contact even if the oxidized junction is not soldered or overheated.

- Grooved twists are made on wires in low-melting insulation (plain PVC, polyethylene), when complete spreading of the solder is necessary with minimal heating. The grooved twists are heated only along the groove.

- With simple twists, you can connect both single-core and stranded wires that have just been stripped of insulation (shiny) wires.

- Simple sequential twisting, the so-called. direct British, or simply British, is applicable for connecting current-carrying wires of flexible cables with a cross section of up to 1.4 square meters. mm, not experiencing regular high mechanical loads, for example. electrical extension cords or makeshift.

Electrical wires subject to regular and/or permanent mechanical stress must be stranded. They are twisted as shown below in the figure: the ends are marked out, the “brooms” are pushed into each other and twisted in the British way. Solder with low-melting solder of increased strength, for example. POSK-50 (see below) with activated flux that does not require residue removal, also see below.

Parallel (dead-end) twisting of wires with a cross section of more than 0.7 square meters. mm, it is desirable to solder by immersion in molten solder, see below. Otherwise, you will have to heat either for a long time, or with a too powerful soldering iron, which is why the insulation creeps, and the flux boils out prematurely.

Note: single-core tinned wires - the leads of radio electronics parts - can be soldered end-to-end or with a hook, see fig. on right.

What is solderable but not solderable

Flexible coaxial cables and cables for computer networks of the twisted pair type (“vituha”) are not intended for soldering. An experienced cableman who has a complete understanding of the electrodynamics of signal transmission lines can, in exceptional cases, make a coupling on them. But when performed by an amateur, even if he is otherwise a qualified electronics engineer and installer, the throughput and noise immunity of the line will fall below the permissible level, up to a complete loss.

How to clean and preserve a sting

The tip of the soldering iron is cleaned of solder residue by rubbing it against a soft, porous or fibrous lining. Foam rubber is most often used, but this is not the best option: it burns and sticks to the sting. The best material for cleaning it is natural felt or basalt cardboard. But even better - 2-step cleaning, first with a tangled sponge made of metal tape, and then with felt. After cleaning, the soldering iron is turned off, another hot tip is introduced into the solid rosin and wait until it stops bubbling. Then the sting is taken out and held down with the end so that excess rosin drains. When it has completely cooled down, the soldering iron can be sent for storage.

Solders and fluxes

Now it's time to accurately select the working solder and flux to it, because. soldering, unlike semi-soldering, must not only adhere firmly to the base metal, but also be strong itself. A summary of information about solders and fluxes of wide application from the old reference book is given in fig. At the present time, there is not much left to add to it.

Characteristics of solders and fluxes for a wide range of applications

Solders

Solders from POS-90 to Avia-2 are soft for low-temperature soldering. Only electrical contact is guaranteed. POS-30 and POS-40 solder copper, brass, bronze with inactive fluxes, and them with steel and steel with steel - with active ones. POSSR-15 can solder galvanized steel with inactive fluxes; other solders at the same time corrode the zinc to steel and the soldering soon falls off.

34A, MF-1 and PSR-25 hard solders, for high-temperature soldering. Solder 34A can be used to solder aluminum in a flame (see below, about soldering aluminum) with special fluxes, see ibid. Solder MF1 solder copper to steel with activated flux. "Low strength requirements" in this case means that the strength of the junction is closer to that of copper than steel. PSR-25 when soldering with a dry soldering iron (see below) is suitable for soldering jewelry, stained glass tiffany, etc.

Fluxes

Soldering fluxes are divided into neutral (inactive, acid-free), not chemically interacting with the base metal or interacting to an insignificant extent, activated, chemically acting on the base metal when heated, and active (acidic), acting on it and cold. With regard to fluxes, our century has brought the most innovations; Most of them are good, but let's start with the bad ones.

First, technically pure acetone for washing rations is no longer widely available due to the fact that it is used in the clandestine production of drugs and itself has a narcotic effect. Substitutes for technical acetone - solvents 646 and 647.

Second, zinc chloride in activated flux pastes is often replaced with sodium tetraborate - borax. Hydrochloric acid is a highly toxic chemically aggressive volatile substance; zinc chloride is also toxic, and when heated, it sublimates, i.e. escapes without melting. The borax is safe, but when heated, it releases a large amount of water of crystallization, which slightly worsens the quality of soldering.

Note: Borax itself is a soldering flux for soldering by dipping into molten solder, see below.

The good news is that there is now the widest range of fluxes on sale for all occasions in the soldering life. For normal soldering jobs, you will need (see figure) inexpensive SKF (alcohol rosin, formerly CE, second on the list of acid-free fluxes in Table I.10 in figure above) and soldering (etched) acid, this is the first acid flux on the list. SCF is suitable for soldering copper and its alloys, and soldering acid is suitable for steel.

Solders from SCF must be washed: the composition of rosin includes succinic acid, which destroys the metal with prolonged contact. In addition, accidentally spilled SCF instantly spreads over a large area and turns into a very long drying, extremely sticky muck, stains from which can not be removed from clothes, furniture, or floors with walls. In general, SCF is a good flux for soldering, but not for goofballs with bunglers.

A full-fledged substitute for GFR, but not so nasty with careless handling - TAGS flux. Steel parts are more massive than allowed for soldering with soldering acid, and more firmly, they are soldered with F38 flux. Universal flux can solder almost any metal in any combination, incl. aluminum, but the strength of the junction with it is not standardized. We will return to soldering aluminum.

Note: radio amateurs, keep in mind - fluxes are now on sale for soldering enameled wires without stripping!

Other types of soldering

Craft lovers also often solder with a dry soldering iron with an untinned bronze tip, the so-called. soldering pencil, pos. 1 in fig. It is good where solder spreading outside the soldering zone is unacceptable: in jewelry, stained-glass windows, soldered objects of applied art. Sometimes surface-mounted microchips are also dry-soldered, with a pin spacing of 1.25 or 0.625 mm, but this is a risky business for experienced specialists: poor thermal contact requires excessive soldering power and prolonged heating, and it is impossible to ensure heating stability during manual soldering. For dry soldering, harpis from POSK-40, 45 or 50 and flux pastes are used, which do not require the removal of residues.

