Today, in the construction markets, you can find a lot of all kinds of tools, and therefore, it is sometimes very difficult to choose the right device for a particular type of work. Particularly necessary power tools, without which it is extremely difficult to do when making holes, niches and openings, are hammer drills and impact drills. Often people do not distinguish them, but they have differences, both in the design of the product itself and in the specifics of working with them.

The main purpose of the tools

The main difference between an impact drill and a hammer drill is their functional purpose:

- for an impact drill, this is drilling of materials that are characterized by low density(wood, plastic, soft metals, etc.). In addition, the percussion functions of the drill allow you to drill even concrete and brick. For conventional models, the working effect produced largely depends on the pressure force of the master. Therefore, to obtain optimal and acceptable impact energy, the pressing force should reach 10-15 kg;

- for a perforator - this is chiselling. The percussion function was built into the puncher from the very beginning, as well as drilling. In this case, it is not recommended to apply pressure to the punch, as this can lead to breakage of the tool. The maximum pressure limit must be no more than 5 kg.

Depending on the general functions, a fairly wide range of work can be performed with a hammer drill compared to the functionality of an impact drill:

- chopping work and driving in rods;

- chipping of concrete walls;

- drilling surfaces of various nature, including wood, concrete and steel;

- chipping, chipping bricks, knocking down tiles, removing plaster and making holes;

- driving bolts, screws or self-tapping screws

Distinctive characteristics

Like any other construction tool, an impact drill and hammer drill have a number of distinctive features:

- Impact mechanism

Tools have a different scheme of the impact mechanism:

- The perforator has an electro-pneumatic and electro-mechanical unit of the percussion mechanism. It generates impact force and provides the most efficient performance parameters of this type of construction tool. In the electromechanical type, two coils cause the core to move under the influence of electromagnetic influence. The pneumatic mechanism involves the transfer of working energy through a rotating rotor that drives the piston. Due to the reciprocating amplitude of the drill, the perforator does not require additional physical exertion or effort, unlike an impact drill;

- the drill has a more simplified design of the percussion mechanism. Often it consists of two ratchets that are connected to a rotating chuck and tool body.

The existing differences in the design of the impact mechanisms of the drill and hammer determine their different technical and operational standards.

- Operating modes (or functionality)

Modern types of hammer drills are significantly ahead of the drill, since they have full-fledged three modes of operation:

- single-mode or drilling - in the operation of the device only rotations are used without the use of shocks;

- three-mode - strikes without rotation (they are also called work in the jackhammer mode);

- dual-mode (rotation with impacts) - drill in combination with impacts.

Thanks to these three modes, the hammer drill can be used not only for drilling, but also for other types of work - chipping off excess material, gouging strobes or niches in stone walls.

The drill will not be able to provide a high level of speed, because its shock function is just one of the additions to the main

Drills have only two modes and are presented in several varieties:

- Due to its versatility and with additional tools, an impact drill can perform the functions of a mixer, grinder, puncher and screwdriver. Ordinary ones allow you to drill holes in wood and metal products. They also have a subspecies called "angle drills" - they make holes in hard-to-reach places;

- mixer drills - have an elongated additional handle and high torque. Used to prepare a variety of building mixtures;

- percussion - in their design they can combine the functions of drilling and impact. With their help, you can drill brick and concrete;

- drill drivers - in addition to their main function, they can wrap or unscrew screws.

- Total weight of the power tool

Depending on the weight, hammer drills are classified as:

- light - the weight of the structure reaches 2-4 kg;

- medium - within 5kg;

- heavy - weight exceeds 5 kg.

The average weight of an impact drill can range from 1kg to 4kg.

- Equipment

A hammer drill and an impact drill differ in the number of parts used and how they are attached:

- for drilling in an impact drill, drills with a victorious surfacing are most often used. Ratchets are the most vulnerable part of the tool. Therefore, when choosing a drill, it should be borne in mind that under heavy loads and severe vibration, they wear out very quickly;

- in perforators, in addition to drills, drills are also used, which are fixed in cartridges using a special system of clamps and grooves of a special shape

Having a certain degree of freedom in the movements of the drills in the chuck, the impact load is significantly reduced in the perforator.

The possibility of using small or large drills when working depends on the diameter of the cartridges.

