A garage is a building that receives special attention, especially in terms of burglary resistance. And such an element as a gate should have twice the strength and reliability, and of course, an attractive appearance. Traditionally, garage doors are a two-leaf hinged structure hung on a box. Making them with your own hands is not a problem if you have the skills to work with simple plumbing tools and a welding machine. This will be discussed in the article: options for swing gates, manufacturing technology and the nuances of the installation process.

Types of garage doors

In addition to the fact that swing garage doors are traditional and very reliable, they have other advantages.

- The cost of construction is cheaper than all other models.

- The swing modification can be insulated using various heat-insulating materials.

- Can be installed in limited space.

- They can open outside or inside the garage, depending on the requirements of the owner.

- Possibility of installation of the electric motor for automatic opening.

The only big drawback is that free space is required to open the doors of the structure. This is sometimes problematic in winter when snow piles up in front of the garage. Therefore, you have to wave a shovel.

Minus swing gates - in front of them you have to clear the area from snow

In addition to swing gates, other varieties are also installed in garages.

folding

This is a sectional type of gate, the elements of which are installed vertically and connected to each other in a hinged way. The extreme sections are attached, like the swing ones, to the box with loops. Additional fastening - on the top or bottom rail. Sections are made from different materials, most often from aluminum alloys or wood.

Design advantages:

- unusual appearance,

- ease of opening and closing

- do not take up much space when open

- sections can be individually changed, repaired,

- low price.

Cons: rapid wear and low protective functions.

Folding gate

lifting and turning

Purely constructively, this is a one-piece shield that covers the entire entrance opening. To open, the gate is raised and rotated 90° so that it is at the top in a horizontal plane. For this, a system of levers, a gearbox and an electric motor are used.

Model pluses:

- high reliability,

- when open, the gate does not take up any space,

- are insulated,

- amenable to automation.

- high precision installation is required,

- the gate remains in the opening, reducing its height by 20-30 cm,

- it is not recommended to use them intensively.

Overhead gate

Lifting sectional

This is a construction of several sections arranged horizontally and interconnected by special loops. With the help of a lifting mechanism located on the ceiling, the gates are lifted along the guide profiles and positioned horizontally along the ceiling. Sections are mainly made of sandwich panels.

Model pluses:

- versatility in terms of opening dimensions,

- saving free space when opening,

- good resistance to deformation and mechanical stress,

- full automation,

- presentable appearance,

- high heat and sound insulation qualities,

- long term operation.

- high price,

- constant maintenance is required: lubrication of hinges and guides, checking electrics and automation,

- low burglary resistance.

Overhead sectional doors

Rolled

These garage doors got their name from the way they open. Purely constructively, these are several strips (lamellas) assembled into one sheet, which is twisted into a roll. Therefore, in addition to the leaf, the structure of the gate includes two guides that hold the structure in the opening, a shaft on which the lamellas are wound, and an electric drive.

Advantages:

- compactness,

- acceptable price,

- ease of installation,

- long term service

- presentable appearance,

- possibility of automation.

- almost zero burglary resistance,

- there is no way to conduct insulation, because there are always gaps between the lamellas,

- do not work well at low temperatures.

roller shutters

Rollback

In this design, there is one sash, which rests on a guide profile located on top, and abuts against the rail from below. The device is opened by rolling to the side along the wall.

The advantages include:

- functionality does not depend on snowdrifts,

- does not take up space when opened,

- high burglary resistance,

- possibility of automation.

- rapid wear of rollers,

- the width of the wall along which the gate moves must be greater than the width of the sash.

Sliding gates

Do-it-yourself manufacturing technology for swing garage doors

So, swing gates for a garage are two leaves (often the same in width), which are hung on a U-shaped box through hinges. Therefore, when the task is set - to make a gate of this type, then several questions are solved:

- sash manufacturing,

- manufacture of a box (frame),

- installation of the last

- installation of shutters on the frame.

Before you start making swing gates, you need to decide on their size.

garage door dimensions

There are no strict size requirements. The main thing is that the car can freely enter the garage without hitting the gate. And this allows you to make any opening, the width and height of which is 30 cm more than the dimensions of the car on each side. But this is inconvenient, especially for novice drivers.

- height for cars - 2.0-2.2 m, for minibuses - 2.5 m;

- the optimal width is 2.5-3 m, the maximum is 5 m.

Standard sizes of swing gates

Preparation for the manufacture of the gate

Required tools:

- welding machine and electrodes;

- grinder with cutting and grinding disc;

- tape measure, ruler and marker (chalk);

- level and angle.

Required materials. The outer side of the gate is a sheet steel sheet with a thickness of 3-4 mm or corrugated board with a thickness of at least 1.2 mm. If the first material is used in the design, then the entire connection process is carried out by electric welding. If the second, then fastening the corrugated board to the frame can be carried out with metal screws.

As a material for assembling the frame, you can use either a 63x63 mm corner or a 40x40 mm profiled pipe with a thickness of 2-3 mm. The second option is cheaper and easier to use.

