Multi-purpose drilling rig with a mechanical drive of a movable rotator. Mounted on various models of trucks. The drive of the installation is carried out from the engine of the transport base through the K.O.M.

Specifications

| Feed force, kgf | 6000 |

| Reverse force, kgf | 12000 |

| Feeding stroke, m | 3.85 |

| Spindle speed, rpm | 14-101, 24-171 |

| Torque, max., kgm | 2000 |

| Nominal drilling depth, max., m | |

| augers | 70 |

| flushed | 200 |

| Drilling diameter, max., mm | |

| augers | 500 |

| auger drill | 1050 |

| with washing (con.) | 190 |

| Winch load capacity, max., kgf | 2500 |

The drilling mast of the unit simultaneously serves as the guide frame of the feed mechanism, along which the carriage of the movable rotator moves with two hydraulic cylinders. The lower part of the mast, when transferred to the working position, is located at a small distance from the ground. At the same time, jacks located symmetrically to the mast axis in its lower part, in the extended position, provide increased stability of the structure during drilling and tripping operations. The mast is transferred to the working and transport position by special hydraulic cylinders. In the upper part of the mast, a crown block of single-string equipment is mounted.

The movable rotator is a five-stage gearbox driven by a vertical shaft with a shaped section. Hinged on the carriage, the rotator rotates away from the borehole axis when performing tripping operations, percussion drilling and when working with casing pipes. In the transport position, the rotator can also be moved to the side.

To perform work in the dark, the unit is equipped with headlights mounted on the upper traverse of the mast. The installation control panel is located on the left along the transport base. For ease of management and increased safety of the drilling operator, his workplace is equipped with a removable folding platform.

Modification LBU-50-04 is equipped with a hydraulic pipe hanger, a drilling gland, additional front jacks on the drilling table, which increase the stability of the rig, and tool platforms on both sides of the platform.

Types of jobs

- rotary auger and percussion drilling of engineering, hydrogeological and technical wells in rocks up to category IV in terms of drillability

- drilling with straight augers in the construction of piles and sheet piles

- driving pits in rocks up to category IV in terms of drillability in a rotary way (flights) using an auger drill

- rotary core and coreless drilling of exploration, hydro- and engineering-geological, technical wells in rocks up to category VII in terms of drillability, using water and aqueous solutions as a cleaning agent

- rotary core and coreless drilling of wells for various purposes with cleaning of the bottomhole with a stream of compressed air in rocks up to category VII in terms of drillability

- percussion-rotary core and coreless drilling of wells for various purposes using pneumatic percussion downhole machines in rocks up to category X in terms of drillability

Equipment (on request)

- shock absorber

- welding generator ADS-500, GD-4002 or GD-4004 for auxiliary work

- two additional hydraulic jacks mounted on the frame in the front

- tool trailer

- two platforms for transportation and storage of drilling tools and casing pipes with a lifting capacity of 500 kg each

- power supply and welding generator STEMP (mounted on the chassis)

- drilling pump NB-4 or NB32 or NB50

- compressor PK-5.25

- drilling table (for modifications LBU-50-02, LBU-50-021, LBU-50-04, LBU-50-042): maximum through diameter 500 mm, maximum load capacity - 12000 kgf

Applied tool

- tool kits for drilling with standard augers up to 500 mm in diameter

- tool kits for drilling with equal bore augers up to 470 mm in diameter

- a set of drilling tools for the construction of pits with a diameter of up to 1050 mm

- set of drilling tools for drilling wells by shock-rope method

- set of drilling tools for core drilling with purging

- set of drilling tools for core drilling with flushing

- hammers and special bits

The Russian enterprise "Geomash" has earned credibility and popularity thanks to reliable tools for making wells. The head office of the plant is based in Moscow, and the production lines are in the Kursk region.

General parameters of drilling rigs LBU-50

The drilling machine is equipped with a mechanical drive. The technique is mainly used for wells:

- used in the construction of a variety of objects;

- having a technical purpose;

- geological developments;

- calculated for water intake.

