We will send the material to you by e-mail

Cement is one of the most common building materials. It is used both as a component for the preparation of solutions, and as an independent product. It is used as a binding material, which, when interacting with water, forms a plastic mass, and then, upon drying, becomes a hard stone-like. Let's talk about what cement is made of in production.

Cement is the most demanded product used in construction

These products are used equally widely around the globe. Builders in ancient Rome already knew how to make mortars that had hydraulic properties. Today, world developments have stepped far ahead. Mankind has learned to create a product that can harden not only in dry conditions in the air, but also in wet ones.

Today, such countries as China, the USA and India are considered leaders in production. Moreover, China produces several times more products than the other two leaders combined, the pace of construction in the Middle Kingdom is also extremely high. Factories for the production of products are built in close proximity to the points of extraction of raw materials, so that its cost is not affected by the price of delivery of components.

So what is cement made of? Its composition may vary slightly depending on the type. For example, let's take the most popular type of cement - Portland cement, which is most in demand in construction. It consists of:

- calcium oxide (CaO) - minimum 62%;

- silicon dioxide (SiO 2) - at least 20%;

- alumina (Al 2 O 3) - at least 4%;

- iron oxide (Fe 2 O 3) - at least 2%;

- magnesium oxide (MgO) - minimum 1%.

Additionally, additives are added to it. The chemical formula of cement is not defined, since there are different types and brands of the product. For the producer and the consumer, much more important information is provided by indicators of the mineralogical composition.

Stages of production and regulatory documentation

It's time to find out how cement is produced. It should be noted that this production belongs to the category of complex. Technically, it is a process of mixing clinker and gypsum.

The manufacturing process can be divided into two main steps:

- obtaining clinker;

- grinding of the main substance and the introduction of additives.

Cement is obtained in one of the following ways:

- dry;

- wet;

- a combination of both.

The choice of technology directly depends on the quality of raw materials. At all stages of production, the laboratory determines the characteristics of future products, in accordance with established standards. In Russia, the GOST system operates. Each type of cement has its own specifications, which it must comply with. Most of the standards were adopted during the existence of the Soviet Union. Most often used:

- GOST 969-91 (technical specifications for aluminous and high alumina products);

- GOST 10178-85 (technical specifications for Portland cement);

- GOST 30515-97 (general specifications);

- GOST 22266-94 (technical specifications for sulfate-resistant products).

Product Main Features

Specifications are determined according to the brand of products. It is indicated on the packaging in the form of numbers with the letter "M" in front. In fact, the number means compressive strength and is a conditional value.

Let's discuss the main characteristics of the product.

| Characteristic | Description |

|---|---|

| Strength | It is this number that appears in the brand of cement. The test sample is compressed for 28 days, after which the calculation data is recorded in the documentation. Strength is measured in MPa. |

| Dependence of cement on water | The density of the product itself exceeds the density of water, which is why different brands absorb different amounts of liquid. It is very important in the production of cement mortars how much water is required for a certain part of the product. Its excess will make the top layer of the cement structure fragile. |

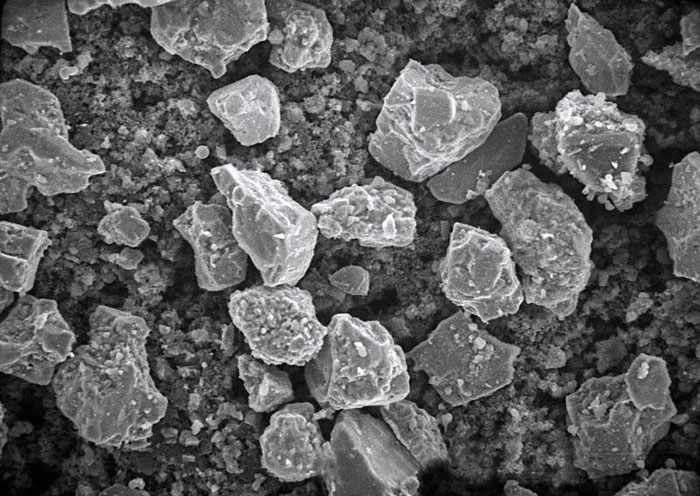

| Fraction of finished products | The finer the grinding of cement particles, the more expensive it will cost. In production, the fineness of grinding is determined by sifting particles through fine sieves, this characteristic is indicated on the packaging. However, it should be taken into account when working that too small particles (40 microns) will require more water when creating a solution. Many manufacturers mix fine and coarse fractions to create the perfect product. |