Other types of soldering, feasible at home

Dead-end twists of thick wires (see above) are soldered by immersion in a futorka - a bath with molten solder. Once the futorka was heated with a blowtorch (pos. 2a), but now it is primitive wildness: an electric futorka, or soldering bath (pos. 2) is cheaper, safer and gives better soldering quality. The twist is introduced into the futorka through a layer of boiling flux supplied to the solder after it has melted and heated to the operating temperature. The simplest flux in this case is rosin powder, but it soon boils away and burns even faster. It is better to flux the futorka with brown, and if the solder bath is used for galvanizing small parts, then this is the only possible option. In this case, the maximum temperature of the tube should not be lower than 500 degrees Celsius, because zinc melts at 440.

Finally, massive copper in products, for example. pipes are soldered by flame brazing. There are always unburned particles in it, eagerly absorbing oxygen, so the flame has, as chemists say, reducing properties: it removes residual oxide and prevents a new one from forming. At pos. 3 shows how the flame of a special soldering torch literally blows out everything unnecessary from the soldering area.

Manual flame brazing

High-temperature soldering is carried out, see fig. on the right, evenly rubbing the soldering area 1 with pressure with a stick of hard solder 2. The flame of the burner 3 should follow the solder so that the hot spot is not in the air. Previously, the soldering area is heated until the tint colors go. To the hard-tinned surface, you can solder something else with soft solder as usual. See below for more information on flame brazing when it comes to pipes.

Curiously, in some sources, a soldering torch is called a soldering station. Well, a rewrite is a rewrite, what do you get from him. In fact, a desktop soldering station (see the following figure) is equipment for fine soldering work: with microchips, etc., where overheating is unacceptable, solder spreading where it is not necessary, and other flaws. The soldering station precisely maintains the set temperature in the soldering zone, and, if the station is gas, it controls the gas supply there. In this case, the burner is included in its kit, but the soldering burner itself is nothing more than a quarry - St. Basil's Cathedral.

Desktop Soldering Stations

How to solder aluminum

Fluxes for aluminum brazing

Thanks to modern fluxes, brazing aluminum has become generally no more difficult than copper. Flux F-61A is intended for its low-temperature soldering, see fig. Solder - any analogue of Avia solders; There are different ones for sale. The only thing is that it is better to insert a tinned bronze rod into the soldering iron with notches on the tip, approximately like a file. Under a layer of flux, it will easily scrape off a strong oxide film, which does not allow aluminum to be soldered just like that.

Flux F-34A is intended for high-temperature soldering of aluminum with solder 34A. However, it is necessary to heat the soldering area with a flame very carefully: the melting point of aluminum itself is only 660 Celsius. Therefore, high-temperature soldering of aluminum is better to use flameless chamber soldering (soldering with furnace heating), but the equipment for it is expensive.

Aluminum copper plating for soldering

There is also a "pioneer" method of soldering aluminum with preliminary copper plating. It is suitable when only electrical contact is required, and mechanical stresses in the soldering area are excluded, for example, if you need to connect an aluminum casing to a common PCB bus. "In a pioneering way" aluminum soldering is carried out on the installation shown in fig. left. Copper sulphate powder is poured in a slide into the soldering area. A stiffer toothbrush, wrapped in bare copper wire, is dipped in distilled water and rubbed with vitriol with pressure. When a copper spot appears on aluminum, it is tinned and soldered as usual.

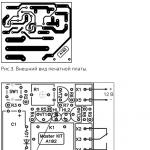

small soldering

Soldering printed circuit boards has its own characteristics. How to solder parts on printed circuit boards, in general, see a small master class in the drawings. Tinning of wires is eliminated, because. the conclusions of the radio components and chips are already tinned.

In amateur conditions, firstly, it makes little sense to tinker all current-carrying tracks if the device operates at frequencies up to 40-50 MHz. In industrial production, boards are tinned using low-temperature methods, for example. sprayed or electroplated. Heating the tracks with a soldering iron along the entire length will worsen their adhesion to the base and increase the likelihood of delamination. After mounting the component, it is better to varnish the board. Copper will immediately darken from this, but this will not affect the performance of the device in any way, unless we are talking about microwave.

Soldering electronic components on a printed circuit board

Then, take a look at something ugly on the left of the trail. rice. For such a marriage, and in bad memory, the Soviet MEP (Ministry of the Electronic Industry), the installers were demoted to loaders or helpers. It's not even about the appearance or overspending of expensive solder, but, firstly, that during the cooling of these plaques, both the mounting pads and the parts overheated. And large heavy solder flows are rather inert weights for already weakened tracks. Radio amateurs are well aware of the effect: I accidentally shoved the “cuttlefish” board onto the floor - 1-2 or more tracks peeled off. Without waiting for the first soldering.

Incorrectly and correctly soldered printed circuit boards

Solder beads on printed circuit boards must be round, smooth, with a height of no more than 0.7 of the mounting pad diameter, see on the right in Fig. The ends of the leads should protrude slightly from the sags. By the way, the board is completely homemade. There is a way at home to make printed circuit as accurate and clear as a factory one, and even display the inscriptions you want there. White spots - glare from varnish when photographing.

The influxes are concave and even more wrinkled - also a marriage. Just a concave influx means that the solder is not enough, and wrinkled, in addition to the fact that air has entered the soldering. If the assembled device does not work and there is a suspicion of non-soldering, look first of all at such places.

ICs and chips

In fact, an integrated circuit (IC) and a chip are one and the same, but for clarity, as is generally accepted in technology, we will leave ICs in DIP packages with microcircuits - “mikruhs”, up to and including a large degree of integration, with conclusions through 2.5 mm, installed in mounting holes or solder caps if the board is multilayer. Let the chips be super-large ICs - "millionaires" mounted on the surface, with a pin pitch of 1.25 mm or less, and microchips - miniature ICs in the same cases for phones, tablets, laptops. We do not touch processors and other "stones" with rigid multi-row pin terminals: they are not soldered, but are installed in special sockets, which are soldered into the board once when it is assembled at the enterprise.

