Every year there are all kinds of devices that greatly facilitate the performance of hard work in agriculture. And it is especially worth highlighting among such equipment the PLN-3-35 plow, which today is one of the most popular mounted plows with an affordable price and trouble-free repair.

This model, new or used, due to its technical characteristics, is used for arable work on soils of various types: light, smooth, as well as medium-heavy, in which all types of grain are planted. The land must be previously cleared of weeds and stone. There are a lot of videos on the Internet on this subject.

Plow body design

Cases LN-3-35 can be screw, cultural and semi-screw. Cultivated are the weakest and are suitable only for the cultivation of old arable soils. Screws are able to plow the land, heavily overgrown with weeds and virgin lands.

Plow frame PLN-3-35

Harrow modification

The semi-screw body is a medium power unit that allows you to plow stale soils. An elongated pen is mounted to it, with the help of which the power of the semi-screw body becomes higher than that of the cultural one.

The hull structure directly depends on the type of soil that is supposed to be processed. If, for example, it is necessary to plow the soil of a heavy type with crushing for planting root crops, you will have to resort to the use of a combined body. In it, the blade and plowshare are shortened, however, there is a rotor that is driven by the PTO of the traction unit and which crushes heavy-type soil with its blades.

Specifications

PLN-3-35, new or used, is quite easy to adjust and operate, so one person can handle it.

Device

The mounted unit consists of the following elements shown in the drawing:

- hitch;

- coulter;

- support wheels;

- frame;

- trailer for harrows;

- frame.

On the support wheels there is a special screw, with which it is possible to adjust the plowing depth. There are many videos that describe in detail the device of the plow and its coupling with the tractor. Depending on the calculated depth of processing, a skimmer can be installed, which has several positions;

- for plowing depth 200 mm;

- plowing depth 220 mm;

- processing depth 250 mm;

- cultivation depth 270 mm

- plowing to a depth of 300 mm.

The plow stand in LN-3-35 is made in one piece and the main plowshares, blade and field board are installed on it. The skimmer has a small-surface plowshare shank with a crop residue removal function. By means of the wheels, the depth of tillage is adjusted. There is also a device due to which the tractor is connected to the LN-3-35.

Unit setup

Before the equipment is taken out for direct work, it is necessary to adjust it on a special site. It is required to take special stands, as shown in the drawing, corresponding to the depth of the intended processing, minus 2-5 cm, and install them under the tractor left wheels and the supporting plow wheel. Next, the unit with shares must be lowered onto the site. With the help of a screw, the support wheel is tightened until the shares come into contact with the platform surface.

After that, it is necessary to align the LN-3-35 with the help of the central link and the brace of the tractor hitch. The main thing that needs to be done when setting up the unit is to adjust the position of the equipment parallel to the site. In addition, the adjustment must be carried out both in the longitudinal and in the transverse planes. Plow braces are attached to the longitudinal rods to the front holes. Fastening the frame with the top link through a special hole must be done only with an automatic hitch. If fastening is carried out through a recess, then this can lead to the fact that when plowing the unit will take an unstable position.

Adjustment of the limiters of the PLN-3-35 unit is carried out so that a slight sag remains. During transportation, the plow must not fluctuate more than 20 mm. To properly adjust, you can watch the thematic video.Between the hinged axles, it is required to install the left brace of the traction unit hitch with a distance of 515 mm.

Before laying the initial furrow, it is necessary, according to the marks on the support wheel stand, to set the processing depth, which is 2/3 of the specified one. When laying the first strip, you should make sure that the rear body of the device plows to the depth set by the support wheel, the front - only half of this value. After passing 2-3 furrows, it is necessary to make a final adjustment.

The mounted plow must be stable and move smoothly along the furrows, as seen in the video

It is required to control that the frame does not skew, and it is constantly parallel to the ground. You also need to check whether the width and uniformity of the processing depth suits you.

In the event that the right side of the frame is higher or lower than the left side, then the right brace of the traction unit canopy rod should be lengthened or shortened. If the rear body plows deeper or shallower than the front body, increase or decrease the top link.

After setting up the entire system, plowing can begin. In this case, you can not change the settings throughout the entire processing of the site. After processing one area, and the need to move to another field, the system must be set up again, adhering to the same scheme.