The technique has a list of significant advantages:

- from the very beginning of work, the soil breaking tool is under enormous pressure from a special device;

- during drilling, the rotator can be deflected from the hole being made due to its unique configuration;

- the equipment is designed for installation of casing strings;

- the machine makes it possible to make wells by the cable-impact method, simultaneously involving a winch in the work.

A minor disadvantage of drilling equipment is the fact that it is driven by a motor from the transport base.

The drilling rig LBU 50 has the following serial models: 05, 07, 08, 10, 20.

As optimal mobile bases can be used:

- ZIL-131;

- URAL;

- KAMAZ.

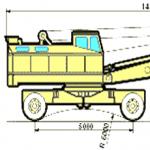

Photo of drilling rig LBU-50 on KamAZ chassis

With the help of the drilling system, you can perform the following actions:

- to make wells with augers up to 500 mm in size;

- to form pits up to 850 mm;

- make wells according to the shock-rotational method with a diameter of 550 mm;

- drilling holes with a flushing or blowing method with a diameter of up to 490 mm;

- with the dry method, the hole size reaches up to 172 mm.

Design features

The machine is equipped with a driving device based on mechanics, and there is also a rotator, while the feeding structure is driven by the mast, which is the guiding force.

The mast has a transport and working position. Their change is carried out by hydraulic cylinders. The mast is also equipped with a single-string equipment, which is located at the top.

To ensure stability and balance of mobile drilling rigs, the machine is equipped with hydraulic jacks.

The drilling device has powerful headlights, thanks to which operability is preserved in the dark. The whole system is controlled by reliable panels, which are placed on the mast structure and on the frame. It is also important to create comfortable working conditions for the driver of the installation. For this purpose, the design is equipped with a convenient removable platform.

Drawing winch drilling rig LBU-50

Basic equipment

In the basic version, the plant is equipped with the following equipment:

| Device | Unit measurements | Data |

| Auger drills | mm | 135, 180, 230, 300, 330, 350, 400, 500 |

| Equal bore augers | mm | 200, 320, 470 |

| Screws with removable chisel | mm | 300 |

| Sliding chisel augers | mm | 350 |

| Breaker shells | mm | 121 |

| Set for shock-rope works: | ||

| - impact. - driving glass | mm | 89 |

| - percussion cartridge | mm | 108 |

| - casing system | mm | 127 |

| Dry Run Kit | ||

| column device | model | SKS-127 |

| Purge kit | ||

| Flushing device | ||

| Devices for continuous technology | ||

| Boers | mm | 650, 850 |

| Sliding augers | mm | 650, 850 |

| Submersible Pneumatic Hammers | mm | 550 |

Additional equipment for the formation of downhole systems

The unit is designed, if necessary, to work with the following equipment:

Modifications

Well formation equipment has several modifications:

| Equipment | 20 and 05 | 07 | 08 | 10 |

| Winch | + | + | + | + |

| Balance | + | — | — | — |

| Pump | — | + | — | — |

| Compressor | — | — | + | — |

| Generator | — | + | Optional | + |

| Front jacks | — | + | + | + |

| rear jacks | + | + | + | + |

| Additional rear jacks | — | + | + | + |

| cargo platform | + | + | + | + |

| Driver's platform | — | + | + | + |

| Swivel | — | + | + | — |

| clamping table | — | + | Optional | — |

| Desktop | — | Optional | + | + |

| The basis | ZIL, URAL, KAMAZ | KAMAZ | KAMAZ | KAMAZ |

Photo modification LBU-50-08

Technical characteristics of the LBU-50 drilling rig are presented in the table:

| Characteristics | Unit measurements | Indicators |

| Drive power | kW | 95-165 (depending on chassis) |

| Innings | m | 3,25-3,9* |

| Top feed | kgf | 12000 |

| bottom feed | kgf | 4000 |

| Frequency about. spindle | rpm | 14-101, 14-220* |

| Torque | kgm | 2000 |

| Winch lifting capacity | kgf | 2500 |

| Well depth | m | 16-200 (depending on drilling method) |

| Hole diameter | mm | 190.5-850 (depending on drilling method) |

* - depends on the installation model

Auger drilling of wells in a summer cottage

- Features of drilling with a blade cutter

- Well drilling equipment

- Arrangement of a well with auger-type pumps

- Conclusion

Need a well for water, but do not know what method to use for its construction? You need to choose the simplest, cheapest and most effective way, for example, drilling with LBU 50 machines.