Soldering iron grounding

Modern CMOS (CMOS) ICs in terms of sensitivity to static electricity are the same as TTL and TTLSH, hold a potential of 150 V for 100 ms without damage. The amplitude value of the operating voltage of the network is 220 V - 310 V (220x1.414). Hence the conclusion: a low-voltage soldering iron is needed, for a voltage of 12-42V, connected through a step-down transformer on the iron, not through an impulse or capacitive ballast! Then even a direct breakdown on the sting will not spoil the expensive chips.

There are still random, and all the more dangerous, mains voltage surges: welding was turned on nearby, there was a network throw, the wiring sparked, etc. The most reliable way to protect yourself from them is not to divert "stray" potentials from the soldering iron tip, but not to let them out of there. For this, even at the special enterprises of the USSR, the scheme for switching on soldering irons was used, shown in Fig.:

Grounding diagram of a low-voltage electric soldering iron

The connection point C1 C2 and the core of the transformer are connected directly to the protective earth loop, and to the middle point of the secondary winding - the screen winding (an open coil of copper foil) and the ground electrodes of the workplaces. This point is connected to the circuit with a separate wire. With sufficient power of the transformer, you can connect as many soldering irons as you like to it, without worrying about grounding each one individually. At home, points a and b are connected to a common ground terminal with separate wires.

Microcircuits, soldering

Chips in DIP packages are soldered like other electronic components. Soldering iron - up to 25 watts. Solder - POS-61; flux - TAGS or alcohol rosin. It is necessary to wash off its remnants with acetone or its substitutes: alcohol takes the rosin tightly, and it is not possible to completely wash it between the legs with either a brush or a rag.

As for chips, and even more so microchips, it is strongly not recommended for specialists of any level to solder them manually: this is a lottery with a very problematic win and a very likely loss. If it comes to such subtleties as repairing phones and tablets, you will have to fork out for a soldering station. Using it is not much more difficult than using a hand soldering iron, see the video below, and the prices of quite decent soldering stations are now available.

Video: chip soldering lessons

Microcircuits, desoldering

“In the right way”, ICs are not soldered for verification during repairs. Their diagnostics is carried out on the spot by special testers and methods, and the unusable is removed once and for all. But amateurs can not always afford it, so just in case, below we give a video about the methods of desoldering ICs in DIP packages. Craftsmen also contrive to solder chips with microchips, for example, by slipping a nichrome wire under a number of leads and heating with dry soldering irons, but this lottery is even less winning than manual installation of large and extra-large ICs.

Video: desoldering chips - 3 ways

How to solder pipes

Copper pipes are soldered in a high-temperature way with any hard solder for copper with an activated flux paste that does not require the removal of residues. The following are 3 options:

- In copper (brass, bronze) couplings - soldering fittings.

- With full distribution.

- With incomplete distribution and compression.

Soldering copper pipes in fittings is more reliable than others, but requires significant additional costs for couplings. The only case when it is indispensable is the diversion device; then a tee fitting is used. Both soldered surfaces are not pre-tinned, but covered with flux. Then the pipe is inserted into the fitting, securely fixed and the joint is soldered. Soldering is considered complete when the solder stops going into the gap between the pipe and the coupling (0.5-1 mm is needed) and protrudes from the outside in a small roller. The latch is removed no earlier than 3-5 minutes after the solder hardens, when the joint can already be held by hand, otherwise the solder will not gain strength and the joint will someday leak.

How pipes are soldered with full expansion is shown on the left in fig. The pressure of the "distributed" soldering keeps the same as the fitting, but requires additional. special tools for expanding the socket and increased solder consumption. Fixing the soldered pipe is not necessary, it can be pushed into the socket with a twist until it jams tightly, so soldering with full extension is often done in places that are inconvenient for installing the latch.

Soldering copper pipes

In home wiring from thin-walled pipes of small diameter, where the pressure is already small and its losses are insignificant, it may be advisable to solder with incomplete expansion of one pipe and narrowing of the other, pos. I on the right in fig. To prepare the pipes, a round stick made of hard wood with a conical tip of 10-12 degrees on one side and a truncated-conical hole of 15-20 degrees on the other is enough, pos II. The ends of the pipes are processed until they fit into each other without jamming approx. by 10-12 mm. Surfaces are tinned in advance, flux is applied to the tinned ones and connected until jammed. Then they heat until the solder melts and support the narrowed pipe until it jams. Solder consumption is minimal.

The most important condition for the reliability of such a joint is that the narrowing should be oriented along the flow of water, pos. III. Bernoulli's school law is a generalization for an ideal fluid in a wide pipe, and for a real fluid in a narrow pipe, due to its (liquid) viscosity, the maximum pressure jump is shifted opposite to the current, pos. IV. A component of the pressure force arises, pressing the narrowed pipe to the extended one, and the soldering is very reliable.

What else?

Oh yes, soldering iron stands. Classical, on the left in the figure, suitable for any rod. Where there are baths for solder and rosin on it is up to you, there is no regulation. For low-power soldering irons with an apron, simplified stand-brackets are suitable, in the center.

Correct and incorrect soldering iron stands

Soldering stations are equipped mainly with spring or tubular nests for soldering irons. In them, the entire hot part of the tool is inaccessible to touch, but it is more likely to miss them with a soldering iron, concentrating on soldering a small “placer”. But what certainly should not be done, and what is expressly prohibited by TB is a stand made of improvised materials, in which the soldering iron lies on trays for consumables, on the right in fig.

Display all materials with a tag:

- electrical work

- metal work

- tool

- technique

Go to section:

vopros-remont.ru

How to solder? and what to solder?

Everyone knows what a soldering iron is and what it is for, but not everyone knows how to use it. And this tool is very useful not only in the television workshop, but also in the household. With it, you can qualitatively restore a broken cable, repair power tools, household appliances and much more. However, you must be able to wield a soldering iron, and you must also be able to choose the right consumables.

If we are not talking about soldering microcircuits and high-voltage equipment, then the process itself does not present any difficulty. Most household tasks can be done on your own, without contacting a specialist.

Soldering iron device

An electric soldering iron must have a heater. The heater can be nichrome or ceramic. Ceramic heaters are good in their own way, but they are quite demanding on working conditions. Therefore, for the household, electric soldering irons with a spiral heater (EPSN) are best suited. These are quite unpretentious and, importantly, inexpensive devices.

