When installing plastic windows, many do not even suspect that there are special, simple and laconic-looking platbands for them. And it is completely in vain - when placing an order for the installation of such window systems, it is quite possible to immediately coordinate the installation of these elements.

However, this is not the only possible solution to the issue. Platbands for plastic windows can also be made of wood and decorated with artistic carvings. If you use this option to decorate the front of the house, then the window openings will be framed in the same way as Russian masters of wooden architecture have done for centuries.

There is no need to think that platbands perform an exclusively decorative role. In fact, they are very functional, and are designed to close the gaps between the window frame and the wall, which nowadays are most often sealed with polyurethane foam. Platbands protect this filling from negative external factors, such as ultraviolet rays, which have a destructive effect on polyurethane foam, direct moisture, etc.

Platbands and their functions

Briefly, the process of installing a plastic window is as follows:

- If old windows are installed in the openings, they are dismantled, and the vacated opening is cleaned of insulating materials and contaminants.

- Then, a plastic frame is inserted into the opening, which is leveled to the building level and secured to the walls in several places with special metal elements - anchors or plates (subverses). Double-glazed windows are installed and fixed with special glazing beads.

- Next, all the gaps left between the frame and the wall are sealed - filled with polyurethane foam, closed with special sealing and hydrophobic tapes, etc.

- After the foam hardens, its excess is cut off. Then the top is filled with putty and the slopes are installed.

- And finally, platbands are installed, which close the foam-filled gaps from the outside or inside.

Installing a plastic window yourself is not an easy task.

When installing such a system, it is necessary to provide for many nuances. The process is described in detail in a special publication on our portal.

The standard package of a metal-plastic window with double-glazed windows, as a rule, does not include platbands, especially since these finishing elements are not suitable in all cases. For example, if the windows are deeply recessed into the wall, then you need to choose very narrow trims, or install them around the window opening. Moreover, in the second option they will serve exclusively as a decorative element, therefore they are installed only at will.

However, it should be noted that platbands have their own advantages, which attract many owners of private houses:

- Neatness and aesthetic appearance of windows.

- In its own way, there is a certain exclusivity in the design of standard plastic windows, since most owners do not use these elements of facade decoration.

- And the functionality already mentioned is the protection of the sealed gap from the influence of the external environment.

It should be noted that there are platbands designed for finishing windows on the inside. Such products are usually intended only for decorative purposes, so they are purchased mainly in cases where the interior of the room needs to be maintained in a certain style. For example, such a design is suitable for “rustic Russian” or “country” style - both of these trends have been actively coming into fashion lately.

Varieties of platbands by shape and material of manufacture

Platbands for plastic windows can be of various types and profiles, made using a variety of materials:

- Flat strips made of plastic, aluminum, polyurethane and wood.

The simplest ones are platbands in the form of flat plastic strips

The simplest ones are platbands in the form of flat plastic strips Most often, flat-shaped platbands are used to frame plastic windows, since they are easy to install, create a neat appearance, are easy to maintain and have the most affordable price of all existing configurations.

- Carved platbands, which are made of plastic or natural wood.

This version of the parts is made mainly to order from wood, and therefore is quite expensive. Plastic versions of carved window frames are not easy to find in construction stores, since their mass production is not organized everywhere and is not large enough.

- Shaped-type platbands can have a smooth semicircular shape or almost flat, but with a relief pattern in the form of stripes of different depths. This type is made from almost all of the listed materials.

- Profile trims are made of plastic, wood, polyurethane or aluminum. They have a certain cross-sectional shape, sometimes made in a rather intricate configuration.

The peculiarity of profile platbands is their complex cross-sectional shape

The peculiarity of profile platbands is their complex cross-sectional shape Selecting a platband based on material of manufacture

It is important to choose the right platband, which would match in appearance not only the window frame, but also the material of the facade walls or its external decoration.

- Plastic options have the most affordable price and a very aesthetic appearance, however, they do not have a very long service life.

Typically, all manufacturers have in their product range also platbands of the same color as the profile for the frames. Therefore, when placing an order, you can immediately ask which types of decorative trim can be offered.

As a rule, plastic trims are made in different colors, but the most popular option is white. After it, “on the popularity ladder” is brown-chocolate, and then other colors follow, which are used much less frequently. Therefore, not all window manufacturers can offer the profile of the desired rare shade.

The color of the frames is usually matched to the shades of the walls or roof of the house, and sometimes the design of the facade is carried out on contrasting principles.

Plastic framing options are produced in sets that are assembled into a single frame on site, or in a finished, solid form, in the likeness of a frame, which can only be secured around the perimeter of the window opening.

There are special plastic profiles for platbands, which are mounted on the wall and snapped into place with a special locking connection on the slopes installed around the window. This option allows you not only to create a neat frame, but also to securely connect the slopes with the decorative frame of the opening, without any gaps.

- Platbands made of polyurethane also deserve attention, as they are often used to decorate windows.

Profiles made of this material can have different relief shapes, they are light in weight and can be easily adjusted to size and mounted on a window opening or even directly on a window.

Polyurethane framing options withstand moisture and sunlight, so they will last for a very long time.

This material can be coated with paint, so if you decide to change the facade design, there will be no problems with changing the color of these elements. When painted, polyurethane becomes even more resistant to external influences, acquires an aesthetic appearance and is very easy to clean from dust deposits.

Platbands are also made from polystyrene foam, which usually have additional internal reinforcement. Their quality is somewhat inferior to polyurethane foam, but they can also be used for both external and internal finishing of window openings with plastic windows.

- Natural wood frames are very durable and beautiful, provided they are well treated with protective compounds. Such parts, with high-quality performance, have a fairly high cost.

