Pneumatic wheel tower crane KS-5363 is used in the process of building structures and working with bulky materials. Produced until 1994 in Odessa.

Device and advantages

For the entire cycle of serial production, several modifications of the KS-5363 pneumatic wheel crane with markings A, B, C, D, E were developed and produced.

The power plant of the crane is represented by a two-stroke diesel four-cylinder and electric power unit, two electricity generators. The kinematic scheme of the winch includes: an electric motor, a gearbox, a clutch, brake pads and a drum with a crown of teeth.

Advantages of the crane KS-5363:

- performance is not reduced when running from a diesel generator;

- simple and affordable service;

- the possibility of using assistive devices;

- rotation of the platform in the absence of materials on the hook;

- ease of control thanks to the pneumatic wheel system;

- availability of spare parts for repairs.

Sufficient distance of the wheels from each other balances the stability of the crane and its stability during work operations.

Technical and cargo-altitude parameters

Technical characteristics of the crane KS-5363:

- load lifting device lifting rate- 7.5-9 m / min;

- sinking rate – 0,7-9;

- turntable revolutions per minute – 0,1-1,3;

- driving speed per hour– 20 km;

- engine- YaMZ-M204A;

- power unit power- 180 hp;

- power of the electrical unit- 166 kW;

- operating weight of the equipment- 33 tons;

- counterweight weight- 4 tons.

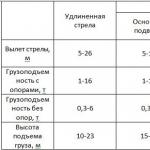

Cargo-altitude indicators of equipment model KS-5363:

- the largest mass of cargo on supports with the smallest and largest hook reach- 25 tons and 3.3 tons;

- maximum weight of the load to be lifted without a hook at maximum and minimum reach- 2.1 and 7.5 tons;

- hook reach – 2,5-13,8;

- boom length- 15 or 17.5 m;

- lifting height at minimum and maximum reach- 16.3 and 6.4 m;

- payload in motion- 14 tons.

Installation of lattice extensions 5 or 10 meters long is allowed.

Hydraulic system

The hydraulic system of the KS-5363 crane is based on a pumping device of the NSh-32E brand with a performance parameter of 35 l/min and a working pressure of 10.5 MPa. The system also includes cylinders, a hydraulic tank and other components.

The mechanism of operation is to supply oil to the pump from the hydraulic tank, from where it then follows to the cylinders after the distribution stage. In the latter, pressure is maintained thanks to special valves. The created pressure and oil exert an influence on the piston, which drives it.

Chassis

This part of the machine is represented by several bridges. There are 4 wheels per axle, two axles in total. To increase the lifting characteristics, outrigger hydraulic supports are installed, thanks to which the base of the equipment expands by 80 cm.

The rear axle drives all wheels. Transportation of equipment is carried out by towing or by a railway platform. In the first case, the crane must be folded, in the second, the wheels and boom must be removed.

Equipment

Crane KS-5363 is equipped with basic and additional devices. Basic fixtures:

- arrow- 15 m;

- main rope- 21 mm in diameter and 140 meters in length;

- additional rope– 21 mm in diameter and 95 m in length.

Replaceable devices and their parameters:

- interchangeable boom- 20-30 meters;

- boom reach- 5.5-26.3 meters;

- maximum load lift on supports– from 0.5 tons to 16.2 tons.

An arrow with a lattice extension is also installed, a tower device, the reach of which can reach 17.1 m.

Control system

Various parts of the equipment are driven by electrical, mechanical and hydraulic control systems. Mechanical is implemented by a remote control that regulates the operation of the supports, wheels, brake system and power take-off.

The hydraulic system realizes crane lifting operations. An electric motor controls the operation of the crane and winch. The margin of safety is reported to the technique by an all-welded frame and drive axles of the base chassis.

Crane Operator's Cabin

In the front part of the KS-5363 crane cabin there is a dashboard. It has a thermometer, pressure gauge, ampere and voltmeter, switches and levers. On two sides of the panel are controllers, power take-off devices, on the one hand - steering.

An electric heater works in the KS-5363 cab, it is possible to warm up the windows, a fan and windshield wipers are installed. The operator's seat is adjustable in height and recline.

Self-propelled full slewing single-engine diesel crane KS-4361 with a maximum load capacity of 16 tons is designed for construction and loading operations with piece and bulk cargo at construction sites, warehouses.

The set of working equipment includes the main lattice hinged folding an arrow 10 m long, a hook with a lifting capacity of 16 tons and a grab with a capacity of 1.5 m 3, mounted on 10- and 15-meter arrows. Interchangeable equipment is elongated booms 15, 20 and 25 m long, obtained from the main boom by inserting 5 m sections, and an uncontrolled jib 6 m long. The boom is equipped with a limiter that prevents it from tipping onto the platform when working at a minimum reach.

The crane uses a mixed control system - pneumohydraulic. The winch and reverse shafts, as well as the drums, are switched on with the help of pneumochamber clutches; the direction of movement of the mechanisms of rotation and movement of the crane is changed by the reversing mechanism and bevel gears. The inclusion of the reversing mechanism is also provided by pneumochamber clutches. The working speeds of the crane are regulated over a wide range by means of a torque converter fed from the hydraulic system of the crane.