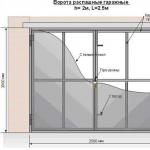

Drawing of swing gates for a garage from a profile pipe

And the last element is the hinges, which are made of a steel bar with a diameter of at least 25 mm. There should be at least four loops, two for each leaf.

Now, as for the U-shaped box. It consists of two racks and a crossbar (crossbar). The first can be made from a 63x63 corner or a round pipe with a diameter of 80-100 mm, or a profiled pipe with a cross section of at least 80x60 mm. Crossbar from the same materials. If it is planned to build a two-story garage, then it is better to use channel No. 12 as a crossbar.

Assembly drawing of the gate

Manufacturing of sash frames

The first stage is cutting eight pieces of material prepared for frame assembly. Four of them should be equal to the height of the gate minus 1-2 cm, four to the width of the leaves, that is, half the width of the gate structure minus 2-3 cm. For example, if the total width of the gate is 3 m, then it is necessary to cut four elements by 1, 48 m

Setting the frame on blocks in a horizontal plane

An important point - the assembly of frames should be carried out on a horizontal plane. It is not necessary that it be a flat area, any type of stand is suitable, the upper ends of which are set in the same horizontal plane. To do this, you can use bricks or blocks. They are installed in the corners of a rectangle, the length of which is equal to the height of the leaf, the width is equal to the width of the gate section. Respectively cut segments are laid on them, and then they are checked with a level whether they lie on the horizon. Deviations are leveled by lining under blocks of thin boards, pebbles or sheet metal.

The laid segments are fixed to each other by spot welding with precise alignment of adjacent elements to each other at 90 °. For this, a building corner is used. This is an important point that determines the exact dimensions of the future gate structure, which will fit exactly into the box without distortions and large gaps.

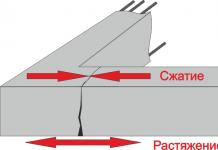

Diagram of stiffeners

Two frames are formed, now it is necessary to increase the rigidity of the structure by installing additional elements: horizontal or vertical. If the gate is large, then both are used. Sometimes they are supplemented with oblique elements. As a material, a corner or a smaller profile pipe is used. For example, if the frames were assembled from a 40x40 mm pipe, then 40x20 mm can be used for reinforcement. Additional elements are evenly distributed relative to each other.

After assembling the frames, it is necessary to weld the joints on both sides and grind them from scale and metal smudges.

The rigidity of the frame structure is determined by additional elements installed vertically and horizontally

Connection of frame and steel sheet

From a sheet of iron for each sash, you need to cut a rectangular segment. There are certain requirements for their sizes:

- the length of the segments should be 3-4 cm more than the height of the gate opening;

- one of the rectangles in width should be 2 cm less than the width of the frame, and the second one should be larger by the same size.

For example, if the width of the wings is 1.5 m, the height is 2.5 m, then one sheet will be 1.52x2.54 in size, the other 1.48x2.54 mm.

Now, in height, two sheets are stacked on the frames so that their edges protrude beyond the frame structure by 2 cm on each side. The protrusions of the sheets will close the gap between the doors and the box. As for the width, from the side of the hinges, the sheets are laid flush with the profile pipe. In one sash, the sheet will protrude from the opposite side by 2 cm, in the other, on the contrary, its edge will not reach the edge of the frame. This is done so that when the gate is closed, the protruding leaf closes the gap between the leaves.

Attention! Sheets are welded to the frame pointwise from the edge to the center. After that, welding is carried out in small segments within 3-4 cm in increments of 10-15 cm.

The sheet is fastened to the frame with short seams.

Swing gate box assembly

The dimensions of the box are determined by the dimensions of the opening. At the same time, half a meter is added to the length of the support posts, with which the structure will be recessed into the prepared pits, followed by concreting.

The box is assembled using the same technology as the sash frames, with installation on bricks or blocks. The dimensions of the box along the inner contour in width are slightly larger than the total width of the valves. The difference is 2-3 cm. In height, the difference can be significant - up to 5-6 cm. Although optimally - 3-4 cm.

Swing gate box

Hinge installation

To do this, the sashes are laid on a U-shaped box with an exact location in a plane with the formation of gaps between all elements. Assembled hinges are applied at the place of their required location and welded: their lower parts to the box posts, the upper ones to the sash frame.

To strengthen the fasteners, metal strips or fittings can be additionally welded to the hinges.

Correct and high-quality welding with a loop

Swing gate installation

Ideally, the gate box should be mounted during the construction of the garage, when the walls are already half raised from bricks or blocks. But regardless of this, the installation is carried out according to the same technology.

- Pits are dug under the racks with a depth of 0.5 m.

- One or two crossbars made of reinforcement or a corner 10-20 cm long are welded to the lower edges of the racks, the purpose of which is to perform the functions of retaining elements in concrete.

Preparation of the rack before concreting the pit

- From the bottom of the supports, metal plates are welded in the form of a penny to rest on the ground.

- The half-meter ends of the racks are treated with a waterproofing compound, for example, with hot bitumen or covered with roofing material.