Unlike an impact drill, a hammer drill has a special adapter that allows you to change cartridges if necessary.

Another positive point when choosing a hammer drill is the impact of a lower level of vibration on the hands of the master due to the softening air cushion located in the pneumatic percussion mechanism.

- Performance

Determined by the impact energy value. In a hammer drill, it ranges from 1.5-20J and is always an order of magnitude higher than that of an impact drill. This largely depends on the mass of the device and the pressure force of the master. The technical characteristics of perforators may also indicate the frequency of strokes per minute: from 4 to 4.5 thousand strokes in more powerful models and 2-3 thousand in less powerful ones.

- Price

Given the same power of tools, a hammer drill is always much more expensive compared to the price of an impact drill. However, we should not forget that the hammer drill belongs to the category of professional tools, so its cost fully justifies itself - drilling speed and durability in operation.

Remember that when working with a hammer drill, you need to apply three times less effort than when using an impact drill.

Tool Selection Criteria

When choosing a power tool, you should pay attention to the following criteria:

- Power - the higher the power level, the more comfortable it is to use the tool in work.

- Rotation speed adjustable.

- Equipped with additional nozzles.

- The number of revolutions at idle (rotation speed).

- Volume of speeds (one, two, three, etc.).

- The presence of the possibility of movement (rotation) in both directions (reverse movement). In some cases, this helps to remove a stuck drill.

- Ability to create holes of different diameters in different building materials.

What to choose?

Hammer drill and impact drill can perform each other's functions. However, replacing a hammer drill with a drill can lead to its rapid wear.

The choice of tool directly depends on the material with which it will be necessary to work: In such a matter, it is better to proceed from the purposes for which the construction tool is purchased. If you need to do housework around the house, a functional drill will suffice. For long, constant and voluminous work, it is better to use a puncher.

- if the work involves the processing of concrete structures or objects from similar materials, then it would be preferable to choose a perforator;

- the drill is suitable when working with wood or steel products.

And in the office, it is important to purchase the right set of power tools. An electrician has to do construction work, such as: chasing walls for cables, drilling through holes for laying a line, holes for installing sockets, switches, etc. All these works are united by the need to make a selection of the material from which the walls, floor or ceiling are made. To do this, use drills with a percussion mechanism or perforators. Let's see how they differ and which is better to choose: an impact drill or a hammer drill?

Hammer drill

It differs from the usual built-in mechanism for making translational movements - strikes. Their cartridges are similar in design, look and work the same. To hold the working equipment, drills, for example, three-jaw chucks are used. This design shifts the cams towards each other during rotation of the outer holder of the chuck, with the help of which the drill is clamped.

The picture below shows the internal structure of the tool:

There are two modes for operation:

- drilling.

- Impact drilling.

The impact mechanism is implemented using a ratchet from a movable and stationary ring with teeth on one side. This mechanism does not involve longitudinal movement over a long distance - the amplitude of the movement of the drill is within a couple of millimeters, and its energy depends on the pressing force of the impact drill against the wall and is within units of Joules (J). That is, it rather does not hit, but vibrates into the material being processed.

Perforator

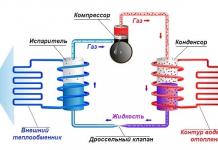

The main difference between a hammer drill and an impact drill is the design of the impact mechanism. It can be electromechanical and electropneumatic. The latter is found in most models of the modern market.

The principle of operation is as follows: the electric motor rotates the gear of the gearbox, on the output shaft of which a swinging or, as it is also called, drunken bearing (1) is fixed. It drives the piston along the cylinder. As a result, the piston interacts with the ram (2), which hits the striker (3), transferring energy to the equipment installed in the SDS cartridge (4). In this way, greater energy and depth of impact is achieved.

Interesting: with a similar power, the impact energy of a perforator is 2 or more times higher than the impact energy of an impact drill, which is more suitable for concrete.

The second difference between a hammer drill and a drill with a percussion mechanism is the way the drills are attached to the chuck. If in the previous version cam chucks were used, here SDS chucks are used. You cannot install an ordinary drill in them - only special drills with an appropriate shank. There should be 4 slots in it, which in pairs have different diameters, they are needed to hold the snap.