Wooden trim is, of course, a “classic” façade decoration

Wooden trim is, of course, a “classic” façade decoration Wooden frames for plastic windows are perfect for a house that has wooden walls or is finished with a material that reliably imitates wood. As mentioned above, wooden platbands with figured carvings are most often made by hand and ordered individually for each style of selected facade design.

Wooden options can be painted in different colors, which are selected depending on other shades present in the overall ensemble, so as to achieve harmony with the decoration of the facade and the color background of the roof of the house.

The disadvantage of wooden platbands is that they need to be painted much more often than polyurethane ones - paint on wood is more susceptible to fading.

Installation of platbands on windows

Platbands are installed in different ways. This depends on both the material of manufacture and the installation location, since the window can be recessed into the wall or be located in the same external plane with it.

- If the window is recessed into the wall, then they are first installed around it, which will cover unsightly areas of the wall around the frame that can spoil the overall aesthetic appearance.

To do this, a special plastic starting profile is attached to the window frame, into which the slope panel will be inserted.

The figure clearly shows the principle of installing the slope into the starting profile, and then the plastic casing.

To join the platbands at the corners, their edges are cut at an angle of 45 degrees. The cuts will turn out neat and accurate if you follow some recommendations:

- sawing should be carried out using a special template - a miter box;

Smooth joints of the platbands at the corners are ensured by using a special device for cutting them - a miter box

Smooth joints of the platbands at the corners are ensured by using a special device for cutting them - a miter box — if the miter box is not used, and the casing is sawed off in a horizontal position, then the cut should be made from the outside;

- If the platbands have special grooves for fastening them to the slopes, then they are simply installed with tenons in them and snapped into place.

Video: example of installation of plastic trims - flashings on a PVC window

- In the case of fastening the platbands to the wall surface separately from the slopes, the prepared parts are tried on the window opening, and their location is marked on the plane of the wall. After this, “liquid nails” or “Moment” glue is applied to the back side of the trim panels, and the frame is glued along the markings. The joints at the corners are also glued together with glue.

Applying “liquid nails” to the back side of the platband

Applying “liquid nails” to the back side of the platband Wooden trims are fixed to the walls using dowels or self-tapping screws. To do this, through holes are first drilled in wooden parts, which are then slightly expanded on the front side so that the head of the fastening element is hidden in the thickness of the wood. Using the markings, a hole is made on the wall where the dowel is installed, and then a self-tapping screw is screwed into it through the platband. The remaining hole in the platband, in which the screw head is “hidden,” is sealed with epoxy resin mixed with fine sawdust. This putty will make the installation sites of fasteners almost invisible.

Manufacturing of platbands

Some craftsmen prefer to make carved frames themselves. They are cut out according to a pre-made template, through which the design is transferred to a perfectly processed high-quality board.

You can also make platbands in the form of smooth panels, which will be quite simple to make, but in this case, the board must be even and smooth. It is treated and then with water-repellent compounds. Sometimes the wood is darkened with stain and then coated with a moisture-resistant yacht varnish.

Choosing wood for platbands

Properly selected wood will greatly facilitate and speed up the work on platbands, so the choice of material must be taken seriously.

It would be optimal to choose wood that is easy to process. Thus, linden, alder and aspen are well suited for cutting out complex lace elements of the casing. You should not choose coniferous trees:

- for example, spruce has a large number of knots, which can significantly spoil the design;

— pine is an excessively fragile material that may chip during operation;

— cedar and larch, in principle, are well suited for long-term use of platbands in outdoor conditions, however, they have a very high structural density, so they are difficult to process.

The wood must be moderately dried so that when drying, the finished parts, on which a lot of effort will be spent, do not become deformed or crack.

The thickness of the boards for platbands is selected depending on the height of the relief pattern, and can vary from 10 to 40 mm. Therefore, before buying material, you need to decide on the choice of ornament.

If the relief contains small protruding elements, it is recommended to manufacture and process them separately, and then glue them into the place provided for them.

If the trim is not going to be painted, then you need to choose boards with a beautiful textured pattern, without a large number of knots, and having an even “healthy” structure of one shade, which will be in perfect harmony with the design of the entire facade.

Platband dimensions

Calculations are made as follows:

- The height and width of the window opening are measured - these will be the parameters of the internal perimeter of the platband.

- Then, the width of the platband is measured from the opening line to determine how much it will cover the wall. This is especially important when the window frame is in the same plane as the wall.

- The height of the casing should be equal to the height of the window opening plus two widths of the casing panel. Thus, the calculation is carried out if the horizontal top and bottom bars of the frame being created will have the same width as the vertical ones. If the horizontal panels are planned to be made wider, then the vertical ones should have a height equal to the height of the window opening plus the width of the upper and lower sides of the casing.

- The size of the sides of the platband will also depend on which corner joint will be chosen, so before you start cutting the board, you need to carefully consider all the nuances.

Manufacturing and processing of wooden platbands

The selected pattern is applied to the prepared boards. As already mentioned, this process is best done using a pre-cut stencil.

If you have no experience in cutting out designs, then it is better to choose a design that is not the most complex.

When the drawing is completely transferred to the board, you can start cutting it out. An electric jigsaw is used for work. In each closed section of the drawing, a through hole is drilled with a drill into which a vertical jigsaw file will be inserted, and from this place this fragment of the board will be carefully, slowly cut out.

When cutting out a figured pattern, special care and caution will be required - any awkward movement can ruin the whole work

When cutting out a figured pattern, special care and caution will be required - any awkward movement can ruin the whole work In addition to a jigsaw, you can use a router for work. It will help smooth out sharp corners in a through drawing, and it is more convenient to cut out some relief elements with this tool.