- The box is being installed in the pits with precise alignment in the opening, for which the building level is used.

- Racks are welded to embedded parts that are installed during the laying of the wall. Reinforcement with a diameter of 12-16 mm and a length of 50 cm is often used as mortgages. The laying step is every 6-8 rows.

- Concrete is mixed at the rate of cement-sand-crushed stone in a ratio of 1:2:2, if the grade of cement is M400.

- Pouring concrete into pits with a rammer. This is done not only in order to compact the concrete solution, but also in order to squeeze out of it the air that got there during the kneading process. Air pores are a decrease in the strength of concrete.

- You can hang the sashes on the box after the concrete has set and dried.

How to make a gate with a gate?

The process of assembling a swing gate with a door is exactly the same. Just four elements are inserted into one of the wings, forming an opening for the door. Vertical are installed in full height, horizontal between them in the form of crossbars. The design of the doorway is assembled at the stage of manufacturing the frame for the sash.

Location of the door in the gate with standard dimensions

The door itself is made in exactly the same way as the gate sections, with the assembly of the frame and the installation of a metal sheet. The complexity of the manufacturing process of the sash itself, in which the door is installed, lies in the fact that the doorway remains an uncovered sheet of metal, and the remaining planes must be closed with them. All of them will not be equal to each other, so each section must be accurately measured, transferred to the sheet and cut out. After that, each cut piece is transferred to the frame with spot welding around the perimeter. In this case, the stacked sections of sheets must be joined on additional profiles that create rigidity of the frame structure.

Drawing of a garage swing gate with a gate

The size of the gate is chosen taking into account the convenient passage through it, as well as the dimensions of the gate leaf. For example, if the leaf width is 1.5 m, then the width of the gate should not exceed 1 m. As for the height, the height of the gate and the location of the door itself relative to the lower elements of the gate frame are also taken into account. At the same time, the maximum location height is 40 cm. The very same door height is within 1.8-2.1 m.

Welded gate for garage doors

Swing gate options

Video - how to make a garage door with your own hands

Conclusion

With the seeming simplicity of the assembly process, it should be noted that the manufacture of swing garage doors requires attention from the manufacturer, the ability to accurately carry out all measurements and calculations. In this case, do not let go of the measuring instruments. A slight deviation in shape or size may cause the sashes to simply not fit into the frame. You will have to make adjustments in place, which will affect the evenness of the elements.

Detailed information about

Today, manufacturers can offer many varieties of gates, but swing gates attract consumers more than other types. Such products have a lot of advantages: low cost, low labor intensity when building them with your own hands, high durability and ease of operation. This can explain the increased interest on the part of many owners to the gates of this type.

Product Feature

If you decide to install the gate yourself, then you need to choose the right size. For a design with two wings, the optimal will be width 4400 mm and length 2150 mm. With a lack of space, these dimensions can always be reduced.

If you decide to install the gate yourself, then you need to choose the right size. For a design with two wings, the optimal will be width 4400 mm and length 2150 mm. With a lack of space, these dimensions can always be reduced.

To correctly determine the size of the gate, it is imperative to measure the dimensions of the car that will pass through them. On average, a standard car is two meters wide. When calculating, add to this value 50 cm on each side to enable the vehicle to maneuver. As a result, the total length of the gate will be approximately three meters. As for the height of the valves, the optimal value for them will be from 1.8 to 2 m.

Components of the structure

It is equally important to familiarize yourself with their design before installing the gate, in which the following set of basic elements can be distinguished:

With all its ease of installation and low consumption of materials, it is necessary to take into account the following design characteristics:

- The weight of the gate must not exceed 500 kg;

- The walls of the hinged pole, which acts as the basis for attaching the hinges, must have a thickness of at least 4 mm;

- The structure must be able to handle the wind load.

Advantages and disadvantages

Before you go to the store outside the gate, it will be useful to get acquainted with their positive and negative sides, which will help you make the right choice.

Of the advantages of swing gates, it should be noted:

At the same time, swing structures have a number of disadvantages:

- The need to take into account the wind load in the region of residence;

- The need to allocate a fairly large free space for opening and closing.

Having carried out simple calculations, you can find out that swing gates have much more advantages than disadvantages. Moreover, the latter are removable or do not look so critical against the background of merits. The main thing is that these systems are highly reliable. And this is once again able to confirm the long history of their existence.

Preparatory activities for manufacturing

Having become acquainted with the features of these designs, you can think about how to make them yourself. And, first of all, you need to prepare tool and consumables for the manufacture of swing gates.

Tool for the job

To make a frame and equip racks, you will need the following tools:

Among the accessories you should have available:

- Riveter and a set of rivets;

- Drill. May be required to fasten the skin;

- Compressor, spray gun or brushes for painting the frame.

Necessary materials

Without material, it is impossible to do any work with your own hands. And the manufacture of swing gates is no exception. To assemble them yourself you will need:

- Pipe for racks. When choosing it, be sure to consider the weight of the finished structure.