What is the construction of water wells with the use of this equipment, what are the advantages of such structures and what equipment are used to equip these wells? We will answer these and similar questions in this article.

LBU-50 performs the following types of work:

Rotary auger and percussion drilling of hydrogeological and technical wells in rocks up to category IV in terms of drillability; - drilling of pits in rocks up to category IV in terms of drillability in a rotational way (flights) using an auger drill; - rotary core and coreless drilling of exploration, hydro- and engineering-geological, technical wells in rocks up to category VII in terms of drillability, using water and aqueous solutions as a cleaning agent; - rotary core and non-core drilling of wells for various purposes with cleaning of the bottomhole with a stream of compressed air in rocks up to category VII in terms of drillability; - percussive-rotary core drilling and coreless drilling of wells for various purposes using hydraulic percussion downhole machines in rocks up to VII (with VIII interlayers) category in drillability; - percussive-rotary core drilling and coreless drilling of wells for various purposes using pneumatic percussion downhole machines in rocks up to category VII (with VIII interlayers) in drillability.

Specifications LBU-50:

Drive power: 95 - 165 kW Feed stroke: 3.25 - 3.9 m. Feed up / down force: 12000/4000 kgf Spindle speed: 14-101; 14-220 rpm Torque: 2000 kgf m Winch load capacity: 2500 kg. Conditional drilling depth: with augers up to 500 mm in diameter - 60 m with flushing (final diameter 190.5 mm) - 200 m with blowing (final diameter 190.5 mm) - 100 m.

Read also:

Drilling machine Wikipedia

This term has other meanings, see Machine.

Machines on caterpillar carts

Drilling rig - a drilling machine mounted on a self-propelled platform or a mobile frame, used for drilling explosive and exploratory wells and holes in open and underground mining, with continuous chamber and especially floor-chamber and block development systems for drilling wells.

It is used for drilling vertical and inclined, mainly blast holes.

Classification

- rotary drilling rigs

- rotary drilling rigs

- rotary percussion drilling rigs

- combined drilling rigs

- percussion drilling rigs

Characteristics

Tools

Other

Museum of Exploration Technology [where?] (collected unique samples of drilling equipment)

Notes

Links

Characteristics and photos of the DML drilling rig and its modifications: LP 1200 and SP

The complete set of the drilling rig depends on the conditions in which it has to work, the purpose of the well, the properties of the soil and the method of drilling.

Manufacturer and purpose of drilling rigs DML

Founded in 1873 in Stockholm, Atlas Copco manufactures equipment for the construction, drilling, and railway industries. The constant striving for perfection has made the technique from the Swedish brand unsurpassedly effective.

The four main industries that Atlas Copco focuses on are:

- equipment for mines and drilling;

- mobile equipment for construction and power generation;

- compressors;

- tools for industry.

The Atlas Copco DML series of drilling rigs is designed for drilling wells using the rotary method. The depth of the wells is in the medium range.

Drilling performed with these rigs:

- rotary - rotary drilling, when a bit (a tool for rock destruction) deepens the depth of a cylindrical well; rotation is transmitted to it from the rotor by means of a string of pipes for drilling;

- the rotor receives rotation from the engine;

- drilling with the use of a submersible drummer - multi-start.

Design features

DML units are mobile equipment, they are equipped with caterpillars and hydraulic drive. The top hydraulic drive is a development designed for drilling explosive type wells up to 53.3 meters deep. When replacing the pipe, it is possible to achieve a depth of 62.5 meters. For standard and additional pipes (9.15 and 10.7 m), additional carousels with different volumes are provided.

Photo of DML drilling rig

During drilling, a load of 267 kN is created on the bit. Additional equipment makes corner drilling available when the column deviates from the vertical by 30 degrees or more.

