Quite a long time has passed since the official launch of the modern fifth class harvester "Acros-530" (May 16, 2007). Then it was called a "significant event" for all of Russia; "the start of a new life" not only for Rostselmash, but for the entire agricultural sector of the country as a whole. Today we can say that this model was basically able to justify the epithets so generously handed out to it. Even in the changed economic conditions, Acros-530 firmly occupies far from the last place in the agricultural machinery market, remaining one of the most profitable options in its class in terms of price / quality ratio.

The Rostselmash company is one of the few domestic manufacturers of agricultural machinery, which, after a crushing blow during the collapse of the Soviet Union, not only survived, but was also able to continue its systematic development. First of all, to launch the production of new models of competitive equipment that meet modern requirements and economic realities.

One of these models was the Acros-530 (project name PCM-142), a new generation of high-performance combine harvesters designed for the needs of large farms with large areas of high-yielding fields.

On May 16, 2007, the first harvesters of this brand left the assembly line, in the presence of the governor and other leaders of the region, solemnly consecrated and blessed by the Archbishop of Rostov and Novocherkassk Panteleimon. The first recipient of "Akros" - the director of the SPK "Voskhod" from the Krasnodar Territory Nikolai Bukreev did not hide his joy from the purchase.

In June 2007, after a personal acquaintance with the "Acros-530" V.V. Putin uttered the famous dictum: "Such combines are no less important for Russia than missiles." And three months later, the harvester number 100 had already left the gates of the plant. In the autumn of the same year, Acros-530 completely replaced its predecessor, “”, on the conveyor.

Vladimir Putin about the AKROS 530 combine: "I'll be brief!". Below - Sergei Ivanov.

These solemn moments were preceded by three years of development, approvals, and testing of the new model. The chief engineer of the Acros-530 project, Vladimir Kulikov, noted that in creating this model, he and his colleagues relied both on the experience of developing and manufacturing the Don-1500 combine, and on advanced foreign analogues, in particular, the German company Claas ".

It was a truly large-scale project, in which Rostselmash invested more than 800 million rubles. During the development process, 11 new production sites were created, more than 60 units of modern high-performance equipment were purchased. Including - laser cutting and bending complexes, semi-automatic welding machines, milling and turning machines, hydraulic and eccentric presses and other modern equipment of world manufacturers. 26 experimental pre-series units of equipment have passed serious tests in different climatic zones of Russia.

"Acros-530" became the "first sign" of the new model range of the company. A qualitatively new family of combines aimed at increasing shift productivity and reducing the cost of bunker grain. As well as providing the machine operator with unprecedentedly comfortable (for domestic equipment) working conditions.

Technical characteristics of the harvester «Acros-530»

The Acros-530 harvester received a modern layout, as in Western technology: a cabin in the middle; behind it is a bunker; the engine is in the back. This significantly reduced the noise / vibration level in the cab and gave a more spacious area for engine maintenance. The cab, located in the center, provided an excellent overview of the entire working area.

Acros-530 is a single-drum harvester. It is designed for direct and separate harvesting of all spiked crops. As well as corn and sunflower (if you install additional attachments: PSP-8/05 and PSP-10M, respectively).

The general technical characteristics of this agricultural machine are as follows:

- Overall dimensions: Length 10.5 m plus header 6 m; Width 3.85 m; height 4.01 m.

- Weight: (without header / with header): 13740 kg / 15030 kg.

- Engine: diesel, turbocharged YaMZ-236BK.

- Threshing: Drum diameter - 80 cm; drum length - 150 cm; rotational speed - from 400 to 1045 rpm. Coverage angle - 130 degrees; concave area - 1.38 sq.m.

- Separation: 5-key seven-cascade straw walker 4.1 m long; with a separation area of 6.15 sq.m.

- Cleaning: sieves with an area of 4.74 sq.m. plus a six-bladed fan with a speed of 335 to 1050 rpm.

- Bunker: volume 9 cubic meters, unloading height 4.3 meters, unloading speed 90 liters per second.

- Fuel tank capacity - 540 liters.

- The transmission is hydrostatic.

- Gearbox - three-speed.

The first of the "Akros" is equipped with a V-shaped 6-cylinder four-stroke diesel engine with turbocharging, liquid cooling. Brand - ""; manufacturer - Yaroslavl Motor Plant (PJSC "Avtodiesel"). The same motors were installed on the combines of the "Krasnoyarsk Combine Plant," "who ordered to live long." Engine power - 250 horsepower (184 kW). Rotation speed - 2000 rpm. Minimum specific fuel consumption, g/kW h (g/hp h) – 215 (159). The mass of the YaMZ-236BK engine is 985 kg.

YaMZ-236BK engine.

With regard specifically to the Acros-530 model, this motor has an additional power reserve of at least 50 “horses”, which reveals the potential of the combine and guarantees an appropriate increase in traction in any harvesting situation. The use of turbocharging, coupled with a 240-liter fuel tank, made it possible to increase the operating time of the combine without refueling to at least 12, and in fact - more than 14 hours!

Harvesting part of the Acros-530 combine

Simultaneously with the launch of Akros harvesters, Rostselmash mastered the production of completely new harvesters, called Power Stream. The capture width of different variants of this unified attachment is 6.7 and 9 meters. Compared to the previous Rostselmash harvesters, Power Stream has become much lighter and stronger at the same time.

The harvester is suspended frontally to the feeder house by means of hinges, equipped with an auger and a balancing mechanism; a system of automatic control of the earth's relief in two directions (longitudinal and transverse) and a 5-blade, eccentric reel. Reel rotation speed - from 15 to 50 revolutions per minute.

Long tines and a reel with a special trajectory of movement easily cope with twisted and laid bread. The large auger diameter prevents winding of high-stemmed loaves. Deep flights of the auger eliminate the need for additional fingers. The header provides a high-quality cut of raw materials at an adjustable height of 6, 10, 14 and 18 cm.

"Power Stream" accurately copies the longitudinal and transverse structure of the field, which allows you to use the entire working surface with maximum efficiency. The reel is driven by a hydraulic drive. It makes the operation of the main components softer, which reduces wear on parts. For fast cleaning of a harvester, the reverse is used. All header control (up and down movements, reel movements in vertical and horizontal planes, reel rotation speed control) is carried out using electro-hydraulic equipment. And to start absolutely all functions, the operator does not need to leave the cab. And I don't want to leave her, and here's why.

When Deputy Prime Minister of the Russian Federation Sergey Ivanov and the then Minister of Agriculture Alexei Gordeev “received” the new agricultural machine of Rostselmash, they called the cabin of Akros-530 the spacecraft control room. Indeed, the working conditions of a machine operator on domestic combines have never been so modern and comfortable. Cabin "Acros-530" (Rostovites called it "Comfort Cab") is completely double, for a combiner and a helmsman. It is sealed, reliably protected from noise, vibration and dust. Mounted on a sprung base, on four shock absorbers.

In the cabin of the AKROS 530 combine.