- Frame tube. A profile pipe with dimensions of 60 × 40 × 1.5 is best suited for this. Other sizes can also be used, such as 40×20×1.5. When choosing a pipe, be sure to consider the finishing material used and the wind load.

To avoid errors when preparing for assembly, you can follow these recommendations:

If all the preparatory points are met, then you can proceed with the installation of the structure.

DIY assembly process

Those who associate self-made gates with not very attractive and unreliable structures are wrongly considered. Often it is just the opposite. In the manufacture of such structures, the owner has the opportunity to create an access system to the site that best meets his requirements both in terms of security and aesthetic characteristics.

The manufacturing process of such gates involves two main stages:

- installation of racks for fastening gates;

- door leaf installation.

The above steps can only be done in this order. But after installation, the racks will have to be allowed to stand for at least 7 days. So that this time is not wasted, you can do the welding of the door leaves.

Pole installation

For the role of racks of the structure, you can choose:

- Wooden beam with dimensions 100 × 100 mm;

- Brick or natural stone. The latter is more suitable for decoration due to its non-standard dimensions;

- Concrete pillar. You can buy a ready-made version or fill it in at the place of work;

- profile pipe. When calculating the pipe section, consider the above recommendations.

The easiest method for installing poles is to drive the pipe to a depth approx. 1.5 m. It not only requires a minimum of time, but also provides significant material savings due to the absence of concrete costs. If necessary, you can always replace the rack. But when using this method, it is necessary to correctly set the level and then the design will not turn out to be skewed.

The second method involves fixing the column with a concrete solution. In other words, you will need to prepare the foundation for the foundation of the gate.

Considering that the first method is more understandable and is unlikely to cause difficulties, the second option will be discussed below.

With this method of installing racks, you must adhere to the following algorithm of actions:

- The first step is to dig a pit with a depth of at least 1 meter. The easiest way to do this is with an earthen drill, the diameter of which should be at least 200 mm, which will be enough for a pipe with a cross section of 100 × 100 mm.

- When calculating the depth of the pit, it is imperative to take into account the level of soil freezing in the region of work. When determining the width of the sides, pay attention to the quality of the soil and the dimensions of the supports used.

- A sand-gravel cushion under concrete is being carried out. Its optimal height is no more than 200 mm. It will help to avoid deepening the post and provide a base for concreting.

- A pole is installed, then it is leveled using a building level.

- A concrete solution is being prepared, with which a dug-in rack is poured.

- After installation, concreted pillars must be allowed to stand for at least a week. The concrete must be well cured. During this time, it is recommended to periodically wet the concrete with water. Although cracks in such a small area are less dangerous than those that have arisen in the foundation of a house, they are also undesirable.

- If you decide to use brick or concrete instead of a pipe, then it is recommended to make a recess under it the same (one meter).

- To ensure high reliability of the rack, it must be reinforced with reinforcement. First, 2-3 reinforcing mortgages should be removed for the subsequent installation of loops.

After that, they move on to the second stage.

There are also some points that must be taken into account when carrying out work.

You need to start the workflow by choosing the installation location. After all, the appearance of the structure largely depends on the location.

If it is planned to install a gate to the backyard, to the entrance to the garden or to fence the construction site with their help, then you can limit yourself to a simpler material and design. It is a completely different matter when front doors or gates to the garage are installed. In this case, the costs will increase significantly.

It is best when the gate is installed along with the fence. If the latter replaces a hedge, or it is simply planned to expand the passage and new gates are required, then measurements must be taken before installation.

It is necessary to find out the height and width of the opening for the installed gate. When measuring the height, one should not forget that a technical clearance should remain in the lower part of the structure. To correctly calculate this distance, it is necessary to take into account the type of coverage of access roads. If asphalt, tiles or concrete lie in the gate area, then 5-7 cm of clearance will be sufficient.

For unreinforced soil, as well as uneven surfaces, this distance will have to be increased to 10 cm. The presence of a technical clearance is also due to the need to solve such an important task as reducing the wind load, if it is necessary to install solid gates without ventilation gaps.

Do not forget also about the gap between the wings, thanks to which you can level the slight displacement of the racks.

In recent years, many of our compatriots have managed to appreciate the full benefits of installing swing gates in their summer cottage or in the courtyard of their own house. Such devices provide not only reliable protection against penetration into the territory, but also are simple and reliable in operation.

Some owners install them themselves, which is a perfectly reasonable solution. After all, this way you can not only save on installation, but also get an access system that will meet the requirements of the owner to the maximum extent.

If you doubt that you will be able to do this task, or if you do not have enough time, then it is best to entrust this work to professionals who will quickly and efficiently install swing gates, saving you from all problems.

The view of beautiful decorative gates against the background of a corresponding fence always impresses passers-by, and if they are also made by the hands of the owner, they are doubly impressive. To say that it is easy to create an entrance group of the site on your own means to deceive the reader. But the fact that this is unrealistic, too, can not be argued. Making the right gate with your own hands is difficult, but doable.