| Low temperature resistance | Weather conditions in some countries are quite severe. Cement is required to be resistant to repeated freezing and thawing. If the building structure consists only of cement and does not have additives, after freezing, the water inside increases in volume, which gradually leads to cracking. |

| Corrosion resistance | The environment negatively affects the construction of cement. To ensure its resistance to corrosion, polymer additives are added to the composition or the mineralogical composition is corrected by replacing some components with hydroactive ones. |

| Curing speed | This indicator is also important. Manufacturers take it into account so that the speed is not fast or slow. Adjust the indicator by adding gypsum. |

Product types by area of use

Before we get to the question of how to make a cement standard, let's talk about the types that are produced and used everywhere today.

| Name of cement | Description | Scope of use |

|---|---|---|

| Sulfate resistant | Resistant to chemical attack in aggressive environments, made of crushed clinker, has a low degree of hardening. | Concreting of underground, underwater structures, arrays, when creating products that will be operated in difficult weather conditions. |

| Portland cement (including white) | Does not contain mineral additives, hardens both in air and in water. | To create monolithic structures, decoration, is considered the most popular type of product. |

| Aluminous | The composition includes alumina slag and gypsum, works well in high humidity conditions, has a high solidification rate. | For watertight constructions requiring corrosion resistant cement. |

| Pozzolanic | Contains clinker and active mineral additives. | It is used to create structures underwater and in the Far North. |

| plasticized | Contains additives that make the cement mortar soft and plastic. | For creating structures with curves. |

| acid resistant | Contains sodium silicofluoride and quartz sand, dissolves with liquid quartz glass, not with water. | Resistant to aggressive acids. |

| Slag Portland cement | A quarter consists of slag granules. | It is used to create massive structures in large construction. |

Many mistakenly believe that The concrete structure itself is a fairly durable product. This is not true. When exposed to aggressive environments, cement bonds are destroyed, therefore, in construction it is very important to choose the right type and brand of product.

Important! In the vast majority of cases, cement is understood to be Portland cements and other types made on the basis of clinker.

Whatcementclinker

Before describing the technological process in detail, let's touch on the main component of cement - clinker. This granular intermediate product is obtained by kilning a mixture of clay and limestone at a temperature of +1450°C. Limestone is required 3/4, and clay - 1/4 part. They can be replaced with materials of similar quality. Limestone is chalk, marl or other rocks.

During the firing process, melting occurs, as a result of which granules of different sizes are formed - clinker. When it is ground and combined with additives, mainly with gypsum, cement is obtained.

What is cement made of: the main raw material

The basis of any type of modern product is a minimum of components. All of them are created by nature. Based on cement:

- carbonate rocks;

- clay;

- corrective additives.

Let's talk about each of them in more detail.

Carbonate rocks are chalk, marl, limestone and limestone-shell rock, calcareous tuff, marble. All of them are used in the production of cement, the only exception is marble. The exact amount of a component is determined by analyzing its properties and content. The rock may contain gypsum, quartz, dolomite. The more substances with a crystalline structure are present in its composition, the harder it melts.

Clay rocks used in cement production are clay, loam, loess, montmorillonite, shale. Clay is a rock of sedimentary origin with a fine structure. Its main quality is plasticity in contact with water. It also has the ability to swell.

To adjust the composition, manufacturers make additives containing silicon, iron, alumina. For them, most often they order waste from other industries, for example, dust from blast furnaces or pyrite cinders.

Additionally, the composition of cement may include mineralizers, belite sludge, and other waste from production.

How cement is made in production: three main ways

As we said earlier, there are several ways to make cement in an industrial enterprise. Three main methods:

- dry;

- wet;

- combined.