Nuances

During plowing with PLN-3-35, due to its technical characteristics and in order to avoid unscheduled repairs, the following rules should be followed:

- turning around with a tractor to lay the next furrow is possible only with the machine in the transport position, as shown in the video below;

- circular plowing is prohibited;

- making sharp turns is strictly not recommended;

- in order to avoid an accident, it is necessary to control the ground clearance.

- when plowing with power setting, it is necessary to remove the support wheel beforehand. In this case, the exposure of the required depth occurs automatically by means of a power regulator.

Where can I buy a plow PLN 3 35

It is desirable to purchase LN-3-35 directly from the manufacturer. In this case, its price can be 50-60,000 rubles. You can also buy a used device at a fairly low price. If it is decided to buy a PLN-3-35 plow from agricultural machinery dealers, then its price can reach up to 80,000 rubles. This largely depends on the region and the margin set by the seller.

PLN-3-35, regardless of whether this equipment is new or used, due to its technical characteristics, it allows high-quality plowing of almost all types of soil, except for stony soils, to a depth of up to 30 cm. When cultivating the soil, ridges are not formed, and the furrows are even , without the formation of collapses. The unit does not allow idle runs, which allows you to cultivate the soil efficiently, while saving fuel.

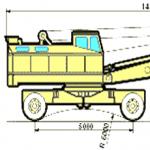

The four-furrow mounted plow PLN-4-35 (Fig. 1) is designed for plowing to a depth of up to 30 cm for grain and industrial crops of various soils that are not littered with stones, flagstone and other obstacles, with a specific resistance of up to 0.09 MPa (0 .9 kgf/cm2) and hardness up to 3.0 MPa.

The PLN-4-35 mounted plow is aggregated with the MTZ-1221 tractor (130hp).

The plow can also be aggregated with other tractors, the attachments of which are similar to MTZ-1221.

Wheel track: MTZ-1221-1540 mm. Other tractors - similar. The method of aggregation is the movement of the energy source outside the furrow.

A four-furrow mounted plow consists of the following main assembly units: frame 1, body 4, skimmer 3, wheel mechanism 2, reflector 5. The plowing depth is set by the wheel screw.

Rice. 1. Four-furrow mounted plow PLN-4-35 and main parts

1 - frame; 2 - wheel mechanism; 3 - skimmer; 4 - body; 5 - retroreflector

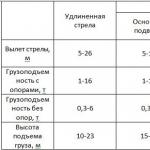

Main technical characteristics and parameters of the plow PLN-4-35

Productivity for 1 hour of main time (calculated), ha / h - 0.98 ... 1.26

Operating speed, km/h - 7...9

The constructive width of the plow, m - 1.4

Distance from the reference plane to the bottom plane of the frame, mm, not less than - 620

Distance between cases along the course, mm - 800±25

Number of buildings, pcs. - 4

Case type - cultural

Hull capture width, mm - 350±20

Coulter grip width, mm - 230

Mounted plow weight, kg - 663

Plow dimensions, mm:

Length 3530

- width 1780

- height 1315

Overall dimensions of the unit in transport position (with MTZ-1221 tractor), mm:

Length 6900

- width 2200

- height 2740

Transport speed, km/h up to 12

Ground clearance, mm, not less than 250

Mounted plow assembly PLN-4-35

Operations for assembling a mounted plow PLN-4-35:

The plow gathers supports 650-700 mm high.

Lay out the parts in a convenient order, fasteners - in size.

Lock the frame in the places indicated by the "chains" and place it on two stands. To stabilize the frame, place wooden spacers between the bars and stands.

Install two reducers on the cross bar of the frame to the extreme left position, insert the fingers into the lower holes of the reducers.

Gather the hanging. Connect the brace to the bracket on the frame with a bolt. Install the racks on the pins of the lowerers and secure them with nuts. Place spring washers and washers 24.01 under the nuts. Connect the posts to the brace with a bolt.

Insert two bolts (M22x85) and a bolt (M22x120) into the holes for fastening the bodies on the frame of the mounted plow PLN-4-35. Hang the housings and tighten the bolts with nuts and locknuts.

Bolt the hull struts to the stiffening bar. When installing the vertical body bolt, loosen the body post to shoe bolts, drive the vertical bolt from above and attach the post to the frame rail, and then tighten the bolts.

Attach the support wheel with two brackets, spring washers and nuts to the outside of the stringer. Lower the support wheel to the extreme position (up to the stop of the screw nut against the end of the wheel holder).