Swing design preference

Novice craftsmen, of course, do not dare to immediately make complex structures with intricate mechanisms at home, and you can make and install well-known and beloved designs of swing gates on your own.

But, before you start creating in the garden from improvised material or from boards, it is still better to make or order a drawing of the gate, calculate the amount of material needed, provide the workplace with equipment and tools, and only after that you can make the gate with your own hands to the garden fence , or, to the front entrance of a private estate.

Preference is often given to such an option as swing structures for several reasons:

- they are easy to manufacture;

- in comparison with other entry groups, it requires less material and labor costs for manufacturing;

- a well-made product will last a long time to its owner;

- a huge selection of material for cladding;

- the possibility of installing automation;

- a lot of decoration options;

- simple operation.

The listed advantages are accompanied by only one, but a significant drawback - you need the necessary distance to open the gate leaves into or out of the yard. And garden plots do not always have enough space. But if there is no such problem, then you can safely proceed to manufacture.

Gate elements

This is the oldest structure that has been modified for centuries, but nothing has fundamentally changed, all the constituent elements have remained the same:

- Support posts are an important part of the gate, which holds the entire weight of the leaves and the wind load. Therefore, their installation must be taken with the utmost seriousness. The material is often metal. And even if the supports are made of brick, then their core will in any case be metal, since the hinges for the sashes need to be attached to the metal.

- Gate leaves consist of a frame, the material of which can be both metal and wood. Although the same metal is more popular, as it is stronger, more reliable and more durable.

- We have already mentioned the finish, that is, the sheathing of the sashes, but this is also an integral attribute of the design, and you should not forget about the weight of the material. The heavier the sheathing, the more reliable the frame needs to be made, taking into account the wind load of the region.

- Loops for the design also play an important role, so when choosing them, it is advisable not to think about saving, it is better to do it on something else.

- The owner selects locks, latches, latches and other accessories at his own discretion, but also taking into account the total weight of the structure.

We figured out the general view of the product, so you can start thinking about how to make a gate according to the drawing and calculate the material.

Often, the place of installation of the product directly affects the material and appearance of the product. If, for example, you need to install an exit gate in an almost imperceptible backyard or garden area, or simply fence off a construction site with a temporary fence and entrance gate, then the design requirements will be simplified.

For front decorative entrances, the requirements are more stringent, and, accordingly, the costs of the entire event can double.

The choice of material is directly related to the size of the entrance group, the weight of the structure and many other factors, including natural ones.

But according to experts, for the frame of the valves, a profile pipe with a cross section of 60 * 40 mm is more often used, where the metal thickness is 1.5 - 2 mm. A pipe with a cross section of 40 * 20 mm may also be suitable, it all depends on the weight of the skin.

The cross section of the pipe for supporting pillars also depends on the weight of the structure, but it is better to be guided by the knowledge of specialists who say:

- for a total leaf weight not exceeding 150 kg, a pipe with a cross section of 80 * 80 mm and a metal thickness of 4 mm can be used;

- above 150 kg and up to 300 kg - it is advisable to use a pipe 100 * 100 mm with a thickness of 5 mm;

- above 300kg, apply 140*140mm pipe, with 5mm thickness.

Regarding the hinges, you can choose any mechanisms - adjustable or non-adjustable, but the material from which they are made must be of high quality so that the mechanisms can withstand the weight of the gate leaves made independently.

Installation of support poles

Maybe someone thinks that home-made entry products in the garden or on the site will never turn out neat and beautiful. But, as practice has shown, if you approach manufacturing with all responsibility and even pedantry, then you can by your own work surpass the products that are offered on the construction market.

Do-it-yourself gates, whether they are the simplest summer cottages, made from improvised material, but correctly calculated and made strictly according to the drawing, will be unusual and unique.

So, we build, observing the dimensions, distances and constantly measuring the correctness of all angles, verticals and horizontals.

First of all, it is necessary to install the supporting elements on which the sashes will be hung. Embedded elements must be provided in brick pillars. One part of the loops is welded to them.

If the garden gate supports are supposed to be made of metal, then they should definitely be strengthened. To do this, holes are drilled to a depth of 80 - 120 cm, the bottom of the hole is covered with sand or gravel, poles are installed at the level, fixed with wooden or metal spacers, filled with cement mortar and tamped.

Calculation and welding of frames

While the solution hardens, you can start making frames. There is no need for welding here. Strictly sized pipes are cut off by welding. It is important to carry out the welding process on a special table or on a flat surface so that it does not skew.

Welding should take place in stages. First, all the parts are stuck in several places, then, the correctness of welding along the diagonal and in the corners is checked, if everything is extremely accurate, then you can start finishing welding.

If rusty pipes are used for the manufacture of garden gates, then it is advisable to clean them of rust before welding. Then the seams will turn out to be more even and of high quality.

After welding, carefully clean all seams, cover the frames with a primer, wait until it dries completely and paint.

For a standard frame, you will need the following material:

- the perimeter of frames and lintels can be made from a pipe 60 * 40 mm. In total, you will need to purchase 22 m;

- the inner frame for reinforcing the frames is made of a 40 * 20 mm pipe, it will take 15 m for it. The lining will be attached to this inner frame.