The working part of the soldering iron is the tip. The heater brings it to a high temperature, allowing it to melt the tin solder that is being soldered. The body of the soldering iron usually has a screw that fixes the tip and with which you can adjust its reach. The soldering iron handle has an extension or a separate apron that prevents the hand from even accidentally slipping onto the heated part.

In recent years, compact gas soldering irons have appeared that immediately competed with electric soldering irons. They are filled with purified butane, exactly the same that is used to refuel lighters. Soldering with a gas soldering iron occurs due to the action of an open flame of a miniature nozzle. The flame temperature can be adjusted within 750-1200°C. At one gas station, the soldering iron can work 60-90 minutes, depending on the setting. Such a tool can completely replace a 150 W electric soldering iron. For domestic needs, it is more than enough, unless, of course, we are talking about soldering pipes or pans.

Soldering iron selection

First of all, it is necessary to determine for what purposes the soldering iron is purchased. For the home, they usually take a device that can be used to solder cables, wires, repair equipment plugs, etc. For these purposes, a device with a power of 25 watts is suitable. More powerful devices are used for soldering massive parts, and this is already an industrial application. At the same time, you should not buy too low-power soldering irons for 5-15 watts. They are designed for soldering microcircuits and fine equipment, for example, for repairing mobile phones.

Pay attention when buying a soldering iron for the home and its input voltage. It is necessary that it be a device operating from 220 V, and not from 12 or 24 .... It is desirable that the soldering iron has a European-style plug. Modern houses are already increasingly equipped with grounding, which in this case will eliminate electrical injury in the event of a breakdown on the body.

If the tip in the soldering iron is removed, then, if necessary, it can be replaced. It is very easy to find out - soldering irons with a replaceable tip have a fixing bolt (bolts) on the body. The bolt allows you to adjust the length of the overhang, and it in turn affects the temperature of the open part.

Stings are copper and nickel-plated. The latter do not burn, so they practically do not need care. However, they are somewhat more expensive. Red-copper tips from time to time need to be cleaned of solder and filed. There are no difficulties in these operations - a file is taken and with its help the sting is given the required shape. It is advisable to do this with the sting removed, clamped in a vise.

As for the shape of soldering irons, in addition to the classic "handle" form, the so-called "guns" can be found on sale. The difference between them is only in the shape of the handle. There are also fast-heating soldering irons with a transformer, but they already belong to professional class devices. Many experts believe that the classic shape of the soldering iron is more convenient to use.

Consumables for soldering

Solder. The connection of parts by soldering involves the use of solder - an alloy of tin and lead. The soldering process can be compared to hot bonding. The glue in this case is solder.

The proportions of tin and lead in solders can be different. Manufacturers apply markings, where the percentage of tin is indicated by a number, for example POS-61 - tin-lead solder, in which the tin content is 61%. Solder from such an alloy will melt at a temperature of 180 ° C. This is much lower than the melting point of copper or aluminum, which are the most commonly soldered.

Changes in the ratio of lead and tin are also reflected in the melting point of the solder. For example, if there is 40% tin in the solder, then the melting point of such an alloy will be 240 ° C, and if tin is 90%, then the alloy begins to melt only at 310 ° C.

The labeling of imported solders differs from the domestic one. To understand what kind of alloy is in front of you, you need to look at the accompanying documents or look for a decoding of the marking on the Internet. However, in household soldering, the solder alloy does not really matter. The most refractory solder melts at 300°C, which is also below the t(pl.) of copper or aluminum. But it is easiest to work with low-melting solders, so you should give preference to balanced solders, where tin and lead are approximately the same.

It is most convenient to use solder in the form of a wire with a diameter of 1-3 mm. On sale there are solders in the form of a tube filled with flux. Such solder is not for everyone; many professionals prefer a simple solder wire, which leaves the possibility of more accurate dosing of solder and flux.

Flux is needed to protect metal parts from thermal oxidation. The copper tip of a soldering iron quickly oxidizes, resulting in the formation of a non-metallic film on it, to which the solder does not adhere well. The flux removes the oxide film and promotes uniform solder distribution. Processing parts and contacts with flux is called tinning.

There are two types of fluxes - acidic and non-acidic. Acid fluxes are most often used when soldering iron alloys (cast iron, steel). After working with acid flux, it is necessary to remove its residues so that the acid does not corrode the metal. It is necessary to work with acid fluxes very carefully, because. acid easily corrodes the skin.

Of the non-acid fluxes, rosin is the most common - purified pine sulfur. For most household tasks, rosin is enough. Quality rosin is transparent and has an amber color; it does not stain the sting so quickly and does not smoke much. Orthophosphoric acid may also be on hand for cases where oxidation is significant.

Soldering technology

When you need to solder one part to another, solder a contact or the ends of wires, our task is to fix the solder with solder.

- Good contact and soldering strength depends on the quality of the work. The parts to be soldered must be well cleaned, degreased and warmed up.

- If you are soldering an electrical wire or any other electrical components, you must make sure that they are not energized.

- It is best to solder under a kitchen hood so that the rosin smoke is immediately removed from the room.

- It is very important not to overheat the soldered parts. They themselves are unlikely to melt from a soldering iron, but plastic (for example, wire insulation) can suffer from heat. Therefore, the time of exposure to high temperature on the parts should be minimal. It is advisable to solder in one go.

- The parts to be joined by soldering must be tinned - treated with flux and solder. Tinned wires stop bending, so they are twisted without tinning and only then soldered.

- When splicing cables or wires, the ends are stripped of insulation, the wire itself is mechanically stripped and treated with a flux using a soldering iron. In order to qualitatively insulate the soldered wires, it is necessary to first put on them tubes made of heat-shrinkable polymer. After that, the ends of the wire are twisted together and fixed with solder, which should eventually cover the entire contact part.

- The place of the soldering is closed with a heat-shrinkable cambric, which, after heating, envelops the soldering and reliably isolates it from contact with other wires.

- Wire solder is conveniently fed to the place of soldering, and not to pick up tin with a sting. But since a person has only two hands, solder can only be applied if the parts are securely fixed. Do not try to solder the navis - just waste your time and nerves. It is better to first fix the parts to be soldered with a clamp, and only then solder them.