In order for the pattern on the casing to look aesthetically pleasing and professional, it must be sanded with sandpaper, first with medium grain (140 ÷ 180), and then with fine grain (220 ÷ 400). Processing is carried out manually, and to make it less labor-intensive, you must first work well with a milling machine.

If individual relief parts were made separately, they are secured using wood glue after processing all surfaces. When the glue dries, the entire casing, including all relief elements, is impregnated with antiseptic compounds and also left to dry.

The final stage of work is coating all surfaces with a waterproof protective composition for wood. The best option for external parts would be to use yacht varnish. Naturally, if desired or if the façade color scheme is observed, the trims can be coated with paint of the desired color.

Curly platbands will help to “revive” the look of standard plastic windows

If you want to try your hand at making this façade decorative detail, then it’s best to start by practicing on pieces of board to “get your hand.” Then, when it works out, you can go directly to. Detailed instructions can be obtained in a special publication on the portal.

In conclusion, we can summarize that whatever type of platbands is chosen, they will make the appearance of the facade of the house more aesthetically pleasing and neat. In addition, these parts will create additional protection for the gaps between the window frame and the wall that are hermetically sealed with insulation.

Hand-made window trims are a wonderful decoration for the facade of a house (ready-made stencils and templates will be given in the article below). They make the house unlike any other, visually changing its proportions.

Today, with certain skills, you can independently create elegant frames for windows in a wooden building. Moreover, they can be made not only from wood, but also from other materials.

Specifics

When the owner decides to install platbands, he strives to arrange traditional decor in his possessions.

When the owner decides to install platbands, he strives to arrange traditional decor in his possessions.

Platbands have the following advantages:

- Excellent decorative function. This visually enlarges the building.

- Complementing the overall style of the architectural design.

- The space between the window opening and the wall plane is protected from moisture and dust.

- Heat losses and noise levels are reduced.

- The individual features of the house and the style of the chosen era are highlighted.

Platbands also have some disadvantages:

- Wood needs certain treatment to prevent high humidity and deformation.

- Products require regular care and treatment.

- They do not harmonize with metal-plastic windows. In this case, the platbands are made in the same color scheme.

Create your own templates

Today there are many platbands. Their types are determined by the methods of their installation to the window. According to this criterion, there are two varieties:

Today there are many platbands. Their types are determined by the methods of their installation to the window. According to this criterion, there are two varieties:

- Telescopic. Their specifics: L-like protrusions that coincide with the grooves of the window frame.

- Invoices. Installation takes place on the window frame. Fasteners - construction glue or nails with screws.

Note: finished samples are created in full size. They are printed in compliance with the required parameters.

An elegant solution is the installation of carved products. It is possible to independently implement such plans only if you have special equipment.

Popular materials

- The most common material for platbands is wood. Products made from it have an elegant and harmonious appearance.

- Plastic versions are also often used. They are characterized by strong resistance to temperature changes and ultraviolet radiation. Plastic options are sold ready-made.

- Another popular material is MDF. It is prepared from wood waste. It is more environmentally friendly than plastic. In addition, products made from it have a look reminiscent of natural wood.

- Polyurethane. Variations from it are highly practical. Facade stucco molding is often made from this material.

The nuances of choosing the right wood

As already noted, wood is the most popular material for platbands. And the performance characteristics of wooden platbands depend on the type of wood used.

As already noted, wood is the most popular material for platbands. And the performance characteristics of wooden platbands depend on the type of wood used.

Here we usually pay attention to such options.

- Hard deciduous. These varieties include oak and beech. They are very durable. But it is quite problematic to create patterns on them.

- Soft deciduous. These are: linden, aspen and alder. They are easier to process. Patterns are even created on their surface by hand. And such surfaces are thoroughly treated with special means.

- Cherry and apple tree. They are optimal for creating small components that can be attached to the base.

- Pine and birch. They are also easy to handle. And they have excellent working qualities.

- Various combinations of wood types. The use of special protective compounds for powerful impregnation here is mandatory.

Using high-quality wood, a beautiful, original design of the window opening is obtained.

The nuances of creating templates with your own efforts

The basis of the work comes down to creating stencils and design.

Printing stencils on your own is something that everyone can do. It is important to achieve a combination of the chosen ornament with the entire style. Mixing geometric and floral patterns is not allowed.

When working on platbands, the following subtleties are taken into account:

- There should be harmony in the color palette of the walls and decorative elements.

- It is imperative that the appropriate parameter is selected correctly. The platbands should not be very wide or small.

- A high-quality version of the coating is selected. Special paints and varnishes are used.

- A template is required for making external carved components.

- The pattern is correctly positioned on the workpiece. The details follow along the wood grain.

When it is possible to achieve a color combination of platbands and the plane of the walls, a complete and harmonious facade is obtained.

Manufacturing stages

Before creating window decor, carved platbands are selected from photographs. You need to make a template in advance. It should turn out to be the same for the design work of all openings.

The following methods for creating patterns are usually used:

- Overlay thread. It has separate pattern elements. They are attached to the same base.

Installation of overhead components should be on the base in compliance with the template pattern.

- Slotted thread. Here they make a through ornament. It looks like wood lace.