Advantages:

- the ability to lift a column with a carousel, in which there are six drill pipes, in less than a minute;

- the operator remotely, being in the cabin, changes the pipes and fixes the carousel; cab equipment is FOPS certified;

- view from the cab allows you to control the operation of the rotor;

- the high pressure compressor is equipped with an on-off system that eliminates the load during work not related to drilling;

- it simplifies start-up, saves energy, extends the life of the compressor;

- The DML drill rig is configured for high or low pressure drilling.

Specifications

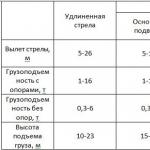

Specifications of the DML drilling rig in the table:

Modifications

There are several modifications of DML drilling rigs, which differ in the type of work performed and have design features.

DML-SP

DML-SP - drilling rig for drilling with a submersible hammer or shock; drilling depth is equal to one rod; well diameter - 25 cm. Well depth - 18.3 m. The unit string is designed for drilling clean wells, there are settings for drilling at an angle of up to 30 degrees.

This modification is designed to work in soft, non-abrasive terrain.

Advantages:

- saving time: installation runs 18.3 meters in one go;

- fast raising and lowering of the column;

- the operator remotely secures the column while in the cab;

- The rig can be configured for rotary and DTH drilling.

Photo of DML-SP drilling rig

Specifications:

DML LP 1200

This unit is designed for pneumatic percussion (rotary) drilling, drilling and blasting: crushing, loosening rocks, ice. For severe climatic conditions, fuel filter and engine heating is provided before starting.

Photo of drilling rig DML LP 1200

Specifications:

On the video, the DML 1200 drilling rig in operation:

Mini drilling rig MOZBT M1

MOZBT M1 mobile equipment has a wide range of applications:

- in construction work for the placement of piles;

- when performing engineering and geological surveys;

- for drilling a well for water.

The M1 design is designed for drilling vertical wells. The temperature range at which this model can operate lies within -20 - +40 0С. The work of such equipment with blowing or flushing (rotary method) can be carried out on a rock that is in the 10th place in terms of drillability.

Mini drilling rig for water well drilling

Compact models manufactured by MOZBT are designed for drilling wells up to 60 meters deep. Often this is enough to equip a well "on the sand", so MOZBT M1 is used to drill water intake points for private houses.

All about transportation and accessories

The small-sized MOZBT M1 model was designed to be placed on a light single-axle trailer. The main elements of the drilling rig are a rotator, a gasoline drive and a mast with a tool installed on it.

Its maximum weight is 650 kg. Thus, the transportation of this equipment can be carried out using a category “B” car with a tow hitch.

All attachments and accessories fit freely in the trunk.

Ease of maintenance

MOZBT equipment is designed by our engineers together with drilling specialists, the main consumers of our products. At each stage of production, we took into account the comments and wishes of users, making the small-sized plant easy to operate and easy to maintain.

How to order and arrange delivery

The price of a mobile drilling rig for water pays off with a number of undeniable advantages:

- ease of transportation;

- ease of positioning;

- reliability and efficiency;

- small weight and compactness;

- balanced specifications.

You can buy a small-sized drilling rig for wells by placing an order on our website. To do this, you just need to send an application by clicking on the link below, or contact the MOZBT office in Moscow or one of the representative offices in the regions by calling one of the phones listed on the site.

| APPLICATION AREA: | OPTIONS AND BENEFITS: | |

| constructionengineering and geological surveyswater intake wells | modularity, compacof additional options | |

| Chassis, drive | drilling depth | |

| Light trailer 1-axlePetrol engine (LIFAN) 16 kW | Augers Ø 135 mm up to 12 m Chisel (crown) Ø 132 mm with flushing / blowing up to 50 m | |

| Mast | Overall dimensions and weight | |

| Height 2.7m (up to 4.5m) Load capacity 10 kN, Force down - 8.6 kN | LengthWidthHeightWeight (with trailer) | 2300 mm1262 mm1200 mm750 kg |

| rotator | Drill pipes | |

| Hydraulic, movableTorque 500 Nm at 71 min-1 | Diameter 42 mm, thread Z-56 Length 1.5 m | |

| Innings | ||

| Up / down 10 / 8.6 kN Tool lifting speed 0-0.2 m/s | ||

| OPTIONALLY CHANGED/ADDED: | DRILLING TECHNOLOGIES IMPLEMENTED: | |

| Electric winch Piston, screw compressor Screw, piston pump, etc. | Auger drillingDirect flush rotary |

Complete set

Source:

Small drilling

If you decide that you need an independent source of water, then order well drilling. If you do not have enough space on the land, then the use of small-sized drilling rigs is suitable.