To install conventional drills in an SDS chuck, you can install an adapter on a cam chuck, but in this case it will not be possible to achieve high quality drilling due to runout.

It is also worth noting that there are two types of shanks and cartridges:

What is the difference

To sum up, to understand what is better than a hammer drill or hammer drill, let's compare the general characteristics. We assume that the power is the same. Then the rotary hammer will have about 800-1000 rpm, and the drill will have 2500-3000 rpm, the torque differs similarly.

Typical impact energy depending on the model within:

- Impact drill - small, determined by pressing against the wall. The amplitude of the longitudinal movement of the drill is also small.

- Perforator - 0.5-27 J.

Tooling:

- Impact drill - for crowns and drills of various configurations with a cylindrical shank.

- Perforator - drills, chisels, crowns with an SDS shank. When installing an adapter on a cam chuck, it is possible to install any equipment from drills and screwdrivers.

Operating modes:

- Impact drill - drilling without impact and drilling with impact.

- Perforator - drilling, drilling with a blow, only blows.

The cost of devices of the same power at the time of writing:

- The cheapest hammer drill on Yandex.Market is 800 rubles, 400 watts.

- The cheapest puncher - 1839 rubles, 400 W, 1.5 J.

What is better to buy and where to apply

We have considered the general structure of these tools, now let's move on to work in everyday life. For example, we have compiled a selection of tasks that are encountered by an electrician and an ordinary builder.

- and distribution boxes. This procedure is performed using a crown. Different crowns are used for wood, brick and concrete. For concrete, tooling with victorious soldering or diamond coating is used. It is performed without impact, so both a conventional and impact drill or hammer drill will do.

- Drilling blind holes in hard materials. When drilling concrete and brick, you need a blow, both versions of the tool are suitable, and for through ones - only a puncher.

- - performed with a puncher with a chisel or a wall chaser. The hammer in this case is switched on in the "only blows" mode.

- Chiseling niches under the shields - only a perforator.

If you look at a number of tasks that both of these tools solve, you can come to the conclusion that it is better to take both. For a home to drill a hole in the wall a couple of times a year and hang a picture, for example, it is worth choosing a good impact drill rather than a bad hammer drill. For repairs with a limited budget, a rotary hammer will be a more versatile solution. It is not entirely objective to talk about “what is better ...”, because these are different tools, although they are used for similar tasks.

We hope the material provided has helped you decide what is best for you: an impact drill or a hammer drill. If you have any questions, ask them in the comments below the article!

materials

People far from construction believe that a drill and a hammer drill are tools designed for drilling holes that can easily replace each other. However, each of them has its own unique features that allow you to perform operations that are not available to the other. What are their differences? What is more useful at home?

The difference between these tools lies in their main function: a drill is used for drilling, and a hammer drill hammers a work surface to make a hole in it.

To understand the other differences, we need to look at both of these devices in more detail.

Impact drill device

This tool has a less complex percussion mechanism than a perforator, consisting of a pair of ratchets. One of the parts is connected to the tool body, the other - to the cartridge. If it is necessary to turn off the impact mechanism, the stopper is activated, preventing the contact of the ratchet. When the hammer function is on, the stopper moves so as not to interfere with the ratchets. Contacting, they set the chuck with a drill in motion.

Impact drill device

Even a person without special building skills can handle a drill. For domestic use, most home repair work and in the absence of the need to make many holes in hard materials, a drill is more suitable, since it has a wide range of applications and is much cheaper than a hammer drill. The cost of consumables for it also differs downwards.

This tool is used in cases where you need to drill holes of various diameters and exact sizes in various materials (wood, metal, plastic, and others). An impact drill can punch concrete, but the process will take longer than when working with a hammer drill.

Impact drill functions

Thanks to a variety of drills, it is possible to make holes in various materials:

- for drilling wood, they take drills for metal or wood, in some cases, feather drills;

- if necessary, make a hole in the metal, use durable drills of a special design;

- spear-shaped, designed to work with glass and ceramics, help to drill neat holes in tiles without damaging them;

- crowned ones help in cases where it is required to make holes of large diameter;

- drills with a pobedit tip allow you to work with hard materials (brick and concrete).

hammer drill

hammer drill In addition to the usual, you can use additional nozzles. They allow you to significantly expand the functionality of the device.