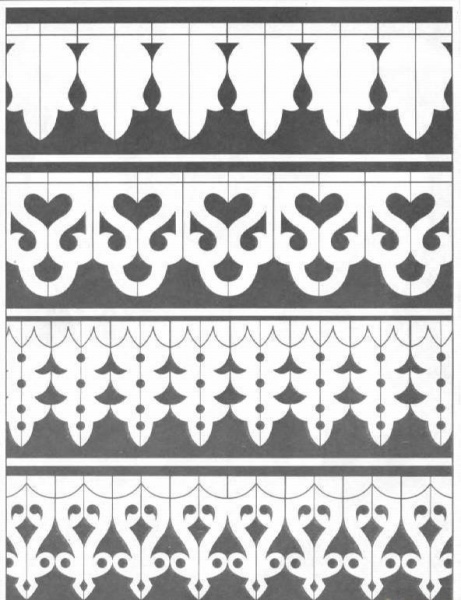

For all working methods, the presence of stencils is mandatory. This is what they look like:

Advice: For simple patterns it is not necessary to make a large-scale stencil. A piece of notebook paper is enough.

Also in your work you must have the following tools:

Also in your work you must have the following tools:

- Jigsaw.

- Hacksaw (oriented for wood).

- Knives and chisels.

- Drill.

- Milling technology

Platbands must be created from prepared materials. The working stages are:

- Meticulous measurements are taken.

- The selected tree must be dry. If it is wet or humid, then it must be brought to dry conditions. The width of the boards is determined by the parameters of the window opening. The thickness of the material reaches at least 3 cm if a slotted thread is made, and at least 1 cm when an overhead thread is made.

All workpieces are pre-treated with a protective compound. They are cut using templates. And the cutting of ornaments is done using a jigsaw. It is better to use different types of files for this tool.

All workpieces are pre-treated with a protective compound. They are cut using templates. And the cutting of ornaments is done using a jigsaw. It is better to use different types of files for this tool.

Working with an electric jigsaw requires certain skills and special care. The created holes must be filled. An excellent tool for this is sandpaper. After powerful grinding, the part is treated with special impregnation.

Next, all prepared parts are installed on the base. Here you need to use glue or special nails. In such work, it is better to avoid using self-tapping screws. They will cause the products to crack.

Installation specifics

The created platband can be attached to the desired position using the following methods:

The created platband can be attached to the desired position using the following methods:

- On a dull thorn. Installation of such parts is carried out on the inside. Special holes should be made in the frame for them. Glue is applied to the spike and distributed evenly. The tenon is inserted into the groove. This fastening protects the platbands from dust and moisture.

- Using a through tenon. The joint area here is thoroughly treated with varnish.

These methods are justified when working with a wooden window. To attach to metal-plastic, a special powerful liquid glue is used.

Required care

The installed platbands require constant attention and care. For processing, special preparations are used - powerful impregnations. They create high-quality protection against:

The installed platbands require constant attention and care. For processing, special preparations are used - powerful impregnations. They create high-quality protection against:

- wood pests;

- appearance of cracks;

- sudden fire.

Carved versions must be coated with a primer, then varnish or paint. The intensity of such treatments is once every 3-5 years. This way the service life of the products will be seriously extended, and at the same time their attractive appearance will be preserved.

When installing plastic or metal products, no special care is required. It is necessary to provide high-quality protection against corrosion for products. Periodic paint updates are also required.

Thus, it is very possible to independently make platbands of extraordinary beauty with elegant patterns. Some carpentry, carpentry and tool handling skills are required. This way you can decorate window openings in a very original way and add an elegant twist to your chosen architectural style.

How carved frames are made using the slotted carving technique, see the following video:

It is rare to see wooden platbands on multi-storey buildings, but in private construction this is the most common element. A modern private house can be made original and stylish by installing homemade carved frames on the windows. In former times, each house had unique patterned platbands installed, which were not only decorations, but also served as amulets. Today in Russia there is a tendency towards the revival of traditions, and many owners prefer to install beautiful wooden cash instead of “boring” metal-plastic frames. In this article we will tell you in detail how to make a carved platband with your own hands.

Modern platbands are made not only from wood, but also from metal, plywood, PVC and laminated MDF. Plywood and MDF products are not intended for outdoor use, since they are not able to withstand temperature changes, humidity and exposure to ultraviolet radiation.

Useful: the correct name for the external elements of window decoration is casing, and the casing is the internal frame.

What functions does cashing perform:

- decorative – window openings acquire a complete and aesthetic appearance. A correctly chosen form of platband can visually lengthen a low building or expand a narrow one;

- with the help of a well-chosen pattern or ornament on the platband, you can express individual preferences, traditional characteristics of a family or region;

- platbands help to unite all buildings on the territory into a single architectural style;

- cashing performs a protective function, preventing moisture, litter and dust from getting into the gap between the wall and the window;

- due to the additional wooden frame of the window, heat loss at the points where the window frames adjoin the walls is reduced;

- sound insulation increases;

- often wooden frames are the only acceptable way to decorate a window, especially if we are talking about a wooden house or log house.

There are no disadvantages to platbands as such, but there are a number of features that you need to know in order to install them correctly and extend their service life. Thus, wooden carved frames will sooner or later deteriorate from exposure to the external environment - after all, wood does not last forever and over time is destroyed by moisture, frost and sunlight. But at the same time, treatment with anti-corrosion compounds will extend the “life” of beautiful home-made structures.

It is very important to choose the right type of wood for making platbands, as well as to properly process all areas. It is necessary to regularly monitor their condition, promptly replace damaged parts, tint the surface, etc.

If you plan to install wooden casing on plastic windows, you need to choose the design and color very carefully, otherwise such a design will look ridiculous. But often wood and plastic are simply incompatible. It is better to install wooden double-glazed windows, wood lamination or paint the casing itself white.

Types of platbands

To make carved window frames, you need to decide on the installation method and the type of design itself. So, there are telescopic and overhead trims. Telescopic ones are often installed not on windows, but on doorways. Special L-shaped protrusions are made on them, which slide into the grooves of the box. This is a rather complex connection, but the result is a very beautiful and harmonious frame of the passage.