Since pipes are sold in linear meters, the best option would be to order the required dimensions that correspond to the dimensions of the scheme. This approach has a double benefit - it will not be necessary to measure and cut off the desired length at home, and delivery will also be simplified.

Product dimensions

Ideally, the gate should be built along with the fence. But there are cases when it becomes necessary to expand the passage, or old products are out of order, then it is necessary to make the calculation extremely accurately before manufacturing new structures.

And it is desirable that the stylistic decision fully appeals to the fence. If, for example, a fence is made of bricks, then bricks will definitely have to be used for the gate posts of such a fence. If the fence of the garden plot is low and made of boards, then the option of decorative high forged gates is unlikely to harmonize with such a fence.

When taking measurements and calculating the material, the coverage of access roads should be taken into account. If there is asphalt, concrete or tile at the entrance, then it is enough to leave a gap of 5 cm. And when the garden path is overgrown with grass, then in this case it is better to leave a gap of 10 cm for the doors to open freely.

It is also desirable to provide a gap between the leaves in order to level out the slight displacement of the pillars from time to time.

Sash installation

This process begins with the fastening of the hinges, which are welded to the main frame of the sash and to the supporting posts. If the pillar is made of brick, but the mortgage element was not provided, then a channel is attached to the brick with a dowel, and loops are welded to it. Well, if everything is provided for in a brick pillar, then there should be no problems with fastening the hinges.

By the way, these small but important elements also have their own installation instructions that come with the kit. Therefore, it is better to carefully study the instructions before welding.

When all welding work is completed, a control cleaning of the seams and painting should be done. Only after the paint has dried can the doors be mounted on hinges.

Further, the installation of all the remaining fittings is carried out - locks, latches, latches, automation. These elements of the entrance group, no doubt, must be mounted strictly according to the diagrams attached in the kits. And if the valve can still be attached without instructions, then it will not work to install automation without a diagram, and it is difficult to attach the lock without carefully studying the diagram or instructions.

Finishing

We will send the material to you by e-mail

Gates are an integral part of any fence or garage. Today they can be made independently, the main thing is to choose the right type of construction. They will help you make the gate with your own hands: drawings, photos and videos. This information will also help determine the material from which the construction will be performed.

Gate in a private courtyard

The usual option for all are swing products. They are used in summer cottages, in private houses and in the construction of garages. A gate can also be located next to such options. The design involves the installation of two supporting elements along the edges of the canvas. Today, it is quite simple to make swing gates with your own hands. Drawings, photos and videos will help to study all the details of the work.

The device of the supporting elements

At the first stage of construction, it is necessary to install supports. Most often, these are metal poles of a suitable diameter, which are concreted into the ground. Very often done with brick columns. In this case, they can also be a support for the product. But do not forget when laying bricks, make metal mortgages to which hinges will be welded.

Leaf preparation

From which side such hinges will be welded, it depends in which direction they will open. That is why, when making a gate with your own hands: drawings, photos and videos must be viewed without fail. To make the sashes, a metal frame is most often used, to which sheet material is attached. If the fence is wooden, then it is more expedient to make the gate from wood. The frame in this case can be made both from metal corners and from a bar. It is important that the sashes are not too heavy, otherwise they will put a lot of stress on the posts and hinges. Over time, this can lead to deformation and the sashes will not close well.

Therefore, it is worth studying some information before making swing gates with your own hands. Photo and video drawings will help you get acquainted with all the subtleties in the work and prevent all kinds of defects. At the final stage, a locking system must be installed on the sashes. The simplest option may be a simple deadbolt.

Video: swing gates made of corrugated board and metal profiles

Features of the sliding gate device

Sliding options are increasingly used during the construction of fences. They take up relatively little space. In addition, the machine can be located only a few centimeters from the fence and this will not interfere with their opening or closing. The presence of a variety of building materials makes it possible for everyone to make sliding gates with their own hands. Drawings, photos and videos will allow you to more carefully study all the features of the work.

Sliding option

The main types of sliding gates:

- console;

- suspended;

- retractable.

Hanging variety

The hanging version is not very popular. This is due to the fact that a rail is installed in the upper part, along which the canvas moves. This rail is a kind of limiter, so not every vehicle will be able to enter the yard.

Recoil products

For the operation of retractable options, the rail is installed along the wall and directly in the opening itself. In the northern regions, such a system is not practical to use. Since with a large amount of snow, the operation of the valves will be difficult, and it will be necessary to constantly clean snow-covered places.

Cantilever Benefits

The console type is by far the most popular. They can be used in both southern and northern regions. The movement of the canvas occurs above the ground, so there is no need to constantly clear the path. In addition, the advantages include the fact that there are no limiters at the top. This makes it possible to drive into the yard even for cars with a high height.

For this type of installation, only one support column is required, which will carry the entire load from the canvas. Therefore, it is important to make it as high quality and reliable as possible. The cantilever beam itself on the gate can be located below, above or in the middle of the leaf.