The Acros-530 comes standard with a cabin equipped with a luxury unheard of in the old days: climate control, a refrigerator for drinks, a radio tape recorder with an acoustic system! For the first time in the history of domestic production, the combine cabin was equipped with an on-board computer with an Adviser voice alert system. The steering column is adjustable in height and angle; panoramic glazing of 5 sq.m. allows you to perfectly see the field, the stubble behind the header and the unloading auger.

The peasants of Russia and other republics of the former Soviet Union highly appreciated the first of the Rostselmash family "Akros". First of all, in terms of the economic efficiency of its use. "Acros-530" consumes much less fuel per ton of produced grain than any domestic harvester of the previous generation. And this despite the fact that in terms of performance it replaces two such combines at once.

"AKROS 530" in the field.

In JSC "Agrariy" (Ryazan region, Sasovsky district), the peasants were able to compare "Acros-530" with its closest competitor on the market - Gomselmashevsky combine: in 2008, to replace the old "Nivam", they purchased one Rostov and one Belarusian combine. Following the results of the 2009 harvest,

- Seasonal threshing amounted to: at Akros - 1639 tons; on "Polesie" - 1388 tons.

- Seasonal fuel consumption: "Acros-530" - 8050 tons; "Polesie KZS-1218" - 8330 tons.

- Average fuel consumption, liters per ton: Akros – 4.9 l/t; at Polesie - 6 l/t.

The "appetite" of the engine of the Acros-530 combine is expressed in the following indicators: fuel consumption for grain crops - 10-12 liters of diesel fuel per hectare; on corn and sunflower - 15 liters per hectare. High-quality and clean harvesting of not only grain, but also sunflower is noted: “The combine harvests very cleanly - not a speck. A very pure seed - I have never seen such a thing in my life. The new cab received high praise. It is easy to establish a comfortable microclimate in it and work in one shirt both in the summer extreme heat and in the autumn season of sunflower harvesting, at sub-zero temperatures outside.

Harvester "AKROS 530" with a header for harvesting sunflower.

Among the shortcomings, the low quality of bearings and drive belts of domestic production, which is equipped with the Acros-530 combine, is noted. Bearings often do not withstand even one year of operation, they crumble. They are advised to change to imported ones.

Also, a lot of ridicule, and sometimes fair sharp criticism, is caused by “Americanisms” in the names of the components and systems of the combine: “Comfort Cab”, “Power Stream”, “Smart Launch”, “Adviser”, etc. After all, this is, by and large, equipment for the domestic market. And the countries to which it is exported are far from English-speaking: the former republics of the USSR. So why all this circus with “pseudo-imported” names, and why is the name of the combine generally written in English letters?

Prices for harvesters "AKROS 530"

To date, the official price list of the Rostselmash plant no longer lists new harvesters of the Acros-530 brand. Since this first model of the brand was replaced by others, even more modern and productive, with new, more powerful Akros engines, with digital indices “-550” and “-585”.

However, there is no shortage of used Acros-530 harvesters on the secondary market. Indeed, over the past seasons since 2007, the model has been replicated in thousands and thousands of copies. Here, for example, some of the offers for sale:

- "year of issue 2008 , in excellent condition, no repairs required, header 6 meters with cart, running time about 2000 hours - RUB 2,350,000.»;

- ""year of issue 2008 , in great condition, - 4 100 000 rub., bargaining is possible”;

- « 2008 year of manufacture, excellent condition, service at the dealer, does not require investment, running time 2456 m.h. 3.1 million rubles».

- « 2007 year of manufacture, in good condition, operating time 3200 hours, with a 7-meter header, RUB 2,100,000

In general, it should be noted that the Acros-530 combine has become one of the most successful models of agricultural machinery in the post-Soviet space. This combine laid the foundation for the goals of a series of new high-performance agricultural machines of the Rostov enterprise. In practice, it turned out to be no worse than the German "classmates" of the Claas company, which are much more expensive, and surpassed in all respects its approximately equal in price, also a modern Belarusian competitor - the Polesie combine.

Combines "Acros" - agricultural machinery for harvesting crops, which is produced by the Russian company "Rostselmash". He considers 1929 to be the founding date of the base plant, although the line of Akros combines was created much later - in 2004. Then these high-tech and modern machines replaced their predecessors - Don combines, the production of which was suspended.

Today, the Acros trademark is one of the five world leaders in agricultural engineering. The factories that produce Akros combines are located not only in Russia itself, but also in Ukraine, Kazakhstan and even Canada, and in total there are 13 branches. The export of this technique has been established in more than 20 countries of the world, where their popularity is not inferior to other brands.

Features of the combined units "Akros"

- economical 6-cylinder engines;

- equipment with beater-analyzers (combs and fingers, the output of which is regulated by the operator) of the inclined chamber;

- harvester "Power Stream", the capture of which can reach 5, 6, 7 and 9 m;

- grain-friendly drum thresher;

- the presence of a blade for additional threshing;

- all kinds of auxiliary equipment options that allow you to operate combines for other agricultural work.

Harvester Akros 530

Akros engine

Harvester harvester Akros 530

Photo header combine Acros

- extended header table;

| reaper | ||

| Type | power stream | |

| Header width | m | 6/7/9 |

| mm | 45-75/85-115/125-155/165-195 | |

| Knife cutting speed | slices/min | 946 (1080 - Schumacher) |

| Reel Speed | rpm | 15-49 |

| Threshing | ||

| Drum diameter | mm | 800 |

| Drum length | mm | 1500 |

| rpm | 400 | |

| rpm | 1045 | |

| Concave Angle | deg. | 130 |

| Total concave area | sq. m | 1,38 |

| Separation | ||

| Straw walker type | 5 keyboard | |

| Straw walker length | m | 4,1 |

| sq. m | 6,15 | |

| cleaning | ||

| Total sieve area | sq. m | 4,74 |

| Cleaning fan type | six-bladed | |

| rpm | 335-1050 | |

| Engine | ||

| engine's type | ||

| Engine model | ||

| Engine manufacturer | ||

| Engine power | kW | |

| Engine power | hp | |

| g/hp h | 159 | |

| Fuel tank capacity | l | 540 |

| grain bin | ||

| Grain tank capacity | cube m | 9 |

| Dumping height | mm | 4300 |

| Hopper unloading speed | l/s | 90 |

| Overall dimensions and weight | ||

| mm | 16500 (header 6 m) | |

| mm | 3843 | |

| mm | 4012 | |

| Weight without header/with header | kg |

Device

Engine

Transmission

Hydraulic system

Steering

Attachment

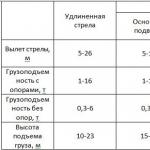

| Characteristics | Indicators |

| 5; 6; 7; 9/3,4 | |

| Blade speed, stroke/min | 1140 |

| Thresher width/diameter, mm | 1500/800 |

| 180-490/400-1045 | |

| 130/1,38 | |

| Number of straw walker keys | 5 |

| 6,15/4,74 | |

| 335-1050 | |

| Hopper volume, l | 9000 |

| Unloading speed, l/s | 90 |

| Unloading height, mm | 4300/4700 |

| Engine power, h.p. | 255 |

| 0-27 | |

| Fuel tank capacity, l | 540 |

| 8600/3880/3940 | |

| 13380 |

Harvester Akros 530

Combine harvester Akros (Acros) 530 is a grain-harvesting agricultural unit developed by Rostselmash for true professionals in their field.