The running gear of the crane is equipped with outriggers with screw jacks having small shoes at the ends.

On the site, the crane can move under its own power, including with a load on the hook at a speed of up to 3 km/h. Movement with a load on the hook is allowed on the platform with a boom of 10 - 15 m, directed along the longitudinal axis of the crane.

Over long distances by road, the crane is transported in tow to a tractor using a hitch. In the process of relocating the crane, the gearbox is set to the neutral position, the wheel turning cylinders are turned off, the cardan shaft of one of the axles is removed. The speed of movement in tow should not exceed 20 km/h, and on slopes and turns, the speed should be reduced to 3 km/h.

By rail, the crane is transported on a four-axle platform. Before the crane is loaded onto the platform, all pneumatic wheels are removed, the boom sections are disconnected, laying the upper section on the lower one. The crane is loaded onto the platform using an erection crane with a lifting capacity of 25 tons. If there are replaceable boom sections, they are placed on the second platform.

Reference:

Crane KS-4361 has an improved modification - model KS-4361A with a redesigned body and driver's cab.

The crane is not currently in production.

| faucet specifications echo $name; ?> | |

| Load capacity maximum, t | |

| on supports | 16 |

| without supports on wheels and in motion* | 9 |

| Engine | SMD-14A |

| Engine power, h.p. | 75 |

| Hook lifting height, m | |

| with main boom | 10 |

| with full boom equipment | 25 |

| with additional equipment (extension + jib) | 30 |

| Lifting speed (stepless control) of the load, m/min | |

| with a boom length of 10.5 m | 0…20 |

| with a boom length of 15.5 m | 0…35 |

| with an arrow length of 20.5 and 25.5 m | 0…50 |

| Turning part rotation speed, rpm | 0,4…2,8 |

| The highest speed of movement, km / h | |

| with a load on the hook | 3 |

| self-propelled without cargo | 18 |

| The smallest turning radius, m | 12,1 |

| Gradeability of the track (without load) | 12° |

| Permissible high-speed wind pressure, kgf / m 2 | 15 |

| Structural weight of the crane, t | 23 |

| during crane operation | 8 350 |

| when moving a crane with a boom of 10.5 m | 3 950 |

| front | 22 340 |

| rear | 19 040 |

| Overall dimensions, mm: | |

| length | 14 500 |

| width | 3 150 |

| height | 3 900 |

*The lifting capacity in motion is indicated with the boom located along the axis of the crane.

Ks 5363 is a Russian pneumatic wheeled crane, which embodies advanced technologies developed back in the days of the USSR, which are still relevant. With this crane installation, the development of modern pneumatic wheeled cranes began, which in terms of performance and functionality are practically not inferior to more expensive foreign analogues. The model received outstanding technical characteristics and time-tested technological solutions. The capabilities of this self-propelled machine are not limited to work in urban environments. Quite the contrary, the KS 5363 is a multi-purpose crane adapted to the most inaccessible conditions. It will be appreciated by professional users, for whom stable and uninterrupted operation for many years is very important.

Description and purpose

KS-5363 is a high-performance crane unit developed in 1971. Until 1994, several thousand copies of this model were produced, which was considered one of the most popular pneumatic cranes in the USSR. The truck crane was produced in the Ukrainian USSR, in Odessa. The scope of this truck crane is in many ways similar to the tasks that use classic cranes built on the basis of the KamAZ truck chassis. Thus, the KS-5363 model is widely in demand in the construction of residential and industrial buildings, handling bulk cargo with a grab, and is also used to transport bulky technical equipment. In addition, the capabilities of this truck crane installation include work in large logistics centers and other serious organizations that lack the power of relatively weak manipulators. Moreover, the technique is considered to be more in demand in search and rescue activities - for example, when unloading and pulling away rubble resulting from the destruction of urban infrastructure, natural and natural disasters, etc.

Technical and lifting characteristics

- Load capacity - up to 30 tons

- Speed when lifting the main hook - 7.5 - 9 m / min

- Hook lowering speed – 0.7 – 9 m/min

- Maximum speed - 3-20 km / h

- Engine type - diesel, YaMZ-M204A

- Power 180 horsepower

- Power of electric motors - 166 kW

- Front wheel track - 2400 mm

- Rear wheel track - 2400 mm

- Weight - 33 tons

- Carrying capacity in the process of movement - 15

- Grab capacity - 2 cubic meters.

Features of the device and operation

KS-5363 is equipped with a multi-motor DC drive, which is powered by the torque of the power plant. To adjust the speed of the actuating moving parts and organs, adjustment is required according to the generator / engine scheme, by changing the settings in the main generator. If the platform moves without load, then it can be rotated. Also pay attention to the possibility of adjusting the mechanisms in a wide range of speeds. Including, working and transport modes are provided. To set the desired mode, you must move the switch to one of three positions - mechanical, hydraulic or transport. You can also control the main mechanisms using the remote control. The gearbox is powered by a hydraulic system that controls the outriggers, steers the wheels, applies the brakes and locks the differential. So, a remote control is provided to adjust the supports and locks, and the remaining elements are controlled using the control panel from the driver's cab.

