A business on a CNC machine for wood can bring a pretty good income. Since most household items are made of plastic, which people are tired of, many people want to buy things made from natural materials, such as wood. If you correctly draw up a business plan for this type of commercial activity, then you can make good money on this. About all the nuances of a business on a CNC milling machine later in the article.

Why can a CNC machine business become a very profitable business?

By purchasing such a machine, you can provide services not only for processing wood, but also other materials. For example, a CNC machine can process leather, rubber, non-ferrous and hard metals, and composite materials. In principle, such a machine is designed to work with almost any material, except for hard ones.

Income and expense plan

A similar business on a CNC machine can be opened with both minimal and more serious investments. Here the main difference will be in the type of machines and the volume of planned services provided.

Income and expenses with a normal budget

If an entrepreneur has enough cash to open a CNC machine business, he will have to cover the following expenses:

- computer: about 12 thousand rubles;

- machine model 6090 (1 pc.): about 160 thousand rubles;

- furnishing furniture: about 20 thousand rubles;

- storage facilities for materials: about 60 thousand rubles;

- equipment for procurement of materials: 5 thousand rubles.

In general, the amount of initial investment will be about 260 thousand rubles.

Also in terms of income and expenses, it is worth considering the monthly costs for:

- advertising: about 40 thousand rubles;

- rent of premises: about 20 thousand rubles;

- electricity: about 6 thousand rubles;

- purchase of consumables: about 15 thousand rubles.

As a result, the entrepreneur will need to count on monthly expenses in the amount of 81 thousand rubles.

Income

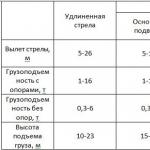

The cost per linear meter will depend on the material being processed. It can range from 20 to 500 rubles. If we take an average cost of 60 rubles/m and a speed of 6,000 mm/min, then about 360 meters can be cut in an hour, and 2880 meters in a whole day (8 working hours).

That is, you can earn about 172 thousand rubles a day. Monthly income with such volumes of work is 3,800 thousand rubles.

When an entrepreneur has a customer base with regular orders, he can start the round-the-clock operation of the machine to fulfill urgent orders. Also, the cost will vary depending on the material being processed. Thanks to such conditions, you can make an extra charge of 50-100%.

A business on a CNC machine is designed for an average payback period of 2-3 months. If we take into account tax rates and cover monthly expenses, then in the first month you can get a net profit of 375 thousand rubles.

If in the first month of idle operation of the machine (taking into account the maintenance of the customer base, reporting, etc.) will be 88%, then the profit will be 375 thousand rubles. With a downtime of 83%, profit will increase to 565 thousand rubles.

If you open a business on a CNC machine with minimal investment?

When opening a business with us on a CNC machine, the starting investment for an entrepreneur with a minimum budget will be as follows:

- cost of CNC machine 4060: 95 thousand rubles;

- purchase of a computer: 12 thousand rubles;

- arrangement of the workplace with furniture: 2 thousand rubles;

- cost of materials warehouse: 30 thousand rubles;

- equipment for processing materials: 5 thousand rubles;

As a result, a novice entrepreneur will need to invest about 144 thousand rubles.

Monthly costs will amount to 33 thousand rubles. Of them:

- electricity costs: 3 thousand rubles;

- expenses for renting premises: 5 thousand rubles;

- advertising costs: 20 thousand rubles;

- purchase of consumables: 5 thousand rubles.

If you have a CNC machine 4060 and an 8-hour working day, your daily income can be about 43 thousand rubles. It is realistic to earn about 946 thousand rubles a month on such a business and with such investments. The average payback period will also be about 2-3 months.

What services can be provided with a CNC milling machine?

Business on a CNC machine is a vast field of activity in which you can show maximum imagination. The most popular services that can be provided with a CNC machine are:

- carrying out curvilinear cutting of a tree;

- cutting of metals;

- production of details for furniture;

- decorating materials.

The main customers of an entrepreneur with a CNC machine will be representatives of small and medium-sized businesses. Basically, they order the manufacture of small parts and parts of complex mechanisms. Representatives of a small furniture business or other types of industry cannot afford to purchase an expensive milling machine; for them, this is not a profitable expense at all. Therefore, such a type of commercial activity as CNC processing of materials will always have a good demand.

An individual order for the manufacture of decorative unique items as souvenirs, toys, etc. is also popular.

You can also open your own linear production of a certain product, for which there will be a demand in the market. For example, you can start making boards for cutting food and other kitchen items.

5 ways to make money with a CNC machine in 2018

One of the popular ways to make money on a CNC machine is the manufacture of furniture and furniture decor. A unique designer finish is something that will always be in demand.