That's actually the whole technology. As you can see, she is simple. The main thing is to follow a few simple rules and understand what is being done for what and in what order.

www.domastroim.su

Soldering iron: what materials and fixtures are needed, how to solder wires correctly

If we consider the methods of soldering, then the work performed by the soldering iron is the most common and convenient. Despite this, soldering with a soldering iron has two important limitations that should be considered when choosing a method. Soldering with a soldering iron should only be done with low-melting solders and it is difficult to perform the necessary manipulations if the parts to be soldered are too massive.

If we consider the methods of soldering, then the work performed by the soldering iron is the most common and convenient. Despite this, soldering with a soldering iron has two important limitations that should be considered when choosing a method. Soldering with a soldering iron should only be done with low-melting solders and it is difficult to perform the necessary manipulations if the parts to be soldered are too massive.

The last difficulty can be overcome if you use additional heat sources, such as a gas or electric stove, gas burner. Using these sources, you can achieve the desired result by heating the soldered part, although this will complicate the whole process.

To start the soldering process, you need to prepare the right tool and special materials. First of all, of course, the soldering iron itself is needed, and it is clear that you cannot do without flux and solder.

Types of soldering irons

Specialists distinguish between the following types of soldering tools:

Electric soldering irons are considered the most common soldering tools, as they are easy to use and easy to purchase. The desired soldering tool is selected depending on its power, which shows the level of heat flow directed to the soldered parts.

It will be correct to solder electronic components with a device whose power will not exceed 40 watts. If the parts to be soldered have walls or wires that do not exceed one millimeter, then it would be appropriate to choose a tool in the range of 80–100 watts. If the wall of the part is two millimeters or more, then the power needed is more than 100 watts. Just such powerful tools include hammer-type soldering irons powered by electricity, which have a power of 250 watts, and also higher. Such powerful devices are required, as a rule, for the industry where you need to solder large parts. The price of such non-household appliances is correspondingly high.

The thermal conductivity of the soldered material must also be taken into account when choosing the power of the soldering iron. For example, when soldering steel products, it should be in a less heated state than when working with a copper structure.

Solders

For soldering with an electric tool, pure tin, tin-lead, tin-silver and other types of solders are used.

If it is necessary to solder the utensils used for cooking, then it will be correct to use only pure tin.

Fluxes

According to experts, materials such as bronze, silver, nickel silver, copper, tin, gold, brass, and lead are well soldered. It is quite acceptable to solder nickel, low-alloy and carbon steels, zinc. Materials that are difficult to work with include aluminum, stainless, as well as chromium, high-alloy steels, aluminum bronze, cast iron, magnesium, and titanium. In practice, it can be noted that only an unprepared part or wire, an incorrectly selected flux and an incorrectly selected processing temperature lead to poor soldering.

So a properly selected flux is the key to a perfectly done job with minimal time and physical costs. It is the flux that is responsible for whether the desired metal will be soldered, what the strength of the joint will be, how difficult it will be to go through the whole process. The whole task of the flux is to destroy the oxide film of the soldered metal.

Flux "Soldering acid", which refers to acidic active fluxes, must not be used when soldering electronic parts. Due to its aggressiveness, such a flux can cause corrosion. But it is precisely this property that will allow you to perfectly connect metal parts. Thus, the more chemically resistant the metal, the flux used should be more active. But we must not forget that what remains of the active fluxes must be removed after the process is completed.

For soldering steel structures, an aqueous solution of zinc chloride and soldering acids produced on this basis are considered effective fluxes. At the moment, manufacturers have introduced a wide range of strong fluxes that can also be used in soldering.

When working with stainless steel, unlike low-alloy and carbon steel, you need to use more active fluxes that will destroy the layer of persistent oxides covering the surface of stainless steel.

When figuring out how to solder iron products with a soldering iron, it is obvious that an electric soldering iron will not be suitable for these purposes, since it will not be able to complete the task assigned to it. It is necessary to solder cast iron only by high-temperature soldering.

To perform high-quality work with stainless steel, it is necessary to use phosphoric acid (F-38). Since it best overcomes the oxide resistant film covering this material.

Galvanized iron will easily allow you to solder flux, which includes zinc chloride, ethyl alcohol, ammonium chloride, rosin (LK-2).

Fixtures and materials

Not all devices and materials are necessary when carrying out soldering work. But all of them simplify and make working with a soldering iron more convenient and comfortable.

Not all devices and materials are necessary when carrying out soldering work. But all of them simplify and make working with a soldering iron more convenient and comfortable.

A soldering tool stand is needed not only for convenience, but also for safety. To ensure that the heated tip of the device does not touch foreign objects that can be damaged by such contact.

There are three options for obtaining such a necessary device:

- The stand is sold in a set with a soldering tool.

- Purchased.

- Produced independently from a sheet of thin tin.

To remove excess solder, there is a special braid, which is made from fluxed thin copper wires. Its unwound end is applied to the solder, and then pressed on top with a soldering iron. Subsequently, all excess solder with the help of capillary forces, it is possible to collect in it, as in a blotter. The used tip of the braid, which is already saturated with solder, is cut off and discarded.

When soldering, it will be very appropriate to have a device called a “third hand”. This device, with its clamps, solves the problem with a catastrophic lack of hands during the soldering process, where a soldering iron is held in one hand and solder in the other. In addition, this device can also be equipped with a magnifying glass, which will help you better see soldered small items or thin wire.

And of course, you can not do without soldering procedures without tweezers, clamps, pliers. After all, the parts can get very hot, and it will be impossible to hold them with your hands.

Soldering iron technique

There are several ways to work with a soldering iron:

- Delivery of solder from the tip of the tool directly to the desired parts.

- Supply of solder directly to the area of the soldered part.

But before you start soldering, you need to make preparatory manipulations with the details. Preparation consists in fixing the parts, heating the soldering iron and wetting the soldering place with flux.

If soldering in the first way, a small amount of solder is melted on the soldering iron and presses its tip to the necessary places on the soldered parts. The steady movement of the tip of the soldering iron along the intended seam contributes to the ideal distribution of solder over the soldered surface.