Acros 530 (another name for PCM-142) is suitable for direct and separate harvesting of winter and spring wheat, barley, oats, rye, and other cereal crops, as well as corn and sunflower, for this you need to install additional attachments.

Currently, the Akros 530 combine is the most profitable offer in the class of high-performance harvesting equipment. In addition to this model, there is also an ACROS 580 combine.

Combine harvester Acros 530

Combine "Acros" 530 has a modern layout: cabin - bunker - engine. Due to this, the noise level in the cab is significantly reduced and a more spacious area for engine care has been obtained. The cab is located in the center, which provides a good overview of the working area. Its competitor is the Claas Mega-208 combine.

Akros engine

Photo of the Akros 530 combine engine

Combine harvester Akros 530 is equipped with a powerful (250 hp at 2000 rpm) and productive (14 t/h) 4-stroke 6-cylinder engine. The engine is cooled by a system of tubular radiators and a water-oil heat exchanger located directly on the engine.

Harvester harvester Akros 530

ACROS combines are equipped with new unified headers of the Power Stream series with a working width of 6, 7 and 9 m.

Compared to the previous ZhU header, Power Stream headers are stronger and lighter, provide more reliable process flow, reduce losses and increase harvesting productivity.

The harvester creates the basis for the maximum productivity of the combine and, in terms of its characteristics and design, is the most progressive among those produced in the CIS and is not inferior to the best foreign models.

Photo header combine Acros

The main differences between the Power Stream series header:

- increased diameter of reel tine arms, integrated discs and reel beams;

- hydraulic drive of the reel;

- extended header table;

- additional counter-cutting surface in the cutting unit;

- universal feeder house with beater-normalizer, increased by 40 mm clearance between the conveyor slats and the bottom of the feeder house;

- knife drive with Pro-drive planetary gearbox;

- reel double tine tines.

Header control (header movement up and down, reel movement in vertical and horizontal planes, reel rotation speed control) is carried out using electro-hydraulic equipment.

Long tines and a reel with a special trajectory of movement easily cope with twisted and laid bread. The large auger diameter prevents winding of high-stemmed loaves. Deep flights of the auger eliminate the need for additional fingers.

For the convenience of work, auxiliary equipment in the form of a minitractor and Uralets 220 can be used.

Technical characteristics of the harvester Akros 530

| reaper | ||

| Type | power stream | |

| Header width | m | 6/7/9 |

| Cutting Height Presets | mm | 45-75/85-115/125-155/165-195 |

| Knife cutting speed | slices/min | 946 (1080 - Schumacher) |

| Reel Speed | rpm | 15-49 |

| Threshing | ||

| Drum diameter | mm | 800 |

| Drum length | mm | 1500 |

| Drum rotation frequency, min | rpm | 400 |

| Drum rotation frequency, max | rpm | 1045 |

| Concave Angle | deg. | 130 |

| Total concave area | sq. m | 1,38 |

| Separation | ||

| Straw walker type | 5 keyboard | |

| Straw walker length | m | 4,1 |

| Straw walker separation area | sq. m | 6,15 |

| cleaning | ||

| Total sieve area | sq. m | 4,74 |

| Cleaning fan type | six-bladed | |

| Cleaning fan speed | rpm | 335-1050 |

| Engine | ||

| engine's type | 4-stroke, liquid-cooled, turbocharged | |

| Engine model | YaMZ-236BK (ACROS 530) QSC8.3 (ACROS 540) | |

| Engine manufacturer | Autodiesel (ACROS 530)CUMMINS (ACROS 540) | |

| Engine power | kW | 184 (ACROS 530)194 (ACROS 540) |

| Engine power | hp | 250 (ACROS 530)260 (ACROS 540) |

| Specific fuel consumption, nominal | g/hp h | 159 |

| Fuel tank capacity | l | 540 |

| grain bin | ||

| Grain tank capacity | cube m | 9 |

| Dumping height | mm | 4300 |

| Hopper unloading speed | l/s | 90 |

| Overall dimensions and weight | ||

| Length with header in transport position | mm | 16500 (header 6 m) |

| Width in transport position | mm | 3843 |

| Transport height | mm | 4012 |

| Weight without header/with header | kg | 13740±412/15030 (ACROS 530) 13480±404/15030 (ACROS 540) |

Source: http://selhoztehnik.com/kombajn-akros-530

Combine harvester Akros (acros) 530: specifications, device, photo and video

The final profit will also depend on how well the grain crops are harvested, which is why it is necessary to apply for equipment only to leading manufacturers.

Rostselmash produces the Akros 530 harvester, which stands out for its large size and capacity, as well as excellent performance, which makes it an ideal solution for professionals in agribusiness.

The production of Akros 530 harvesters is carried out by Rostselmash, which is the largest manufacturer of agricultural machinery in Russia and one of the leading manufacturers in the world.

Rostselmash is currently part of a group of companies that includes 13 global brands.

At factories in Europe, the USA, Canada and Russia, they are developing new equipment, improving the production line, and also testing manufactured products.

Read also Harvester case 2388 technical specifications

Combine harvesters are designed for harvesting grain crops.

For this, various attachments are used, which cut the stem and crush it as much as possible. After that, through the transport channel of the combine itself, the crop enters the bunker, in which it remains until it is full, after which it is unloaded.

Device

The acros 530 combines are made using modern technologies, thanks to which it was possible to achieve high productivity and accuracy when harvesting. The percentage of lost grain does not exceed 5 percent, which is a pretty good result for modern technology.

Engine

It is in Akros 530 that a 6-cylinder YaMZ engine is installed, which boasts 255 horsepower. The main feature of all Rostselmash combines is a 20% power reserve at peak loads. Thanks to the huge fuel tank of 540 liters, the time of continuous work in the field can reach up to 15 hours.

Transmission

The transmission, as in all heavy equipment, is hydrostatic, which, in comparison with the more traditional mechanical, has a lot of advantages: less wear due to the absence of mechanical friction; does not require frequent maintenance; allows you to adjust the speed as accurately as possible in a wide range; provides stepless speed control. Thanks to all these advantages, maximum efficiency is achieved when harvesting. Photo of the acros 530 combine

Hydraulic system

The hydraulic system consists of several hydraulic pumps that power the steering, hydrostatic transmission and attachments. However, they share a hydraulic oil tank. By dividing the entire system into separate independent circuits, it is possible to achieve uninterrupted operation of all nodes, regardless of the load of the others.

For example, if the steering and transmission were powered by the same pump, there would not be enough power when used at the same time, which would reduce efficiency.