With the help of a nozzle from a grinding wheel, you can quickly and accurately grind the surface. The steel wire brush attachment will help clean any metal surface. For roughing, a twisted wire nozzle is used, and a better one is performed with a corrugated brush.

If you purchase a special nozzle, then the drill can act as a mixer: it is able to quickly and thoroughly mix the solution.

In addition, a drill with a disabled percussion mechanism replaces a screwdriver. With its help, you can screw and unscrew screws, self-tapping screws or screws, assemble furniture, hang shelves at home and carry out other operations.

Perforator device

The impact mechanism of the perforator can be electropneumatic or electromechanical. The former is more common, since it provides maximum impact force with relatively little power.

There are 2 versions of the electro-pneumatic percussion mechanism: in light devices, an oscillating bearing is used, in heavy or medium ones, a crank mechanism.

When the tool is turned on, the electric motor starts to rotate, the movement is transmitted to the inner sleeve of the oscillating bearing. At this time, the outer sleeve begins to oscillate. The air between the ram and the piston sets the ram in motion, it oscillates in time with the piston, striking the striker.

The striker hits the drill fixed in the chuck.

The advantages of working with a hammer drill are less recoil and faster work.

Punch features

Unlike a drill, a hammer drill can operate in three modes: impact, rotation, and a combination of these actions. Therefore, a hammer drill can be used not only for drilling, but also for wall chasing, creating holes and recesses of the desired size. It is indispensable when performing work on the replacement of wiring at home. An impact drill, even comparable to a hammer drill in terms of power, will not cope with such a load.

Perforator device

Perforator device Perforator can:

- to make holes in solid materials (brick, artificial and natural stone, blocks, concrete). A core drill is used when large diameter holes are required.

- Remove plaster, dismantle brick or tile from the walls. To do this, you need to select a chisel from the nozzles.

- Carry out chasing the walls of the house. Need a pickup.

The disadvantage of the tool is that some operations may require adapters for nozzles - this increases the already considerable weight of the device and makes it less convenient, lengthening the entire structure.

The perforator is a professional tool with a well-thought-out and reliable design. It allows you to perform heavy work at high speed. With self-repair at home, the presence of such a powerful device is most often not required, therefore, for domestic purposes, an impact drill is more often used.

Differences between an impact drill and a hammer drill

Differences between an impact drill and a hammer drill

Differences between an impact drill and a hammer drill Once you've learned the basic properties of both tools, it's easier to understand how one differs from the other.

Main differences:

- Performance. According to this indicator, the hammer drill is many times superior to the impact drill, since the device has a powerful impact force and a greater weight than the drill, which contributes to its increase. If you take 2 devices with the same power, then the hole made with a drill will be 1.5 times smaller than the hole made with a puncher. The difference will be even more noticeable if you choose a crown nozzle instead of a regular drill.

- Drill attachment. The drill has a chuck with a cam clamp, which does not provide a quality fixation of the drill that can prevent it from turning. A new type of cartridge is used to mount the drill in the perforator. It holds the drill better and ensures its free movement. The process of changing the drill takes a few seconds.

- Purpose of the device. The main characteristic of a drill is the amount of torque, while the work of a hammer drill is evaluated by the impact power. Therefore, it is incorrect to compare these tools - they initially have different purposes.

- Processing accuracy. The hammer drill is designed to work with hard materials, and it is undesirable to drill metal or wood with this tool - the result may be of poor quality and, most likely, the hole will not exactly correspond to the intended diameter. If you want to make a thin hole of a certain size, you should choose a drill.

- Life time. In the rotary hammer, the internal parts are protected from shock loads and vibrations during tool operation thanks to the pneumatic mechanism. In addition, the device has a protective sleeve that protects it from breakage if the drill gets stuck in a hole or stumbles upon a reinforcing mesh in concrete.

What to prefer?

The decision which is better - an impact drill or a hammer drill, depends solely on the consumer and the work that he plans to perform with the tool. For working with hard materials and wall chasing, it is more reliable and easier to choose a hammer drill. The drill has a percussion function - not the main one, but an additional one, and its use for these purposes is impractical.

However, most often, home repairs do not require long-term work with concrete, so the drill as a versatile and affordable tool is more popular.