Overlay casings are attached to window frames using weatherproof wood glue or nailed into place. Very often, cashing is complemented by carved shutters, which make the facade of the house even more picturesque and authentic.

Wood selection

Since the cashbox is placed outside the house, it must be made from the strongest and most durable wood possible to withstand the elements. To make carved frames, the material must also be pliable so that intricate patterns can be easily cut out.

What to make the platband from:

- Deciduous hardwood species are ash, beech and oak. They are very strong and durable, but it is impossible to make “lace” trim from such wood, since they are very difficult to process. When choosing these breeds, it is better to limit yourself to a simple ornament.

- Deciduous species with soft wood - aspen, linden, alder. In this case, the tree, on the contrary, is very malleable and allows you to carve unimaginable motifs, but if processed incorrectly, all your work will very quickly deteriorate. If the finished casing is poorly coated with moisture-resistant varnish, it will very quickly crack and rot.

- Birch and pine are the best option for making carved platbands. In addition to the fact that these rocks are inexpensive, they have sufficient hardness for external use, they allow you to create fairly small designs and make neat cuts.

- Apple and cherry are mainly used for cutting out small inserts, which are then applied to the main pattern of the canvas.

Select a template

To choose a pattern for carved window trim, you need to determine what you want to achieve or demonstrate with the pattern. If you just need to “revive” the facade, you can choose a not too complex design, especially if you need to add windows to all the buildings on the site. This way you will save time and effort.

If you want to emphasize with the help of carved frames your belonging to an ancient family or any nationality, or to reflect the cultural heritage of your homeland, we recommend studying traditional motifs and symbols. Moreover, each region, moreover, each village or city may have its own distinctive features.

If possible, decorate all windows with the same trim. The carving may be slightly different, but the same motifs must be present. For example, on the kitchen window there is a frame with a deer framed by flowers, on the window in the living room there may be a bear surrounded by the same flowers, etc.

Below we will show several examples of patterns for carved platbands, but in order not to repeat someone else’s work, you can copy only part of the design, adding your own patterns to it. This way you can be sure that your windows have a unique frame.

Useful: if you are dealing with wood carving for the first time, practice first on a separate piece of wood of the same species from which the platbands will be made. Hone your skills in hand placement of chisels, basic movements and cuts. Video lessons and tutorials for beginner woodcarvers will help you do this quickly and correctly.

It is easiest to make patterns with round holes because they are quite easy to drill even for a beginner. If you want the platband to last as long as possible, give preference to templates with large elements; besides, they are easier to cut. Small parts will require much more time and skill, and will become unusable sooner, since moisture and small debris will accumulate in them more quickly.

Important: in the upper part of each platband it is necessary to make a slope so that snow and water do not accumulate on the surface of the tree. Just a few degrees of slope, and moisture will quickly flow down, and the surface will dry out faster.

Manufacturing of platband

The laudable desire to do everything yourself requires not only knowledge and skills, but also special tools. In the case of woodworking, you will need a large set of chisels, a hacksaw, sandpaper of various grits, a router, a drill and a jigsaw. In addition, stock up on impregnation to protect the wood from insects, weather-resistant varnish or paint, and stain if you will be tinting the wood.

To make the same pattern on the trim for all windows, prepare a stencil. It is better to cut it out on thick paper, cardboard or plastic.

Important: place the stencil pattern along the grain of the wood so that the carving does not crack, and place colored dots in places where you will need to make through holes.

There are two carving methods:

Step-by-step instructions for making a wooden carved frame:

- Take measurements from the window.

- The wood for platbands must be thoroughly dried. The height and width of the boards can be any, depending on your preferences, but the thickness should be 3 cm for the slotted carving method, from 1 cm or more for the overhead carving method.

- Sand the wood with sandpaper (first No. 3, then No. 1 and zero) - the surface should be perfectly flat and smooth.

- Cut out the stencils.

- On the back side of the casing, select a layer of wood up to 2 mm thick, leaving small edges along the edges. This way the cash will fit more tightly to the window frame.

- Apply the pattern to the front wooden surface with a simple pencil. Paint over the places where there will be through cuts.

- Start cutting out the pattern. First, it is more convenient to finish the through holes, and then start working with chisels. For through cuts, use drills of different sizes, a jigsaw and a router. Make the entry point of the jigsaw using a drill - this will make the cut more accurate.

- Carefully sand all holes with sandpaper (from larger to smaller grit).

- Remove all dust from non-through patterns with a brush or vacuum cleaner.

- Nail the elements of the applied thread to the canvas with nails without heads. For a more secure fixation, apply weather-resistant glue to the back of the element.

- Wipe the cut out casing with a damp, clean rag to completely remove dust from the surface. The rag should be barely damp to prevent the wood fibers from rising.

- Now you can tint the casing with stain or immediately coat it with weather-resistant varnish. Alkyd or yacht varnish is suitable for this - they will reliably protect the wood from fading and moisture.

Platband installation

The durability of cash depends not only on the correct processing of the carved elements, but also on its proper installation on the windows. For this, two types of fastening are used: blind or through tenon. With the blind tenon method, tenons are attached to the casing, and voids of the appropriate shape are drilled in the window profile. Weatherproof glue is applied to the tenon and inserted into the hole. This is a rather complex mount, but very durable and neat.

To make a through fastening, install the tenon in the most inconspicuous place of the platband and make the fastening. This method is less reliable and durable, but it is much easier to implement.

However, please note that these fastening methods can only be used for wooden windows. To fix carved frames on plastic or metal-plastic windows, use special high-strength glue or liquid nails so as not to violate the integrity of the profile.