When working in areas that are not clogged with plant residues, it is recommended to install the wheel on the inside of the beam.

Attach the skimmer PLN-4-35 to the frame strip on the left side in front of the body with a holder, bracket, washer and nut.

Attach the harrow hitch bar to the frame with bolts, washers and nuts. Fasten the front end of the brace and the trailer bar to the vertical bolts of the first and second bodies.

Install the red reflector to the rear end of the main beam and secure it with a bolt, washer and nut.

Rules for the operation and adjustment of the plow PLN-4-35

For normal operation of the PLN-4-35 mounted plow, it is required that the relative humidity of the soil does not exceed 50-70%, and the soil hardness is up to 3.0 MPa, the temperature is above 0 ° C, all soils except sandy and stony.

The stubble height of the herbage should be no more than 25 cm, there should be no crowded stubble and plant residues on the field.

Inspect the plow carefully. Check fasteners. Lubricate the wheel bearings and the rubbing surfaces of parts that do not have oilers, the screw and the support wheel strut with grease.

Connect the PLN-4-35 plow with the MTZ-1221 tractor. Lower the links of the mounted system to a height equal to the height of the hitch pins from the soil surface, reverse the tractor so that the ball bushings of the lower links of the tractor hitch are against the plow hitch pins.

Put the hinges on the hinge pins and lock them with pins. Align the holes of the ball joint of the central link with the holes of the hinge brace, connect with a finger and lock with a pin. Shorten as much as possible the brace of the right link of the tractor hitch.

Adjust the length of the central link so that the ground clearance under the first body is at least 250 mm.

Adjust the length of the limiter chains so that the ends of the lower links have a lateral swing of no more than 20 mm in each direction.

Plow the plow PLN-4-35 - adjust the plowing depth. Pre-set the plowing depth to about 2/3 of the set depth and start plowing.

During the passage of the first furrow, make sure that the last body plows the soil to the depth set by the support wheel, and the first one to a slightly smaller depth.

The right side of the frame should be slightly higher than the left. Adjust the plowing depth with the last body using the central link.

Only turn the machine to enter the next furrow when the plow is fully raised to the transport position.

To transfer the plow from the transport position to the working position, it is necessary to move the hydraulic system control lever to the position corresponding to the "floating" position.

Make sure that the distance from the tractor to the furrow wall is: for the MTZ-1221 tractor - about 280 mm. For other tractors, at least 250 mm.

After passing two or three furrows, you can begin to adjust the plowing depth. Align the frame. It must be parallel to the surface of the field.

If the right side of the frame is higher than the left side, lengthen the right brace of the linkage of the hinged system.

If the rear part of the frame of the mounted plow PLN-4-35 is higher (lower) than the front, lengthen (shorten) the central link of the mounted system of the MTZ-1221 tractor.

Set the required plowing depth with the support wheel and fix the wheel in the holder with the locking bolt. All bodies must plow the soil to the same depth.

The plow must go steadily, without distortions to the side and along the way; working grip must be normal: all bodies must plow the soil to the same depth; plowing should be without formation gaps; planting is complete.

After the desired plowing depth has been set and the normal working grip is maintained, the plowing quality is checked according to the following criteria:

All hulls leave the same ridges after the passage;

The furrows between the two passes of the plow are the same as the furrows left by the bodies.

When moving, make sure that the ground clearance is not reduced in the event of an oil leak from the hydraulic system or oil overflowing through the piston seals. This can lead to breakage of the plow.

Maintenance work during the operational run-in of the plow PLN-4-35:

In preparation for running-in: clean the working surfaces of plowshares, dumps, field boards from paint with a wash;

Apply the wash with a brush or spray, after softening the paint layer, it is removed with a rag;

Check and, if necessary, tighten the threaded connections;

Check by swinging the play in the bearings of the support wheel and, if necessary, adjust the axial clearance of the bearings, to do this, remove the cap from the hub and tighten the nut;

When removing the support wheel cap, check for grease in the bearings. In case of lack of lubrication, fill the hubs with press grease through a grease fitting with a syringe in the amount of 0.15 kg.

After each pass, check the sticking of the working bodies, if any, stop the MTZ tractor and clean it.

Clean the plow from dust, dirt, plant residues, wash the plow and dry the plow;

Visually check the technical condition of the units and parts of the plow, tighten the threaded connections, if necessary, eliminate the identified deviations.