Dry way

Depending on the properties of the feedstock, a production scheme is chosen. The dry method is divided into the following steps:

- crushing of raw materials;

- drying to a certain humidity;

- grinding the components after their connection to obtain flour;

- roasting flour in a rotary kiln;

- cooling and shipping.

This method of production is considered the most profitable and less energy-intensive.

wet way

This method involves grinding the components and adding water to them. The result is not flour, but raw sludge. It goes into the kiln for firing, and then into the refrigerator. The cooled clinker is ground and, if necessary, additives are added.

Combined method

In this case, raw sludge is first obtained by the wet method, then it is dehydrated, and granules are obtained. They go through a dry kiln. As a rule, the expediency of this method comes from the quality of the feedstock and the reduction in the cost of the final product.

Any of the methods requires the most thorough mixing of raw materials and the finest grinding. The product must be homogeneous. Finished products are stored in cement silos, which are towers. In them, the cement is aerated, which allows it not to cake. Products are packed in paper bags or not packed, but sent in bulk.

How and from what cement is made: video

We offer you to familiarize yourself with the video about the stages of cement production:

How to make cement at home

You can make your own cement. However, this will require two types of equipment:

- clinker grinding mill;

- high temperature kiln.

The output will be cement grades with a low degree of strength (not higher than M200), as a result, such a product can only be used for lightweight concrete structures. Another problem: the complexity will arise with the performance of analyzes, so the quality of the cement will be lame.

You will need chalk and kaolin in proportions of 75% and 25%, respectively. Raw materials are crushed in a mill to a homogeneous powder. It must be well mixed before entering the oven. After firing, grinding is performed again, then it is necessary to add 5% gypsum to the resulting mixture. The product is ready! Whether you bought the product or made it yourself, you will need information on how to make grout.

How to prepare a cement mortar

To begin construction work, you will need to prepare a cement mortar. Every man should know how the mixture is made. Cement-based mortars come in various types, but they all have the same basic composition.

The composition of the cement mortar

As a standard, three components are required for the preparation of a cement mixture:

- bonding cement;

- water;

- filler.

As a filler, sand, gravel, crushed stone and other components are used. The most important rule in obtaining is the observance of proportions.

| Grade of cement | Solution brand | |||

|---|---|---|---|---|

| 100 | 75 | 50 | 25 | |

| 200 | - | 1:2,5 | 1:3 | 1:6 |

| 300 | 1:2,5 | 1:3 | 1:4,5 | - |

| 400 | 1:3 | 1:4 | 1:6 | - |

| 500 | 1:4 | 1:5 | - | - |

| 600 | 1:4,5 | 1:6 | - | - |

Article

1082 10/09/2019 8 min.The word "cement" itself comes from the Latin name, which literally means "broken stone". This loose substance is one of the most common materials on earth used in various types of construction.

Concrete is made from cement, it is poured into the foundation, it is used for plastering, restoration work. Popular concrete products, reinforced and ordinary, are also made on the basis of this bulk material.

What is cement made of and what is it essentially. Depending on the type of mixture and brand, the composition will be slightly different, but the main components will remain unchanged.

What is cement, its chemical properties

M 800

Cement M 800, this is the most rarely used brand. Its number means that concrete made from this cement can withstand loads up to 800 kg/cm3.

It consists of crushed stone from high-strength rocks, plasticizers, additives that increase the strength characteristics of concrete.

It is designed to strengthen structures that have very high requirements for strength, the proportions of the mortar are carefully observed.

Its properties:

- high ability to withstand the aggressive effects of sulfates for a long period;

- frost resistance;

- affects the accelerated hardening of the finished composition;

- does not require a lot of liquid in the manufacture for better mobility.

M 700

Concrete from cement M 700 belongs to heavy concrete and has high strength. The composition of the cement mixture includes substances that accelerate the setting rate of the mortar and, like M 800, increase the strength of structures.

The composition of concrete includes: Portland cement, crushed stone, selected sand, various plasticizers, a small amount of well-purified water. For greater mobility, substances are added that will maintain strength at the desired level.

Cement M 700 has the following advantages:

- aesthetic qualities;

- high strength;

- water resistance;

- use on any type of coating;

- white cement is resistant to sub-zero temperatures.