The second, no less profitable and popular way to make money on such a machine is the manufacture of doors and stairs. The main target audience of customers for such a product will consist of owners of country houses. Usually these are wealthy people who are willing to pay for uniqueness and naturalness, so here you can benefit from a good margin.

A great business idea for a CNC machine is the manufacture of wooden toys. Whoever says that this is the last century will be completely wrong. Now, on the contrary, complex wooden constructors are in great demand among parents. They do not want to give their children plastic toys; they are more attracted to natural materials.

Making souvenirs in the resort town is a seasonal, but very profitable business. In this case, the entrepreneur must draw up his financial plan, taking into account the seasonality of demand.

Recently, the actual direction in the CNC machine business is the manufacture of promotional products. Wooden decor elements fit perfectly into any interior.

How to register a business on a CNC machine?

For this type of commercial activity, it is best to officially register individual entrepreneurship. For such an organizational form, a simplified tax system applies. The amount of the state fee for registering an individual entrepreneur will be 800 rubles. The entrepreneur will need to fill out an application for registration of IP, copies of the passport and TIN.

CNC machine for small business - equipment used for personal economic purposes. For these purposes, any type of machine is suitable. But the performance metric may vary. The choice of unit should be made depending on the purpose for which it will be used.

Considering that the device will be used at home or for production with a small series, it can be made independently.

Features of choice

A number of factors influence the choice of equipment. It depends on them how the equipment will correspond to the purposes for which it was purchased. Not always the highest quality and most productive device will be the most effective. In some cases, a mini machine will be more useful than a standard counterpart. Among the factors on which the choice depends are:

- technologies used;

- the area of the room in which the device will be installed;

- the number of people maintaining the equipment.

The cost of the unit can be more than ten thousand rubles. You should consider how much money will be required for the required model, and how this will affect the initial capital.

If the amount of money is limited, you can try to make the device yourself.

In the production of modern mini CNC machines, it is taken into account that they can be used in small businesses. One of the most popular models is CNC-Magic. The model is represented by a milling and engraving device. It belongs to the list of the most affordable models, and can be used for universal purposes. It is used to process:

- tree;

- metal;

- glass.

The advantage is the possibility of manufacturing parts on the machine that have a complex shape. It will take a little time to write the program. The most requested feature of the device is engraving.

Types of CNC machines

Small business involves less work than industrial production. Given the specifics of the tasks, small highly specialized machines have a higher efficiency indicator. According to the way they work, they are divided into:

- metalworking;

- woodworking machines;

- for cutting MDF;

- for engraving;

- for cutting stone.

Metalworking tools are effective in cold forging. This type of work is one of the most profitable. It allows you to produce a wide range of products at low cost.

Mini machines for milling and turning work can simplify the task. The compact size of the device allows you to place it in a room with a small area. You can work on such a device yourself.

Able to perform the functions of a workshop for wood processing. The advantages of such equipment are compactness, low cost, quiet operation. The mini unit is equipped with various nozzles that can perform a wide range of jobs. With it, you can: drill, grind, saw, sharpen, joint. The device is able to cope with different types of wood.

If the business is based on the production of panel furniture, the best option would be an MDF cutting machine. With it, furniture can be made at home. In addition to MDF, the device can handle other materials of various strengths. Devices that perform this function are of different types. The choice should be made depending on how long the unit is able to cut, what power it has, and the type of carriage.

The engraving laser unit is suitable for processing finished products. Modern mini devices have laser beams, which greatly simplify the work of the machine. Despite the presence of a laser installation, the device is not expensive, but its parts require periodic replacement. It will be effective if the source of income is the production of promotional products, jewelry, souvenirs. Compact dimensions with a laser device allow the installation to be used at home.

Stone cutting tools are suitable for construction. To install such equipment, a room with a large area is required. It is able to cope with various types of stone. The unit offers a wide range of functions. Its cost is quite high, and may not be suitable for many. But, given the number of tasks that the machine is able to handle, it will pay for itself in various jobs.

Small business organization

Before purchasing equipment, you should determine in which industry a small business will develop. The cost of a CNC machine is relatively high. The purchase of various units will require significant costs. Having a large start-up capital will solve this problem. But not all devices will be equally useful. With small financial resources, a CNC machine can be made on your own.

Such a step will save money, and will allow them to be invested in the implementation of other tasks. Expenses will be required not only for the purchase of equipment, but also for the rent of the premises in which it will be located. If a small business involves various jobs, workers will be needed to complete them. Initial costs will require the provision of conditions for the sale of manufactured products.