Steering

The steering also works on hydraulics. For such a huge harvester, this is extremely important, since it is with such a system that you can achieve the best control accuracy and minimize the burden on the operator.

Attachment

Attachments also have several features that enhance productivity and accuracy. Firstly, all headers are equipped with the Power Stream hydromechanical terrain following system, and, if desired, the combine can be equipped with a more modern Level Glide system. The installation of such systems will reduce grain loss to a minimum even in areas with uneven surfaces.

Secondly, the header is equipped with a German-made planetary knife drive, which guarantees smooth and durable work, and the double cutting edge ensures minimal losses due to a quick and clean cut. is obtained as clean as possible.

Technical characteristics of the Akros 530 combine harvester:

| Characteristics | Indicators |

| Header/pick-up width, m | 5; 6; 7; 9/3,4 |

| Blade speed, stroke/min | 1140 |

| Thresher width/diameter, mm | 1500/800 |

| Frequency of rotation of a thresher with/without reducer, mm | 180-490/400-1045 |

| Coverage angle/concave area, deg/sq. m | 130/1,38 |

| Number of straw walker keys | 5 |

| Straw walker/cleaning grate area, sq. m | 6,15/4,74 |

| Cleaning fan speed, rpm | 335-1050 |

| Hopper volume, l | 9000 |

| Unloading speed, l/s | 90 |

| Unloading height, mm | 4300/4700 |

| Engine power, h.p. | 255 |

| Transport speed, km/h | 0-27 |

| Fuel tank capacity, l | 540 |

| Shipping dimensions LxWxH, mm | 8600/3880/3940 |

| Shipping weight without header and fuel, kg | 13380 |

On the video, the Akros 530 combine harvester in operation:

Source: http://allspectech.com/selhoztehnika/dlya-zemledeliya/uborochnaya/kombajny/zernouborochnye/akros-530.html

The very first development in this serial line. It is also known on the market under a different marking - PCM 142. The main purpose of this Acros combine harvester is to direct and separate threshing of grain crops - wheat, rye, barley, etc.

Advantages:

- 6-cylinder engine brand "YaMZ-236BK";

- efficient cooling system;

- perfect reaper;

- the possibility of operating the combine in areas with uneven terrain;

- stepless speed adjustment, which extends the shelf life of rubbing parts;

- 2-seater ergonomic cabin;

- on-board computer.

Specifications:

- Capture width - 5/6/7/9 m;

- Dimensions of the chopper drum (section / length) - 80 / 1.48 cm;

- The storage volume is 9 m3;

- Unloading - 90 l / s;

- Gas tank - 0.54 m3;

- Weight - 13.74 tons.

Akros 550

Another equally popular and productive machine for harvesting cereals, cereals and long-stemmed crops.

The operation of the units of the unit is controlled from the glazed operator's cab. Unlike the previous model, the one under consideration can be equipped with both a domestic YaMZ 236BE engine and an imported one from the Cummins brand of similar power.

Advantages:

- motor system with 20% more power reserve;

- unitary hydraulic connector;

- volumetric grinder;

- built-in concave with an angle of 130 0;

- 5-section straw walker;

- threshing functionality, working as a stand-alone device;

- information indicator "Adviser";

- cabin of the combiner of the increased comfort "Comfort Cab".

Operating parameters:

- Thrust - 280 hp;

- Harvester (min. and max. length) - 6 and 9 m;

- Granary - 7500 l;

- Thresher length - 1.5 m;

- Shipment at a speed of 90 l / s;

- Weight - 13.4 tons.

The Acros 560 combine was released in 2009. According to its performance, it is focused on large agricultural firms where there is a need for harvesting over large areas. At the same time, the creators of the machine managed not only to reduce the operating time, but also to reduce operating costs and increase the profitability of the grain material.

According to its intended purpose, it is a single-drum harvester adapted for harvesting cereals, and when installing adapters (for example, PSP-8/05 or PSP-10M) - for corn and oil crops.

Peculiarities:

- reduced noise level in the operator's cab;

- ease of maintenance of the motor, access to which is simplified;

- 360 0 view from the cab of the combiner;

- innovative headers, which are considered the best examples in the entire post-Soviet space;

- Level Glide technology - adaptability to field irregularities;

- equipment with stem lifters.

Specifications:

- Effort - 280 hp;

- Max. capture range - 9 m;

- Grain bunker - 9000 l;

- Chopper length - 1.5 m;

- Mass unloading - 90 l / s;

- Weight - 13400 kg.

Akros 580

Combine "Akros" 580 belongs to the group of heavy agricultural machinery with a narrow profile of specialization. "Acros" 580 is intended for seasonal harvesting of cereals, legumes and essential oil crops. Built on the basis of advanced design developments not only in Russia, but also in far abroad countries. This is evidenced by the equipment of the model with 4-model hydraulics from the German brand.

Advantages:

- 6-cylinder Cummins engine with an additional turbine to reduce energy consumption;

- unified scheme of hydraulic tank and hydraulic pump;

- stepless transmission;

- capacious moisture-proof bunker;

- separator with 5 keys with a large effective length (up to 4 m);

- central localization of the operator's workplace, which, together with full glazing, creates maximum visibility;

- relief copying technology;

- re-threshing rotary device;

- information block "Adviser".

Specifications:

- Power potential - 300 hp;

- Harvesting width - 9 m;

- Grain receiver - 9000 l;

- Chopper diameter - 800 mm;

- Unloading speed - 90 l / s;

- Weight - 13.4 tons.

Akros 585

Harvester "Akros" 585, the photo of which is shown above, known under the marking "Akros" RSM-142. It is in high demand among domestic farmers. Created on the basis of the 580th model while maintaining the original traction and functional properties. Allows you to process up to 4.15 hectares per hour, which is especially important for large farmer cooperatives. Like its basic counterpart, it has:

- all-welded body;

- system of cross-longitudinal copying of the working surface;

- power steering;

- ability to work with wet grain (up to 35%);

- drive "Schumacher" for high-speed threshing.

Acros 590 Plus

Agricultural machine for the most difficult tasks. Suitable for harvesting large areas, regardless of moisture and straw content. In comparison with the 580, this increase in power was 10%, and with the original, the 530th - 30%. Innovative design solutions in the threshing and separating compartment resulted in clean grain with minimal damage and no straw.

Advantages:

- increased area of the inclined chamber with a beater-accelerator;

- header tilt adjustable by electrohydraulics;

- high-speed CUMMINS 6LTAA engine with push-button control system;

- modified straw walker keys;

- 2-circuit separation system of 3 sieves;

- grain separation area increased to 6.3 m2;

- electrically adjustable gratings on the taskbar in the cab;

- the provided cover on the bunker for protection against a rain;

- extended wheelbase;

Working properties:

- Thrust - 330 hp;

- Reaper - 9 m;

- Bunker - 9000 l;

- Drum width - 1.48 m;

- Unloading speed - 90 l / s;

- Weight - 14.3 tons.

Acros 595 PCM 152

The Acros 595 PCM 152 combine harvester is one of the latest modifications produced by Rostselmash. The combination of performance, easy maintenance, maintainability and economy makes it one of the best-selling cars among classmates.