________________________________________________________________________

With each season, various devices appear that facilitate the work of a person. This is especially true when working with the land, when you need to plow and sow as soon as possible. That is why we would like to note the new plow PLN 3-35, one of the most popular types of plow. Low cost and easy to use.

Short description plow PLN 3-35

The plow device consists of:

- cases and frames, there are models without a case;

- skimmer and trailer for a harrow;

- hitch and support wheels;

- there are also screws for adjusting the depth of plowing the soil;

- the kit may include a support wheel that is installed in front.

The plow performs the work in the following way: a sledgehammer or a skimmer cuts the upper layers of the soil to a depth of about 12 cm. It turns the soil over and puts it in the furrow with the top layer. Plow processing is carried out to a depth of 300 mm.

Plow PLN 3-35 specifications

Specifications table:

Name, PLN-3-35

Number of working elements (pcs), 3

Operating speed (km/h), Up to 9

Depth of processing (cm), 12-30

Capture width (m), 1.05

Weight (without preplough) (kg), 463

Productivity (ha/h), 0.75-0.945

Aggregability (l/s), 80

Main advantages

Semi-mounted plows provide unloading of various tractor units, mainly suspensions. With a simple adjustment of the plowing depth, a guaranteed and high-quality tillage of different types of soil is obtained, with a good overturning of the layers. The PLN 3-35 plow has a number of advantages:

Semi-mounted plows provide unloading of various tractor units, mainly suspensions. With a simple adjustment of the plowing depth, a guaranteed and high-quality tillage of different types of soil is obtained, with a good overturning of the layers. The PLN 3-35 plow has a number of advantages:

- strong and reliable frame;

- high-quality, deep and complete incorporation of crop residues and weeds;

- simplicity and ease of use;

- have wheel suspension with a displaced center of gravity for safe delivery;

- in operation - a small turning radius, which allows you to save on fuel and lubricants;

- The device has shear bolts to protect against stones.

A feature of the plow is the adjustment of the working width, which provides the least resistance when plowing the soil. Frame hinges help to adapt to different ground contours, even with significant soil irregularities. Plow PLN 3-35 video

Plow storage

For storage, the PLN 3-35 plow is supposed to be under a canopy or indoors; it can be stored in an equipped open area with mandatory sealing and conservation. Pre-removing components that require storage in a warehouse. The plow is subject to storage at the following times:

For storage, the PLN 3-35 plow is supposed to be under a canopy or indoors; it can be stored in an equipped open area with mandatory sealing and conservation. Pre-removing components that require storage in a warehouse. The plow is subject to storage at the following times:

- with interruptions in the operation of the plow up to 10 days;

- for a short time - more than 10 days, and up to 2 months;

- for a long time - more than 2 months.

Complete set of plow PLN 3-35

The kit includes the following:

- Plow PLN 3-35 is sent from the factory assembled. The plow can be sent disassembled at the request of the client.

- The instruction manual and other documentation must be included.

- The warranty period is 24 months from the beginning of the operation of the plow (with the exception of replaceable parts), with the correct observance of the rules of operation by the consumer, storage and preservation conditions.

- Units for the PLN 3-35 plow can be tractors with a power of 1.4 kN, for example, the MTZ-82, MTZ-80 tractor. One worker is enough to control such a plow.

Prices for plows

The price for the PLN 3-35 plow is democratic, and fully meets its technical qualities and guarantees. When purchasing, you also need to take into account the cost of delivery to the consumer.

Conclusion

Plows PLN 3-35 are guaranteed to produce high-quality plowing of different types of soil, with the exception of stony soils, with a depth of 300 mm. When plowing the land, they do not form ridges, and the furrows produce even ones without collapses. The plow works without idle runs, thanks to which the tillage is of high quality, and fuel resources are saved.

The plow is one of the revolutionary technical inventions that radically changed agriculture and influenced the development of mankind as a whole.

The tool that appeared after the domestication of pack animals, with the help of which it was possible to change the surface soil layers depleted by plants for the fertile land underlying them, made it possible to effectively grow cultivated plants in one place and significantly increased the productivity of agricultural work.

The main task of mechanical cultivation, which is the foundation of effective farming, is to create the most favorable conditions for the development of cultivated crops by giving the soil a cloddy structure with lumps up to 10 millimeters in size, which allows plants to receive a sufficient amount of moisture, air and nutrients.