The hydraulic system is an integral component of the KS-5363 pneumatic crane. It consists of a gear pump. Its productivity reaches 35 l / min, and the pressure is 10.5 MPa. Also included are winches. The length of the main boom in the initial position is 15 m, but it can be extended with additional inserts. As a result, the total length of the boom can reach 30 meters. Moreover, a jib with a length of 8 or 15 m can be mounted in the boom. Thus, together with it, the length of the entire structure will exceed 43-44 m.

Tower boom equipment is another integral part of this self-propelled machine. The undercarriage includes drive axles with double wheels size 14.00-20. For stability when performing heavy tasks, the wheels were equipped with hydraulic bearings, without which the load capacity would be much lower. The wheelbase can be extended from 4.2 to 5 meters using special attachments. We also note the possibility of towing with a coupling device at speeds up to 20 km / h. It is noteworthy that the crane can be transported by rail. To do this, the wheels are removed, and a 60-ton four-axle railway platform is installed instead. To load the crane onto this platform, another crane is used, designed to carry 25 tons of cargo.

The KS-5363 pneumatic wheeled vehicle is equipped with a 4-cylinder two-stroke diesel engine, an electric motor, two generators, and a gear pump with a working pressure of 7.5 MPa. All these elements are the power part of the crane, which ensures the smooth operation of all moving parts and systems.

The slewing mechanism of the crane includes a gear reducer with bevel and cylindrical gears. The design also includes a runner gear and a ring gear. A chain coupling is used to securely connect the motor and gearbox.

In addition to the gearbox and diesel engine, two DC generators are responsible for the movement of the unit. The power of the auxiliary electric motor is 50 kW. In fact, this unit is used as a DC generator. To be able to work from an external network, an electric motor with a voltage of 380 V is used. The engine, as well as its equipment, is started under the influence of two batteries with a total voltage of 12 V. These batteries are powered by their own battery powered by the internal combustion engine torque.

In the front part, in the area of the windshield of the truck crane, there is a dashboard on which instrumentation is ergonomically located - an ammeter, a voltmeter, a thermometer, a pressure gauge, as well as various switches and switches. In addition, the cab is equipped with an independent heater, which can be turned on at full power when the outside temperatures are too low. In addition to increasing the temperature in the cabin, the heater also performs the function of preventing the windows from fogging up. In the summer, you can turn on the fan and windshield wipers. The operator's seat can be adjusted in height, as well as adjust the distance between the seat and the control panel for easy entry and exit.

The overload limiter is one of the safety elements of the KS-5363. This system prevents overheating, and also protects the truck crane and the operator from contact with the power line.

Prices

The average cost of a pneumatic wheel crane KS 5363 in the Russian market is 2-3 million rubles. The price is for a used copy.

An electric mechanism is used to drive the mechanisms of the boom and the undercarriage of the crane. The sources of electricity are the on-board generator or an external 3-phase AC electrical network with a voltage of 380 V. A special electric motor operates from the external power supply, which rotates the on-board generators through a system of belts and pulleys. The generated direct current has a voltage of 220 V.

The electrical installation includes a main generator with a power of 50 kW and an additional unit that develops a power of 14 kW. From the main network, the electric motors for movement and the winch drive are fed. The auxiliary network is used to turn the crane tower and operate the control system. The main generator is connected to the engine through the clutch, the auxiliary generator is powered by a belt drive, the drive pulley is made on the outer part of the clutch.

To drive the generator, a power plant is used, consisting of a 4-cylinder 2-stroke 180-horsepower YaMZ-A204M diesel engine equipped with a mechanical supercharger. In later versions of the crane, a 4-stroke atmospheric diesel engine YaMZ-236M began to be used. Both motors were equipped with an automatic centrifugal clutch.

The control cabin is made of steel sheet, equipped with a fresh or heated air supply system. An electric heater is used for heating. Cabin walls are sheathed with sheets to protect against noise and vibrations. The type of material and layer thickness depend on the modification of the machine. The crane is controlled by keys and 2 command controllers. A dashboard is installed in front of the driver. The operator's workplace is regulated in 2 directions. On version 5363ХЛ, additional glass heaters are installed in the cab.

See also: Specifications of popular truck cranes based on ZIL trucks

Pneumowheel crane KS-5363 is based on an all-wheel drive undercarriage, which includes 2 bridges. On the hubs there are twin wheels with tires measuring 14.00 * 20. The outer wheels on the front axle are mounted on a special bushing and are not driving. In difficult road conditions, the outer wheels are connected to the inner ones. The bridges are mounted on a welded beam scheme frame. The front axle is not equipped with a suspension, the rear axle has a balancing support.

To increase stability, the chassis is equipped with outrigger hydraulic supports. It is allowed to operate the machine without installing supports, but with restrictions on the weight of the transported goods. It is possible to install extension attachments that increase the length of the support extension.

The transmission consists of an electric motor and a 2-speed manual gearbox. The output shaft is connected to the axle gearboxes by cardan shafts. Each bridge is equipped with a differential mechanism of a unified design. The front axle of the crane is equipped with steering knuckles and is used to change the direction of movement. The steering consists of hydraulic cylinders, the rotation of the wheel is performed by the movement of the rod. When installing the towing device, the swivel wheels are controlled by turning the drawbar.