Repair is, first of all, drilling and chiselling of walls and ceilings. Impact drill or hammer drill - which one to choose? After all, it is with the help of these tools, as practice shows, that such work takes place.

The hammer drill, compared to a drill, which is equipped with a percussion function, is much more reliable.

So how does one tool differ from another? By what criteria and principles to choose them, so that later it would not be excruciatingly painful for wasted time, as well as for stupidly spent money? Are there any pitfalls and currents in this case?

What is the difference between a drill and a hammer drill?

Basically, these two tools are very similar to each other, which is often the cause of all sorts of misunderstandings and bewilderment: I wanted, they say, to buy a drill for myself, but I bought it - a hammer drill or vice versa. However, these tools differ from each other, and any self-respecting owner should know about such differences.

First of all, the difference between a hammer drill and an impact drill lies in the sense of their own design and purpose. A drill is drilled, and a puncher is drilled. But then an important question arises: how exactly does drilling differ from drilling?

Is there any difference in these repair actions? There is a difference. If the owner, in order to equip his own home, intends to make all kinds of holes in brick walls, in wooden walls, in some metal structures (that is, in all sorts of more or less soft and pliable surfaces and planes), then for these creative purposes he needs a drill. If the owner wishes to make holes in concrete walls for the same purposes, then a puncher is more useful.

Why exactly? It all depends on the principle of operation of these mechanisms. A drill (its full name is a “drill with a blow”) is able to drill only when the one who drills presses on it - and the harder he presses, the better and faster the hole can be drilled with a drill. And let no one here be confused by the term "strike". Yes, the drill is designed in such a way that in order to make it easier to drill, a blow is applied to the drill (hitting a mechanism called a toothed ratchet). However, this very mechanism strikes with a very small amplitude and force, and therefore there is not much use from it.

And in order to drill a lot, successfully and with impact, the driller needs to make an effort - that is, to press the drill against the surface that he wants to drill. And the more efforts are made here, the harder the work. However, there is also a negative point here. When someone tries to drill holes in hard surfaces with a drill, the ratchet mechanism wears out quickly and has to be changed frequently. In addition, the harder you lean on the drill, the more it vibrates. So, among other things, when working with a drill, you need a fair amount of skill, as well as remarkable physical strength.

Another thing is a perforator. The perforator has a slightly different principle of operation. One might even say - fundamentally excellent. If, as already mentioned, it is necessary to press the drill, then the puncher, on the contrary, does not tolerate any pressure. On the contrary, when working with a perforator, physical effort must be avoided in every possible way.

When applying physical impact on the puncher, it breaks down very quickly. And all - because of the design features of the perforator. And its design is as follows: a mechanism called a free-floating drill is built into the puncher. Another mechanism strikes this mechanism with regular equal force - the striker. These blows are strong enough, and thanks to this, the perforator droops into the surface. That is, a hammer drill is a much more powerful mechanism than a drill. And therefore, with its help, they are drilled (you can also say that holes are hollowed out in all sorts of hard surfaces such as concrete).

This is the difference between an impact drill and a hammer drill. That is, if someone needs to drill holes in more or less pliable surfaces, then a drill will do for these purposes. And if someone has to deal with concrete walls, then you can’t do without a perforator.

It would seem: if the very principle of the drill is clear, then you can choose it, as they say, without straining. However, it only seems so. In fact, choosing an impact drill has its own little secrets.

It is very important when choosing a drill to pay attention to the speed. In particular, the ability to adjust this frequency. Those. how much faster the rotation speed of the drill can be if you press it. And, accordingly, with what force will you have to press it? Otherwise, it may happen that you buy a drill, but you don’t have enough strength to work with it. So why did you buy it then? And then it will be excruciatingly painful for the money spent in vain.

The power of the drill also matters. In general, there is no trick in this case. The more powerful the tool, the more holes can be drilled, and the sooner they can be drilled.

You should pay attention to how comfortable the drill will be in work. Otherwise, it may happen that because of its original design features, it will simply fall out of hand regularly. And then, maybe, it also injures the reckless owner. Therefore, before buying a drill, you must at least hold it in your hands. It would be better, of course, to drill something at the same time, but only - who will allow drilling the walls in the store? However, in some stores for such trial purposes, samples of surfaces of varying degrees of hardness are provided.