M 600

Cement M 600. This grade is made, like most other frequently used grades, from clay and limestone and is processed at high temperature.

This cement is durable and most often used in the construction of strategic structures and military facilities.

It is also used for:

- emergency work;

- reconstruction;

- restoration work.

This type of cement is not used in the manufacture of general purpose reinforced concrete products. Of course, this brand can be used, for example, in private construction to increase the service life of structures, but this will lead to a complete lack of savings that will not be justified.

Grade of cement, similar to brand 600, but has a wider scope:

- production of reinforced foundations;

- reinforced slabs and columns;

- emergency recovery work;

- production of beams and floor slabs;

- pavement installation.

A mixture is made from intermediate clinker, gypsum stone and blast-furnace charge, which has thermal strength.

The brand has two varieties.

The first is M500 D0 in which there are no impurities and additives, this pure mixture of clay and limestone rocks, concrete from this mixture is waterproof and quickly hardens.

The second - M 500 D20, involves additives in the composition of cement no more than 20%.

The first option is used in the construction and manufacture of concrete, the second option with additives is more often used for the preparation of finishing mixtures and for masonry work, a mixture of such cement resists corrosion well.

Cement is used in many types of construction, refers to Portland cement.

The mixture is applied:

- in the manufacture of reinforced concrete products;

- in multi-storey construction;

- during the construction of bridges;

- for the manufacture of retaining walls;

- in the device of pile and strip foundations.

Cement M 300 is one of the most common brands, and it is used:

- in low-rise construction;

- in civil engineering;

- for installation work.

An economically justified scope of this mixture is the construction of monolithic.

According to its characteristics and composition, this brand is also well suited for the manufacture of belt-type barriers, retaining structures, roads and pavement, tile frames, floor slabs, walls, stairs, etc.

M 200, M 100

These two brands have a lower cost than the others and do not differ in increased durable characteristics. The main area of use of the M100 is finishing work, floors, rough road work.

Cement M 200 is used to prepare a concrete mixture that is suitable for the construction of light weight structures.

Both brands are currently out of production.

Each brand of cement has an additional letter designation, for example:

- PC stands for Portland cement;

- ShPTs - slag Portland cement;

- PL - plasticizer;

- SS - sulfate-resistant cement;

- BC - white cement; GF - hydrophobic;

- VRTs - cement with fast hardening.

Hydrophobic cement, which is able to repel water and be resistant to moisture, is made with the addition of finely ground substances that do not soak in water. Such cement in a dry form is stored longer. Hydrophobic dry material gives concrete and increased frost resistance compared to conventional.

A wide choice of cement and constantly developing technologies in its production and mining make it possible to translate into reality many ideas for construction or repair, architectural work, even under any climatic conditions.

This was not always the case, and although concrete buildings existed more than 5,000 years ago, a truly high-tech cement manufacturing process appeared only in the 20th century and continues to develop.

Cement is included in many compositions: concrete, reinforced concrete, plaster, putty, masonry mortar. It is used in the construction of complex structures, in underwater, underground construction, for autoclaved materials.

Speaking of such a sought-after building material, one immediately recalls a homogeneous loose mixture of gray color. However, the definition will be inaccurate if not supplemented - this is an artificially obtained, inorganic binder. When interacting with water, it is converted into a rather plastic mass, which subsequently hardens and becomes stone-like. For the ability to gain strength under wet conditions, it is classified as a hydraulic substance.

The brand of cement is the main indicator of its strength. There are many classes: M100, 150, 200, 250, 300 and even M600. But grades from M350 to 500 are in the greatest demand. The numerical value indicates what load 1 cm2 of the hardened composition can withstand. For example, the ultimate strength of M400 for bending and compression is 400 kg / cm2.

What is the material made from?

Cement is made from 2 main elements: gypsum and clinker. The latter should be understood as the product of uniform firing of the raw mass, consisting of clay and limestone of a certain composition, before sintering. Sometimes the clinker may additionally contain marl, nepheline sludge, blast-furnace slag. With the introduction of mineral additives (up to 15-20% by weight), the properties change somewhat. The most common modifier impurities are: bauxites, pyrite cinders, sands, flue dust. If the content of additives exceeds 20%, a pozzolanic cement is obtained, which is not afraid of interaction with sulfate and fresh waters.