Plows are technical means of mechanical processing of the earth, intended for plowing the soil.

Plowing is the main tillage operation, the essence of which is to grind the soil and lay its top layer in a furrow, followed by powdering the earth raised from below, as well as embedding organic fertilizers and crop residues into the soil.

Basic requirements for the quality of mechanical plowing:

- The same size of the soil layer throughout its length;

- High density of soil ridges to each other;

- Strict straightness and parallelism of the furrows.

Design

The design of the most common general-purpose plow consists of working bodies and auxiliary elements mounted on a metal frame.

The main working elements of the plow:

- The skimmer is a working unit designed to cut the soddy surface of the soil and lay it in the resulting furrow.

- The body is the main working element of the plow complex, cutting off and turning over the soil layer located on the side of the furrow made by the skimmer. The housing consists of a plowshare and a blade forming the working surface, as well as protecting it from moving towards the unplowed part of the field under the action of soil resistance of the field board.

- Ploughshare - the working body of the body, carrying out the undermining of the soil from below and its direction to the dump.

- Dump - the main working element, made in the form of a metal surface of a special configuration, designed to shift and crush the soil layer raised by the plowshare and lay it in the furrow.

- Knife - a flat metal part with a cutting surface designed to level the vertical surface of the furrow.

Auxiliary structures:

- Support wheel - a wheel device, adjustable in height with a special screw, which limits the depth of immersion of the plow bodies into the soil, moving along the unplowed part of the field;

- Frame suspension - a frame consisting of metal bars, stiffening beams and transverse struts, which serves to fasten the elements of the plow and its aggregation with tractors.

In most cases, various types of tractor equipment are used as traction devices for working with plows - tractors, mini-tractors and walk-behind tractors. Options for installing plow equipment on them depend on the technical and operational characteristics of machines and plows, as well as cultivation conditions and soil composition. The most widespread in modern agricultural production is the installation of plow complexes on the rear hitch of tractor equipment.

Features of installing plow equipment on tractors, mini-tractors and walk-behind tractors are discussed in detail in the following sections of the article.

Classification and types

Depending on the characteristics of the cultivated soils and the specifics of growing plants on them, plows of various designs and purposes are used during arable work.

The classification of plows used for tillage is based on the features of their design and direction of application.

The following main groups are divided:

- According to the arrangement of working bodies - plowshares (revolving), disk and peeling.

- According to the installation option on the base tractor - mounted, semi-mounted and trailed.

- By appointment - general and special use.

- According to the method of plowing, they are furrowed, cultivating the soil with the formation of dump ridges (into a dump), leaving furrows on the surface of the earth (tossed) and smoothly plowing.

On most plows for general and special use, share devices for plowing are installed. Equipped with working bodies in the form of a spherical disk, disk-type plows are much less common and are used mainly for processing virgin and cleared land, as well as for plowing the soil after thick-stemmed crops.

General purpose plows are used for cultivating soils to a depth of 27 centimeters.

Share plows are produced with 1-5 bodies, disk plows - with 1-3.

Mounted on the linkage of the traction unit, controlled from the operator's cab, with greater productivity, mounted units are in higher demand than trailed units.

Special-purpose plows intended for work in different from standard plowing conditions are divided into the following main types:

- Swamp-shrub - a mechanism for plowing marshy and covered with shrubs and woody vegetation up to four meters high, as well as soils with a high peat content.

- Cultivating the soil to a depth of a meter, a plantation plow is used to create the most favorable conditions for the root system of plants. Equipped with double shares working at different depths, it can be used for fertilizing the soil.

- Allowing the laying of the raised soil layer in various ways, longline-type models produce plowing of solonetzes and podzols.

- Garden - devices, the design of which allows you to plow areas of soil located under the crowns of garden trees.

- Equipped with a device for sowing seeds of coniferous trees, the forest plow is used to prepare holes for planting forests in unuprooted areas.

- Devices for plowing stony soils, which include a system that provides working bodies around solid obstacles and automatic deepening after overcoming the obstacle, are used when cultivating land saturated with stony inclusions. Their parts are made of materials with high strength, and the elements experiencing the greatest load during operation can be changed to others.

- Flatbedless or smooth plowing is used for soils that are significantly affected by wind erosion.