Advantages:

- a beaterless feeder house, which made it possible to adapt the harvester for row crops;

- improved grain permeability due to the longitudinal groove pattern of the straw walkers;

- separation block of 2 cascades;

- electro-hydraulic adaptation to complex field geometry;

- after-threshing device, which is a 3-blade rotor for gentle cleaning of the crop;

- improved blowing by 6-blade fan;

- chaff spreader, which will become an indispensable thing for adherents of plowless farming.

The performance characteristics of the 595 modification are similar to the 590.

Harvester Akros 530

Combine harvester Akros (Acros) 530 is a grain-harvesting agricultural unit developed by Rostselmash for true professionals in their field.

Acros 530 (another name for PCM-142) is suitable for direct and separate harvesting of winter and spring wheat, barley, oats, rye, and other cereal crops, as well as corn and sunflower, for this you need to install additional attachments.

Currently, the Akros 530 combine is the most profitable offer in the class of high-performance harvesting equipment. In addition to this model, there is also an ACROS 580 combine.

Combine harvester Acros 530

Combine "Acros" 530 has a modern layout: cabin - bunker - engine. Due to this, the noise level in the cab is significantly reduced and a more spacious area for engine care has been obtained. The cab is located in the center, which provides a good overview of the working area. Its competitor is the Claas Mega-208 combine.

Akros engine

Photo of the Akros 530 combine engine

Combine harvester Akros 530 is equipped with a powerful (250 hp at 2000 rpm) and productive (14 t/h) 4-stroke 6-cylinder engine. The engine is cooled by a system of tubular radiators and a water-oil heat exchanger located directly on the engine.

Harvester harvester Akros 530

ACROS combines are equipped with new unified headers of the Power Stream series with a working width of 6, 7 and 9 m.

Compared to the previous ZhU header, Power Stream headers are stronger and lighter, provide more reliable process flow, reduce losses and increase harvesting productivity.

The harvester creates the basis for the maximum productivity of the combine and, in terms of its characteristics and design, is the most progressive among those produced in the CIS and is not inferior to the best foreign models.

Photo header combine Acros

The main differences between the Power Stream series header:

- increased diameter of reel tine arms, integrated discs and reel beams;

- hydraulic drive of the reel;

- extended header table;

- additional counter-cutting surface in the cutting unit;

- universal feeder house with beater-normalizer, increased by 40 mm clearance between the conveyor slats and the bottom of the feeder house;

- knife drive with Pro-drive planetary gearbox;

- reel double tine tines.

Header control (header movement up and down, reel movement in vertical and horizontal planes, reel rotation speed control) is carried out using electro-hydraulic equipment.

Long tines and a reel with a special trajectory of movement easily cope with twisted and laid bread. The large auger diameter prevents winding of high-stemmed loaves. Deep flights of the auger eliminate the need for additional fingers.

For the convenience of work, auxiliary equipment in the form of a minitractor and Uralets 220 can be used.

Technical characteristics of the harvester Akros 530

| reaper | ||

| Type | power stream | |

| Header width | m | 6/7/9 |

| Cutting Height Presets | mm | 45-75/85-115/125-155/165-195 |

| Knife cutting speed | slices/min | 946 (1080 - Schumacher) |

| Reel Speed | rpm | 15-49 |

| Threshing | ||

| Drum diameter | mm | 800 |

| Drum length | mm | 1500 |

| Drum rotation frequency, min | rpm | 400 |

| Drum rotation frequency, max | rpm | 1045 |

| Concave Angle | deg. | 130 |

| Total concave area | sq. m | 1,38 |

| Separation | ||

| Straw walker type | 5 keyboard | |

| Straw walker length | m | 4,1 |

| Straw walker separation area | sq. m | 6,15 |

| cleaning | ||

| Total sieve area | sq. m | 4,74 |

| Cleaning fan type | six-bladed | |

| Cleaning fan speed | rpm | 335-1050 |

| Engine | ||

| engine's type | 4-stroke, liquid-cooled, turbocharged | |

| Engine model | YaMZ-236BK (ACROS 530) QSC8.3 (ACROS 540) | |

| Engine manufacturer | Autodiesel (ACROS 530)CUMMINS (ACROS 540) | |

| Engine power | kW | 184 (ACROS 530)194 (ACROS 540) |

| Engine power | hp | 250 (ACROS 530)260 (ACROS 540) |

| Specific fuel consumption, nominal | g/hp h | 159 |

| Fuel tank capacity | l | 540 |

| grain bin | ||

| Grain tank capacity | cube m | 9 |

| Dumping height | mm | 4300 |

| Hopper unloading speed | l/s | 90 |

| Overall dimensions and weight | ||

| Length with header in transport position | mm | 16500 (header 6 m) |

| Width in transport position | mm | 3843 |

| Transport height | mm | 4012 |

| Weight without header/with header | kg | 13740±412/15030 (ACROS 530) 13480±404/15030 (ACROS 540) |

Rostselmash Combine Plant LLC approaches the production of any unit with all seriousness and responsibility. The Akros 530 combine harvester is a vivid confirmation of this. This is a professional equipment for true professionals in their field.

ACROS 530 or RSM-142 is suitable for direct and separate harvesting of winter and spring wheat, rye, barley, oats, other cereal crops, as well as corn and sunflower, provided that additional attachments are installed (PSP-8-05 and PSP-10M, respectively) .

Technical characteristics of combines

Consider the technical characteristics of the Akros Combine. Dimensions of the self-propelled harvester model 530 of the RSM 142 wheel type in working position (LxWxH, m): 10.3x8.8x4.87. The total weight with header and chopper is 15.72 tons. Wheelbase width: 4.028 m. Ground clearance at the lowest point under the auger - 35cm. The maximum track width left by the driving wheels is 3.12m, and the track from the steered wheels is 2.9m. At the same time, the turning radius of the Akros 530 harvester will be 8.9 m.

The maximum permitted speed during transportation is no more than 20 km/h. on public roads. The working speed is selected depending on the task that needs to be solved at the moment. So, for example, when working on fields with a large slope (over 80), slopes or areas where movement is difficult due to weather conditions (mud and puddles after rain), the optimal speed is up to 5 km / h, work in normal mode can be carried out at a speed of up to 12 km/h, transportation of an unloaded harvester on paved or rolled dirt roads - up to 28 km/h.

The standard equipment of the ACROS 530 combine includes: driver's cab, header, feeder house, motor unit (engine with cooling system), harvester cart, pick-up platform, threshing unit, chopper, hydraulic and electrical equipment.

The harvester is equipped with a sealed spacious sprung cab. Inside there is a soft driver's seat adjustable in height and degree of inclination of the backrest. For convenience, the driver's seat has folding armrests. The cabin has a freon-type air conditioner and a heating system that takes heat from the engine radiators.