At the very beginning of the article, we mentioned that previously carved wooden frames were used not only as protection and decoration of the house, but also as security amulets for residents. The application of certain symbols and ornaments protected the family and created a barrier to evil intentions and black witchcraft.

In former times, our ancestors believed that evil forces entered the house through doorways and windows, so they tried to protect these places with all possible methods. The most common and “reliable” way to protect houses was to apply magical patterns.

Even today, in most templates for platbands posted on the Internet, you can find these protective symbols, but now they play more of a decorative role. If you want to make not only an aesthetic, but also a useful element on the windows, you can combine various security symbols with decorative elements. It should be taken into account that each country (region, village) has its own traditions. So, for example, it was customary for the Scandinavians to apply runes, and for the Slavs it was common to have object images (animals, plants, birds).

The images on the platbands helped not only to protect houses from evil spirits, but also to strengthen or develop certain qualities in a person. Thus, plant patterns have always meant unity with nature and love for Mother Earth. The wings meant strength of spirit, and the bird entirely personified the unity of times. The snake symbolizes wisdom, and the cross indicated that the owners of the house strive to maintain harmony between the spiritual and material worlds.

Carved platbands: photo

In most cases, carved frames are used to decorate the windows of wooden houses. But due to the fact that buying a ready-made platband today is quite problematic, it is easier to make it yourself.

Important! All platbands, even the highest quality ones, have one significant drawback - they need protection from precipitation. The production of window trims traditionally begins with the preparation of everything necessary.

Stage 1. Equipment

During the work you will need the following tools:

Stage 2. Material selection

For ordinary frames it is better to use pine, while for carved products it is recommended to take soft wood, for example, linden (the latter, moreover, is much easier to process by hand).

Important! The only disadvantage of linden is its hygroscopicity, which can be easily eliminated by applying several layers of paint and varnish.

Hard wood species should be chosen in three cases:

- with high climate humidity;

- when the air is too dry;

- in the presence of significant temperature fluctuations.

Hardwoods include birch and oak. They are quite difficult to process with hand tools, so you will need a milling machine, but such wood will last several times longer than linden.

Stage 3. Important points during manufacturing

Finished wooden trims should not prevent the doors from opening by at least 90ᵒ. Regarding other parameters, they are selected individually in accordance with the size of the opening. For fastening, you can use spikes or connect elements in half a tree.

Important! In the future, to apply large images to the surface, the upper part of the casing can be extended. Spikes are used for fastening, and the decoration itself is popularly called “kokoshnik”.

The lower part of the product is made in the same carved way and must include the bevel required for the drainage. It is typical that the thickness of the lower part should exceed the thickness of the upper by at least 1 cm.

Small slats are nailed on both sides of the opening - they will hide differences in the walls (if any). The thickness of the slats should match the width of the gap, at least approximately. The final fastening is carried out only after careful adjustment of the joints.

Important! If the shutters open to the street, then the platbands must be installed 3 cm above the window itself.

Stage 4. Pattern selection

Since ancient times, platbands have been decorated with the most bizarre patterns, which were believed to protect the house from evil spirits and the evil eye. Today, the production of carved frames is carried out mainly by qualified craftsmen.

Important! To dodo-it-yourself window platbands, you first need to choose a good stencil that will allow you to create a pattern of any complexity, even without special wood carving skills.

Often, professionals themselves use stencils; without them, only one-time individual orders are carried out.

Stencils today are freely sold in a fairly wide range. They consist of the following components:

- bottom bar;

- top bar;

- vertical slats.

In addition, there may be additional decorative details - hangers, etc.

Stage 5. Making the frame

First, a frame is formed from pre-cut elements. Fastening is carried out using spikes, which are fixed in the hole with nails. A jigsaw is usually used to create the tenons, although a regular fine-toothed hacksaw will also work. A small knife is used to remove sawdust.

The width of the finished frame, as well as the platbands described above, should not interfere with the free opening of the sashes by 90ᵒ. The frame itself should be at least 2 cm larger than the window.

Stage 6. Manufacturing of platbands

Step 1. First, the design from the stencil is transferred onto the wood using carbon paper.

Step 2. Then take a jigsaw with a thin blade and cut out small curly elements.

Step 3. From the outside, the contours of the pattern are cut out so that the fabric runs along the edge of the workpiece.

Step 4. In any case, you will have to turn the saw in the workpiece. This is quite simple to do; you just need to use one of two existing methods:

- upon reaching the turn, several mutually parallel cuts are made (the saw should be able to turn to any angle inside the hole);

- you can go the other way - make a small loop that will allow you to enter from the other side.

Important! Modern jigsaws allow you to make cuts at an angle of 45-90ᵒ, thanks to which you can not only make the smallest cuts, but also give the decorative element a more saturated and voluminous shape.

Step 5. If it is necessary to cut out a closed figure in the center of the product, then a hole is drilled in the middle of the part to be removed. After this, the jigsaw blade will be easier to move in one direction or another.

If the workpiece is thin enough, then when processing it you can do without an electric drill. To do this, take a jigsaw and press it against the workpiece at a right angle. Next, the tool is turned on and the hole is scratched as the blade deepens into the wood.

These are all key aspects of making window casings. Actually, the whole procedure comes down to repeating the steps described above many times, but their specific combination depends only on the skills and complexity of the pattern.

It is worth noting that there are other manufacturing methods that differ from those described above. For clarity, we recommend watching the thematic video.

Video - Production of window casings

Find out which ones are best to choose, and also consider the types and installation methods from our new article.

Prices for platbands and accessories for windows and doors

Platbands and trims for windows and doors

Basic rules. What not to do

Below is a list of rules that will help you avoid the most common problems.

- It is recommended to use a board 3-4 cm thick as the starting material.