Installation on MTZ tractor equipment

MTZ equipment is one of the most common types of tractor machines operating in the fields of agricultural enterprises in the post-Soviet space, aggregated with a large number of devices and mechanisms, including plows of various designs and purposes.

Installation and adjustment on the tractor MTZ-80 and 82

The option of installing a plow on a tractor is selected depending on the number of plow bodies and the size of the working grip during plowing.

With a working width of up to 1.05 meters and the number of bodies from 1 to 3, the plows are connected to the tractor hitch according to a three-point scheme, where the attachment points are the ends of the longitudinal and central rods of the machine.

The two-point aggregation scheme, which allows to achieve greater adaptability of the plow to plowing conditions, is used for plow complexes equipped with a supporting wheel with a working width of 1.05 meters and more than three bodies.

A plow mounted on a tractor in a two-point way during plowing can deviate in a horizontal-transverse direction by an angle of up to 25 degrees in each direction, choosing the optimal load trajectory.

When aggregating with a tractor, the track width is adjusted to the width of the working grip of the plow. So, models with a plowing width of 1.05, 0.9 and 0.6 meters must be installed on base machines with a distance between the wheels of 1.5, 1.4 and 1.3 meters.

When plowing with a working width of less than 1.05 meters, the right and left wheels of the tractor unit work in different conditions: the right wheels move along the furrow, experiencing a large load of the tractor moving at an angle, and the left ones move along an unplowed surface, slipping on it. To balance the load on the wheels during plowing, they are set asymmetrically with respect to the direction of movement. With a track width of 1.5 meters, the distance from the central axis of the tractor to the right wheel should be 0.8 meters, and to the left 0.7 meters.

Adjustment and adjustment of a three-furrow share plow

The plow is adjusted on a site with a flat and hard surface.

If it is necessary to use skimmers when plowing, they are set up first. The immersion depth of the skimmer, which must remove the upper soddy layer of soil up to 0.1 meters thick during plowing, is set using a number of vertical holes located on its rack. To achieve a greater plowing depth, the skimmer is installed in the holes located in the upper part of its rack.

To prevent clogging during operation, the main body should be at a distance of 0.25-0.3 meters from the skimmer share, and the field cut surfaces of these elements should be parallel to each other.

The depth of immersion of the hulls into the soil is adjusted with the plow lowered to the site by changing the length of the upper link and the right brace of the tractor hitch, under the wheels of which wooden blocks are placed with a height of 2-3 cm less than the desired plowing level. With a properly adjusted plow, the blades of the shares of all bodies lie completely on the surface of the site.

Lateral deviation from the horizontal axis of the tractor is set by changing the length of the restrictive chains. Their length should allow the longitudinal rods to deviate no more than 0.12 meters from the central position in each direction.

In different models, the width of their working grip can be changed by the adjusting axle (models PLN-3-35, PN-ZOR / 2-ZOR and others) or depends on the position of the wheels of the base chassis (PN-8-35, PKS-3-35).

The final adjustment is made at the plowing site. The deviation of the plowing depth from the required one is regulated by increasing or decreasing the length of the central link, and the transverse warping is eliminated by changing the position of the braces.

With a properly adjusted plow, the central link is parallel to the main axis of the tractor with loose limiter chains.

Installation on walk-behind tractors

Motoblocks are multifunctional units mounted on a single-axle chassis designed for agricultural work in small areas with limited access for larger equipment.

On motoblocks, both plows designed to work with certain models and universal devices that work on most motoblock units are installed. So, the MTZ P1-20 installed on walk-behind tractors is aggregated with Mobile K G85, Agros, Ghepard and other devices.

Preparing the walk-behind tractor for the installation of the plow

Equipping motoblocks structurally different from tractors with plows has its own specifics.

For aggregation on a lightweight walk-behind tractor, the transport wheels are replaced with lugs made in the form of a corrugated metal wheel, designed to reduce the load on the unit during plowing. Grousers are installed using special hubs mounted instead of transport wheel holders on the drive axle of the walk-behind tractor. The long lug hubs, which increase the stability of the machine during plowing, are fixed on the drive shaft with studs and cotter pins.

The most convenient for working with walk-behind tractors are plows weighing up to 60 kilograms, the width of which is from 0.2 to 0.25 meters.

In addition, additional ballast weights weighing from 20 to 30 kilograms are installed on walk-behind tractors with a small mass.