Helpful information! The beam located in the middle is considered the best option, since it generally strengthens the entire structure.

Rollback model

Everyone cope with the implementation of sliding gates with their own hands. Drawings, photos and videos allow you to study the principle of a sliding system. It is important to take into account all recommendations when performing work.

Features of the implementation of sliding gates

Retractable options can significantly save space in the yard. But at the same time it is necessary to control the space along the fence. For the normal functioning of the system, it is first necessary to clear the place of debris and any vegetation.

Installation of support elements

The beginning of work is the device of the main support column, on which the main load will be applied. If you wish, you can perform and the video will help to comply with the technology. To work, you need to prepare the following tools:

To make the doors themselves, it is best to use galvanized material. It is able to serve for a long time, while retaining its original appearance. Polymer-coated profiled sheets are often used.

Helpful information! The use of a profiled sheet is considered the most successful solution, since it is treated with special agents that prevent corrosion.

Products of this type can be equipped with automatic or manual drive.

Retractable drawing

At the beginning of work, it is worth preparing the drawings according to which the work will be performed. Drawings and diagrams also allow you to calculate the exact amount of material needed. The height of the gate must match the fence. The width of the opening can be very different. Retractable products exert pressure not only on the rails, but also on the pole, so special attention must be paid to its design. Its lower part must be immersed in the soil and concreted with high quality.

The device rails for the movement of the canvas

Sliding gates will walk along the rail, which is located on the ground. To do this, choose a U-shaped metal profile. Its length should be like two lengths of the canvas. For the stock, you need to make another 30 centimeters. It is important that the rail is installed on a concrete base. Only in this way can you get the most reliable design that will last a long time. After all the rail systems are installed and fixed to the support post, the electric drive can be installed.

Fabric assembly and installation

The door leaf is made from a metal frame, to which a profiled sheet will subsequently be attached. Rollers are attached to the bottom of the metal frame. The door leaf is installed last. Do-it-yourself sliding gates: drawings, photos and videos provide complete information about the design and the process of doing the work.

Tips and tricks for do-it-yourself work

To execute the gate of any design is within the power of each person. It is important to follow the recommendations of experts and first study some information.

- Materials for work to choose only high quality. This will allow the structure to be operated for a long period and no repairs will be required.

- It is important to pay attention to all drawings and diagrams. Only strict adherence to the scheme will allow you to do all the work correctly the first time. Compliance with dimensions and parameters make it possible to make a functional design that will work without problems.

- The installation of an electric type drive must be carried out with a full understanding of the matter. If there is no experience in this area, it is worth entrusting all the implementation to specialists. They will do everything efficiently and quickly. Products will open and close without difficulty.

- If the use of a roller system is envisaged, special attention should be paid to its choice. It is best to purchase it in specialized stores. In this case, the operation of such a system will be flawless for a long time.

Today, you can supplement the fence with a gate made by yourself. Various materials can be used for manufacturing. The most commonly used wood and metal. Before proceeding with the implementation, it is worth considering which type of design is best to use. Starting the implementation of the gate with your own hands: drawings, diagrams and photos will help you solve even complex problems. Swing gates are a classic option with a performance that everyone can handle. For their device, you need a lot of space so that they open freely. You can save space in your backyard with sliding or sliding gates.

Save Time: Featured Articles Every Week by Mail

Gates and gates made of corrugated board belong to the budget category: their manufacture does not take much time and materials. True, if you choose a model of ordinary swing gates without artistic additions. There are also options with forging elements, here the complexity of the work is greater, the costs are much higher. Even an amateur welder can make simple swing gates from corrugated board with their own hands: there are few seams, they are simple.

Sash designs

Even in such a simple design as a gate leaf or a gate, it can be done in different ways, and there are many options. First of all, the location of the jumpers differs:

- obliquely;

- horizontally;

- crosswise.

Each method has been tested and works, providing a sufficient degree of rigidity. Here you choose what seems to you more correct or reliable.

There is a difference in the design of the gates themselves - with or without a stationary frame (top bar). With a frame, the gate is more stable, but then there are height restrictions: tall cars - trucks or special equipment - will not be able to drive into the yard. With proper reinforcement of racks (pillars) and normally made wings (with reinforcement at the corners), gates without a frame will also be reliable.

When installing a gate with a frame, the metal consumption is greater - by the length of the jumper, but at the same time, the pillars can not be additionally strengthened: the load on them is less.

To make it more convenient to fasten the profiled sheet, a thin-walled metal profile 1 cm wide is welded along the outer (sometimes inner, as in the figure above) perimeter of the wings. This must be taken into account when determining the dimensions of the blanks for the doors.

To make the structure as rigid as possible, so that it does not “walk” and does not make noise in the wind, reinforcement is made in the corners. And again there are two ways. The first is to weld the corners cut from sheet metal.

The second is to put short corner braces from the same pipe that welded the frame of the wings.