- Don't jump into complex patterns right away. First, it is better to practice on ordinary round parts that are easy to make with a drill.

- The width of the workpiece should be such that it is enough to cover the ends of the walls and protect it from moisture.

- Carved elements should be placed along the grain of the wood - this will prevent cracking.

- When choosing a stencil, it is better to pay attention to patterns with large elements, since small ones will look crumpled, as a result of which the finish will not have the desired decorative effect.

Important! Before starting work, you should calculate the future costs of time and money, as well as the feasibility of the idea itself. In the absence of high skills in working with wood and interest in the process itself, it is easier to buy ready-made platbands.

Moreover, it is advisable to first familiarize yourself with photographs of different products. This way you can find a suitable option or get inspiration for creating something yourself.

Stage 7. Installing the product on the window

Now all that remains is to install the finished carved platbands on the windows, for which special glue is used. It is important that it is not organic, otherwise, due to its susceptibility to biological influences, it will harm the products themselves.

You can also use plumbing glue - there should be no problems with it.

Important! If the fastening will be carried out using nails, then the spikes and joints should be coated with an adhesive solution in advance.

Another option that can further simplify the installation procedure is to use self-tapping screws instead of nails. It will be easier, if only because there is no risk of damaging the casing or surrounding surfaces with a hammer.

Important! Self-tapping screw caps are very easy to disguise. It is necessary to mix sawdust with glue and spread the resulting mixture on the caps. It is advisable to do this before painting the windows so that the hidden fasteners also acquire the required color.

The final painting procedure is also quite simple. Some protective material is applied over the finish (not only paint, but also, for example, varnish, impregnation). It is advisable to do this in any case, since such a coating significantly extends the service life of the products.

Paint is known to peel, so it is advisable to use it instead. It is much easier to periodically renew the impregnation than to remove cracked paint. And the latter, as you know, will definitely crack.

As a conclusion

It is commendable that people strive to follow the traditions of their ancestors, because this is especially important in the current conditions of active urbanization. Making your own window frames will require a little time and appropriate equipment. The procedure is complicated, but the result will more than pay for all the costs. Moreover, this way you can save a considerable amount of money, since making custom-made trim for one window will cost an average of 2.5-15 thousand rubles.

Video - Platband options

Old Russian architecture is invariably associated with carved window frames. This form of house design is distinguished by its diversity of species. Just a few decades ago, each region had craftsmen with their own style of creating decorative elements. Today's return to origins is accompanied by a revival of interest in window decoration using carved frames.

Purpose of framing

The word “platband” itself speaks of its location - “on the face”, that is, one of its functions is to decorate the facade of the building. Therefore, people tried to express their individuality through it and decorate their windows with carved frames. In addition to their decorative role, window casings, first of all, perform a constructive function, closing the gap between the frame and the opening. This prevents dust from entering the house, protects against precipitation, drafts and extraneous sounds.

In the old days, magical properties were also attributed to carved frames. It was believed that framing a window with a certain shape of a strip protects against the evil eye and serves as a kind of amulet. Therefore, in the bizarre patterns one could see various figures and plants carrying a specific meaning.

In modern architecture, the functional purpose of window frames is as follows:

- Properly selected carved design allows you to visually elongate a low building or expand a narrow wall.

- The opportunity to show individuality and decorate the building in accordance with the spirit of a certain era.

- Allows you to achieve a unified architectural ensemble between all buildings on the site.

- Protection of cracks from penetration of external negative factors (precipitation, noise, dust).

- It is one of the elements of thermal protection of the house.

Note! Sometimes platbands are the only option for framing a window. This mainly applies to wooden log houses, when the use of other materials is unacceptable due to the loss of a harmonious appearance.

Carved finishes, especially those made of wood, have a number of features that should be taken into account during operation:

- Dependence on the influence of atmospheric factors. Moisture and temperature changes invariably cause damage to decoration.

- When selecting a frame, you should take into account the properties of the rock from which the frames are made and take care of high-quality processing. Timely preventive measures extend the service life of window products.

- Difficulties often arise when combining wooden carved elements with modern plastic frames. With this combination, it is preferable to install windows that imitate wood texture.

The meaning of carved elements

The desire to comply with ancient traditions requires knowledge about the meaning of the various elements of carved frames:

- The sun is usually placed on a kokoshnik. It symbolizes life and energy.

- The personification of wisdom and fertility is contained in the image of a snake.

- A symbol of harmony between spiritual and material aspirations is a cross in a carved frame.

- The feeling of unity with nature is emphasized through vegetation.

- The earrings testify to the hospitality of the owners of the house.

- The connecting element of all times is the silhouette of a bird on the window.

Characteristics of materials and forms

Natural and artificial materials are used to produce window frames. Traditionally, carved elements were made from weather-resistant wood. Characteristics of the properties of individual rocks will help determine the most suitable type:

- Larch is minimally susceptible to rotting processes, but is not suitable for the production of carved frames due to its fragility.

- Aspen, alder and linden are the most convenient species for creating openwork decor on windows. However, the pliable and soft wood of carved frames requires special treatment due to its ability to absorb moisture well.

- Window frames made of oak, ash or beech are characterized by resistance to negative atmospheric influences, but the processing of carved elements is burdened with difficulties, overcoming which you will get a durable decor.

- A good choice would be birch or pine wood, which allows you to create neat carved decor. At the same time, the platbands are strong enough for external use.

- Small carved window decorations that are fixed to the main elements can be made from cherry or apple trees.

Advice ! Regularly updating the coating of wooden frames with waterproof paint or varnish will ensure their long service life.

What other materials are used in the production of window trims and what their features are, we will consider below:

- Laminated MDF allows you to accurately imitate the color of any type of wood, but is intended exclusively for indoor use.