Overview of the parameters of the main working bodies of the combine

The harvester is suspended frontally to the feeder house by means of hinges, equipped with an auger and a balancing mechanism, a system of automatic control of the ground relief in two directions (longitudinal and transverse) and a 5-blade, eccentric reel. The harvester width is adjustable and is 5m.,6m.,7m. and 9 m. The rotation speed of the reel varies from 15 rpm. up to 50 rpm.

Header control (header movement up and down, reel movement in vertical and horizontal planes, reel rotation speed control) is carried out using electro-hydraulic equipment.

Model 530, produced in the line of Akros combines, has 2 ways to pre-set the cutting height of the ears. The first method provides for height control using the "autocontour" system, in which case the height can be set to 6 cm, 10 cm, 14 cm or 18 cm (error 1.5 cm). If it is required to set the cutting height to more than 18 cm, the second adjustment method is used - using 2 hydraulic cylinders. The maximum height at which the harvester can operate: 90cm.

The amount of grain harvested directly depends on the set header width. So with a working width of 5m. grain tonnage will be 1.455t., at 6m - 1.656t., at 7m. - 1.73t., and at 9m. - 2,131t.

The feeder house is equipped with a floating type chain-slat conveyor and a reverser. The lifting speed of the conveyor is about 3.2 m/s. The harvester is transported on a special trolley with a load capacity of 3 tons. The maximum speed of movement of a combine with a trailed cart must not exceed 20 km/h. The optimal speed of movement on fields and dirt roads is 10 km / h.

Combine harvester Akros 530 is equipped with a powerful (250 hp at 2000 rpm) and productive (14 t/h) 4-stroke 6-cylinder engine. The engine is cooled by a system of tubular radiators and a water-oil heat exchanger located directly on the engine.

The thresher, 150 m wide, consists of a threshing drum (1.485 m in length and 80 cm in diameter), a lattice, one-section concave, an electric drive, a 6-blade beater, a five-key straw walker, a system of two-grid grain cleaning, scraper elevators with top feed and domolachivayuschie device. The driver can adjust the speed of the threshing drum from the cab. Drum speed limits: 201-945 rpm; breaker beater: 794 rpm; pre-threshing device: 1334 rpm.

Also, ACROS 530 has a 2-level grain storage bunker with a capacity of 9 m3. If necessary, the roof of the bunker is transformed, and the bunker itself is put on an alarm.

Approximately, today the average price of the Akros 530 combine is 4,500,000 rubles.

Photo of the innovative harvester Akros

Video review of the Akros combine

Below is an overview of the Akros line harvester from Rostselmash. Model 530, its main parameters and characteristics are considered. It should be noted that Rostselmash is the undisputed leader among Russian manufacturers of agricultural machinery. All production facilities and factories of the company are located in Canada, so all manufactured products undergo rigorous inspections by certification commissions. At the same time, the latest developments, modern technologies and innovations of the level of the world's leading manufacturers are embodied in the technique. Manufacturing is located in Canada, thanks to the country's more relaxed business environment, where technology-driven farming enterprises enjoy large tax credits and government subsidies.

Acros 530 PCM 142 is the debut representative of a new generation of harvesters from the Rostselmash brand. Grain harvesting equipment of the fifth class was presented in May 2007, its premiere became a landmark event for the whole country. At that time, there were no combines capable of competing on equal terms with foreign machines on the domestic market. With the advent of the Akros 530 PCM 142, everything has changed. In terms of the "cost / quality" ratio, the model turned out to be one of the most advantageous offers in its class. The significance of the event is evidenced by the fact that the words of gratitude to the developers of the technology were spoken by the President of Russia. Shortly after the premiere of the Acros 530, PCM 142 replaced the Don 1500 in the brand line.

It was the new line of harvesters that allowed the Rostselmash brand to survive the crisis period associated with the collapse of the USSR. With the Acros 530 PCM 142, the company regained its leading position in the grain harvesting segment. When creating the model, the experience of using the Don 1500 and foreign developments were used. Separate elements were made by analogy with the units of Claas combines. The development of the machine lasted 3 years. At the end of this period, Rostselmash presented a truly competitive product designed for enterprises with large areas of sown crops.

Akros 530 was suitable for direct or separate harvesting of wheat (winter or spring), rye, barley and other cereal crops. Additional units were offered for the combine, allowing you to harvest corn and sunflower. The harvester could be used on soils of various types, including off-road, and showed high harvesting efficiency in all weather conditions. A modern threshing drum made it possible to harvest crops that were in a position close to horizontal. With all its merits, the model also stood out for its comfortable working conditions for the operator. It was no longer a Soviet harvester, but a modern high-performance and affordable machine, equipped with everything necessary for high-quality harvesting.

Modifications and features

Consumers liked the novelty of the Rostselmash company. Despite the fact that Acros 530 PCM 142 was produced in one version with several headers and options, the demand for it was huge. This was explained by the presence of the following features:

- availability. Among analogues, the combine had one of the lowest prices;

- economy. The technique consumed significantly less fuel per ton of grain mass than any other machine produced in Russia in earlier periods of time;

- high performance. Akros 530 could replace several similar Soviet combines;

- modern attachments (a wide range of headers and other adapters). The machine has been used to harvest various crops;

- the ability to work on a two-level system. Such functionality provided the highest quality harvesting not only of grain crops, but also of sunflower;

- powerful and reliable engine. The unit allowed to perform heavy operations, while consuming little fuel;

- comfortable work area. Ease of use reduced the burden on the operator, who could fully concentrate on operating the equipment.

The Acros 530 PCM 142 also had disadvantages:

- low quality drive belts;

- regular problems with bearings, which were enough for 1 year of operation.

To increase the duration of the combine, it was recommended to change the problem nodes to similar elements of foreign production.

Specifications

Dimensions:

- length (without header / with header) - 10500/16500 mm;

- width - 3850 mm;

- height - 4010 mm;

- clearance - 350 mm;

- wheelbase - 4028 mm;

- track width (driving / steered wheels) - 3120/2900 mm;

- turning radius - 8900 mm.

The weight of the harvester without the reaping part is 13470 kg, with the harvester - 15030 kg. The maximum transport speed reaches 28 km/h. When harvesting, the speed of the equipment is 0-12 km / h, when working on a surface with a slope or difficult terrain - 0-5 km / h.

Performance indicators:

- productivity - 3.3 ha / hour;

- harvester width - 6000/7000/9000 mm;

- drum diameter - 800 mm;

- drum length - 1500 mm;

- rotation speed - 400-1045 rpm;

- concave wrap angle - 130 degrees;

- concave area - 1.38 sq.m;

- area of cleaning sieves - 4.74 sq.m;

- bunker capacity - 9000 l;

- unloading speed - 90 l / s;

- unloading height - up to 4300 mm.

Cleaning quality:

- losses behind the thresher - up to 1.5%;

- losses behind the header - up to 0.16%;

- crushing of the grain part - up to 1.2%;

- percentage of weed impurities - up to 0.4%.