In the second version of soldering, you must first heat the necessary parts with a soldering iron to the required soldering temperature, and then the solder is fed end-to-end between the necessary parts or on the surface to be soldered. The solder, when melted, will fill the gap between the parts, which will provide the desired result.

Wire tinning

Tinning is the process of coating the top layer of metal with solder. Such an operation is carried out both as a preparatory operation before soldering, and as an independent operation.

Tinning is the process of coating the top layer of metal with solder. Such an operation is carried out both as a preparatory operation before soldering, and as an independent operation.

The most common area where tinning is used is the tinning of the ends of electrical wires. How to properly solder wires with a soldering iron and produce tinning to get the desired effect, we will consider in detail.

Depending on what the wires are made of and their condition in which they are at the time of work, the processing to which they must be subjected also differs.

Solid copper wire is best suited for tinning. The new wire is not protected by oxides, so it does not need to be manipulated to clean it. The process consists in applying flux to the tip of the wire, solder is applied to the hot end of the soldering iron, and the soldering iron is carried along the wire, while trying to turn the wire.

In some cases, when the conductor does not intend to tinker, a simple tablet can help. This can happen if the wire is varnished or enamelled. In this case, it is necessary to place an aspirin tablet on the planks and, pressing the conductor tightly against its surface, heat it up with a soldering iron for several seconds. With such actions, the tablet melts, which causes the destruction of the varnish. After that, you can carry out tinning of the wire without problems.

Fumes from a melted aspirin are harmful to health, so you can use a special flux that removes varnish from the surface of the wires.

If the wires are old, then they are usually covered with oxides, which will interfere with the tinning process. You can solve the problem with the help of the already mentioned aspirin. To do this, you need to unwind the conductor, put it on a tablet and heat it with a soldering iron for several seconds, moving the conductor from side to side.

To carry out tinning of aluminum wire, you need to purchase a special flux, for example, Flux for Aluminum Soldering is ideal. It can also be used when soldering metals with a resistant oxide film. The only thing that should not be forgotten when using such a flux is the cleaning of the soldered surface from its remnants. If this is not done, corrosion may appear at the soldering site.

To carry out tinning of aluminum wire, you need to purchase a special flux, for example, Flux for Aluminum Soldering is ideal. It can also be used when soldering metals with a resistant oxide film. The only thing that should not be forgotten when using such a flux is the cleaning of the soldered surface from its remnants. If this is not done, corrosion may appear at the soldering site.

To remove the remaining solder formed during tinning, you can place the wire vertically and press a hot soldering iron to the place of excess. All excess will drain to the soldering iron from the wire.

Using all the knowledge and the right materials, you can achieve perfectly done work when using a soldering iron.

elektro.guru

How to learn how to properly solder with an electric soldering iron: working rules

The soldering procedure is a very simple operation, subject to the technological process and the availability of skills. This article will tell you how to solder correctly at home and explain the basics of soldering. Starting from the simplest soldering of strands of wires and gradually mastering more complex actions, the skill and quality of the connection of parts will increase. How to properly solder with a soldering iron with rosin, acid, is described in the technological process of soldering, which is radically different from welding. In addition to conventional electric soldering irons, experienced craftsmen have professional soldering stations for repairing printed circuit boards of complex devices.

Soldering Technology

There are four types of devices used for soldering: electric, induction, gas, hot air. Electric soldering irons have a heater of a spiral or ceramic type, gas ones work with a burner, and hot air ones use an air stream. The most used are electric soldering irons, which are very convenient to use and affordable. They are subdivided by power, which determines the release of heat flux to the contacting parts.

Soldering of electronic elements is carried out with electric soldering irons with a power of up to 40 W, and devices of the order of 80-100 watts are used for thin-walled parts. More massive fixtures are used to work with metal having a wall thickness of 2 mm or more. These tools include hammer-type soldering irons with a power of over 250 watts. The choice of an electric soldering iron is also influenced by the thermal conductivity of the workpiece.

The soldering process takes advantage of the molten metal's ability to spread well. This connection method makes the parts one-piece, united by a layer of solder after the hot mass solidifies. The value of electrical conductivity depends on the quality of the soldering of the contacts. To learn how to work with a soldering iron, it is recommended to watch the corresponding video, as well as study the instructions for working with this electrical appliance.

Connection of parts by soldering is possible under two conditions:

- cleanliness of the place of soldering;

- compliance with temperature conditions.

Cleanliness of the soldering area

The presence of an oxide film on the legs of radio components makes it difficult to attach to the surface of the solder. This process takes place at the atomic level, so the presence of contaminants will not ensure its reliable adhesion to the elements. Fluxes are used to prevent the formation of an oxide film. In order to understand how to properly solder with rosin or acid, check out the technology for their use.

Compliance with temperature conditions

Before you start soldering, you need to decide on the choice of alloy for the elements used. The temperature at which the solder passes into a molten state must be below the allowable parts to be soldered. This is especially true for aluminum compounds, as well as elements with high shrinkage during solidification, which interferes with the normal crystalline formation of the solder mass.

The main mistakes when working with a soldering iron

The process of soldering only to the uninitiated seems to be a very simple matter. However, it requires some knowledge and certain skills, depending on experience. Learning how to properly solder with rosin, solder and acid is not difficult at all. To do this, you need to familiarize yourself with the technology, the basic principles of the work, try to avoid the main mistakes. Before you learn how to solder with a soldering iron, you should carefully study the basic techniques of work, as well as some of the nuances. Skill comes gradually, as does the quality of the connections made. Common mistakes newbies make when using a soldering iron include:

- don't drink;

- overheat;

- solder rolling;

- chemical destruction.

Don't drink

Bad soldering threatens to fail electrical parts and is obtained for several reasons. This is due to a poorly heated soldering iron tip, the use of a refractory alloy, the movement of contacts during the solidification of the mass, and also an excessively cold soldering surface.

Overheat

This process occurs when using an electric soldering iron with more power than necessary, as well as a high temperature of its tip for a certain type of soldering work. In addition, overheating occurs when a heated soldering iron is exposed to the work area for a long time, and refractory solder is used to connect elements with low temperature resistance. This leads to thermal destruction of connecting wires, parts, changes in their characteristics.