The composition of the binder product is determined by the firing of the raw mixture. Calcium oxides are formed from limestone at certain temperatures, which, upon further heating, enter into a complex reaction with clay components. As a result, compounds are formed that, after fine grinding and mixing with water, harden and turn into a stone-like body.

Chemical composition:

- CaO - calcium oxide 67%;

- SiO 2 - silicon dioxide 22%;

- Al 2 O 3 - amphoteric aluminum oxide 5%;

- Fe 2 O 3 - iron oxide 3%;

- foreign elements 3%.

Varieties of cement

Characteristics largely depend on the content of mineral compositions and the proportions of the components. In industrial and private construction, the most popular compositions are:

1. Portland cement.

It is a mixture of finely ground gypsum, cement clinker and corrective additives (tripoli, flasks, pyrite cinders) with a predominant proportion of calcium silicates (up to 80%). The greater its mechanical strength, and the sooner it is achieved, the better the material is considered. In this regard, PC, which is characterized by a high increase in strength, is called fast-hardening. It is called superstrong when maintaining the maximum load on compression and bending. These characteristics are reflected in the marking. It is used in almost all areas, from building cladding to mass production of precast concrete/reinforced concrete structures. Read about such an indicator as cement density.

2. Portland slag cement.

It is created by grinding a certain amount of gypsum, clinker and granulated slag (usually blast furnace - a product obtained by smelting iron in a furnace). The manufacturing technology of the binder implies the mandatory drying of waste from metallurgical production to a moisture content not exceeding 1%. At the end, the material does not come out as frost-resistant as ordinary cement, and it hardens more slowly. However, low cost and excellent resistance to sulfates make it popular.

Scope of use: preparation of concrete mixtures, wall blocks, all kinds of mortars. It can be used to create not only ground structures, but also underground ones that are exposed to mineralized / fresh waters.

3. Aluminous.

They are made according to a proven technology: the initial components are enriched with alumina - pure limestones and bauxites. The latter should be understood as rocks whose content is based on hydrates and impurities. The predominance of monocalcium aluminate in the clinker composition is inherent. This determines the main characteristics: to set quickly, to be resistant to moisture, thermal influences, in particular, open fire.

Due to the water resistance, it is often used in winter. And due to the high speed of hardening, it is indispensable for operational emergency work. Another area is the production of various heat-resistant concretes on its basis.

4. Magnesian.

The key difference is that magnesium oxide acts as the active ingredient here. To obtain it, finely dispersed magnesite (or dolomite) is taken, which is subsequently subjected to calcination. By itself, the mineral, when dissolved with water, almost does not reveal astringent properties. But after dilution with magnesium salts (sulfide / chloride), the final mixture acquires the necessary parameters and is quite suitable for construction work.

It is famous for its good adhesion to various fillers, including those of organic origin, strength, and low thermal conductivity. Due to such unique qualities, it can be used in the production of facing plates, stair steps, partitions, thermal insulation products (foam, gas magnesites). But the main area is the arrangement of seamless monolithic floors.

5. Pozzolanic.

The production technology is based on the use of clinker, active additives (pozzolana - a mixture of volcanic ash, tuff, pumice; burnt shale; fly ash; microsilica), the share of the total mass of which is 20-40%. Auxiliary additives may be included. Gypsum is poured in the amount necessary to regulate the setting time.

Pozzolanic differs from the classical composition in that it has a higher resistance to corrosion and sulfate waters. Sufficiently frost-resistant, shows minimal heat release during the hardening process. Due to the addition of light mineral additives, it has a lower specific gravity, but the same additives increase the yield of cement slurry. Most often used for the preparation of concrete / reinforced concrete products in underground / underwater structures. If we are talking about ground buildings in a dry climate, it is inappropriate to use it, since it will be much inferior to Portland cement.