Engine

Acros 530 PCM 142 is equipped with a V-shaped diesel unit YaMZ-236BK of domestic production (Yaroslavl Motor Plant). Yenisei 860 models were equipped with similar engines. The YaMZ-236BK unit with liquid cooling, direct fuel injection, air-to-air intercooling, mechanical speed control and turbocharging proved to be the best. It is unpretentious, adapted to the Russian climate and able to operate on low quality fuel. YaMZ-236BK in relation to the Akros 530 combine has a power reserve, which allows you to use the full potential of the machine and, if necessary, provide an increase in traction.

Characteristics of the YaMZ-236BK motor:

- working volume - 11.15 l;

- rated power - 184 (250) kW (hp);

- design speed - 2000 rpm;

- maximum torque - 1030 Nm;

- number of cylinders - 6;

- cylinder diameter - 130 mm.

The average fuel consumption is 215 (159) g/kWh (g/hp per hour), which is approximately 10-12 liters per hectare when harvesting crops. The combine's fuel tank holds 540 liters.

Device and operating features

Acros 530 PCM 142 has a standard single-drum design, but at the same time differs significantly from other domestic harvesters. The cabin of the equipment is located in the middle, immediately behind it is a bunker, the engine is installed in the rear. Due to this, the level of vibration and noise in the cabin is reduced, while there is a lot of space for servicing the motor. The location of the cabin in the center provides excellent visibility of the entire cleaning perimeter.

The harvester is based on a welded metal frame with additional reinforcement in the form of cross braces and bolted connections. The main elements and nodes are installed on it. The model has driven and steered axles with large tread wheels. Due to this, the technique moves perfectly on any terrain. The main mechanisms are covered with a metal casing located on the sides and in the upper part of the combine. This provides increased protection for key elements.

The drive from the engine is carried out by a combined method using chains and belts. Kinematic transmissions distribute the force almost symmetrically, while the power circuits go without crossing, and there are no more than 2 consumers on the shaft. Each belt drive has its own adjustment, which allows you to quickly set up.

The harvester has a hydrostatic transmission (GST-112 type), which has stepless speed control within the transmission limits. The presence of an extended range allows you to choose the desired level of loading.

The Acros 530 PCM 142 uses a hydraulic system consisting of 4 hydraulic systems:

- basic;

- reel drive;

- running system drive;

- steering.

The hydraulic system of Akros 530 almost completely repeats the hydraulic system of Don 1500B. It is distinguished only by a modernized pumping station, a single hydraulic tank, more reliable hydraulic equipment units and improved piping routing.

Working elements of the combine:

- harvest part. For the Acros 530 PCM 142, Power Stream branded headers have been developed with high harvesting quality and a robust design. They have no equal in the territory of the CIS countries. In relation to the feeder house, the header is mounted frontally. Among its design features, the presence of a mechanism for auto-control of the soil relief (transverse and longitudinal direction), a modern auger, balancing mechanisms and a 5-blade reel are distinguished. The header allows cutting heights of 60,100, 140 and 180 mm. Reverse is used to clean the reaping part. The movement of the header, the movement of the reel and the speed adjustment is carried out by means of electro-hydraulic equipment directly from the cab. Additional equipment is offered for Akros 530. The most popular are the PSP-8/05 (corn harvesting) and PSP-10M (sunflower harvesting) units;

- threshing and separation device. It uses a large diameter drum (800 mm) with a drive that has an automatic belt tension (Posi-Torque system). Such features allow you to withstand extreme loads. The drum speed is controlled from the passenger compartment. The separation system includes a 5-key straw walker and excellently separates the grain and straw mass. By means of a chopper, the remaining straw can be cut and distributed in an even layer over the field;

- cleaning system with a powerful fan;

- large bunker with the ability to quickly unload (no more than 2 minutes).

The cabin of the Acros 530 PCM 142 is one of the key differences between the harvester and the previous models. It is sealed and has increased protection against dust, vibration and noise. The cab is mounted on a sprung base with 4 shock absorbers. Its equipment includes a refrigerator, climate control and radio. Another feature is a special system with an on-board computer and Adviser voice notification.

Photo

Video

Price

The production of Akros 530 harvesters ended quite a long time ago. Currently, only used models are offered on the market. Their cost ranges from 1.5 to 2 million rubles for the 2008-2009 version, from 2.5 to 3.4 million rubles for the 2010-2011 modification.

Good performance data, versatility, ergonomics, gentle milking and the ability to preserve the natural qualities of harvested products - that's what made the Acros harvesters very popular in the world market. They became followers of the legendary domestic developments from the manufacturer Rostselmash - the Niva SK and Don combines, whose history goes back almost 100 years.

Combine harvesters "Akros" include more than a dozen models, which, according to their technical characteristics and capabilities, belong to different productive classes. Despite the differences, they have a similar internal structure.

The main working units of the Acros combines:

- running block;

- reaping model;

- threshing and separating device;

- granary;

- motor;

- combiner cabin;

- electrical equipment involved in the control and management of the life support of the machine;

- hydraulics with drive to wheels, steering wheel, reel and other elements.

They operate according to the classical scheme. During the movement of the combine, the rotating reel tilts the ears, which are picked up by the cutterbar and mowed. There are rakes for cutting the laid grain. Once in the reel of the combine, the grain mass is transferred through the narrowed auger to the chopper drum, where it is threshed and separated.

After threshing, the crop enters the deck, where it is blown and enters the bunker. The straw from the straw walker keys is brought out, and the grain, which has not been completely cleaned, enters the autonomous rotary thresher.

Until today, it is considered one of the best developments of Rostselmash. Perfectly adapted to a large harvest area and the natural conditions of central Russia.

Equipped with a 6-cylinder Cummins/6LTAA or domestic YaMZ engine, which, together with a large gas tank, allows you to work non-stop for up to 15 hours. It has a 3-speed transmission, which is operated by hydrostatics. As in later modifications, a universal header with a variable working width was used.

Peculiarities:

- universality;

- harvester "Power Stream" with a knife drive "Schumacher", providing rotation of the blades up to 1.14 thousand rpm;

- enlarged auger, eliminating the winding of the stems;

- technology of copying the relief in several versions - hydromechanics "LEVEL GILDE" or electro-hydraulics "AUTO CONTOUR";

- 1 beater chopper with increased concave angle (up to 130 0) and separation area.

Specifications PCM 142 "Acros" 585:

- Power - 300 hp;

- Harvester - 5/6/7/9 m;

- Drum size - 80 cm;

- Gas tank - 540 l;

- Storage for grain - 9 m3;

- Shipment - 90 l / s;

- Weight - 13.38 tons.

The PCM 142 "Acros" 530 combine is designed for mowing and milking cereals, their cleaning from non-grain impurities, temporary storage and swathing of straw mass. It can be used in all grain-producing geographic areas and in fields with a surface slope of up to 80.

Powered by a power plant from the Yaroslavl Motor Plant, the rated power of which is 250 hp. Traditionally for harvesters, Acros is equipped with a Power Stream header with a beater-normalizer, a Pro-drive gearbox and double reel tine arms. The separation of grain from the heap takes place on a 5-key straw walker, which makes it possible to obtain high-quality grain and straw.