Brake mechanisms of drum type, equipped with a pneumatic drive. The source of compressed air is a reciprocating compressor located on the power plant.

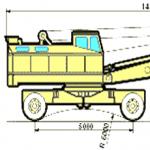

The movement of equipment between construction sites is carried out by the following methods:

- on a rigid hitch on public roads (speed up to 20 km/h);

- by rail in a partially disassembled form (without wheels and boom).

Specifications

At the time of creation, the cranes of the KS-5363 series were not inferior to foreign equipment in terms of their technical characteristics. Wide unification of nodes and a duplicated power drive make it possible to work in urban conditions, as well as in an open field or in a quarry. To ensure the safety of work, a limiter is installed that does not allow starting work with an overload.

See also: Frequency of full (PTO) and partial (WHAT) technical examination of cranes

Machine parameters:

- lifting capacity of the crane in motion - 14 t;

- maximum load capacity - up to 36-40 tons (depending on modification);

- weight - 33 tons;

- machine length in transport condition - 20.3 m;

- transport width - 3.29 m;

- width with outriggers - 4.2 m

- height (excluding boom) - 3.9 m.

Modifications

The Janvarets plant produced the following variants of equipment:

- The basic version of the machine was the KS-5363 model, designed for operation in a temperate climate with an air temperature of -40 ... + 40 ° С. The carrying capacity is 25 tons.

- On a separate order, a version of the KS-5363KhL was produced, adapted for operation at temperatures up to -70 ° C. The materials from which the loaded elements are made have been changed. Additional thermal insulation of the driver's cab has been introduced.

- An upgraded version of the KS-5363A, featuring improved units that have an increased resource and simplified maintenance.

- A further development was the KS-5363B crane, equipped with a special device for increasing the lifting capacity up to 40 tons. The machine can operate as a tower crane with a jib 15 m long.

- Modification of KS 5363V, which uses a different scheme for installing counterweights on a remote frame. The design of the extension inserts on the boom has been changed. Improved versions with a carrying capacity of 36 tons and improved technological parameters are designated KS-5363D and KS-5363E.

- Army vehicles KS-5363M and AM. Difference of machines is the increased accuracy of positioning of working bodies. The equipment was used in army warehouses, including for loading strategic nuclear weapons.

- The last serial machine KS-5366, which was distinguished by hydraulic drives in the control of the angle of inclination of the boom and in the turret rotation mechanism. The crane was produced until 1994.

scheme

The crane scheme is based on the use of a lattice boom with a swivel assembly mounted on a turntable. To ensure strength, braces made of an angle steel profile are installed. The standard boom has a length of 15 m, but the design allows you to install extension sections with a length of 5 or 10 m, bringing the reach up to 30 m. Short inserts are used on later machines that adjust the length of the boom in the range of 15-32.5 m. performed without the aid of additional equipment.

On the upper part of the boom, it is possible to mount a controlled or fixed jib.

By special order, a set of tower-jib equipment was supplied for the crane. The set included a controlled jib with an increased length, which depended on the size of the boom. The connection points of the nodes are equipped with fingers that provide quick changeover of the design and reliable fixation. Another type of equipment is a 2-rope grab designed to move bulk cargo. The volume of the standard bucket is 2 m³, it is possible to use units with a reduced capacity.

See also: foldable and non-folding type hydraulic garage cranes

When operating the crane, a steel rope with the following characteristics is used:

- diameter - 21 mm;

- length on the main drum - 140 m;

- length on the auxiliary winch - 95 m.

Self-propelled jib cranes

Crane KS-5363 (K-255a) with a lifting capacity of 25 tons

The crane KS-5363 (K-255A) has a diesel-electric drive. The 15 m main boom consists of two sections and can be extended to 20, 25 and 30 m with inserts. The 20, 25 and 30 m booms can be equipped with a 10 m steerable or non-steerable jib for auxiliary lifting. The jib is controlled by the main lift. BSO is provided: a tower of 15 m with a beak of 10 and 15 m; tower 20 m with a beak 10, 15 and 20 m; a tower of 25 m with a beak of 10, 15 and 20 m. The mass of the crane with the main boom is 39 tons. The wheel track is 2500 mm. The turning radius of the crane along the track of the outer front wheel is -10.25 m. Maximum load: on the outrigger - 300 kN (30.4 t), on the axle in the transport position - 185 kN (18.8 t).

Rice. 1. k-255 OP boom 32 m

Rice. 2. K-255 VP boom 32-7 m

Fig 3. Pneumatic wheel crane KS-5363

Rice. 6. KS-5363 OP boom 15 m: 1 - with additional counterweight; 2 - without additional counterweight

Rice. 7. KC-5363 OP boom 20 m: 1 - with additional counterweight; 2 - without additional counterweight

Rice. 11. KS-5363 boom 20-10 m (unguided jib): 1 - main lift; 2 - auxiliary lift

Rice. 11. KS-5363 boom 25-10 m (unguided jib): 1 - main lift; 2 - auxiliary lift

Rice. 12., KS-5363 boom 30-10 m (uncontrolled jib): 1 - main lift; 2 - auxiliary lift

Rice. 13. KS-5363 boom 20-10 m (guided jib)

Rice. 14. KC-5363 boom 25-10 m (guided jib)