Rarely used materials are romancement (a combination of clinker with dolomitic marl and gypsum) and acid-resistant products based on quartz/diabase, whose mixing is carried out not with water, but with liquid glass. White and colored compositions, on the contrary, are in demand, but only in the field of architectural and finishing works.

Production technology

To obtain cement, refer to the following steps:

- heating a mixture of slaked lime and clay to temperature marks + 1450-1480̊ С; at the end of this process, the desired clinker granules are formed;

- the connection of the intermediate product (clinker) with gypsum and their further grinding until acquiring a powder state;

- the introduction of additives and additives (if necessary), which will positively affect the properties.

In the manufacture of the binder composition, not only production processes are strictly observed, but also preparatory measures, the ratio of components. After the cement gets its finished look, it is transported to warehouses, where it waits for shipment to the consumer.

The cost of different brands

Many factors influence the formation of the final price:

- packaging - it is more profitable to purchase in large volumes, therefore it is not surprising that a bag weighing 0.05 tons will cost less per 1 kg than a 5-kilogram package;

- seasonality (activity of the period) - spring / summer, part of autumn - the time when construction and repairs are in full swing, and, therefore, the rise in the cost of binders is not unreasonable;

- territorial pricing policy;

- prestige of the manufacturer;

- strength characteristics are the main aspect in determining the cost: the higher the compressive strength limit of cement, the better it will be, and its price is higher.

| Price depending on the brand for 50 kg, rubles | ||||||||||

| M100 | M150 | M200 | M250 | M300 | M350 | |||||

| Articles |

Cement is an astringent substance that tends to harden in water and in the open air. Let's figure out what cement is made of, however, everything is still jealous of. It is formed by grinding clinker, gypsum and special additives. Clinker is the result of firing a raw mixture that includes limestone, clay and other materials (blast furnace slag, nepheline sludge, marl). The ingredients are taken in a certain ratio, which ensures the formation of calcium silicates, alumino-ferrite and aluminate phases.

The first patent for cement was registered in 1824 in England by D. Aspind. Then the author of the patent mixed lime dust with clay, processed the mixture by means of high temperature. The result was gray clinker. Next, the material was ground and filled with water.

What is cement made of today? As before, clinker is the main component that is part of the cement. The properties and strength of the building material depend on it. In addition, the composition includes active mineral additives (15%) in accordance with production standards. They slightly affect the basic properties and technical characteristics of the building material. If the amount of additives is increased to 20%, then the properties of the cement will be somewhat changed, and it will be called pozzolanic cement.

In a scattered state, it is 900-1300 kg / cubic meter, compacted - up to 2000 kg / cubic meter. m. Calculating the capacity of warehouses for storage, the weight of cement is 1200 kg / cu. m. The production of cement without additives is regulated by GOST 10178-76, with additives - GOST 21-9-74.

Main characteristics of cement

Depending on what cement is made of, the material has different properties. The main ones include:

1. Strength. This is a parameter that is responsible for the destruction of the material under the influence of certain conditions. Depending on the mechanical strength, there are four types of cement: 400, 500, 550 and 600.

2. . It is determined by laying a cement paste of normal density on a flat surface - the cement should evenly change its volume when it dries. Otherwise, it cannot be used in construction due to possible destruction of the coating as a result of excessive stress. Changes in volume are checked by boiling hardened cakes of cement.

3. Grit size. The parameter affects the drying rate and strength. The finer the grinding, the better and stronger the cement, especially at the first stage of hardening. Grinding granularity is determined by the specific surface of the particles that are part of 1 kg of cement, and ranges from 3000-3200 kg / cu. m.

4. Density. The cost of water to create a mixture. This is the amount of water during mixing, necessary for normal installation and drying of the material. To reduce its consumption and increase the plasticity of cement, plasticizing organic and inorganic substances are used. For example, sulfide-yeast brew.

5. Frost resistance. The parameter allows you to determine the ability to withstand temporary freezing of water, as a result of which its volume increases by 8-9%. Water presses on the walls of the cement (concrete) coating, and this, in turn, disrupts the structure of the solution, gradually destroying it.