A business plan will help you manage your money wisely. Many business start-ups fail because of a bad plan. The availability of CNC machines does not yet guarantee a successful project. Wood and metal processing on machine tools is the most profitable industry for small businesses. They allow you to perform a complex of works and produce various products. They are used to make:

- paintings and icons;

- furniture products;

- various models;

- advertising products.

Numerical control allows you to compensate for the lack of experience. But for high-quality production, it is recommended to use the help of specialists. The most popular CNCs are Type3 and ArtCam. You can manage the workflow using a special control panel. A quality program will ensure high precision in the production of parts.

Nowadays, quite a high popularity among the goods of the most diverse purpose that are found on the market, consumers especially appreciate handmade products. As a result, making all kinds of products with your own hands, you can earn good money. To facilitate this task and produce the highest quality products without spending a lot of your time, you can use various additional devices, among which the most convenient to use are CNC engraving, milling or turning machines.

With the help of such equipment, even at home, you can make all kinds of wood products - decor elements, furniture and accessories for it, souvenirs and the like, while earning significant material resources. To do this, you just need to have the appropriate equipment and have certain skills in working on it.

It would also be a good solution to establish cooperation with firms involved in home decoration or construction companies, manufacturing for them one or another product using a CNC machine. In this case, you will not have to worry about finding buyers for your products that were made on such equipment.

How to set up work using a machine

Before starting such an execution of such work on earning money using a machine, you should carefully study the market, decide on the direction of activity, familiarize yourself with the cost of raw materials for working on the machine, as well as prices for finished products. As a result, it will be possible to determine the approximate amount of earnings.

The next step is to purchase all the equipment you need to earn money. The best option would be to buy:

- CNC machine for complex processing;

- milling machine;

- a set of cutters and all necessary additional tools.

It is not recommended to purchase mini-machines because of their low reliability, it is best to choose a line for sawing and subsequent partial processing of workpieces. Of course, the purchase of such CNC machines requires considerable material costs, but by doing everything right, you can immediately start making good money, recouping all costs as soon as possible.

Preparation of raw materials for work and personnel

The following types of wood are suitable as raw materials:

- ash;

- pine;

- larch, as well as some others.

The specific choice of wood for the production of certain products depends on the products that will be manufactured.

In addition, when choosing such materials for making money, it is necessary to pay attention to their moisture content, since the quality of the final product largely depends on this.

In addition, we should not forget that it is possible to produce certain high-quality parts on CNC machines in order to earn a living if you have the appropriate skills to perform such work. The best option would be to select personnel in such a way that each machine has its own master, although you can cope with such tasks on your own to perform work on a home machine.

Making money using a lathe

The easiest way to make money using a lathe, which is available to every person with certain skills in working on such equipment, is to independently manufacture various wood products.

The most competent solution for such earnings would be to prepare several types of products in advance, take photographs of finished works, make your own price list, offering your services to potential customers, demonstrating the work already completed.

In the case of making various souvenirs on a lathe for the purpose of earning money, you can give your own products for sale to specialized stores. In addition, such and any other products made by hand on the machine can also be sold using the Internet.

Thus, the use of a lathe in order to make money can lead to amazing results, because modern models of such equipment make it possible to make figures, products and parts for anything of any shape and level of complexity on it.

Earnings on the CNC machine

A modern alternative to a conventional lathe is the CNC machine. With the help of such equipment, it is possible to quickly produce any products according to a template made on a computer using special programs.

In order to start this way of earning, of course, you must first purchase the machine itself, which will work in conjunction with a computer on which the appropriate software is installed.

In most cases, such CNC machines are used in the woodworking industry to make money. So, with the help of such equipment, various furniture sets are often made.

In itself, making money on CNC machines is a very profitable occupation, since such equipment allows you to process parts made of wood and metal. In addition, CNC technology makes it possible to engrave marble, as well as natural and artificial stone.

Advantages of CNC milling machines

The best solution for making money would be to use a CNC milling machine. Such equipment in skillful hands makes it possible to implement a wide variety of ideas.

In the woodworking industry, CNC milling machines allow you to select a variety of curved surfaces of irregular and regular shapes, sawing and rough calibration of products, making grooves, grooves, ridges and much more.

Other areas where the use of such machines is most common are the following:

- furniture manufacturing. Extraordinary exclusive furniture from a variety of materials, including precious woods;

- souvenir products. Carved boxes, photo frames, chess and more;

- Promotional Products. Logos, signs, clichés and the like.

- development of master models for subsequent mold casting.

A particularly promising way to make money with CNC equipment is to use it to produce a variety of forms. In this direction, the CNC machine is the most popular equipment, since only with its help you can quickly prepare the highest quality master model with any required parameters. Such forms are used to replicate certain products from any materials.