Rice. 15. KS-5363 boom 30-10 m (guided jib)

Rice. 16. KS-5363 BSO 15-10 m

Rice. 17. KS-5363 BSO 15-15 m

Rice. 18. KS-5363 BSO 20-20 m

Rice. 19. KS-5363 BSO 25-10 m

Trust "Uraltsvetmetremont" developed projects: improvement of the load characteristics of the crane by installing an additional counterweight; installation of shortened arrows with a length of 6.8 and 11 m.

stroy-technics.ru

KS 5363 / Large machines

Today this article will be about the KS 5363 pneumatic wheel crane, we have this colossus at work - in the port. About this interesting thing, I asked the person who works on it, a crane operator named Alexei, and also, as is usually the case, the main technical characteristics, I asked the Internet =)

By the way, at first I thought that it was just a crane-trailer, but it turned out that it was a self-propelled machine running both on diesel and on electricity (with the help of a connected cable). The lifting capacity of the crane is 25 tons. It is equipped with two lifting hooks - main (25 tons) and auxiliary (5 tons).

This miracle of technology has 8 wheels. 4 for each axle. The crane is equipped with its own power plant paired with a diesel engine. Rulitsya with the help of a lever. The hydraulics widely used in this apparatus help to turn the mighty wheels.

All-wheel drive is also implemented here in a very peculiar way - on the rear axle, the drive goes to all 4 wheels, and on the front axle, the drive extends only to the inner wheels, while the outer ones can rotate freely. The outriggers are controlled by 4 levers located outside under the cab.

When the installation is powered by a cable, it moves very reluctantly, according to the same Alexei, even climbing a slight slope is already a big problem. On a diesel, the device rides more willingly. The maximum speed here is limited to a ridiculous 19.5 km / h, but do not forget that this is not a car, but a crane, which needs wheels only to move from place to place. It is transported in a folded state, clinging to a cargo tractor.

This particular instance of 1985 and the wheels apparently never changed at all. Metsami rubber has already cracked and looks, let's say, not very fresh =) But nevertheless, the device drives and lifts loads every day.

The engine here is Yaroslavl 180-horsepower YaMZ-M204A. Power of electric motors - 166 kW. The mass of all this splendor is 33 tons. for those who want more technical information, as well as diagrams and drawings of the main components and mechanisms, I recommend that you follow this link.

Pneumowheel crane KS-5363  C2 - DC generator P62, 11.5 kW; M - AC motor A2-72-4, 30 kW, 380 V; Glossary, LG1 - DC motor DK-309B 50 kW with auxiliary winding; Ml, LM1 - electric motor DC DK-309A, 46 kW with auxiliary winding; M2, LM2-DC motor P62, 14 kW with auxiliary winding; M3, M4, LM3, LM4 - DC motors DK-309B, 50 kW with auxiliary windings-M5 LM5 — DC electric motor П62, 8 kW with auxiliary winding; LM6 - independent winding of the electric motor M2: QF1 automatic switch A3114 / 1 for 100 A; QF2 - automatic switch A3163 for 50 A; Sh1,KM2 - contactors KPV-603 for 160 A; ShZ-Sh5 - contactors KTPV-623 for 160 A; KM7 - contactor KTPV-622 for 100A; KM8-KM10 - contactors MK1-10 for 40 A; KM11 - contactor KP-102-Ana 75 A; KM12, KM15 - contactors MKi-66 for 10 A; KM6, KM20, KM13, KM14, KM16, KM17 - contactors MK1-44 for 10 A; KT1-KT6 - time relay REV-811; KA1-KA6 - maximum current relay RV-571; SQ1 - limit switch VPK-2110; SQ2 - limit switch KU-701; SQ3-SQ6 - limit switches VU-250A; SQ7, SQ8 - limit switches VK-200A; SOL, SA2 - command controllers 1203; SA3-SA6 - universal switches UP5313 / S322; Ql, Q2 - packet switches PVM2-10, vers. 3; R1, R2 - resistance boxes NF-1, cat. No. 2TD.754.005.4; YB1-YB5 - brake electromagnets MP-201 for 220 V; SB1-SB14 - control buttons KE-011; SB16, SB17 - control buttons PKE-212-2; R3-R10 - resistance boxes YaS-3; TA1, TA2 - current transformers; PV1, PV2 - voltmeters M-4200, 0- 300 V; PRYATEL PA2 - ammeters M-4200, 0-100 A; XA1-XA10 - ring current collectors K-3112A; EH1 - electric furnace PET-7; EH2-EN5 - glass heaters ET-44; EL1 - searchlight PZM-25; UZ - single-arm converter OP120F2; L1 - winding of a single-arm converter; BE - selsyn receiver BS-484A for 100 V, 11 W; VS - selsyn sensor BD-404A for software B, 11 W; KM18 - contactor KP-1002A; KM19 - magnetic starter PA-411; KM20 - load limiter contact; RP1 - rheostat; the rest - contacts C2 - DC generator P62, 11.5 kW; M - AC motor A2-72-4, 30 kW, 380 V; Glossary, LG1 - DC motor DK-309B 50 kW with auxiliary winding; Ml, LM1 - electric motor DC DK-309A, 46 kW with auxiliary winding; M2, LM2-DC motor P62, 14 kW with auxiliary winding; M3, M4, LM3, LM4 - DC motors DK-309B, 50 kW with auxiliary windings-M5 LM5 — DC electric motor П62, 8 kW with auxiliary winding; LM6 - independent winding of the electric motor M2: QF1 automatic switch A3114 / 1 for 100 A; QF2 - automatic switch A3163 for 50 A; Sh1,KM2 - contactors KPV-603 for 160 A; ShZ-Sh5 - contactors KTPV-623 for 160 A; KM7 - contactor KTPV-622 for 100A; KM8-KM10 - contactors MK1-10 for 40 A; KM11 - contactor KP-102-Ana 75 A; KM12, KM15 - contactors MKi-66 for 10 A; KM6, KM20, KM13, KM14, KM16, KM17 - contactors MK1-44 for 10 A; KT1-KT6 - time relay REV-811; KA1-KA6 - maximum current relay RV-571; SQ1 - limit switch VPK-2110; SQ2 - limit switch KU-701; SQ3-SQ6 - limit switches VU-250A; SQ7, SQ8 - limit switches VK-200A; SOL, SA2 - command controllers 1203; SA3-SA6 - universal switches UP5313 / S322; Ql, Q2 - packet switches PVM2-10, vers. 3; R1, R2 - resistance boxes NF-1, cat. No. 2TD.754.005.4; YB1-YB5 - brake electromagnets MP-201 for 220 V; SB1-SB14 - control buttons KE-011; SB16, SB17 - control buttons PKE-212-2; R3-R10 - resistance boxes YaS-3; TA1, TA2 - current transformers; PV1, PV2 - voltmeters M-4200, 0- 300 V; PRYATEL PA2 - ammeters M-4200, 0-100 A; XA1-XA10 - ring current collectors K-3112A; EH1 - electric furnace PET-7; EH2-EN5 - glass heaters ET-44; EL1 - searchlight PZM-25; UZ - single-arm converter OP120F2; L1 - winding of a single-arm converter; BE - selsyn receiver BS-484A for 100 V, 11 W; VS - selsyn sensor BD-404A for software B, 11 W; KM18 - contactor KP-1002A; KM19 - magnetic starter PA-411; KM20 - load limiter contact; RP1 - rheostat; the rest - contacts |