- Plastic windows are harmoniously combined with platbands made of a similar material (PVC), which is not subject to rotting and has a wide color palette that is resistant to solar radiation. The color of the trim is selected taking into account the finishing of the house to match or contrast with the facade.

- For round windows, polyurethane products are ideal, as they are lightweight and easy to maintain.

- Metal strips are attached to protect the assembly seam, connecting them into a single unit with the profile box.

There are two main ways to install platbands:

- The invoice is the most common method when decorating windows. For fixation, special glue or nails are used.

- The telescopic method involves an L-shaped form of manufacturing the platband, which allows you to secure the product by entering into the grooves of the box. Most often used for finishing doorways. Its characteristic difference is the absence of traces of fasteners.

Patterns and types of threads

The carved shapes of the platbands give the window individuality, but to make them, you will definitely need templates. Having wood carving skills allows you to choose a complex ornament. If the ability to work with wood is not enough, it is better to find a light pattern for window trim. We suggest studying:

- variants of single element templates and their general appearance;

- top, bottom and side decoration details.

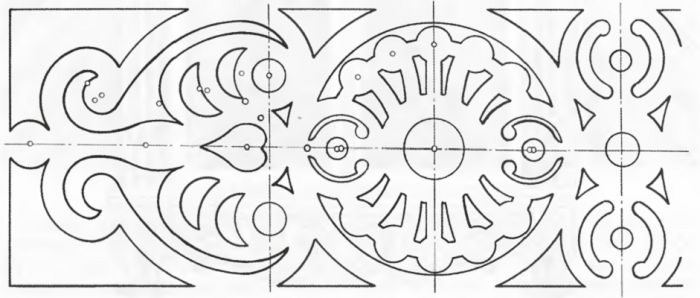

You can copy them completely or add your own details to the pattern. The carved frame design you like or a fragment of it needs to be enlarged to a scale taking into account the size of your window. To make carved templates, fiberboard, thick cardboard or paper are used. It is advisable to decorate windows with platbands with the same carvings. Please note that making small carved elements is much more difficult, and they deteriorate faster than others. In this case, partial replacement of the frame will be required.

Warning ! Be sure to take into account the slope at the top of the carved platband. This will prevent snow accumulation and ensure timely drainage of water.

The upper part of the window casing is called a kokoshnik, the lower part is called a towel. The most widespread ornaments of carved frames are the contours of plants, images of animals and geometric shapes.

The key details of the drawing for any window casing are:

- bottom strip or window sill;

- vertical rail;

- top bar.

The pattern can also contain all kinds of hangers, flowerpots or a tiara. A detailed description of the names of carved decorative elements is presented in the diagram below:

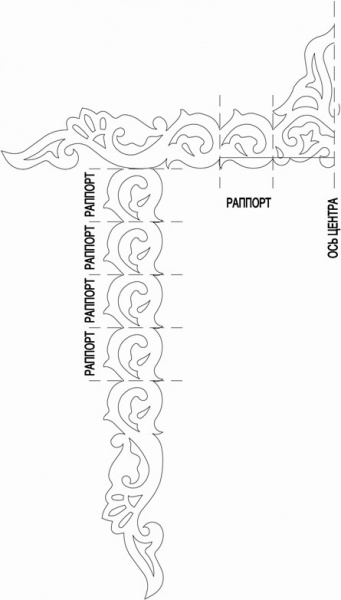

If your windows have different sizes, experts advise making a drawing with an intermediate repeat repeating the required number of times. For rapport, you can choose one or two elements that are repeated alternately. An example of such a scheme is shown in the photo below:

There are several ways to make carved wooden frames for windows:

- Carved platbands are characterized by the greatest decorativeness and delicacy. The product is made of light-colored wood or is subsequently coated with white paint. This window design on a darker wall looks sophisticated and elegant, vaguely reminiscent of Vologda lace.

- With overlay carving, separately cut parts are fixed to a continuous board by gluing or nailing. This technique allows you to design a window with a simple platband. Protruding elements are often coated with contrasting paint.

Sometimes both types of carving are combined.

Manufacturing process

Having decided on the pattern, material, type of carving and method of fastening the trim, you can proceed directly to the manufacture of carved frames for the windows.

Important ! The drawing on the workpiece needs to be placed correctly. The placement of elements along the fibers of wooden blanks will prevent cracking of the thread.

It is better to mark the places in the pattern where slits need to be made with color. The work on manufacturing platbands consists of the following stages:

- Taking measurements from the window.

- For slotted carving, boards with a minimum thickness of 30 mm are selected; the overhead method allows the use of wood with a thickness of 10 mm. All work is carried out with dry lumber.

- Blanks are cut out.

- To ensure a tight fit of the carved frame from the inside, the wood is selected to a shallow depth (1-2 mm).

- The pattern applied using the template is cut out. Drills of various diameters are used to form holes; a jigsaw will be needed to make the slots. To create a beautiful cut, the jigsaw insertion point is marked with a drilled hole.

- All carved elements of the window casing are cleaned with sanding paper. Wood dust is removed from non-through holes using a vacuum cleaner.

Overhead thread involves fastening finished elements to a wide casing using nails with their heads removed. The strength of the connection will be strengthened by applying glue to the underside of the casing. It is not recommended to use self-tapping screws due to the risk of damaging the carved section of the connection.

Carved platbands are installed on wooden windows using blind or through tenons. The first option is distinguished by a reliable connection and a complex installation process. The second method is simpler, but less reliable. Installation of carved elements on a plastic window is carried out using liquid nails.

Preliminary protective treatment of carved frames and regular preventive maintenance will ensure long-term preservation of the attractive appearance of the window.