Why is small-sized well drilling popular in the Moscow region?

The water reservoirs in the Moscow region are quite heterogeneous to the surface, so small-sized water well drilling is applicable in most cases. It also has many benefits:

- This is the cheapest way to drill a well.

- Small-sized drilling successfully takes place in cramped conditions.

- There is no need to prepare the site or access to it. The drilling rig does not take up much space.

- Suitable for areas that are equipped with various structures: fences, platforms, flower beds. It will be necessary to eliminate only those structures in the place of which there will be a well.

- Small consumption of electrical resources.

- You will need to use a small team - 2 people.

- The work is done quickly.

- The guarantee for the work and the well will be 3 years. This is enough to recoup the costs.

- Drilling is suitable in most cases, exceptions and complications are rare.

Drilling wells with small-sized equipment is a convenient and quick way to provide a site with drinking water. At the same time, the plumbing system will also be inexpensive. The budget proposal is to organize a summer column instead of a full-fledged water supply. This option is ordered for non-residential cottages and garden plots for summer use.

We carry out small-sized drilling throughout the Moscow region. Thanks to the professionalism of our employees, we can serve everyone during the season and you do not have to wait in line.

How much does it cost to drill water wells with small equipment?

It largely depends on individual conditions. Call us and get a comprehensive answer to this question.

The price for drilling in cramped conditions with small-sized equipment starts from 2,000 rubles, per meter of drilling using casing pipes 133 metal. When using 133 metal + 117 plastic, the food price of drilling will be from 2,400 rubles per meter.

*Check with the company's specialists for the cost of small-sized drilling.

Consulting a specialist will help you get a comprehensive answer. The cost of such a well is cheaper than our customers expect. Access to the water source will appear within a few days.

The cost includes materials spent on the well and its manufacture. The well lasts longer if better materials are used initially. It is cheaper to make a pipeline from more expensive materials than to make a new well.

Characteristics of the small-sized MGBU installation

Our small-sized drilling equipment is a serious competitor to the widespread drilling rig of the URB 2a2a brand on the ZIL-131, KAMAZ, URAL chassis.

The small-sized installation is capable of extracting water from various layers and has a maximum drilling depth of up to 160 meters! Our equipment is on caterpillar tracks, and this contributes to a careful attitude to the land, and also has an increased cross-country ability. This drilling technique allows you to drill wells even indoors, while it is necessary to ensure a check-in and have a room height of more than five meters.

- Mast: the height of the mast in the raised state is 5 m.

- Chassis: crawler

- Drilling depth: up to 160 m.

- Dimensions (LxWxH): 5200 x 1500 x 2100 (mm)

- Weight: 3600 kg.

Our crawler-mounted drilling equipment opens up new opportunities for drilling wells in hard-to-reach places on your site, and has an increased cross-country ability. We can drill where others can't!

Source:

Drilling wells with a small-sized installation

Both large-sized URB-2A-2 drilling rigs and mobile rigs with a small mass and compact dimensions can drill individual wells in the private sector, at their summer cottage. Modern small-sized drilling rigs are capable of performing almost any task in the field of drilling, except for drilling deep artesian wells.

Mini installations do not harm the area where drilling is being carried out, and they can be drilled anywhere and at any time of the year in the Moscow region, they are very mobile - this is their main advantage.

Many people want to drill in a convenient place without damaging the soil and are willing to pay for it: the cost of a meter of drilling with small-sized rigs is from 2,500 to 4,000 rubles.

Possibilities of large drilling rigs

The maximum drilling depth for large rigs is 300 meters. The ability to use one of three options for rotary drilling with flushing, blowing, using an auger allows users of the rig to open an aquifer in any soil.

