Mankind has accumulated vast experience in construction throughout its existence. The basis, the base of any building is a solid and reliable foundation. Today, the most common type of foundation is the one that allows the foundation, because it is this construct that evenly distributes the weight of buildings on the ground, which in turn affects the shrinkage process of the house. And the reinforcement of the strip foundation is a way to make the foundation of the structure stronger and more reliable.

Steel and concrete are the main load-bearing building materials. The properties of materials differ from each other. Comparative table of properties of some materials:

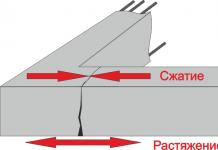

As you can see, steel is much stronger and more reliable than concrete, but at the same time, concrete is 80 times cheaper than steel. Therefore, a composite material reinforced concrete appeared. Since concrete works well in compression, the location of steel in reinforced concrete structures is in places subject to tension and bending.

Many believe that the foundation only works to compress and reinforce the strip foundation - money thrown to the wind. This is correct if the foundation is placed on rocky soils. But in most cases, the soil is not a solid monolith. There are many factors that make a bending base work:

- Soil heterogeneity. Different density of layers leads to uneven shrinkage.

- Erosion of soil by atmospheric precipitation or groundwater.

- Mobility of the surface layers of the soil.

- Frosty swelling. The close location of groundwater and negative temperatures cause clay soils to increase in size by 10-15% (swell). In this case, the base begins to squeeze the foundation up.

As a result, stress arises in concrete structures, destroying the material. Cracks and shrinkage of the foundation lead to the formation of cracks in the walls of the house, which spoils the appearance of the building or to its collapse. In other words, saving on reinforcing the foundation is more expensive for yourself, because repairing and restoring a house requires tangible cash costs.

Reinforcement technology is a process of creating a spatial reinforcement cage. It consists of the following elements:

- longitudinal reinforcement;

- transverse;

- vertical;

- reinforcing clamps;

- knitting wire.

Longitudinal reinforcement is laid along the long side of the foundation, and the length of the rod usually reaches 6 or 12 m. It is she who resists stretching. Longitudinal reinforcement is performed along the upper and lower edges of the reinforced concrete structure.

The laying pattern depends on the calculation of the required cross-sectional area of the reinforcement. Such a calculation requires careful consideration of all loads on the foundation, including climatic ones from snow and wind, as well as the own weight of the foundation. The bearing capacity of the soil is taken into account according to geological studies (geological section). In GOST 5781-82, table 1 contains the cross-sectional area for each rod diameter, it remains to decide how many rods to place on the upper and lower sides of the foundation.

However, for those who decide to build a house on their own, with their own hands, you can do without calculations, using the recommendations of clause 10 and section 5 of the Manual "On the design of concrete and reinforced concrete structures made of heavy concrete without prestressing reinforcement." They indicate that the minimum cross-sectional area of \u200b\u200bthe reinforcement is As \u003d µ * b * ho, where:

As is the cross-sectional area of the reinforcement;

µ= 0.1% - percentage for bending structures;

b is the width of the section of the strip foundation;

ho is the height of the working area of the section (equal to half the height of the foundation section).

The diameter of the upper rods can be equal to the diameter of the lower ones or taken smaller. The maximum distance between the axes of the longitudinal rods (step) is recommended to be taken no more than 1.5h or no more than 400 mm in beams and slabs, where h> 150 mm is the height of the foundation cross-section (clause 10.3.8 of the joint venture and clause 5.13 of the Handbook). Only in this case, the effective operation of concrete and reinforcement is ensured, and the width of the crack opening between the longitudinal bars is limited.

The minimum pitch of the rods (distance between the axes) is limited for reasons of convenience of laying and compacting the concrete mixture and is equal to:

- d + 25 mm - for the lower reinforcement row;

- d + 30 mm - for the top.

Consider an example:

It is necessary to reinforce the strip foundation 400 mm wide, 600 mm high. You need to calculate how many rods you need and choose the diameter. The minimum cross-sectional area of the reinforcement is: As \u003d 40x30x0.1% \u003d 1.2 cm². The distance between the rods is 1.5x600 = 900 mm, therefore, we will take no more than 400 mm. That is, 2 rods are installed along the width of the section. We select the diameter of the reinforcement according to GOST 5781-82 table 1: two rods Ø 8 mm have an area As \u003d 2x0.503 \u003d 1.006 cm², which is less than the required 1.2 cm². Consider the following diameter Ø 10 mm. As \u003d 2x0.785 \u003d 1.57 cm². As a result, the layout of the rods looks like this: take the upper and lower reinforcement equal to Ø 10 mm and lay them in two rows.

Many builders today use the following rules to select the diameter of the rods: the diameter must be at least 10 mm if the side of the foundation is less than or equal to 3 m, and 12 mm for a side more than 3 m (see the Manual "Reinforcement of elements of monolithic reinforced concrete buildings" Appendix 1). However, the rules of the manual have been developed for the design of monolithic reinforced concrete structures of multi-storey buildings, taking into account emergency loads and progressive collapse. Of course, for those who build a house with their own hands, the margin of safety will not hurt, but we are no longer talking about a reasonable consumption of reinforcement.

When installing reinforcement, one should not forget about the protective concrete layer - the distance between the side surface of the strip foundation and the reinforcement bar. The protective layer is necessary for several reasons: it protects the steel from the aggressive effects of air and groundwater. In addition, for the normal operation of reinforced concrete, the reinforcement must be inside the concrete. The minimum layer size depends on the operating conditions of the structure and for structures located in soils, foundations with a concrete preparation device, it is 40 mm and not less than the diameter of the working reinforcement (Table 10.1 of the SP and Table 5.1 of the Manual).

Read more about the calculation of reinforcement.

Transverse structural reinforcement

Structural transverse reinforcement means horizontal and vertical bars, which:

- Support longitudinal reinforcement in the design working position.