6. Armature bonding.

7. Heat dissipation- heat is released during the curing of cement. If this happens slowly and gradually, then the coating hardens evenly, without cracking. The amount and rate of heat release can be reduced by using a special mineralogical composition that is added to the solution.

Many types of cement are produced today. What cement consists of, to a greater extent affects its properties. Depending on the raw material basis, the following types of cement are distinguished:

- lime;

- marly;

- clay cement with additives of slag and bauxite. Its feature is water resistance, frost resistance, fire resistance.

Clay and carbonate compounds are mainly used in the manufacture of cement. Sometimes - artificial raw materials (waste, slag) or other natural materials (alumina residues).

Distinguish. Portland cement hardens quickly and may contain mineral additives from 10 to 15%. Clinker and gypsum (the main components) included in its composition are fired at a temperature of 1500 degrees Celsius. Portland cement is actively used for modern construction work. Its main property is the ability to turn into a solid block of stone even when interacting with water.

In addition to Portland cement and Portland slag cement, the following types of cement are distinguished:

- hydraulic;

- straining - tends to quickly set and dry;

- grouting - designed for concreting gas and oil wells;

- decorative (white);

- sulfate-resistant - its distinctive feature is a low hardening rate and increased frost resistance.

Areas of use

Very often, cement is used in construction to create concrete and reinforced structures. Grade 400 is used for pouring foundations and constructing floor beams in high-rise buildings.

Cement is one of the main building materials. It is used in the creation of binding mortars, cement is used in the manufacture of concrete and reinforced concrete products. The quality of this material determines how strong and durable the building or reinforced concrete structure will be.

The history of cement began in England, where a patent for its invention was registered in 1824. At that time, lime dust mixed with clay was used to make cement. The resulting mixture was subjected to a high temperature at which it was sintered.

The fired semi-finished product of cement is called clinker. It becomes cement after grinding the clinker to a powder state.

In construction, the main property of cement is used - when mixed with water, it gradually hardens, and then turns into a durable stone. The strength characteristic of the finished product, the material can acquire even in the air, if there is excess moisture.

Raw materials for the production of cement, what it is made of, manufacturing technology

Today, the process of making cement has changed. It is made in several ways, and the components included in it also differ from those used two hundred years ago.

In order to understand what cement is made of and how it is produced, it is necessary to know what types of raw materials are used today by manufacturers of this important building material.

Since the raw materials for the production of cement are natural rocks, the enterprises involved in its manufacture are most often located close to the mining sites of these rocks.

All fossils from which cement is made are divided into two types:

- Carbonate fossils that differ in characteristics and structural features. It is the structure of the rock that ensures its effective interaction with the rest of the ingredients of the product composition.

- Clay and rocks of sedimentary origin. Having a mineral base, when moistened, they acquire plasticity and increase in volume. Since this type of raw material is characterized by viscosity, they can be used by producing cement in a dry way.

Now it is necessary to name specifically which fossils belong to each of the types of raw materials used in the production of cement.

The carbonate rocks include the following types of natural raw materials:

- Chalk is a type of limestone. Has the ability to be easily crushed;

- marl limestone, found in nature in both loose and solid state. The rock may contain impurities of clay, so this type of limestone is considered a transitional raw material, with properties characteristic of both limestone and clay;

- limestones - shell rocks that do not have silicon inclusions. The rock has a porous structure that easily collapses under compression;

Limestones - shell rocks

- dolomitic rocks and other fossils of sedimentary origin. They contain carbonates, which give the rock valuable properties.

Clay rocks include the following types of fossils:

- clay with mineral inclusions that swell on contact with water;

- loams containing an increased concentration of particles;

- shales with a clay base. This raw material is classified as a rock with increased strength. Under mechanical action, it is divided into lamellar plates. It is characterized by a stable composition and low moisture content;

- loess, porous rock, with inclusions of particles and silicate.

In addition to these types of raw materials, some types of industrial waste are used to produce a cement mixture at the plant. To improve the quality, additives are added to its composition, provided for by the technological process: alumina and silica, fluorspar and apatite.

The use of sand is simply necessary when carrying out a variety of repair and construction work. all about the use of quarry sand.