The large capacity of the installation makes it possible to quickly drill a well for the Moscow region. All these advantages determine the popularity of URB-2A-2 among drillers. But often there are situations that do not allow using these installations to perform work.

In such cases, drilling of wells with small-sized equipment is carried out.

Conditions for placement of large drilling equipment

To drill a well at the site using URB-2A-2, it must meet a number of requirements:

- gate width - at least 3 meters;

- the height of the arch, power line and tree branches above the entry point and above the path along which the installation will move is at least 4 meters;

- availability of free space for a working area ranging from 36 to 60 m2;

- the height above the working platform to the branches, electrical wires and roof slopes is at least 8.5 meters (the tower rises to this height during drilling).

Not always the area where drilling should be carried out meets these requirements. In this case, it is impossible to place large-sized drilling equipment on it.

There is a way out - drilling wells with mini-rigs!

Drilling with a small-sized installation: advantages and disadvantages

Advantages of mobile technology:

- large drilling depth up to 130–150 meters;

- pass through a gate less than 3 meters wide;

- can be placed anywhere on the site;

- requires a small area for installation;

- does no damage to terrain.

"LBU-50"

LBU-50 is a modern multi-purpose drilling rig of domestic production. Its design was developed in the Soviet Union and tested over many years of operation by many drilling organizations in Russia and neighboring countries. It was created for long work in the field with extremely limited possibilities for maintenance. Therefore, the designers tried to make the design of the installation as simple and reliable as possible, thanks to which the LBU-50 has become an indispensable tool in geological expeditions. The unit combines balanced technical characteristics, practicality, endurance and high productivity, which is very important for the work of drilling companies.

The LBU-50 drilling rig is distinguished by its versatility, reliability and unpretentiousness. It is used for drilling water wells, construction and technical wells, engineering and geological surveys. This rig is able to work on any type of soil and perform penetration of various depths and diameters, thanks to the variety of drilling tools that can be used on its basis:

- auger drills and augers (for drilling up to 60 m),

- augers (for drilling up to 25 m),

- DTH hammers

- other drilling tools for the construction of wells for special purposes.

Due to the fact that the unit is equipped with a compressor or pump, it is possible to perform drilling by blowing (up to 100 m) or flushing (up to 200 m). The drilling tool is selected depending on the task and allows drilling wells of any complexity.

The simplicity of the design allows you to repair the unit even in the field, if you have the necessary spare parts.

High off-road qualities of the drilling rig are achieved by its installation on the ZIL, KAMAZ or URAL chassis, which makes it possible to carry out geological surveys and drilling even in hard-to-reach areas. Rotation to the drilling tool is transmitted from the chassis engine through the power take-off.

Spare parts "LBU-50"

The drilling rig LBU-50 is designed for intensive trouble-free operation. Nevertheless, despite the high reliability of components and assemblies, all mechanical parts are subject to wear. Any components and mechanisms have a limited working life, which can be reduced due to errors of the operating personnel and violation of the operating rules set forth by the manufacturer. From time to time, it is necessary to replace worn-out parts of the LCU, especially for heavily loaded mechanisms, such as:

- Transmission

- rotator

- Bevel gear winch

- Reducer top/angular

- Hydraulic drive

It is not so easy to buy new parts for drilling equipment, due to its specificity.

Moscow Experimental Plant of Drilling Equipment manufactures and supplies spare parts for LBU-50 units:

- Shafts, gear shaft

- Gears

- Bearings

- cuffs

- High-pressure hoses

- Hydraulic distributors, components for the hydraulic system

Repair "LBU-50"

MOZBT specialists carry out overhauls of LBU-50 drilling rigs, fully restoring their performance in the factory, on the territory of the main production site of the Plant in the Moscow Region.

Parts and components for drilling rigs LBU-50 are not yet available for purchase through the online store, but you can order them by contacting your nearest representative office of MOZBT in Russia.

The warehouses of the enterprise always have a stock of the most demanded parts. It is also possible to manufacture components to order, in case they are not in stock. With us you will always find everything you need to ensure high-quality repairs and trouble-free operation of the drilling rig.