Pneumatic wheel crane KS5363 for rent in Odessa

OPTIONS

Description of the pneumatic wheel truck crane KS-5363 and its unique characteristics

Crane KS-5363 with a lifting capacity of 36 tons with an individual electric drive is mounted on a special two-axle undercarriage equipped with a towing device and rotary outriggers installed using a hydraulic drive. Both bridges are leading. The front steerable axle has a balanced suspension, switched off during operation by screw stabilizers. Leading at the front axle are the inner wheels, which can be blocked with the outer wheels when driving in difficult road conditions. The slewing bearing is ball, two-row.

Purpose: Pneumatic wheeled truck crane KS-5363 is designed for construction and installation and loading and unloading operations, as well as for reloading bulk cargo with a clamshell. A special advantage of this model is maneuverability, speed of work. Differs in the favorable price of rent from cranes of import production of the same class. It is more convenient for transportation, as it has a pneumatic wheeled chassis. The possibility of easy re-equipment in various designs accelerates the growth rate of work performance.

Crane KS-5363 is a diesel-electric crane with a lifting capacity of 36 tons, equipped with 36- and 5-ton hooks of the main and auxiliary lifting mechanisms, working simultaneously. A two-rope grab with a bucket with a capacity of 2 m3 can be used on the crane. The crane uses a multi-motor DC drive powered by its own power plant. The speeds of the actuators are regulated according to the generator-engine (G-D) system by changing the voltage of the main generator supplying the engines. When moving the crane without a load, the platform can be rotated. The crane has a wide range of speeds of all mechanisms, including the movement mechanism in working and transport positions.

Load capacity, t: on supports:

- ..on outriggers - 36

- ..without outriggers - 14

- ..with the smallest hook reach 25 / 30*

- ..with the longest hook reach 3.3 / 4

- ..when moving a crane with a load on the hook - 10.5

without supports:

- ..with the smallest hook reach 7.5 / 14

- ..with the longest hook reach 2.1 / 2

Hook reach, m:

- ..smallest 2.5 / 4.5

- ..highest 13.8 / 15.9

Hook lifting height, m:

- ..with the smallest hook reach 16.5 / 13.7

- ..with the largest hook reach 36.2

- ..maximum with tower equipment - 50

Speeds:

- ..lifting of the main hook, m/min 7.5; 9

- ..lowering, m/min 0.7 — 9

- ..turntable rotation frequency, rpm 0.1 — 1.3

- .. self-propelled crane movement, km/h 3; 20

Maximum support load, kN 324 Maximum axle load, kN 174 Smallest turning radius (along the outer wheel), m 10.3

- ..mark YaMZ-M204A

- ..power, hp 180

Installed power of electric motors, kW 166 Wheel track, m:

- ..front 2.4

- ..rear 2.4

Crane weight, t 33 Including counterweight, t 4

Pneumatic wheel truck crane KS-5363 for rent in Odessa

KS-5363 specifications

Pneumatic wheel tower crane KS-5363 is used in the process of building structures and working with bulky materials. Produced until 1994 in Odessa.