When carrying out finishing work in the kitchen, in the bathroom or in any other room, it is necessary to know the drying time of the tile adhesive. you can find out how long the tile adhesive dries.

Currently, decorative plaster is rightfully the most popular and progressive finishing method. Going to get acquainted with its independent preparation.

All additives, called plasticizers, are also of natural origin. They affect for the better the following qualities of cement:

- increase resistance to temperature changes;

- enhance strength;

- mobility and elasticity of the product;

- reduces the penetration of water into the finished product.

Depending on the properties of the plasticizers added to the cement, its solution will harden faster or slower.

The composition from which cement is produced

Some people working in the construction industry do not know what cement is made of.

The composition of cement may vary depending on the brand and purpose.

However, regardless of the type of cement, that is, the recipe used in its production, two components serve as the basis for it - limestone with the addition of clay.

The amount of limestone is three times the amount of clay. These are necessary to obtain high-quality clinker, which is a semi-finished product for the production of cement.

Now we can name the main components of the composition, so that it is clear to everyone what cement is made of:

- clinker, the basis of the final product, which determines its strength characteristics. It is used in the form of granules with a diameter up to 60 mm. Its heat treatment is carried out at a temperature reaching up to 1500 °. When melting the clinker, a mass is formed, which is characterized by a high content of silica and calcium dioxide;

- these components affect the performance of the final product. Before firing, the clinker granules are crushed to a dusty state;

- gypsum, which determines the rate of cement hardening. The basic recipes provide for the addition of pure gypsum to the composition of up to 6% of the total number of components;

- special additives (plasticizers, frost-resistant additives, liquid soap, etc.) that enhance the properties already available in the product, or give it special characteristics that can expand the scope of cement.

Production - how cement is made, the process of receiving at the plant

The production of the material is carried out in a certain order, in stages. The technology of its production provides for the following operations:

- The ingredients intended for the manufacture of clinker are pre-mixed. It is imperative to strictly observe the proportions of the composition - 25% clay and 75% limestone.

- The resulting composition is fired at high temperature. During high-temperature firing, clay and lime combine to form clinker.

- The finished product is crushed by ball mills, which consist of drums located in a horizontal position, inside which steel balls are placed. The clinker placed in them is crushed to a state of powder.

- The finer the cement fractions obtained, the better performance characteristics it will have.

There are several methods for manufacturing this building material. Their choice is due to many factors, the main of which is the specifics of the equipment available at the enterprise and the demand for certain brands of cement.

The developed technologies have a difference in the methods of preparation of raw materials used in the production of the composition. The order of its manufacture remains the same.

The following methods have been developed:

- Wet technology that replaces lime with chalk. In the process of mixing the components of the composition, they are crushed in a ball mill. This process is carried out with the addition of water. As a result, a mixture is formed with a moisture concentration of up to 50%.

- The resulting material is then fired in a kiln. After firing, it already becomes clinker. Then it is crushed.

- Dry technology significantly reduces the cost of production, as it combines several technological operations into a single process. When using this technology, the components entering the ball mill are simultaneously ground and dried.

- Hot gases are used for drying. The finished charge mass has the consistency of a powder.

- Combined technology combines the features of the above-described production methods. Depending on the equipment used in the enterprise, a semi-dry composition with a moisture content of up to 18% can be obtained.

- In the second option, dry is initially prepared, then moistened to 14%. In both cases, the prepared composition is then annealed and ground.

For more information about cement production, see the video:

Classification of cement mixtures

There are many varieties and different of this building material. They are distinguished by their basic composition and additives, which give each species special properties.

Among the main types are:

- Portland cement, which began the production of a product popular in construction. It is not used for the manufacture of binder solutions. It is used to create high-strength concrete products, and mortars;

- aluminous cement, characterized by resistance to moisture, rapid hardening;

- acid-resistant cement, which uses quartz and sodium silicofluoride. The material is resistant to acids, but short-lived.

When purchasing any type of cement, you should be aware that its composition actively interacts with the environment, losing its strength during long storage.

Even if it is stored in a dry room, after a few months its brand will change down. Therefore, when purchasing it, you should pay attention to the date of manufacture. You can also read our article on technical specifications.