Engraving work

Another fairly promising way to make money on CNC equipment is to carry out engraving work on the surface of precious metals. This can be the production of certain inscriptions or images on rings, the production of gift medallions and medals, branded inscriptions on lighters, cigarette cases, flasks and similar products.

To perform such work with CNC equipment, which can give a very good income, you only need to have an engraving CNC machine, as well as a computer with the appropriate software.

If you have ever wondered "what can be done on a CNC milling machine", then this article is for you. Today, interesting handmade goods are highly valued and in great demand.

Products for sale, or for your own use, can be quickly and efficiently produced using.

As a result, you can get a variety of wood products:

- decor items;

- furniture;

- souvenirs and other products.

Also on the site we have posted an article about, which may be useful in the production of this type of product. For this production, only certain equipment and some experience in working on it are needed.

And by the way, this is a pretty good way to earn money. After all, such products are always in demand and have a high price.

Preparation of raw materials for products

Almost all solid materials can be used as raw materials:

- wood (including plywood, fiberboard, chipboard, MDF);

- various types of plastic (acrylic, PVC);

- metals;

- polycarbonates;

- Styrofoam;

- polystyrene and other machinable materials.

It is very popular now, as it is used to make fashionable interior details, household items and many other home products.

Wood is the most common raw material for CNC machining.

The best option would be to use such breeds:

- Ash: has a lot in common with oak. However, the degree of resistance to deformation, viscosity, impact resistance is higher for this type of wood. Ash wood is highly valued in the manufacture of furniture, where it is equated with mahogany.

- Pine: resinous, strong and hard, resistant to rot and fungus, excellent for processing. It is highly valued due to the small number of knots and the small change in diameter along the length of the trunk.

- Larch: it is characterized by high strength, resistance to external influences, pleasant color and structure.

The choice of breed depends on the products. Particular attention should be paid to such characteristics of wood as moisture and strength. Because they greatly affect the quality of the finished product.

Advantages of working with a CNC milling machine

Milling cutters have a fairly large number of advantages, including:

- the ability to make a wide variety of products from materials that are completely different from each other (which cannot be processed in any other way);

- accuracy and evenness of the cut, so that the product is neat and beautiful;

- the ability to make the desired shape, depth and even shaped cuts;

- work can be carried out both on a vertical, horizontal and inclined surface;

- high speed of work;

- a wide variety of details: flat, three-dimensional, and even 3D;

- repeatability of a larger number of products, which is practically impossible with other processing methods;

- the ability to cut, make a rough calibration, mill grooves and other types of connections used in the assembly of the product.

Main Products

Today, there are a huge number of items that can be made using a CNC machine, such as:

- Unique furniture made of various materials, including precious woods.

- Souvenirs: various caskets, photo frames, figurines and more.

- Promotional products: beautiful massive letters, signs, etc.

Let's take a closer look at each of the proposed options.

Designer furniture. It surrounds us everywhere: bedrooms, kitchen, nursery. Modern furniture production is very well thought out and has high precision.

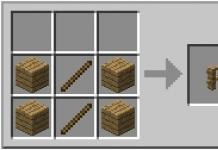

Steps to create a product on a CNC machine:

- Sketch development. For this item, there are a large number of programs that help to virtually simulate the situation. To create a 3D layout of a drawing, use a computer program such as CAD. Prepared computer files will make it possible to obtain a furniture product on a CNC milling machine.

- Preparing the model for the machine. A ready-made sketch in 3D - the basis for the manufacture of any set of parts. To this sketch, you need to add a beam function (a vector that will be responsible for the direction of the cutter relative to the workpiece). There is also automatic model generation, which is quite convenient and will save you time. Modern equipment simplifies the manufacturing process, and transfers even the smallest and most difficult lines.

- Selection of the type of cutting tools, setting the power and processing mode.

- Load files into the machine's memory, install the cutting tool, clamp the workpiece and start production. The CNC milling machine does further work independently according to an already given program.

- Final assembly. It will take a small amount of time, there is no need to fit parts.

Promotional Products. Its creation is a type of activity that is relevant today, in which the use of milling machines with numerical control is very popular. Such machines are excellent for such tasks as the production of light boxes, stands, panels, shaped inscriptions and outdoor advertising signs, as well as the preparation of structures for exhibitions.

The CNC machine helps to perform the following operations that are associated with promotional products:

- cutting wood, acrylic and other materials;

- engraving / cutting of massive inscriptions;

- creating a logo, emblem;

- production of plates, stands, etc.

Summing up, we can say that the number of products that can be made on a CNC milling machine is a huge amount. All you need is equipment, a desire to work and a little experience.