Solder rolling

The rolling process is obtained due to poor cleaning of the connected elements. The oxidizing layer on them does not allow the alloy to spread well and get into small cracks. In addition, this occurs when the joints are poorly treated with flux, as well as when its grade does not match the metal to be soldered. Rolling leads to poor contact, possible mechanical damage at the slightest external impact.

Chemical destruction

Chemical destruction occurs with the wrong choice of flux, which does not correspond to the type of elements connected by electrical soldering. In addition, it can occur if you do not flush the joints at the end of the workflow. This threatens corrosion, as well as the destruction of the metal conductor.

This information will help you understand how to learn how to properly solder electrical connections to ensure reliable contact.

Preparatory process

At this stage, the preparation of the electric soldering iron and the connected products is carried out. To determine what is needed for soldering parts with a soldering iron, you must have a minimum set of components at home. It consists of an electric soldering iron, fluxes for various materials, solder, auxiliary tools. A new electric soldering iron may smoke when initially plugged into the mains. This is quite normal - this is how preservative oils burn out on his sting.

Tips can have a different shape, suitable for various types of soldering. The new tip is tin-plated to protect against wear as well as oxidation. To do this, the heated tip is immersed in rosin, the metal is melted on it, after which it is rubbed against a wooden block. As a result of this procedure, the sting should be completely covered with an alloy. During the soldering process, the flux gradually corrodes the copper tip, which requires its periodic sharpening and repetition of the tinning procedure.

Before soldering with rosin and tin, the place is prepared. The parts used for electric soldering are cleaned of contaminants and degreased. For this, various solvents based on acetone, gasoline and other liquids are used, rust is removed mechanically. This is necessary for the rapid removal of the oxidizing film from the surfaces to be joined.

Tinning or fluxing

Tinning involves covering the surfaces to be joined with a thin layer of solder. This procedure is used in the preparatory process, as well as intermediate and final. The use of a preparatory procedure greatly facilitates the final connection of the elements, since already tinned parts are easily soldered.

Tinning wire ends of various diameters is one of the most common soldering operations. A flux is applied to the core cleaned from insulation, after which a tip with solder is drawn along its surface. The molten metal easily passes to the core and the tinning procedure is completed. To improve the procedure, it is recommended to carry out mechanical cleaning of the surface of the cores of wires and cables. Radio components do not require this preliminary procedure and are easily soldered on boards.

Fluxes are used for different metals to be joined. They are specifically designed to work with certain materials. Fluxes for aluminum electric soldering are also suitable for stainless steel products. At the same time, it is necessary to clean the surface of the products from their residues after soldering in order to avoid corrosion.

Soldering technique

Performing work with a soldering iron is performed by draining the solder from the tip onto the part and directly feeding it to the site of the soldered element. Regardless of the soldering method, the part is prepared, installed and fixed in its working position. After that, the place of processing is wetted with flux and the electric soldering iron is heated. How to solder with a soldering iron with rosin will tell you a video with a detailed demonstration of the process.

When draining the solder from the tip, it is pressed against the soldered element. The flux boils and gradually evaporates, allowing the molten metal to flow smoothly from the tip to the junction. Carrying out translational movements with a sting along the place to be joined, the metal is distributed over the joint area and the treated area is corrected.

The supply of the alloy to the place of soldering provides for the preheating of the elements to the desired temperature of the joint. After that, the soldering iron is fed with molten metal end-to-end between the tip and the part. This working method is more suitable for large parts.

After using a variety of acid fluxes, their obligatory washing is required to ensure that the joint is protected from corrosion.

Solder types

For soldering with electric soldering irons, low-temperature solders of the POS brand are used. These tin-lead materials are in the form of metal rods. According to GOST, these hard alloys have different tin content in their composition. Depending on this, they are marked (POS-61, POS-40, POS-30). In addition to them, lead-free and other non-toxic type soldering compounds are produced. They have a higher melting point and provide high joint hardness.

Some alloys have a low spreading temperature and are used for radioelements and microcircuits of numerous boards, which are especially sensitive to overheating. Tin-silver compositions of the PSr type, as well as pure tin, are also actively used. For numerous parts to be soldered, there are tables with the components used to connect them.

Soldering temperature

The quality of the soldered elements directly depends on the heating temperature of the soldering iron tip. Insufficient heating will not allow the metal to spread over the surface even when using flux. Such a connection will have a loose structure and low strength.

The temperature of the tip should be 40 ° C higher than the temperature value of soldering, and for soldered parts this indicator must be in the range of 40-80 ° C. In this case, the soldering tip heats up by 60-120 °C above the melting value of the solder. At soldering stations, the required temperature is set by a special regulator.

To visually determine the desired heating, rosin serves as an indicator. It should release steam and boil, remaining on the sting in the form of small boiling drops.

Security measures

During the electrical soldering process, corrosive gases are released that are hazardous to health, so work should be carried out in a well-ventilated area. In addition, the technological process is accompanied by periodic splashes of molten metal, flux. Use special goggles to protect your eyes. Please note that corded soldering irons require special precautions as they have exposed metal parts. Pay special attention to the condition of the insulation of the supply wire. Make sure that it does not fall on the hot parts of the electric soldering iron, which can lead to an electrical short circuit and a fire.

Many can solder wires and radio components, but not everyone soldered metal. In this article, I will outline the principle of metal soldering as briefly as possible and with examples.

Introduction

Let's start with a general idea of soldering. Soldering is a physical and chemical process of obtaining a joint as a result of the interaction of solder and the metal to be soldered. It has similarities with fusion welding, but there are still differences between them. When welding at the seam, the parts to be welded melt, and when soldering, the brazed material does not melt. Also, unlike welding, soldering is carried out at temperatures below the melting of the soldered metal. The formation of a seam during soldering occurs by filling the gap between the parts to be joined with solder, i.e. the process occurs due to wetting and capillary effect.

The question arises, why use soldering if welding holds the parts together better. This has its advantages:

- Soldering is more affordable than welding.

- When soldering, the connections are detachable.

- Welding is not amenable to small parts.

Soldering is a fairly strong connection, if you follow the technology.