Advantages:

- radiator cooling system;

- harvester with electrohydraulic drive and system for copying terrain irregularities;

- vibration-, dust-, noise-proof cabin "Comfort Cab" on 4 shock absorbers, which has an acoustic system, a refrigerator and a climate control function;

- batch unloading of grain;

- capacious hopper with a retractable roof that protects the milled grain from rain and dust.

Working parameters:

- Power - 184 kW;

- Diesel consumption - 159 g / hp h;

- Thresher - 800 mm;

- Reaper - 6/7/9 m;

- Concave - 1.38 m2;

- Fuel tank - 540 l;

- Weight - 13.74 tons.

How Akros 530th behaves in operation can be seen in the video.

Arranged according to the classical scheme: "engine-cabin-bunker". Without a header, the unit with dimensions of 8.6 x 3.88 x 3.94 m weighs 13.4 tons. Like earlier models, it is equipped with a bunker with a capacity of 9 thousand liters, which is completely unloaded in 2 minutes. It has a beaterless feeder house, with which you can quickly and easily set up a combine harvester for harvesting row crops. The ideal threshing geometry allows you to work with wet, lodged, contaminated bread, providing 95% separation and minimal risk of grain damage.

Advantages:

- the presence of a single hydraulic connector, which simplifies aggregation with auxiliary hinged adapters;

- cutting block of 76 steel knives;

- gentle threshing device - 3-blade rotor, which facilitates the work of the main thresher;

- 2-grid cleaning system;

- integrated straw chopper-spreader.

Operating parameters PCM 142 "Acros" 580:

- Thrust - 300 hp;

- Cylinder - 8.9 l;

- Capture width - 5.9 m;

- Fuel tank - 0.54 m3;

- Rotation of 80 cm of the drum - 1.8 / 3.4 thousand rpm;

- Straw walker length - 4.1 m;

- The separation area is 6.15 m2.

One of the latest models of Acros combine harvesters, capable of harvesting grain, sunflower, corn crops on several thousand hectares per season. Compared to its predecessors, it has a turbocharged engine, which allowed for a 30% increase in power reserve.

The inclined chamber and the straw walker have undergone modernization. In the first, in addition to the beater-normalizer, an accelerating beater appeared, accelerating the process of feeding ears into the thresher. The width of the straw walkers in the 595 Acros Plus has been increased by 10 cm, due to which it has become possible to operate it in wet areas.

Advantages:

- lightweight aggregation mechanism by adapters;

- relief hydrocopiers, reducing the likelihood of damage to the header;

- inertial drum that preserves the natural properties of seeds and straw;

- 2-stage separation with efficient fan;

- spacious panoramic cab with digital display, multifunctional GST lever, adjustable seat with armrest.

Specifications:

- Power - 325 hp;

- Bunker - 9 tf. L;

- Unloading height - 4.7 m;

- Drum diameter / revolutions / min - 80 cm / 1.05 thousand;

- Concave - 1.38 m2;

- Gas tank - 540 l;

- Weight - 14.3 tons.

A versatile grain harvester that can be used for harvesting rapeseed, rice, oilseeds and sunflowers after appropriate retooling. All functions of the harvester are controlled from a spacious 2-seater cabin. During the day, wide panoramic windows provide visibility, and powerful halogen headlights are provided for night work. In front of the Acros combine there is a hydraulic connector, on which the PowerStream header and a number of other attachments are installed.

Peculiarities:

- efficient and economical YaM236 engine with 20% power reserve;

- wide threshing machine with concave set at 130° and adjustable from the cab

- 2 cleaning sieves, giving an area of 5.1 m2;

- "Smart Launch" - sequentially turns on the unloading and horizontal auger;

- coarse-tread pneumatic tires - 30.5L R32 (leading) and 18.4 R24.

Operating characteristics PCM 142 "Acros" 550:

- Power - 280 hp;

- Track - 3 m;

- The area / length of the straw walker - 6.15 m2 / 4.1 m;

- Max. Speed - 27 km / h;

- Dimensions - 8.6 x 3.88 x 3.94 m;

- Clearance - 400 cm;

- Weight - 13380 kg.

A productive combine that comes with a 6-cylinder imported Cummins engine. It is attractive because it can work in any agro-climatic conditions, demonstrating good productivity and maintaining grain quality.

Unlike domestic harvesters "Don" or "Yenisei", due to the innovative unloading elevator, it overloads the crop many times faster. At the same time, diesel consumption per ton of products is only 2-3 liters.

Advantages:

- “Adviser” functionality that notifies the combiner about malfunctions;

- wide-cut reaping mechanism, which can be equipped with a spring surface copying system;

- the possibility of maintenance and replacement of spare parts by one person;

- 1 beater drum with autonomous re-threshing mechanism;

- a hopper without a protective cover, which allows portionwise unloading of grain in any position of the unloading auger.

Specifications:

- Force - 206 kW;

- Harvester - 5/6/7/9 m;

- Concave / cleaning sieves - 1.38 / 4.74 m2;

- Straw chopper rotation speed - 1.8 / 3.4 thousand rpm;

- Wheel track / base - 3.1 / 4 m;

- Size - 860 x 388 x 394 cm;

- Weight - 13380 kg.

- Universal reaping adapter "PowerStream";

- 6- and 8-row Argus for harvesting corn and turning the stalks into mulch at the same time;

- 8- and 12-row Falcon devices for harvesting sunflower and other tall crops;

- Set for threshing corn PDK-8 and PDK-10;

- Adapter for rapeseed and other easily injured crops with different working widths (6, 7 or 9 m);

- A set of attachments for collecting small seeds and soybeans (“Float Stream” with flexible blades and topography autocopying);

- platform pick-up "Swa Pick" for collecting windrows in separate combination;

- conveyor trolleys "Uni Cart" in one- and two-axle versions for transporting seeders, headers and other adapters.

Maintenance of Akros combine harvesters

Distinguish:

- Every shift - every 10 hours;

- The first - 60 m / h;

- The second maintenance is every 240 m/h.

For each work shift:

- Clean from dust and vegetation residues;

- Inspect fuel and exhaust hoses, oil coolers, hydraulics and brake system for tightness;

- Check the insulation of the wires and the reliability of their fastening;

After 60 m/h:

- Lubricate battery tips;

- Top up the distillate in the electrolyte jars, brake fluid;

- Rinse the breather of the hydraulic tank;

- Tighten the fixing bolts in the range box, in the drive axle gearbox, thresher grinder;

After 240 m/h:

- Check and eliminate axial play and wheel alignment;

- Lubricate the rubbing nodes and parts.

After the end of the harvest campaign, Akros combines are prepared for winter storage:

- Drain the oil from the hydraulic tank;

- Remove drive belts and chains;

- Retract plunger rods;

- Apply a conservation mixture to all surfaces that have been exploited;

- The harvester is installed on horizontal supports in a dry, unheated room, sealing the filler and hydraulic tank necks.