- Prevent the development of cracks.

- Perceive an unaccounted load, for example, lateral buckling of the foundation.

The diameter of the transverse reinforcement in knitted flexible frames is assumed to be at least 6 mm. In Appendix 1 of the Manual "Reinforcement of elements of monolithic reinforced concrete buildings", transverse reinforcement is recommended to be performed in the form of a closed clamp with a rod diameter of at least 8 mm.

Device for bending reinforcement clamps.

The distance between the rods (step) is taken no more than twice the width of the cross section and not less than 600 mm. As for the protective layer, the minimum distance between the rod and the concrete edge is 5 mm less than the minimum layer size for longitudinal working reinforcement, i.e. 35 mm.

Materials used

Reinforcement materials are accepted in accordance with GOST 5781-82. The fittings are made of low-alloy and carbon steel in accordance with GOST 380-2015. The surface of the rods can be smooth or with a periodic profile. Depending on the properties, the material is divided into the following classes:

- A 240 (A-I);

- A 300 (A-II);

- A 400 (A-III);

- A 600 (A-IV);

- A 800 (A-V);

- A 1000 (A-VI).

For the foundation, reinforcement with a sickle-shaped profile is needed.

The numerical code reflects the yield strength, for example 240 corresponds to 235 N/mm². Among them, only A 240 (A-I) is made with a smooth profile. In the range of products are limited to a diameter of 6 to 40 mm.

Frames can be welded or bonded. For bonding and reinforcement, low-carbon steel wire GOST 6727-80 is used, round (grade V-I) or ribbed (grade Vr-I), with a diameter of 3.0; 4.0.

Tip: The best solution for the foundation would be A400 (AIII) reinforcement, the use of higher grades is not justified, because. without prestressing, its strength potential will not be used 100%.

It should be noted that in recent years, fiberglass composite reinforcement has appeared in the construction industry. The material is durable and lightweight. The material has many advantages: easy installation technology, has high anti-corrosion properties.

Photo of composite reinforcement.

However, the material also has disadvantages. It has self-extinguishing characteristics during combustion, but at a temperature of 200 ° C it loses its properties. In addition, it does not bend well, which makes it difficult to use bent elements. Many professional builders refused to work with this material due to the lack of practical experience (foreign experience was not taken into account) and calculation recommendations.

But since July 2015, Appendix L has appeared in SP 63.13330.2012 with rules for the design and calculation of structures. For those who prefer to build with their own hands, there are design requirements for reinforcement.

Rules for reinforcing corners and junctions

Often at the construction site, reinforcement has to be made from remnants, so the rods are overlapped, welded, or special butt joints are used. When overlapping, the ends of the smooth profile reinforcement are bent in the form of paws, hooks and loops, and the ends with a periodic profile can not be bent. The distance between joined bars can be from zero to 4 reinforcement diameters. The length of the joint is calculated according to the design manual, but cannot be less than 15 bar diameters or 200 mm.

Butt welded joints are performed using clips, and in mechanical joints, threaded and crimp couplings are used.

Important! The rules prohibit reinforcing corners with a simple overlap, since in this case the corner will not be integral and motionless.

Angular and T-shaped junctions of frames are made in three ways: with paws, with additional curved collars of L and U shapes.

Photo how to properly reinforce the corner.

Learn more about corner reinforcement.

Knitting armature

It would seem that welded frames are faster and more convenient to use. However, builders prefer to knit space frames. And there are reasons for this:

- Welding reduces the quality of the metal.

- Soil settlement during the production of foundations provokes additional stresses at the joints. Welding joints do not always cope with loads and are destroyed. Connected parts do not change position in space, but have a certain mobility.

Advice! If you need contractors, there is a very convenient service for their selection. Just send in the form below a detailed description of the work to be done and you will receive offers with prices from construction teams and firms by mail. You can see reviews of each of them and photos with examples of work. It's FREE and there's no obligation.

Any building, regardless of its purpose, is unthinkable without a reliable foundation. The construction of the foundation is one of the most important and natural tasks of the entire construction cycle as a whole, and this stage, by the way, is often one of the most time-consuming and costly - often up to a third of the estimate is spent on it. But at the same time, any simplifications, unreasonable savings on the quality and quantity of the necessary materials, disregard for the current rules and technological recommendations should be absolutely excluded here.

Of all the variety of foundation structures, it is most popular as the most versatile, suitable for most houses and outbuildings being built in the field of private construction. Such a base is highly reliable, but, of course, with its high-quality performance. And the key condition for strength and durability is the well-planned and properly carried out reinforcement of the strip foundation, the drawings and the basic principles of the device of which will be considered in this publication.

In addition to the diagrams, the article will provide several calculators that will help the novice builder in this rather difficult task of creating a strip foundation.

Important features of the strip foundation

General concepts. Advantages of strip foundation

So, in short, a few general concepts about the device strip foundation. By itself, it is a continuous concrete strip, without gaps for door or gate openings, which becomes the basis for the construction of all external walls and capital internal partitions. The tape itself is buried at a certain calculated distance into the ground and at the same time protrudes from above with its basement. The width of the tape and the depth of its laying, as a rule, is maintained the same throughout the entire length of the foundation. This form contributes to the most uniform distribution of all loads falling on the base of the building.

Strip foundations can also be divided into several varieties. So, they are not only poured from concrete, but also made prefabricated, using, for example, special reinforced concrete foundation blocks, or using rubble filling. However, since our article is devoted to reinforcement, in the future only a monolithic version of the foundation tape will be considered.

The strip foundation can be attributed to the universal type of foundations. This scheme is usually preferred in the following cases:

- When building houses from heavy materials - stone, brick, reinforced concrete, building blocks and the like. In a word, when it is required to evenly distribute a very significant load on the ground.

- When the developer plans to get a full-fledged basement or even a basement at his disposal, only a tape scheme can allow this.

- During the construction of multi-level buildings, with the use of heavy interfloor ceilings.

- When a building plot is characterized by heterogeneity of the upper layers of the soil. The only exceptions are completely unstable soils, when the creation of a strip foundation becomes impossible or unprofitable, and it makes sense to turn to another scheme. A strip foundation is also impossible in regions with permafrost.

A monolithic strip foundation has a considerable number of other advantages, which include durability, estimated for many decades, the relative simplicity and clarity of construction, ample opportunities in terms of laying utilities and organizing insulated floors on the first floor. In terms of its strength properties, it is not inferior to monolithic slabs, and even surpasses them, while requiring less material costs.

However, one should not think that the strip foundation is an absolutely invulnerable structure. All of the above advantages will be valid only if the parameters of the foundation being built for the house correspond to the conditions of the construction area, the design load, and have a built-in safety margin. And this, in turn, means that special requirements are always imposed on the design of the foundation (any, by the way). And the reinforcement of the tape in a series of these problems occupies one of the key positions.

The width of the foundation tape and the depth of its laying

These are two key parameters on which the very scheme of reinforcing the future foundation tape will depend.

Rebar prices

fittings

But the degree of penetration into the ground strip foundations can be divided into two main categories:

- A shallow strip foundation is suitable for the construction of frame structures, small country houses and outbuildings, provided there is sufficiently stable, dense soil on the site. The sole of the tape is located above the freezing boundary of the soil, that is, it usually does not fall below 500 mm, excluding the basement.

- For buildings constructed from heavy materials, as well as in areas where the condition of the soil is not stable, deep tape is required. Its sole is already falling below the freezing level of the soil, at least by 300÷400 mm, and if there is also a (basement) in the construction plans, even lower.

It is clear that the height of the foundation strip as a whole, including the depth of its occurrence, is by no means arbitrary values, but parameters that are obtained as a result of carefully performed calculations. When designing, a whole array of initial data is taken into account: the type of soils on the site, the degree of their stability both in the surface layers, and the change in structure as they deepen; climatic features of the region; presence, location and other features of ground aquifers; seismic characteristics of the area. Plus, the specificity of the building planned for construction is superimposed - the total load, both static, created only by the mass of the structure (of course, taking into account all its constituent elements), and dynamic, caused by operational loads, and all kinds of external influences, including wind, snow and others.

Based on the foregoing, it would be appropriate to make one important remark. The fundamental position of the author of these lines is that the calculation of the basic parameters of the foundation tape does not tolerate an amateurish approach.

Despite the fact that on the Internet you can find many online applications for carrying out such calculations, it would still be more correct to entrust the issue of designing the foundation to specialists. At the same time, the correctness of the proposed calculation programs is not in the least disputed - many of them fully comply with the current SNiP and are capable of really producing accurate results. The problem lies in a slightly different plane.

The bottom line is that any, even the most advanced calculation program, requires accurate input data. But in this matter, it is impossible to do without special training. Agree that it is correct to assess the geological features of the site for construction, to take into account all the loads that fall on the foundation tape, and - with their expansion along the axes, to provide for all possible dynamic changes - a non-professional simply cannot do it. But each initial parameter matters, and underestimating it may well then "play a cruel joke."

True, if it is planned to build a small country house or an outbuilding, then inviting a specialist designer may seem like an excessive measure. Well, at your own peril and risk, the owner can build a shallow strip foundation, using, for example, the approximate parameters that are shown in the table below. For light buildings, a heavily buried tape is not required (a large depth can even play a negative role, due to the application of tangential forces during frosty swelling of the soil). As a rule, in such cases they are limited to a maximum depth of the sole of 500 mm.

| Type of building under construction | Barn, sauna, outbuildings, small garage | One-story country house, including - with an attic | One- or two-story cottage, designed for permanent residence | Two or three story mansion |

|---|---|---|---|---|

| Average soil load, kN/m² | 20 | 30 | 50 | 70 |

| SOIL TYPES | RECOMMENDED DEPTH | TAPE INSTALLATIONS | (EXCLUDING THE GROUND | FOUNDATION PARTS) |

| Pronounced stony ground, flask | 200 | 300 | 500 | 650 |

| Dense clay, loam that does not disintegrate after being compressed by the force of the palm | 300 | 350 | 600 | 850 |

| Packed dry sand, sandy loam | 400 | 600 | Professional foundation calculation required | |

| Soft sand, silt or sandy loam | 450 | 650 | Professional foundation calculation required | Professional foundation calculation required |

| Very soft sand, silt or sandy loam | 650 | 850 | Professional foundation calculation required | Professional foundation calculation required |

| peat bog | Requires a different type of foundation | Requires a different type of foundation | Requires a different type of foundation |

We emphasize once again that these are only average values that cannot be considered as the ultimate truth. In any case, if an amateur builder uses such sources, he takes a certain risk on his own responsibility.

Now - about the width of the foundation tape.

It also has its own characteristics. Firstly, to ensure the rigidity of the foundation structure, it is customary to adhere to the rule that the total height of the tape should be at least twice its width - but this rule is not difficult to follow. And the second - the width of the tape in the sole area should be such that the distributed load is less than the calculated parameters of soil resistance, of course, also with a certain design margin. In a word, the foundation tape with a full load should stand stably, without sinking into the ground. In order to save materials, often to increase the area of \u200b\u200bsupport, the sole of the strip foundation is made with a broadening.

Probably, it makes no sense to give here formulas and tabular values of soil resistance for independent calculations. The reason is the same: not so much the difficulty in performing calculations, but the problems with the correct determination of the initial parameters. That is, again, it is better to turn to professionals on such issues.

Well, if a light structure or a country house is being built, then you can be guided by the fact that the width of the tape should be at least 100 mm more than the thickness of the walls being built. As a rule, when planning the foundation independently, they take round values that are multiples of 100 mm, usually starting from 300 mm and above.

Foundation tape reinforcement

If a specialist is engaged in the design of a strip foundation, then the finished drawing will, of course, include not only the linear parameters of the concrete belt itself, but also the characteristics of the reinforcement - the diameter of the reinforcing bars, their number and spatial arrangement. But in the case when a decision is made to independently erect a foundation for a building, when planning the structure, it is necessary to take into account certain rules established by the current SNiP.

cement prices

What fittings are suitable for these purposes?

For proper planning, you need at least a little understanding of the assortment of reinforcement.

There are several criteria for classifying reinforcement. These include:

- Production technology. So, the fittings are wire (cold-rolled) and rod (hot-rolled).

- According to the type of surface, reinforcing bars are distinguished into smooth and having a periodic profile (corrugation). The profiled surface of the reinforcement provides maximum contact with the poured

- Reinforcement can be designed for conventional or prestressed concrete structures.

To create a reinforcing structure for a strip foundation, as a rule, reinforcement is used that is produced in accordance with GOST 5781. This standard includes hot-rolled products intended for reinforcing conventional and preloaded structures.

In turn, these fittings are distributed into classes, from A-I to A-VI. The difference mainly lies in the grades of steel used for the production and, therefore, in the physical and mechanical properties of the products. If low-carbon steel is used in the fittings of the initial classes, then in the products of high classes the parameters of the metal are close to alloyed steels.

It is not necessary to know all the characteristics of reinforcement classes during self-construction. And the most important indicators that will affect the creation of the reinforcing cage are shown in the table. The first column shows the reinforcement classes according to the two designation standards. So, in brackets there is a designation of classes, the digital designation of which shows the yield strength of the steel used for the production of reinforcement - when purchasing material, such indicators may appear in the price list.

| Reinforcement class according to GOST 5781 | steel grade | Rod diameters, mm | Permissible cold bending angle and minimum radius of curvature when bending (d - rod diameter, D - bending mandrel diameter) |

|---|---|---|---|

| A-I (A240) | St3kp, St3sp, St3ps | 6÷40 | 180º; D=d |

| A-II (A300) | St5sp, St5ps | 10÷40 | 180º; D=3d |

| -"- | 18G2S | 40÷80 | 180º; D=3d |

| AC-II (AC300) | 10GT | 10÷32 | 180º; D=d |

| A-III (A400) | 35GS, 25G2S | 6÷40 | 90º; D=3d |

| -"- | 32G2Rps | 6÷22 | 90º; D=3d |

| A-IV (A600) | 80C | 10÷18 | 45º; D=5d |

| -"- | 20HG2C, 20HG2T | 10÷32 | 45º; D=5d |

| A-V (A800) | 23X2G2T, 23X2G2C | 10÷32 | 45º; D=5d |

| A-VI (A1000) | 22H2G2AYU, 20H2G2SR, 22H2G2R | 10÷22 | 45º; D=5d |

Pay attention to the last column, which indicates the allowable bending angles and curvature diameters. This is important from the point of view that when creating a reinforcing structure, you come to manufacture bent elements - clamps, inserts, paws, etc. In the manufacture of conductors, mandrels or other devices for bending, it is necessary to focus on these values, since a decrease in the bending radius or exceeding the angle can lead to a loss of strength properties by the reinforcement.

Rods of class A-I are produced in a smooth design. All other classes (with some exceptions, which, however, are more dependent on the individual requirements of the customer) are with a periodic profile.

Reinforcement consumption must be determined at the foundation design stage in order to subsequently know exactly the amount of material purchased. Consider how to calculate reinforcement for a strip foundation using the example of a shallow base 70 cm high and 40 cm thick.

1.2 Reinforcement of the strip foundation (video)

2 Work performance technology

After the amount of reinforcement is determined, a strip foundation reinforcement scheme must be selected, according to which the reinforcement cage will be assembled. The straight sections of the structure are made of solid rods, while at the corner places additional reinforcement is needed with reinforcement curved into a P or L-shape. The use of perpendicular overlap of individual reinforcement bars at corners and junctions is not allowed.

The correct reinforcement of the corners of the strip foundation is shown in the diagram:

Scheme of reinforcement of the strip foundation at the junctions:

Do-it-yourself reinforcement of the strip foundation involves assembling the frame in a convenient place and its subsequent placement inside the formwork. The technology requires bending reinforcement into rectangular clamps, which is easy to do at home with a homemade fixture.

On the 20th channel, grooves must be cut with a grinder, into which reinforcement is subsequently inserted, and a piece of steel pipe is put on the bar, which is used as a lever. Finished rings must be fastened by welding or tied with wire. For bars with a diameter of 10-15 mm, wire 1.2-1.5 mm is used.

Reinforcement of the strip foundation significantly increases its strength characteristics, allows you to create stable structures while reducing weight.

Reinforcement calculations and reinforcement schemes are carried out in accordance with the provisions of the current SNiPa 52-01-2003. The document has detailed requirements for calculations, provides footnotes to regulatory documents and codes of practice.

SP 63.13330.2012 Concrete and reinforced concrete structures. Basic provisions. Updated edition of SNiP 52-01-2003. Download file

The strip foundation must meet the requirements for durability, reliability, resistance to various climatic factors and mechanical loads.

The main characteristics of the strength of concrete structures is the resistance to axial compression (Rb,n), tension (Rbt,n) and transverse fracture. Depending on the normative standard indicators of concrete, its specific brand and class is selected. Depending on the responsibility of the design, safety correction factors can be used, which range from 1.0 to 1.5.

Reinforcement requirements

During the reinforcement of strip foundations, the type and controlled values of the reinforcement quality are established. The standards allow for the use of hot-rolled building reinforcement of a periodic profile, heat-treated reinforcement or mechanically hardened reinforcement.

The reinforcement class is selected taking into account the guaranteed value of the yield strength at maximum loads. In addition to tensile characteristics, plasticity, corrosion resistance, weldability, resistance to negative temperatures, relaxation resistance and allowable elongation before the onset of destructive processes are standardized.

Table of reinforcement classes and steel grades

| Profile type | Class | Diameter, mm | steel grade |

|---|---|---|---|

| Smooth profile | A1 (A240) | 6-40 | St3kp, St3ps, St3sp |

| Periodic Profile | A2 (A300) | 10-40, 40-80 | St5sp, St5ps, 18G2S |

| Periodic Profile | A3 (A400) | 6-40, 6-22 | 35GS, 35G2S, 32G2Rps |

| Periodic Profile | A4 (A600) | 10-18 (6-8), 10-32 (36-40) | 80S, 20HG2C |

| Periodic Profile | A5 (A800) | 10-32 (6-8), (36-40) | 23X2G2T |

| Periodic Profile | A6 (A1000) | 10-22 | 22X2G2AYU, 22X2G2R |

The calculation of the strip foundation is carried out in accordance with the recommendations of GOST 27751, the indicators of the limit loaded states by groups are calculated.

The first group includes conditions that lead to the complete unsuitability of the foundation, the second group includes conditions that lead to a partial loss of stability, hindering the normal and safe operation of buildings. According to the maximum permissible states of the second group, the following are produced:

- calculations for the appearance of primary cracks on the surface of the strip foundation;

- calculations for the time period of the increase in the formed cracks in concrete structures;

- calculations for linear deformations of strip foundations.

The main indicators for resistance to deformation and strength of building reinforcement include the maximum tensile or compressive strength, determined in laboratory conditions on special test benches. Technology and test methods are prescribed in state standards. In some cases, the manufacturer may use the regulatory and technical documentation developed by the enterprise. At the same time, regulatory and technical documentation must be approved by the regulatory authorities without fail.

For concrete structures, these values may be limited by the maximum change in concrete linearity. As generalized indicators, the actual diagrams of the state of the reinforcement are taken for a short-term one-sided impact of the calculated standard loads. The nature of the state diagrams of building reinforcement is established taking into account its specific type and brand. During the engineering calculation of the reinforced foundation, the state diagram is determined after replacing the normative indicators with the actual ones.

reinforcement requirements

Reinforcing cage - photo

- Requirements for the dimensions of reinforced concrete structures. The geometric dimensions of the foundation should not interfere with the correct spatial placement of the reinforcement.

- The protective layer must provide joint resistance to the loads of reinforcement and concrete, protect against the effects of the external environment and ensure the stability of the structure.

- The minimum distance between the individual reinforcement bars must guarantee its joint work with concrete, allow it to be joined correctly and ensure the correct technological pouring of concrete.

For reinforcement, only high-quality reinforcement can be used; mesh knitting is carried out taking into account the calculated design indicators. Deviations from the values cannot go beyond the tolerance fields regulated by SNiP 3.03.01. Special construction measures must ensure reliable fixation of the reinforcing mesh in accordance with existing rules.

SNiP 3.03.01-87. Bearing and enclosing structures. Building regulations. Download file

During the bending of the reinforcement, special devices must be used, the minimum bending radius depends on the diameter and specific physical characteristics of the building reinforcement.

Reinforcing mesh prices

reinforcing mesh

Video - Manual rebar bending machine, video instruction

Video - How to bend rebar. Work on a homemade machine

The reinforcement is inserted into the formwork, the formwork should be made in accordance with the requirements of GOST 25781 and GOST 23478.

STEEL FORMS FOR MANUFACTURING OF REINFORCED CONCRETE PRODUCTS. Specifications. Download file

Formwork for the construction of monolithic concrete and reinforced concrete structures. Classification and general technical requirements

Calculation of the number and diameter of reinforcement

For the strip foundation of baths, building reinforcement with a periodic profile Ø 6 ÷ 12 mm is used.

Current state regulations regulate the minimum number of bars in concrete to give it maximum strength characteristics. The minimum total cross section of the longitudinal bars of the reinforcement cannot be ≤ 0.1% of the sectional area of the foundation strip. For example, if the strip foundation has a cross section of 12,000 × 500 mm (the cross-sectional area is 600,000 mm2), then the total area of all longitudinal bars must be at least 600,000 × 0.01% = 600 mm2. In practice, developers rarely maintain this indicator; the weight of the bath, the nature of the soil and the specific brand of concrete are also taken into account. This calculated value can be considered indicative; deviations from the recommended values should not exceed ≈20% downwards.

To calculate the amount of reinforcement, you need to know the cross-sectional area of the foundation tape and the cross-sectional area of \u200b\u200bthe reinforcing bar. To facilitate the calculations, we bring to your attention a ready-made table.

| Number of rods | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Diameter, mm | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 6 | 28,3 | 57 | 85 | 113 | 141 | 170 | 198 | 226 | 254 |

| 8 | 50,3 | 101 | 151 | 201 | 251 | 302 | 352 | 402 | 453 |

| 10 | 76,5 | 157 | 236 | 314 | 393 | 471 | 550 | 628 | 707 |

| 12 | 113 | 226 | 339 | 452 | 565 | 679 | 792 | 905 | 1018 |

| 14 | 154 | 308 | 462 | 616 | 769 | 923 | 1077 | 11231 | 1385 |

| 16 | 201 | 402 | 603 | 804 | 1005 | 1206 | 1407 | 1608 | 1810 |

| 18 | 254,5 | 509 | 763 | 1018 | 1272 | 1527 | 1781 | 2036 | 2290 |

| 20 | 314,2 | 628 | 942 | 1256 | 1571 | 1885 | 2199 | 2513 | 2828 |

Now the calculations are much easier. For example, to reinforce a strip foundation, you use eight rows of reinforcement with a diameter of 10 mm. According to the table, the total area of the rods is 628 mm. Such a frame can work with a concrete tape 120 cm deep and 50 cm wide. A few extra square millimeters can be ignored, they will be additional insurance in case of violation of the knitting technology or the manufacture of low-quality concrete.

In addition to these indicators, you need to determine the diameters of the rods for the foundations. These indicators depend on many components; for simplified calculations, you can use the proposed table.

Using this table, you can easily select the recommended reinforcement diameter for strip foundations.

Strip foundation reinforcement rules

There are several schemes for knitting reinforcement, each developer can use the most convenient for himself. The choice of scheme must be carried out taking into account the dimensions of the foundation and its bearing characteristics.

The reinforcement can be knitted separately, and then the finished structural elements can be lowered into the foundation trench and connected to each other, or you can immediately knit in the trench. Both methods are almost equivalent, but there is a slight difference. On the ground, all the main straight-line elements can be done independently; when working in a trench, an assistant is required. For knitting, you need to make a special hook, the connection is made with a soft wire with a diameter of ≈0.5 mm.

In some articles you can find tips to use a hand-held electric drill during knitting - do not pay attention to them. So can write those who have no idea about the work.

Firstly, the hand will get tired much more and faster from a drill than from a light hook. Secondly, cables will always get tangled underfoot, cling to the ends of reinforcement, etc. Thirdly, not all construction sites have electric energy. And, fourthly, your wire knots will always be either underdrawn or torn.

For knitting reinforcement, thin soft wire is used, and it has low strength. Pull the wire well, strong binding should occur in two or three turns of the hook. Otherwise, labor productivity is greatly reduced and fatigue increases. There are still options for welding reinforcement, we will talk about them in the next section of the article.

knitting wire prices

knitting wire

How to knit reinforcing mesh yourself

We have already said above that in this way you can knit reinforcement on the ground. Only straight sections of the grid are made, the corners are tied after they are lowered into the trench.

Step 1. Prepare pieces of rebar. The standard length of the bars is six meters; if possible, you do not need to touch them. If you are afraid that such a dyne will be difficult to work with, cut them in half.

We advise you to start knitting reinforcement for the shortest section of the strip foundation, this will give you the opportunity to gain a little experience and more confidently deal with long bars. Cutting them is not recommended, this increases the consumption of metal and reduces the strength of the foundation. Consider the dimensions of the blanks using the example of a strip foundation 120 cm high and 40 cm wide.

The reinforcement must be poured from all sides with concrete with a thickness of at least 5 centimeters. These are the initial conditions. Taking into account such indicators, the net dimensions of the reinforcing cage should be no more than 110 cm in height (minus 5 cm on each side) and 30 cm in width (minus 5 cm on each side). For knitting, you need to add two centimeters on each side to overlap. This means that the blanks for horizontal jumpers should be 34 cm long, the blanks for vertical jumpers should be 144 cm long. But you shouldn’t make the frame so high, it’s enough to have a height of 80 cm.

Step 2 Choose a flat area, put two long rods, trim their ends.

Step 3 At a distance of ≈ 20 cm from the ends, tie horizontal spacers on both extreme sides. For knitting, you need a wire about 20 centimeters long. Fold it in half, slide it under the binding point and tighten the wire with the usual scrolling of the crochet hook. Do not overdo it with force, the wire may not hold. The magnitude of the twisting forces is determined empirically.

Step 3 At a distance of approximately 50 centimeters, tie in turn all the remaining horizontal braces. Everything is ready - set the structure aside in the free space and in the same way make another frame element. You have the top and bottom part, now you need to fasten them together.

Step 4 Next, you should adapt the stops for the two parts of the grid, you can rest them against any object. The main thing is that the connected elements should occupy a stable lateral position, the distance between them should be equal to the height of the knitted reinforcement.

Step 5 At the ends, tie two vertical spacers, you already know the dimensions. When the frame began to more or less resemble the finished product, tie all the other pieces. Don't rush, check all sizes. Even though your blanks are the same length, it doesn't hurt to check the dimensions.

Step 6 According to the same algorithm, you need to connect all the straight sections of the frame on the ground.

Step 7 Lay linings at least five centimeters high at the bottom of the foundation trench, on which the lower bars of the grid will lie. Put the side supports, set the grid in the correct position.

Reinforcement (the frame is installed in the formwork)

Step 8 Remove the dimensions of untied corners and joints, prepare pieces of reinforcement to connect the frame into a single structure. Keep in mind that the overlap of the ends of the reinforcement must be at least fifty bar diameters.

Step 9 Tie the bottom turn, then the vertical posts and the top one to them. Check the reinforcement spacing to all formwork surfaces.

The reinforcement is ready, you can start pouring the foundation with concrete.

Knitting reinforcement with a special device

To make a fixture, you will need several boards about 20 mm thick, the quality of lumber can be arbitrary. It is not difficult to make a template, and it will greatly simplify the work.

Step 1. Cut four boards along the length of the reinforcement, connect them two at a time at the distance of the vertical posts. You should get two identical templates. Make sure that the distance markings between the rails are the same, otherwise there will be no vertical position of the connecting elements.

Step 2 Make two vertical supports, the height of the supports should correspond to the height of the reinforcing mesh. Supports must have lateral corner stops that do not allow them to tip over. All knitting work must be carried out on a flat area. Check the stability of the assembled device, exclude the possibility of it tipping over during the work.

Step 3 Place the legs of the supports on the two knocked down boards, place the two upper boards on the upper shelf of the stops. Fix their position in any way.

You have a layout of the reinforcing mesh, now the work can be done quickly and without outside help. Install the prepared vertical reinforcement struts on the marked places, first temporarily fix their position with nails. Place a rebar on each horizontal metal jumper. This operation should be repeated on all sides of the frame. Check their position again. That's right - take the wire and hook and start knitting. Adaptation is advisable to do if you have many identical sections of the reinforcement mesh.

Video - How to knit reinforcement with a fixture

How to knit reinforced mesh in a trench

Working in a trench is much more difficult because of the cramped conditions. It is necessary to think carefully about the knitting pattern of individual elements, so that you do not have to crawl between the reinforcement bars later. In addition, it will not work to link the grid on your own, you need to work with an assistant.

Step 1. Place stones or bricks at least five centimeters high at the bottom of the trench, they will lift the metal from the ground and allow the concrete to close the reinforcement on all sides. The distance between the stones should be equal to the width of the grid.

In the photo - a latch for the armoframe

Step 2 On the stones you need to put longitudinal bars. Horizontal and vertical rods should already be cut to size, as we have already described how to measure them.

Step 3. Start forming the frame skeleton on one side of the foundation. If you pre-tie horizontal struts to the lying bars, it will be easier to work. The assistant should hold the ends of the bars until they are locked in position.

Step 4 In turn, continue to knit reinforcement, the distance between the spacers should be approximately fifty centimeters.

Step 5 Using the same algorithm, tie the reinforcement on all straight sections of the foundation tape.

Step 6 Check the dimensions and spatial position of the frame, if necessary, correct the position and exclude metal parts from touching the formwork.

Step 7 Now it's time to tackle the corners of the foundation. The picture shows a rather complicated version of knitting in the corners, you can come up with an easier one for yourself. The main thing is that the length of the overlaps is observed. And one more note. In the corners, the foundation works not only for bending, but also for vertical rupture. These efforts hold the vertical bars of building reinforcement, do not forget to install them. As a guarantee, fittings with a larger diameter can be used for these purposes.

You need to know that any welding worsens the physical characteristics of the strength of the reinforcement, this method should be used only in extreme cases.

If you still have to use welding, then do everything possible to put the minimum number of seams in one place, move the step of fixing the horizontal and vertical stops a few centimeters. During welding, accurately maintain the optimal current strength and electrode diameter. The metal in the places where the seam is applied should not overheat.

Rebar welding - photo

And most importantly, only special fittings are suitable for welding, the brands of such fittings are indicated by the letter “C”. By the way, this armature is much more expensive than ordinary.

There are several ways in which you can speed up and facilitate the knitting process, while improving the quality of construction and reducing material consumption.

For spacers, bend the reinforcement in the form of the letter "P". To do this, you can make an elementary machine in a couple of hours, but it will come in handy not only for bending bars. First you need to bend one sample, check its dimensions, and only then, using the sample as a template, prepare all the connections. Such spacers are much easier to knit, they immediately hold the desired size of the structure. Another plus is that the consumption of expensive material is reduced. At first glance, the savings seem insignificant, a maximum of ten centimeters per connection. But if you multiply ten centimeters by the number of pieces and by the price of reinforcement, you get a very “nice” amount.

For spacers, you can use smaller diameter reinforcement and optionally expensive building periodic profile. Even metal rods or wire rod of the appropriate diameter will do.

If you do not have any experience in performing such work, then it is better not to do it yourself. Having an assistant makes the process much easier and safer.

At a price, a reinforced foundation is much more expensive than an ordinary one; use this method of strengthening architectural structures in extreme cases. There are many cheaper ways to increase the load-bearing characteristics of a strip foundation. True, they cannot always be used, it all depends on the features of the bath project, the characteristics of the soil and the landscape.

A few words can be said about preloaded reinforcement. This is a complex method that allows you to significantly improve all the indicators of the strip foundation without increasing the amount of reinforcement. The essence of the method consists in preloading the bars with forces opposite to those that will act on the structure during the operation of the foundation. For example, if the bar will work in tension, then it is pre-compressed, etc.

Video - Reinforcement of shallow monolithic strip foundations

Video - Do-it-yourself foundation reinforcement

Concrete can withstand bending effects well, but cannot cope with bending on its own. To ensure the bearing capacity, do-it-yourself reinforcement of the foundation is performed. To a greater extent, this applies to tape and slab structures. In piles and poles, metal is laid more out of design considerations than real necessity.

Reinforcement rules

Reinforcement of the strip foundation and any other is carried out taking into account the following rules:

- for working reinforcement, rods of a class not lower than A400 are used;

- it is not recommended to use welding to connect the rods, since it weakens the section;

- without fail, it is necessary to tie a metal frame from reinforcement at the corners, welding is not allowed here;

- even for clamps, smooth fittings are not recommended;

- it is necessary to strictly observe the protective layer of concrete, equal to 4 cm, this will protect the metal from corrosion (rust);

- in the manufacture of frames, the rods in the longitudinal direction are connected with an overlap, which is taken equal to at least 20 rod diameters and at least 25 cm;

- with a frequent location of the metal, it is worth controlling the size of the aggregate in concrete: it should not get stuck between the rods.

in strip foundation

Properly prepared reinforcing cage is half the success. It is he who will save the foundation in case of uneven deformations that create bending loads. It is worth considering the issue in more detail using the example of a strip foundation with your own hands.

What reinforcement is needed for the structure

Reinforcement of the strip foundation assumes the presence of three groups of rods:

- workers who fit along the tape;

- transverse horizontal;

- transverse vertical.

Transverse reinforcement under the strip foundation is also called clamps. Its main purpose is to connect the working rods into a single whole. Reinforcement of the strip foundation is carried out in strict accordance with regulatory documents. What reinforcement is needed for the foundation? To give an accurate answer, complex calculations are performed.

In order not to hire professionals, you can get by with a simplified version. The technology of reinforcing a strip foundation for a small house allows you to assign sections constructively. This is due to the fact that the tape perceives relatively small loads and works mainly in compression.

To make a reinforcing frame, use constructive, that is, the minimum allowable, cross-sectional dimensions:

- For working reinforcement - 0.1% of the cross-sectional area of \u200b\u200bthe foundation for the house. However, if the side of the tape is 3 meters or less, the minimum allowable value is assumed to be 10 mm. If the side of the building has a length of more than 3 m, then the diameter of the working reinforcement cannot be less than 12 mm. rods with a cross section of more than 40 mm are not allowed.

- Horizontal clamps cannot be less than one quarter of the workers in diameter. For design reasons, a size of 6 mm is prescribed.

- The diameter of the vertical reinforcement depends on the height of the tape for the foundation of the house. For shallow ones, the dimensions of which are 80 cm or less, rods from 6 mm are suitable.

The rules for reinforcing a strip foundation of a recessed type provide for the use of rods of 8 mm or more.

Scheme of typical sections of reinforcement bars

Scheme of typical sections of reinforcement bars If a brick building is being built, it is worth laying reinforcement with a small margin. This option will give confidence in the reliability of the design.

Rebar knitting

The reinforcement scheme of the strip foundation involves connecting the rods by tying. A bonded frame is more durable than a welded frame. This is due to the fact that the likelihood of burning through the metal increases. But this rule does not apply to factory-made elements. Outside the construction site, it is possible to connect parts without significant loss of strength.

Places for knitting reinforcement

Places for knitting reinforcement It is allowed to reinforce the foundation in straight sections by welding to increase the speed of work. But reinforcing corners is possible only with the use of knitting wire. These sections of the structure are the most critical, so you should not rush.

Before knitting reinforcement for a strip foundation, you need to prepare materials and tools. There are two ways in which metal bonding is performed:

- special hook;

- knitting machine (gun).

The first option is available, but only suitable for small volumes. Laying reinforcement in a strip foundation in this case will take a lot of time. For connection, an annealed wire is used, the diameter of which is 0.8-1.4 mm. The use of other materials is not allowed.

Scheme of knitting reinforcement for a strip foundation

To build your house, you need to show patience and care. It is not worth saving time and money, as this can cause trouble during operation. With the connection of the rods along the length of the problems should not arise. In this case, the process is quite simple, it is only important to observe the minimum amount of overlap.

But how to knit reinforcement for a strip foundation in the corners? There are two types of corner joints: between two perpendicular structures and at the junction of one wall to another.

Both options have several technologies for performing work. For corner walls use the following:

- Hard paw. To perform work, a “foot” is made at the end of each rod at a right angle. In this case, the rod resembles a poker. The length of the foot should be at least 35 diameters, it is better to prescribe more. The bent part of the rod is attached to the corresponding perpendicular section. Thus, it turns out that the outer rods of the frame of one wall are connected to the outer ones of the other wall, and the inner ones are welded to the outer ones.

- With the use of L-shaped clamps. The principle of action is similar to the previous option. But in this case, the foot is not made, but an l-shaped element is taken, the side of which has a length of at least 50 diameters of the working reinforcement. One side is tied to the frame of one wall, and the second to the frame of a perpendicular one. In this case, the inner rods must be connected to the outer ones. The spacing of the clamps should be three-quarters of the height of the basement wall.

- With the use of U-shaped clamps. At the corner you need two elements, the length of the sides of which will be 50 diameters of the reinforcement. Each of their clamps is welded to two parallel rods and to one perpendicular rod.

How to properly reinforce a strip foundation at obtuse corners. To do this, the outer rod is bent to the desired degree value and an additional one is attached to it as a reinforcement. The inner elements are bound to the outer.

Scheme of correct and incorrect reinforcement of obtuse corners

Scheme of correct and incorrect reinforcement of obtuse corners To lay the reinforcement at the junction of one wall to another, they use approximately the same methods as in the previous case:

- overlap;

- L-shaped clamps;

- U-shaped clamps.

The value of overlaps and joints is taken equal to 50 diameters. When performing work, it is worth remembering the most common mistakes:

- binding at right angles;

- lack of communication between external and internal elements;

- longitudinal rods are connected by viscous crosshairs.

Do not repeat these mistakes when building your own home.

Using a crochet hook

Before reinforcing the strip foundation, it is worth learning how to use the working tool. A special gun is rarely used for private housing construction; such equipment requires additional costs. It is profitable to invest in a tool only for the fulfillment of orders, and not for the construction of one house.

For this reason, the hook has become the most common knitting tool in private housing construction. It will be easier to use it if you prepare special templates in advance. Such a detail works like a workbench and greatly facilitates the work. Things will go faster. To make a template, wooden bars are required, the width of which is about 30-50 cm, and the length cannot be more than 3 m, since such a workbench is inconvenient to use.

The most common knitting method is crochet.

The most common knitting method is crochet. In a wooden fixture, you need to drill grooves and holes that will repeat the outlines of the rods in the frame. In such holes, pieces of knitting wire 20 cm long are laid out in advance, and then reinforcement rods are fixed.

In order to understand the knitting technology, you can consider examples. During construction, two options will be required: for crosshairs (when the elements are perpendicular to each other) and for overlap joints. In a strip foundation, the second technology is more often needed; when erecting a slab structure, the first one will be the most relevant.

To connect the laid frame into a single whole when overlapping, the hook should be used in this order:

- connections are made in several places along the length of the joint, the location of the wire is appointed so that it is in the recessed part of the reinforcement profile;

- the wire is folded in half and laid under the junction;

- with the help of a hook, a loop is hooked;

- the free end is brought to the instrument and placed on it with a slight bend;

- begin to rotate the hook, twisting the wire;

- carefully remove the instrument.

For one overlapping connection, the procedure is repeated 3-5 times. Connecting elements at once, as is done with cross-connection, is not enough. The knitting of the reinforcement under the strip foundation in this case will be unreliable, since fixing at one point does not prevent the elements from shifting.

For one overlapping connection, the procedure is repeated 3-5 times. Connecting elements at once, as is done with cross-connection, is not enough. The knitting of the reinforcement under the strip foundation in this case will be unreliable, since fixing at one point does not prevent the elements from shifting.

Proper connection of the frame will ensure the reliability, strength and durability of the supporting part of the building.