Device and advantages

For the entire cycle of serial production, several modifications of the KS-5363 pneumatic wheel crane with markings A, B, C, D, E were developed and produced.

The power plant of the crane is represented by a two-stroke diesel four-cylinder and electric power unit, two electricity generators. The kinematic scheme of the winch includes: an electric motor, a gearbox, a clutch, brake pads and a drum with a crown of teeth.

Advantages of the crane KS-5363:

Crane KS-5363

- performance is not reduced when running from a diesel generator;

- simple and affordable service;

- the possibility of using assistive devices;

- rotation of the platform in the absence of materials on the hook;

- ease of control thanks to the pneumatic wheel system;

- availability of spare parts for repairs.

Sufficient distance of the wheels from each other balances the stability of the crane and its stability during work operations.

Technical and cargo-altitude parameters

Technical characteristics of the crane KS-5363:

- lifting rate of the load gripping device - 7.5-9 m / min;

- lowering rate - 0.7-9;

- the number of revolutions of the turntable per minute - 0.1-1.3;

- speed of movement under its own power per hour - 20 km;

- engine - YaMZ-M204A;

- power unit power - 180 hp;

- power of the electric unit - 166 kW;

- operating weight of equipment - 33 tons;

- counterweight weight - 4 tons.

Cargo-altitude indicators of equipment model KS-5363:

Cargo-altitude characteristics of the truck crane KS-5363

- the largest mass of cargo on supports with the smallest and largest hook reach - 25 tons and 3.3 tons;

- the maximum mass of the lifted load without a hook at the maximum and minimum reach is 2.1 and 7.5 tons;

- hook reach - 2.5-13.8;

- boom length - 15 or 17.5 m;

- lifting height at the minimum and maximum reach - 16.3 and 6.4 m;

- carrying capacity in motion - 14 tons.

Installation of lattice extensions 5 or 10 meters long is allowed.

Hydraulic system

The hydraulic system of the KS-5363 crane is based on a pumping device of the NSh-32E brand with a performance parameter of 35 l/min and a working pressure of 10.5 MPa. The system also includes cylinders, a hydraulic tank and other components.

The mechanism of operation is to supply oil to the pump from the hydraulic tank, from where it then follows to the cylinders after the distribution stage. In the latter, pressure is maintained thanks to special valves. The created pressure and oil exert an influence on the piston, which drives it.

Hydraulic system of pneumatic wheel crane KS 5363

Chassis

This part of the machine is represented by several bridges. There are 4 wheels per axle, two axles in total. To increase the lifting characteristics, outrigger hydraulic supports are installed, thanks to which the base of the equipment expands by 80 cm.

The rear axle drives all wheels. Transportation of equipment is carried out by towing or by a railway platform. In the first case, the crane must be folded, in the second, the wheels and boom must be removed.

Crane chassis KS-5363

Equipment

Crane KS-5363 is equipped with basic and additional devices. Basic fixtures:

- boom - 15 m;

- main rope - 21 mm in diameter and 140 meters in length;

- additional rope - 21 mm in diameter and 95 m in length.

The main boom of the crane KS-5363

Replaceable devices and their parameters:

- replaceable boom - 20-30 meters;

- interchangeable boom reach - 5.5-26.3 meters;

- maximum load lifting on supports - from 0.5 tons to 16.2 tons.

An arrow with a lattice extension is also installed, a tower device, the reach of which can reach 17.1 m.

Control system

Various parts of the equipment are driven by electrical, mechanical and hydraulic control systems. Mechanical is implemented by a remote control that regulates the operation of the supports, wheels, brake system and power take-off.

The hydraulic system realizes crane lifting operations. An electric motor controls the operation of the crane and winch. The margin of safety is reported to the technique by an all-welded frame and drive axles of the base chassis.

Crane Operator's Cabin

In the front part of the KS-5363 crane cabin there is a dashboard. It has a thermometer, pressure gauge, ampere and voltmeter, switches and levers. On two sides of the panel are controllers, power take-off devices, on the one hand - steering.

An electric heater works in the KS-5363 cab, it is possible to warm up the windows, a fan and windshield wipers are installed. The operator's seat is adjustable in height and recline.

Related video: KS-5363

hydraulic system, chassis, device, scheme

The lifting machine KS-5363 was produced until 1994 in Ukraine. The manufacturer was the Odessa company.

Advantages and features of the KS-5363 jib crane

Significant advantages of the crane are:

- the device does not lose efficiency when operating from a built-in diesel generator;

- simplicity and low cost of service;

- allows the use of a grab with a bucket;

- platform turning when there is no load on the hook;

- the pneumatic wheel system makes the crane very easy to operate;

- balance and stability are provided by wheels that are far enough apart from each other.

- Availability of spare parts, which makes the KS-5363 crane easy to maintain.

This technique on pneumatic wheels is one of the most popular in the construction industry. KS-5363 is actively used for loading and unloading bulky goods, as well as directly for the construction of buildings.