Equipment

For soldering metal, the following basic equipment is required:

♦ soldering iron . Power depends on the size of the soldered parts. For soldering small parts (tin, wire, bolts), a 60 watt soldering iron will do, for larger ones - 100 watts and more. I use 2 soldering irons - for 65 and 100 w, for home conditions this is quite enough.

I will not dwell on how to tin a soldering iron, there are separate articles on the Internet about this. I'll just say the basics:

- When you turn on the soldering iron for the first time, you need to let it burn - put it on the street and wait until it stops smelling and smoking.

- The tin should evenly cover the tip. When heated, the sting will burn out, it will need to be sharpened and tinned again.

♦ Soldering acid and solder . A wooden stick is used to apply acid.

♦ Accessories . These include a file and emery, necessary for cleaning the soldering iron and parts.

The soldering iron also needs a stand. The simplest thing that can be used as a stand is any metal object from which the soldering iron will not roll.

To hold the parts to be soldered, various tools are used, such as a vice and pliers. Also, the details can be fixed with carnations on the board.

Soldering Basics

Let's now figure out which metals are easy to solder:

- Silver

- Brass

- Nickel

- Iron

- Stainless steel

The remaining metals are soldered using special fluxes and other technologies. This article will not cover this topic.

We figured out the metals, now we begin to study the soldering process:

- We clean the place where the seam will be located. For this I use .

- We degrease the place of soldering using acetone, gasoline, etc.

- We apply soldering acid to the seam with a wooden stick. We do it as smoothly as possible, because. in the future, the solder will spread exactly over this place.

- Remove oxides (if any) from a pre-tinned soldering iron and touch them to the solder stick. Solder should lie on the sting in an even drop. If this does not happen, then the soldering iron is badly tinned.

- We touch the sting to the place of soldering. It cannot be expected that soldering will occur at the first touch of the soldering iron. To do this, it is necessary to heat the surfaces to be soldered to the melting temperature of the solder. The heat from the soldering iron is not immediately transferred to the place to be soldered. Tin, wires and other thin parts warm up quite quickly, but not instantly. It takes a relatively long time to heat up thick materials.

- To solder thin parts, you need to move the soldering iron rather slowly, moving it further when the solder spreads and floods the seam. When soldering thick objects, you have to keep the soldering iron in one place for a relatively long time and wait until the surfaces to be soldered warm up and the solder spreads along the seam.

- After running the soldering iron for a certain distance, move it back a little, then forward again and back again, until the solder spills out in a smooth and clean path. As the solder is used up, it is collected from the stick. You should not collect a lot of solder, especially if the surfaces to be soldered are evenly and tightly connected; Too much solder will cause streaks to form.

- After soldering, it is necessary to wash off the remaining acid with water. If the acid does not wash off well, use soap. Unwashed acid will oxidize the metal.

It is best to learn how to solder on tinplate. It does not need to be cleaned, but it must be degreased. In the presence of fat, the acid does not wet the surface of the tin. Below are examples of soldering wires and tin. For training, you can repeat all this.

Soldering tin / sheet metal

Connection "Back-to-back"

Quality: Low strength

Connection "Overlap"

Quality: Durable

Connection "To the castle"

Quality: Very durable

Soldering wire

Connection "Back-to-back"

Quality: Low strength

Connection "Overlap"

Quality: Durable

Amplified connection

Quality: Very durable

For reinforcement on the left connection, a copper wire wound round to round is used, on the right - the rod and thread are wrapped with a strip of tin:

A soldering iron is considered one of the most common tools that can be found in the home of any owner. It is not necessary to be a specialist and solder professionally. But every representative of the stronger sex should have general fundamental knowledge. Breaks in wires in electrical appliances, contacts in sockets, headphones, repairing circuit boards are frequent phenomena, faced with which a person wants to learn how to learn how to solder.

What is a soldering iron?

This is a special heat-emitting device with a power of 15 to 40 W, sufficient for soldering wires, boards and microcircuits. There are soldering irons, the power of which is higher. They are intended for light soldering - for soldering badly connected wires of thick diameter or for soldering XLR connectors. The function of the heating element in soldering irons is performed by a nichrome wire, which is wound on a tube containing a "sting" - the working surface of the device. The sting is a copper rod that is heated from

Copper is used in the soldering iron device, since this metal has a high thermal conductivity. The heat supply to the wire is due to electric current. The soldering iron device contains an insulator, which is mica. For safety reasons, it prevents the wires from contacting the metal tube and the soldering iron casing.

Which soldering iron to choose?

Learning how to solder correctly is easy, but with a well-chosen tool. Among the wide variety of these devices, an amateur master who decides to repair office equipment should choose an acoustic soldering iron, which is small in size and has good performance. It has a low heat capacity, which is desirable for fine soldering work in chip assembly. It is better for a novice master to opt for a device whose power does not exceed 40 watts. It is important that the soldering iron is also not weaker than 15 W, since the power in such a product will not be enough even to connect simple office equipment wires. It is preferable to buy a tool with a three-way grounding plug. Its presence will prevent possible voltage dissipation during the movement of electric current to the metal tube.

An industrial soldering iron is suitable for performing work on connecting calibration wires, chassis and stained glass work.

Which sting is better?

The working parts of soldering irons, depending on the size, are of two types:

- ordinary, the diameter of which is 0.5 cm;

- miniature with a diameter of 0.2 cm, used for soldering very thin wires and copper parts.

The working parts of soldering irons can be in the form of a needle, cone and spatula. The latter form is the most common, since it makes it possible to scoop up the required amount of solder. In addition, for the convenience of soldering, the tip can be straight or curved.

What is the principle of soldering?

The soldering procedure consists in joining two metal elements using a third (solder). In this case, the melting temperature of the parts to be joined must be higher than that of the third element, which, in the molten state, penetrates into the gaps of the parts to be joined, as well as into their structure, providing a mechanical connection. At the same time, an electrical contact is observed between the connected parts.

What do you need to work?

The soldering procedure is not difficult. The question of how to learn to solder from scratch is easily solved. To do this, it is enough to acquire the necessary material and, following the instructions, begin training.

Where to learn to solder?

You can train at home by soldering conventional electrical wires. The main thing is to follow the safety instructions.

At work you may need: