The main electrical parameter of light-emitting diodes (LED) is their operating current. When we meet the operating voltage in the LED characteristics table, we need to understand that we are talking about the voltage drop across the LED when the operating current flows. That is, the operating current determines the operating voltage of the LED. Therefore, only a current stabilizer for LEDs can ensure their reliable operation.

Purpose and principle of operation

Stabilizers should provide a constant operating current of the LEDs when the power supply has problems with voltage deviation from the norm (you will be interested to know). A stable operating current is primarily needed to protect the LED from overheating. After all, if the maximum allowable current is exceeded, the LEDs fail. Also, the stability of the operating current ensures the constancy of the luminous flux of the device, for example, when batteries are discharged or voltage fluctuations in the supply network.

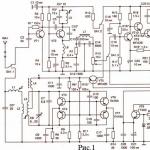

Current stabilizers for LEDs have different types of performance, and the abundance of design options pleases the eye. The figure shows the three most popular semiconductor stabilizer circuits.

- Scheme a) - Parametric stabilizer. In this circuit, the zener diode sets a constant voltage at the base of the transistor, which is connected according to the emitter follower circuit. Due to the stability of the voltage at the base of the transistor, the voltage across the resistor R is also constant. By virtue of Ohm's law, the current through the resistor also does not change. Since the resistor current is equal to the emitter current, the emitter and collector currents of the transistor are stable. By including a load in the collector circuit, we get a stabilized current.

- Scheme b). In the circuit, the voltage across the resistor R is stabilized as follows. As the voltage drop across R increases, the first transistor opens more. This leads to a decrease in the base current of the second transistor. The second transistor closes a little and the voltage across R stabilizes.

- Scheme c). In the third scheme, the stabilization current is determined by the initial current of the field-effect transistor. It is independent of the voltage applied between drain and source.

In circuits a) and b), the stabilization current is determined by the value of the resistor R. Using a subscript instead of a constant resistor, you can adjust the output current of the stabilizers.

Electronic component manufacturers produce a variety of LED regulator ICs. Therefore, at present, integrated stabilizers are more often used in industrial products and in amateur radio designs. You can read about all the possible ways to connect LEDs.

Overview of famous models

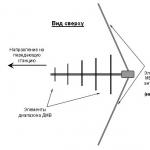

Most microcircuits for powering LEDs are made in the form of pulse voltage converters. Converters in which the role of an electrical energy storage device is performed by an inductor (choke) are called boosters. In boosters, voltage conversion occurs due to the phenomenon of self-induction. One of the typical booster circuits is shown in the figure.

The current stabilizer circuit works as follows. The transistor key located inside the microcircuit periodically closes the inductor to a common wire. At the moment of opening the key, an EMF of self-induction occurs in the inductor, which is rectified by a diode. It is characteristic that the EMF of self-induction can significantly exceed the voltage of the power source.

As can be seen from the diagram, for the manufacture of a booster on the TPS61160 manufactured by Texas Instruments, very few components are required. The main attachments are the inductor L1, the Schottky diode D1, which rectifies the pulsed voltage at the output of the converter, and Rset.

The resistor has two functions. Firstly, the resistor limits the current flowing through the LEDs, and secondly, the resistor serves as a feedback element (a kind of sensor). The measuring voltage is removed from it, and the internal circuits of the chip stabilize the current flowing through the LED at a given level. By changing the value of the resistor, you can change the current of the LEDs.

The converter on the TPS61160 operates at a frequency of 1.2 MHz, the maximum output current can be 1.2 A. Using a microcircuit, you can power up to ten LEDs connected in series. The brightness of the LEDs can be changed by applying a variable duty cycle PWM signal to the "brightness control" input. The efficiency of the above scheme is about 80%.

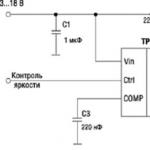

It should be noted that boosters are usually used when the LED voltage is higher than the power supply voltage. In cases where it is required to lower the voltage, linear stabilizers are more often used. A whole line of such MAX16xxx stabilizers is offered by MAXIM. A typical switching circuit and the internal structure of such microcircuits are shown in the figure.

As can be seen from the block diagram, the LED current is stabilized by a P-channel field-effect transistor. The error voltage is removed from the resistor R sens and fed to the field control circuit. Since the field effect transistor operates in a linear mode, the efficiency of such circuits is noticeably lower than that of pulse converter circuits.

The MAX16xxx line of chips are often used in automotive applications. The maximum input voltage of the chips is 40 V, the output current is 350 mA. They, like switching regulators, allow PWM dimming.

Stabilizer on LM317

As a current stabilizer for LEDs, you can use not only specialized microcircuits. The LM317 circuit is very popular with radio amateurs.

The LM317 is a classic linear voltage regulator with many analogues. In our country, this chip is known as KR142EN12A. A typical circuit for switching on the LM317 as a voltage regulator is shown in the figure.

To turn this circuit into a current stabilizer, it is enough to exclude the resistor R1 from the circuit. Turning on the LM317 as a linear current regulator is as follows.

It is quite easy to calculate this stabilizer. It is enough to calculate the value of the resistor R1 by substituting the current value into the following formula:

The power dissipated in the resistor is:

Adjustable stabilizer

The previous circuit is easy to turn into an adjustable stabilizer. To do this, you need to replace the constant resistor R1 with a potentiometer. The schema will look like this:

How to make a do-it-yourself LED stabilizer

In all the given schemes of stabilizers, the minimum number of parts is used. Therefore, even a novice radio amateur who has mastered the skills of working with a soldering iron can independently assemble such structures. The designs on the LM317 are especially simple. You don't even need to design a printed circuit board to make them. It is enough to solder a suitable resistor between the reference pin of the microcircuit and its output.

Also, two flexible conductors must be soldered to the input and output of the microcircuit and the design will be ready. If it is supposed to power a powerful LED using a current stabilizer on the LM317, the microcircuit must be equipped with a radiator that will ensure heat dissipation. As a radiator, you can use a small aluminum plate with an area of 15-20 square centimeters.

When making booster designs, filter coils of various power supplies can be used as chokes. For example, ferrite rings from computer power supplies are well suited for these purposes, on which several tens of turns of enameled wire with a diameter of 0.3 mm should be wound.

What kind of stabilizer to use in a car

Now motorists are often engaged in upgrading the lighting equipment of their cars, using LEDs or LED strips for this purpose (read,). It is known that the voltage of the vehicle's on-board network can vary greatly depending on the operating mode of the engine and generator. Therefore, in the case of a car, it is especially important to use not a 12-volt stabilizer, but one designed for a specific type of LED.

For a car, designs based on LM317 can be advised. You can also use one of the modifications of the linear stabilizer on two transistors, in which a powerful N-channel field-effect transistor is used as a power element. Below are options for such schemes, including the scheme.

Conclusion

Summing up, we can say that for reliable operation of LED structures, they must be powered by current stabilizers. Many stabilizer circuits are simple and affordable for DIY. We hope that the information provided in the material will be useful to everyone who is interested in this topic.

CONVERTER FOR LED

Incandescent lamps have been replaced by LEDs, which in many cases successfully replace them. But due to the non-linear current-voltage characteristic, various voltage converters are used to power the lighting LEDs from the battery. As you know, the LED is powered by a voltage of at least 2 V, and depending on the type, up to 3.5 V. In addition, at least the simplest current stabilizer is needed, because in the process of reducing the battery capacity, the brightness of the LED also drops. Therefore, a simple power supply resistor, from a battery with an increased voltage, will work worse than a converter. Below are diagrams of simple converters that are available for assembly even for beginners.

The circuit is powered by a single finger battery and is a blocking generator. High voltage pulses appear on the collector, are rectified by the Schottky diode and charge the capacitor. Transformer T1 is wound by hand on a ring core. For this, a K10x6x4 ferrite ring is taken and two windings of 20 turns each are wound with a PEL 0.3 wire. In general, the number of turns can be 6:10, and 10:10, and 10:15. For the best efficiency and brightness, they must be selected experimentally. For the frame, everything that is is used.

The circuit uses a low dropout transistor for maximum efficiency. The output current can be adjusted by resistor R1.

Next, we see a somewhat complicated scheme with more stable generation. Current consumption 15 mA. The voltage converter is also made according to the scheme of a single-cycle generator with inductive feedback on a transistor and a transformer. The winding data is the same.

The next upgrade of this converter was a circuit from a Chinese LED lantern:

Here and in other circuits, a Schottky diode with a small voltage drop is used as a diode (after all, every half volt counts). Diodes IN5817, 1GWJ43, 1SS319, or in extreme cases the Soviet D311 are used. These diodes can be taken from the power controller board of a non-working lithium-ion battery from a mobile phone.The following converter circuits are made on two transistors and are distinguished by an increased output current - up to 25 mA. A properly assembled converter does not need to be adjusted if the transformer windings are not reversed, otherwise swap them.

The transformer is similar, but the number of turns in the windings is 40 each. Transistors cost C2458 and C3279. Thanks to the feedback on the C2458 transistor, a simple stabilization of the current and, accordingly, the brightness of the LED is obtained.

Another version of the converter on two transistors:

There is no need to wind the transformer here, since a ready-made choke of 300 - 1000 μH is used.

The last converter circuit was also drawn from a Chinese LED lantern and works great when assembled.

The first power-up of a properly assembled device must be carried out in the test mode, in which battery power is supplied through a 10 Ohm resistor so that the transistors do not burn out if the transformer leads are connected incorrectly. If the LED does not light, it is necessary to swap the primary or secondary terminals of the transformer. If this does not help, check the serviceability of all elements and installation.

From personal experience, I can notice that in all the above schemes, domestic transistors KT315 - KT3102 are often successfully launched. The number of transformer windings should be selected according to the maximum brightness and efficiency. Ready-made "everything that came to hand" from various equipment was used as chokes. It is not recommended to install the cheapest (0.1 W) 5mm LEDs. It is better to pay extra and purchase a 10-mm LED for 0.5 ye. The brightness will increase significantly. Even better results will be after installing special

I've been eyeing these chips for a long time. I solder stuff very often. I decided to take them for creativity. These chips were bought last year. But they never got around to putting them into practice. But not so long ago, my mother gave me her offline flashlight to fix. He trained on it.

There were 10 microcircuits in the order, 10 came.

Paid on November 17, received on December 19. Came in a standard pimply bag. There is another bag inside. Went without a track. I was surprised when I found them in the mailbox. I didn't even have to go to the post office.

Didn't expect them to be so small.

Chips ordered for other purposes. I will not share my plans. I hope that I will find time to bring them to life (plans). In the meantime, a slightly different story, close to life.

My mom, while shopping, saw a flashlight with a good discount. What she liked more flashlight or discount, history is silent. This flashlight soon became my headache as well. She used it for less than six months. Six months of problems, then one thing, then another. I bought her three other pieces to replace this one. But it still had to be done.

Although the flashlight is inexpensive, it has a number of significant advantages: it lies comfortably in the hand, bright enough and the button is in the usual place, the aluminum case.

Well, now about the shortcomings.

The flashlight is powered by four AAA finger-type elements.

I installed all four batteries. I measured the current consumption - more than 1A! The scheme is simple. Batteries, button, 1.0 ohm limiting resistor, LED. Everything is sequential. The current is only limited by 1.0 ohm resistance and the internal resistance of the batteries.

Here is what we end up with.

It is strange that the nameless LED turned out to be alive.

The first thing I did was to make a dummy out of an old battery.

Now it will be powered by 4.5V, like all Chinese lanterns for the most part.

And most importantly, instead of resistance, I will put the AMC7135 driver.

Here is the standard connection diagram.

This chip requires a minimum of strapping. Of the additional components, it is desirable to install a pair of ceramic capacitors so that there is no self-excitation of the microcircuit, especially if long wires go to the LED. The datasheet has all the information you need. There are no long wires in the flashlight, so I didn’t put any capacitors in reality, although I marked them in the diagram. Here is my scheme, reworked for specific tasks.

In this circuit, a large current will no longer flow through the switch button in principle. Only the control current flows through the button and that's it. One less problem.

I also touched the button and greased it just in case.

Instead of resistance, there is now a microcircuit with a stabilization current of 360mA.

Put everything back together and measured the current. I connected both batteries and accumulators, the picture does not change. The stabilization current does not change.

On the left is the voltage on the LED, on the right is the current flowing through it.

What did I achieve as a result of all the alterations?

1. The brightness of the flashlight practically does not change during operation.

2. Unloaded the button on / off the lamp. Now a tiny current flows through it. Damage to contacts due to high current is excluded.

3. Protected the LED from degradation due to the large flowing current (if with new batteries).

Here, in general, and all.

How to properly dispose of the information from my review, everyone decides for himself. I can guarantee the veracity of my measurements. If you have any questions about this review, please feel free to ask. With the rest - throw in a personal, I will definitely answer.

That's all!

Good luck!

And I would also like to draw attention to the fact that my flashlight has a switch on the plus side. Many Chinese lanterns have a switch on the minus, and this will be a different scheme!

I plan to buy +60 Add to favorites Liked the review +58 +118All LEDs, regardless of form factor and electrical parameters, are powered by current. Correctly set current is a guarantee of long-term and stable operation of the lighting device. So why do LED manufacturers often install a voltage stabilizer instead of a current stabilizer? How does this affect the operation of LED lamps, ribbons, lanterns and spotlights? Let's try to figure it out.

Surge Protectors

Based on the name, these devices are designed to maintain the voltage in the load at a certain level. In this case, the magnitude of the output current depends on the load itself. In other words, how much load is needed, how much it will take, but not more than the maximum possible value. Suppose the voltage stabilizer has the following output parameters: 12V and 1 A. That is, 12V will always be maintained at the output, and the current consumption can be in the range from zero to one ampere. There are two types of voltage regulators: linear and switching.

As a rule, the regulating element in the stabilizer circuit is a bipolar or field-effect transistor. If this transistor operates in active mode, then the stabilizer is called linear. If the regulating transistor operates in the key mode, then the stabilizer is called pulsed.

The most common and inexpensive are linear voltage regulators, but they have a number of disadvantages:

- low efficiency;

- at high current loads need a heat sink;

- have a fairly high voltage drop.

In order not to face such shortcomings, it is recommended to use pulse-type voltage stabilizers. They come in three types: step-up, step-down and universal. Switching stabilizers have a high efficiency, do not need additional heat removal at high load currents, but have a higher cost.

Current stabilizers

The simplest current limiter is a resistor. It is often called the simplest stabilizer, which is not true, since the resistor is not able to stabilize the current when the voltage fluctuates at its input.

The use of a resistor in the LED power circuit is permissible only with a stabilized input voltage. Otherwise, all voltage surges are transmitted to the load and negatively affect the operation of the LED. The effectiveness of resistive current limiters is very low, since all the energy they consume is dissipated in the form of heat.

Slightly higher efficiency for designs based on ready-made integrated circuits (IM) of linear stabilizers. IM-based linear stabilizer circuits are distinguished by a minimal set of elements, the absence of interference and simple setup.

To avoid overheating of the regulating element, the difference between the input and output voltage should be small, but sufficient (3-5 volts). Otherwise, the microcircuit housing will be forced to dissipate unclaimed energy, thereby reducing efficiency.

Drivers for LEDs based on ready-made IM linear stabilizers are distinguished by the low cost and availability of elements for DIY assembly.

The most effective current drivers are considered to be pulse-width modulated (PWM). They are designed on the basis of specialized microcircuits with a feedback circuit and protection elements, which several times increases the reliability of the entire device. The presence of a pulse transformer in them leads to an increase in the cost of the circuit, but is justified by high efficiency and service life. Current PWM stabilizers powered by a 12V source are easy to do with your own hands using a specialized microcircuit. For example, the PT4115 IC from PowTech, which is designed specifically for power supply circuits for LEDs with power from 1 to 10 watts.

LED Power Options

For LEDs, in addition to the rated current, there is another important parameter - the forward voltage drop. The role of this parameter is also significant, which is why it is indicated in the first row of technical parameters of a semiconductor device.

In order for current to start flowing through the p-n junction, some minimum forward voltage Umin.pr. must be applied to it. The value of the minimum forward voltage is indicated in the LED documentation and is reflected in the current-voltage characteristics (CVC) graph.

On the green section of the CVC of the LED, it can be seen that only when Umin.pr. current I starts to flow. A further slight increase in Upr leads to a sharp increase in Ipr. That is why even small voltage drops above Umax..pr. detrimental to the LED crystal. At the moment of exceeding Umax.pr. the current reaches its peak and the crystal is destroyed. For each type of LED, there is a rated current and a corresponding voltage (passport data) at which the device must work out the declared service life.

Correct and incorrect inclusion

Motorists make the most mistakes when they try to save on the power supply scheme for LED lighting. Often, motorists turn on LED devices directly from the battery, and then complain about various problems: blinking, loss of brightness, and complete extinction of the crystal. All this is due to the lack of an intermediate converter, which must compensate for voltage drops in the range from 10 to 14.5V. Another mistake of car owners is to connect only through a resistor designed for an average reading of a 12V battery. The resistor is a linear element, which means that the current through it increases in proportion to the voltage. Connection through a resistor is allowed provided that it is calculated at 14.5V, but then you will have to put up with the incomplete light output of the LEDs at low and medium voltages in the on-board network. Therefore, the unambiguous correct way to connect LEDs in a car is to use a current stabilizer, preferably a pulse type.

In various lighting designs based on LEDs, voltage stabilizers are often used. Why is this happening? First, they are much cheaper than quality current drivers. Secondly, in order to get a more or less reliable driver from a voltage stabilizer, it is enough to install a resistor at the output, correctly calculating its power and resistance. Such a circuit solution is often used in low-cost LED lamps and lighting structures using LED strips.

Most LED strips are powered by a stable voltage of 12V. If we consider the design of the tape in more detail, we can see that it is divided into small sections. As a rule, each section consists of three SMD LEDs and one current-setting resistor. The voltage drop across one light-emitting element averages 2.5-3.5 V, that is, a maximum of 10.5 V in total. The remainder is quenched by a resistor, the value of which the manufacturer selects for the type of LEDs used. Therefore, connecting an LED through a bundle of a voltage regulator and a resistor can be considered correct.

The output power of the stabilizer should be more than the power consumption of the load by about 30%.

If you use a simple power supply without stabilization (transformer, diode bridge and capacitor), then with a slight increase in mains voltage, its proportionally reduced part will be evenly distributed on all four elements of each section of the tape. As a result, the current, the temperature of the crystal will increase and, as a result, the irreversible process of degradation of the LEDs will begin.

The most correct circuit solution is the use of a pulse-type current stabilizer. To date, this is the best option, which is used by all leading manufacturers of LED products. The current driver with a PWM controller is practically not heated, efficient and reliable.

So what do you prefer: a cheap voltage regulator with a resistor or a more expensive current driver? The correct answer is hidden in the expression: "Any savings must be justified." If you need to connect a dozen low-current LEDs or no more than one meter of tape, then choosing the first option cannot be called a mistake.

But if your goal is to power proprietary LEDs with a power of each crystal of more than 1 W, then you cannot do without a high-quality current driver. Because the cost of such emitting diodes is much higher than the price of the driver.

Read also

Almost all motorists are familiar with such a problem as the rapid failure of LED lamps. Which are often placed in side lights, daytime running lights (DRLs) or other lights.

As a rule, these LED lamps have low power and current consumption. What exactly is the reason for their choice.

By itself, the LED easily serves in optimal conditions for more than 50,000 hours, but in a car, especially in a domestic one, it is sometimes not enough for a month. First, the LED starts to flicker, and then it burns out altogether.

What explains this?

The lamp manufacturer writes the marking "12V". This is the optimal voltage at which the LEDs in the lamp operate almost at maximum. And if you apply 12 V to this lamp, then it will last at maximum brightness for a very long time.So why does it burn out in the car? Initially, the voltage of the car's on-board network is 12.6 V. An overestimation of 12 is already visible. And the voltage of the network of a running car can reach up to 14.5 V. Add to all this various jumps from switching powerful high-beam or low-beam lamps, powerful voltage pulses and magnetic interference when starting the engine from the starter. And we get not the best network for powering LEDs, which, unlike incandescent lamps, are very sensitive to all drops.

Since often in simple Chinese lamps there are no limiting elements, except for a resistor, the lamp fails due to overvoltage.

During my practice, I have changed dozens of such lamps. Most of them did not serve even a year. In the end, I got tired and decided to look for a simpler way out.

A simple voltage regulator for LEDs

To ensure comfortable operation for LEDs, I decided to make a simple stabilizer. Absolutely not difficult, any motorist can repeat it.All we need:

- - a piece of textolite for the board,

Stabilizer circuit

The circuit is taken from the datasheet for the L7805 chip.

It's simple - on the left is the entrance, on the right is the exit. Such a stabilizer can withstand up to 1.5 A of load, provided that it is installed on a radiator. Naturally, for small bulbs, no radiator is needed.

Assembling a stabilizer for LEDs

All that is needed is to cut out the desired piece from the textolite. There is no need to etch the tracks - I cut out simple lines with a regular screwdriver.Solder all the elements and you're done. Does not need setting.

In the role of the body is a thermal blower.

Another advantage of the scheme is that it is fashionable to use the body of a car as a radiator, since the central terminal of the microcircuit housing is connected to a minus.

That's all, the LEDs no longer burn out. I have been driving for more than a year and forgot about this problem, which I advise you too.