For the entire production cycle, the Ukrainian plant put on the market a whole lot of modifications, which were marked with the letters A, B, C, D, E. The symbols M and AM were sometimes added to the modification letter designations. This is an indication that these models of jib cranes were produced by the exclusive order of the army. They were subjected to strict quality control and testing with the personal participation of representatives of the defense department. Such close attention was explained by the fact that KS-5363 was often used to work with especially important weapons.

Device

The various machinery mechanisms are controlled by three systems:

- mechanical;

- hydraulic;

- electric.

Mechanical control is a control panel responsible for the functioning of the brakes, gearbox, wheels and supports.

Hydraulic control is a complex of elements responsible for the operation of lifting equipment.

Scheme of the crane KS-5363

Electrical control is based on DC generators. The electric motor is responsible for the operation of the winch motors and for the movement of the crane. The generator and diesel are connected in a system, and two batteries are used for the diesel to work. To lift loads, the main lattice boom and an additional 15-meter jib are used. The one-piece frame and two drive axles of the chassis provide special structural strength with a load.

Hydraulic system

The hydraulic control system KS-5363 is based on the gear pump NSh-32E. Its main characteristics:

- productivity 35 l/min.;

- pressure 10.5 MPa.

In addition to the pump, the important components are the hydraulic tank, pump, accumulator, pipelines and slave cylinders. The action begins with the fact that oil enters the pump from the hydraulic tank. From there it enters a special distributor, and through it to the slave cylinders.

The distributor is equipped with a valve that provides pressure in the cylinder. In it, the oil acts on the piston, causing it to move and put the mechanism into operation.

Running gear features

The undercarriage of the KS-5363 machine consists of a pair of bridges. The system includes 8 wheels, 4 per axle. The rear axle gives drive to all wheels, and the front axle only to the internal ones. There are also remote-type hydraulic supports. They increase the base of the device by 80 centimeters and serve to increase the load capacity.

Front axle

The crane can be transported in two ways:

- towing by a tractor, and then the mechanism must be folded;

- on the railway platform, and then the boom and wheels should be removed.

Basic Specifications

Technical characteristics of the pneumatic wheel crane KS 5363 are presented in the table:

Equipment, its types and technical parameters

The KS-5363 equipment is completed with the main and replaceable equipment. The main one includes a lattice boom and ropes, and the interchangeable one includes elongated booms, devices with jibs, as well as tower-boom elements.

Main

Replaceable

| Characteristic name | elongated arrows | Arrows with jib | Tower boom attachment | |

| On the main suspension | On the auxiliary suspension | |||

| Interchangeable boom length, m | 20 - 30 | 20 - 30 | 20-30 | 10 |

| Tower height | - | - | - | 20 - 30 |

| Departure of a replaceable arrow, m | 5,5-26,3 | 5,5-14,2 | 13,4-23,7 | 10,5 - 17,2 |

| Load capacity with supports, t | 0,5 - 16,2 | 1 - 13,5 | 0,5 4,2 | 1,9 - 5,5 |

| Load capacity without supports, t | 0,3 - 6 | 0,5 - 5 | 0,5 - 2 | 0,4 - 3,5 |

| Hook lifting height, m | 10,2 - 23,9 | 15 - 28,9 | 16,4 - 30,5 | 22,1 - 38,2 |

| Lifting and lowering speed, m/min | 1,5 - 11 | - | - | 3 - 22 |

maintrade.ru

Crane KS 5363

Rent a crane KS 5363 in Moscow from 900 rubles per hour: delivery to the facility, commissioning, provision of an experienced operator with the appropriate approvals. Crane KS 5363 with a lifting capacity of 25 tons for construction, installation, loading and unloading operations at an affordable price.

The KS-5363 jib crane was developed in 1970: it is designed for installation and loading and unloading operations. It is used for handling bulk cargo using a grab, lifting building materials weighing up to 36 tons, building buildings, road works, etc. It is equipped with pneumatic wheels, which ensures ease of operation, good stability, the ability to use outriggers, maneuverability and cross-country ability. The crane can be used both on a construction site and in urban areas - it does not spoil the asphalt during operation or delivery to a given place.

Advantages and features of KS 5363

The main technical characteristics of the KS 5363 are indicated at the top of the page - the crane is capable of lifting up to 25 tons to a height of up to 47.5 meters when using a jib. The device works both from electricity, and from diesel fuel. It has two driving axles with 8 wheels and an all-welded frame.

KS-5363 is available in two versions: with an arrow (a three-section boom extends up to 32.5 m and is equipped with a jib that adds another 10 meters to the length of the boom) and a tower (the height of the tower is 15 meters). The crane is powered either from an external network of 380 volts, or from a YaMZ-A204M diesel engine. The speed of movement of equipment is up to 17 km / h, its transportation to the construction site is possible by road.

Rent KS 5363 in Moscow

If you want to rent a crane KS-5363, please contact the Spetstechnika company. We offer a wide range of construction and special equipment of various configurations. Our advantages:

- Affordable prices, pleasant discounts for regular customers and partner companies.

- Guaranteed crane performance and no downtime due to our fault.

- The rental is carried out together with an experienced operator who has the necessary permits and permits.

- Delivery of equipment to a given place on its own, its subsequent removal on a gun carriage or other vehicles.

- The possibility of registering a lease for the required period - a week, a month, six months.