When choosing a drill, it is very important to know if a structure called a depth gauge is built into it. There are drills in which such a design is present, there are also drills in which it is absent. The depth gauge is a very important tool. In drills of old designs, if anyone remembers, they had to make special marks on the drills in order to know exactly how deep the hole was drilled. It was very inconvenient. Another thing is the depth gauge. There is no need to measure anything. But simply - he determined the desired depth of the future hole, and the smart unit will drill just such a depth - no more and no less.

What else is important to consider?

When choosing a drill, it is very important to take into account how long the cord is.

If the repair requires frequent drilling of concrete walls, then you will need a powerful hammer drill.

Everything is clear here: the longer the cord, the more convenient it is to work. Therefore, it is recommended to choose a tool not just with a long cord, but so that this cord is also with a fair margin. You never know in what remote place you want to drill a hole?

There are such modern tools that are protected by a special mechanism from overloads. It is clear that such varieties cost a lot of money, but it is much more convenient and safer to work with them than any of its more primitive counterparts. After all, in the heat of creative creation of holes, you can earn money, thereby overloading the mechanism until it completely fails. And then - it will be painfully insulting ... And if there is a safety mechanism, the tool will stop working on its own, feeling overloaded.

It is very important to take into account this moment when choosing. It happens that a drill is equipped with a lot of all sorts of devices, improvements, options and mechanisms, and its price is surprisingly low. This is where you need to be concerned. Because it is well known: than if a thing is extremely “fancy”, and its price is somehow low, then such a fact indicates that this is not a thing, but a fake for a real thing. And when someone manages to buy such a fake, and it fails in the third minute of its operation, it will be painfully insulting for the money spent in vain.

This is what regarding the choice of drill. If we talk about the choice of a perforator, then it is mainly selected according to similar principles.

For everyone who is faced with the repair of an apartment, at some point the question arises, which tool to choose for work - a drill or a puncher? Each of these devices has its own purpose and features of operation, although in appearance they differ little from each other, and an uninitiated person may allow their misuse, leading to accelerated failure.

The drill is designed for drilling holes in not very hard materials such as wood, plastic, hot iron, etc. As a working nozzle, the drill has a drill with a sharpened end and sharp, cutting materials, edges. For drilling holes in brick and concrete, it is supplemented with an auxiliary mode of shock rotation, when a drill with a hard victorious tip is used as a working nozzle, with which it crushes concrete rubble during translational fast movements combined with rotation. The design of the drill is designed for a short period of shock operation.

The hammer drill is specially designed for punching holes in reinforced concrete products and impact drilling is its main mode of operation. All parts of the tool design are designed for long-term operation under shock pressure. As a working nozzle, the perforator uses a drill, which is a hard alloy rod with a heavy-duty tip designed for crushing stones, and a spiral side surface designed to extract destroyed concrete particles from the hole.

Impact mechanism differences

In a perforator, the rotational motion of the electric motor rotor is transferred to the translational motion of the drill using a mechanical or pneumatic percussion mechanism. The second type is more efficient in terms of performance, so it is used in almost all popular tool models.

A crank assembly or ball bearing converts the rotation of the engine rotor into a fast reciprocating movement of a piston in a sealed cylinder. A massive ram repeats the movements of the piston due to compression in the air space between them and hits the back of the striker connected to a rotating spindle, on which a cartridge with a fixed drill is located.

The impact energy return is insignificant due to the large mass of the tool and the small clamping force applied by the worker, as well as the presence of a longitudinal free play of the drill in the chuck. To fasten the drills, special cartridges of the SDS system are used. In addition, the hammer drill is equipped with various mechanisms that ensure safety and ease of use.

Friction or spring-cam clutch ensures the stop of the chuck when the drill is jammed, protecting the worker from sharp kickback and protecting the engine from overloads. Various vibration dampening systems can significantly reduce its level, making the operation of the rotary hammer not only comfortable, but also safe for health. For this, both spring shock absorbers and rubber gaskets - dampers are used.