There is a difference during assembly: from the joints, the pipes are connected at an angle of 45 ° or just end-to-end. More professional - at 45 °, easier - end-to-end. Some assembly methods do not provide for the possibility of connecting at an angle at all (if both doors are assembled as one-piece, and only when they are hung on poles, they are sawn into two parts).

Another subtlety, which depends on the amount of snow in winter. As you can see in the photo, the lower bar of the wings is raised to different heights from the ground - somewhere a few centimeters, somewhere 20 cm and higher. It depends on the height of the snow cover in winter: if it snows, and the gate is from the ground itself, you will not open it. To prevent any living creatures from climbing into this gap in the summer, after the snow melts, the bar is screwed onto the screws, and in late autumn it is removed again.

The material for the gate is taken the same as for, fasten it to the same self-tapping screws. Before starting work, the metal must be prepared: remove all rust (with a grinder with a metal brush), prime with Anti-Rust and paint. After drying, you can start working.

Photo report on the manufacture and installation of the gate

This is one of the options for how you can make a gate from corrugated board with your own hands. The technology is not the best, but not the worst: everything has been functioning without problems for the past six years.

Hinges are welded to the installed poles 80-80 mm, the counterparts are welded at the required distance on the vertical parts of the racks from the pipe 40 * 40 mm - on the right and left. We hang the racks on the hinges on the pole, put a layer of the required thickness between them and the poles and fix it with a clamp.

We measure the required height and cut off the excess, from above to the racks, not to the poles, we weld the cross member from the same pipe 40 * 40 mm. The quality of welding at this stage is unimportant. We are still grabbing the details, not caring about the thoroughness of the seam - then we will bring it to the norm. The main thing is that everything is smooth and kept together. Therefore, we grab points in several places.

In the same way, we grab the pipe along the bottom.

We find the middle of the cross beams. Set aside 3 mm from the middle in both directions. We make clear marks. We measure the distance between the upper and lower beams, cut off two segments, weld them according to the marks (there should be a gap of 6 mm between the two vertical pipes).

We measure the distance between the two posts of one half of the gate. They should be the same, but it is better to measure separately. Cut the pipes to the desired length and tack them at the desired height. If you need more crossbars, install them too.

On the marked center with a grinder at the top and bottom, we make through cuts, dividing the gate into two halves. So very simply we got a gate that will open and close without any problems.

The frame of the gate leaves is ready. We remove it, lay it on a flat horizontal surface and weld the seams well. Here, the quality of welding is already important, we monitor the fullness of the bath, we try not to burn holes. We clean the finished seams, primer, paint.

We proceed to the assembly of the support for fastening the profile sheet. To reduce the windage, it was cut into two parts, so that the sheet is not solid, but cut. For this we use a profiled pipe 20 * 20 mm. We cut it into segments of the desired length, so that it can be fixed along the inner perimeter.

We expose them in the same plane with the outer part - the sheet will be screwed from the inside. We fix it on self-tapping screws, having previously drilled holes of the required diameter.

We paint the finished frame - inside with light gray paint, outside - red-brown, to match the color of the corrugated board. We leave to dry.

We proceed to the installation of the profiled sheet on the gate. It is cut a little smaller than the main frame - there should be an indent around the perimeter by 2-3 mm. They are laid on prepared supports and fastened from the inside along the perimeter to self-tapping screws.

Installation of profiled sheet on the gate

You can take special ones, with hats and gaskets, but they put them on ordinary ones.

To save money, we used ordinary self-tapping screws for metal

We can say that the gate is ready.

It remains to install constipation. You can, of course, embed a lock and a handle, but the quality of inexpensive ones is very low, and taking expensive ones is currently an unaffordable luxury. Therefore, bolts were welded from the remains of pipes and fittings. They definitely work under any conditions.

One (upper) is mounted on self-tapping screws with a counterpart on the sashes, the two lower ones are attached to the uprights. Small holes were drilled in the ground in the right places, in which sections of round pipes were concreted, the diameter of which was larger than the diameter of the rod. The gate is made according to the same method, only a lock is embedded in it.

Do-it-yourself ready-made gates from corrugated board

With this manufacturing technology, the gate leaves are guaranteed to open and close. If there were some distortions when installing the pillars, they are taken into account. With a step-by-step presentation, the whole process does not look complicated, and indeed it is. If you weld all parts separately, the geometry must be perfect, and you also have to make sure that the pipe does not lead during welding. See several different technologies for making gates from corrugated board in the next section, which contains video tutorials.

How to make a gate from corrugated board: video tutorials

If the work is new, then even after the photo report, questions may remain. Some of them can clarify video tutorials on the topic. To begin with, repeating the technology described above: we assemble the frame directly on the installed pillars.

The same technology, in the photo sequence.

The second video is about how to properly weld the frame when connecting pipes at an angle of 45 °. The approach is professional.

Those who have not experienced welding gates or doors before may have questions about how to weld hinges. It's not as simple as it seems. Watch the next video tutorial.

For a more accurate explanation of what movements to make during welding of the gate hinges, where to direct the electrode and other nuances, see the following video.