The impact mechanism of the drill is simpler. It has two ratchets, one of which is fixed and the other rotates with the spindle. In the simple drilling mode, the ratchets are separated by a stopper and do not interact. The stopper is removed in the shock mode and when pressure is applied to the drill, the ratchet is engaged with wedge-shaped teeth. As a result, the spindle with the chuck receives an additional linear movement of several millimeters due to slipping of the wedge-shaped teeth of the ratchet.

This principle of obtaining shock rotation of the drill requires the application of great efforts on the part of the worker, is characterized by high returns, which leads to rapid fatigue. At the same time, prolonged use of this mode leads to the development of ratchet teeth and work efficiency is significantly reduced. Thus, the drill should not be used constantly in impact mode.

Video: What is the difference between a hammer drill and a drill

Tooling differences

Drills use ordinary drills or with a diamond or diamond tip as a tool. Crowns can be used to obtain holes with a large diameter. Perforators are equipped with drills. The clamping chucks of these tools differ dramatically. If self-centering three-jaw chucks (one- or two-sleeve) are used to clamp equipment in drills, then quick-clamping chucks of the SDS type, plus, max or top modifications, depending on the size of the equipment, have been used in rotary hammers.

The tail part of the drills differs from the drills in that it has longitudinal closed and open grooves that provide reliable fixation of the equipment in the chuck with the possibility of longitudinal free play. To install a simple drill in a hammer drill, you need to replace the chuck or use a special adapter that allows you to fix a three-jaw chuck in the SDS clamp. This results in a complex design for fastening the drill, which does not provide good rigidity and centering of the tooling.

Three-jaw drill chucks have a maximum mounting diameter of 12mm, and SDS-plus chucks provide gripping drills with a diameter of up to 16mm, SDS-max - up to 40mm. The maximum length of drills held in drill chucks does not exceed 400mm, while rotary hammer chucks can hold drills up to 1000mm long. A more diverse range of perforator equipment allows you to expand the functionality of the tool.

Differences in operating modes

The drill has two modes of operation - hammerless and impact drilling, the first of which is the main one. It perfectly copes with metal, wood, ceramics, plastic. In the shock mode, it can drill brick, non-reinforced concrete, expanded clay, sand block, foam concrete. The speed of rotation of the drill can be adjusted by pressing the start button, which helps to obtain accurate holes and use the tool as a screwdriver. The reverse mode makes it easier to remove the drill from a deep hole. It is not recommended to drill hard concrete of a grade above 300 or reinforced concrete with a drill.

The rotary hammer has 3 modes of operation - chiselling, drilling and impact drilling. Each of them can equally be used when using the tool for its intended purpose. This allows you to effectively use the hammer drill when punching holes in the wall, chasing, removing old concrete screed or tiles, removing asphalt. It makes it possible to quickly drill holes and niches in reinforced concrete slabs for pipes, junction boxes and other communications.

Video: Hammer drill and impact drill: do they replace each other?

Performance Differences

The performance of the tools can be compared in impact drilling in concrete, where a hammer drill achieves several times greater performance compared to a drill. Such superiority is ensured due to the impact force, the energy of which in perforators reaches values of 1.5-20J, depending on the power of the electric motor. In drills, the impact energy is small and is determined by the force of pressing the tool by the worker. The amplitude of the impact movement of the drill is also small.

In addition, the weight of the rotary hammer significantly exceeds the mass of a drill equipped with an engine of the same power, which increases the impulse of force directed towards the material compared to the response with the same impact energy. As a comparison of efficiency, we can take such an example that with the same engine power, the diameter of a hole made by a perforator is 1.5 times larger than the diameter of a hole drilled by a drill. When using a crown, the difference becomes even greater.

Differences in conditions and service life

Handling a hammer drill is substantially easier for the worker than using a drill, despite its heavy weight. If a drill requires a clamping force of 10-15 kg, then 5 kg is enough for a hammer drill. At the same time, the level of recoil and vibration of the perforator is much lower, which is ensured by the pneumatic system of the percussion mechanism and special anti-vibration devices.

The service life of the drill is significantly reduced due to the rapid wear of the ratchets and the high level of vibration of the parts in the hammer drilling mode. The hammer drill is more durable, despite the intensive work in shock mode and the complex transmission mechanism. However, to ensure a long service life, it requires more careful maintenance, timely cleaning and lubrication of moving parts and mechanisms.