Building your own winter greenhouse is an excellent solution for any practical summer resident. Not every country has a climate that allows you to pamper yourself with delicious vegetables. You can solve this problem by making such a design yourself.

- structures that have to be dismantled and hidden in the fall;

- products in which it is possible to grow plants in winter.

Winter greenhouses have a complex design, so it’s not easy to build them yourself. They need the construction of a reliable frame, which must be located on the foundation. In addition, you will need to install a heating system. The efficiency of the building depends on it. A winter greenhouse must have:

- heating system;

- lighting;

- irrigation system;

- ventilation.

The dimensions of the structure are determined based on the number of crops that will be grown. It is important to use high-quality coating material. A thin film will not be able to protect crops from frost and snow. The advantage is additional insulation of the walls.

Photo gallery: DIY winter greenhouses - the best projects

Small greenhouse made of polycarbonate  Greenhouse of unusual shape

Greenhouse of unusual shape  Ventilated roof structure

Ventilated roof structure  Greenhouse roof made of glass and tiles

Greenhouse roof made of glass and tiles  Product coated with athermal glass

Product coated with athermal glass  Plants inside a greenhouse

Plants inside a greenhouse  Greenhouse with ventilated roof

Greenhouse with ventilated roof  Greenhouse with glass cover

Greenhouse with glass cover  Greenhouse with a high stone base

Greenhouse with a high stone base  Connecting a greenhouse to a private house

Connecting a greenhouse to a private house  Frame frame design

Frame frame design  Winter underground structure covered with glass

Winter underground structure covered with glass  Greenhouse with reinforced frame and film covering

Greenhouse with reinforced frame and film covering  Metal frame for winter greenhouse

Metal frame for winter greenhouse  Gable winter greenhouse

Gable winter greenhouse  Greenhouse with glass cover

Greenhouse with glass cover  Greenhouse with polycarbonate coating

Greenhouse with polycarbonate coating  A greenhouse covered with cellular polycarbonate

A greenhouse covered with cellular polycarbonate

A greenhouse can be built from various materials. The construction market is overflowing with a variety of coatings that are characterized by high strength, low weight and low price. This makes it possible to choose materials within a small budget. At the preparation stage, you will need to create a design plan.

Greenhouses can be divided not only by coating materials, but also by external shape:

- Single-pitch product. It is wall-mounted and has a filling of earth.

- The gable structure has solid walls and a glazed roof.

- Arched structure. Can be oval and asymmetrical.

- Combined construction. It can be rectangular or arched on a high base.

- A rectangular structure with an arched, pitched or gable roof.

Various forms of greenhouses can be seen in the figure:

Greenhouses of different shapes

Based on the location of the structure, it can be divided into the following:

- thermos products that go deep into the soil;

- detached buildings;

- greenhouses that are adjacent to the main building: a bathhouse, a private house, a garage.

The latter product is capable of receiving additional heat from a common wall. As a result, it will be possible to reduce heating costs.

Design selection criteria:

- First of all, you will need to calculate the parameters, since further calculations depend on them.

- It is important to take into account functionality: first clarify the characteristics of the plants that will be grown.

- The microclimate inside the building depends on the correct placement of the product at the ground level. If desired, the greenhouse can be immersed underground and get the effect of a thermos. Most often, buildings are erected on the ground surface. Some craftsmen advise making greenhouses in old buildings (garage or barn).

A large number of architectural solutions makes it possible to realize any ideas. You can build the product yourself or purchase a ready-made building. Summer residents often grow flowers for sale. If the choice fell on exotic plants, then you need to calculate the costs and study the construction requirements.

Their advantages and disadvantages

A lean-to greenhouse is a wall-mounted structure. The width varies from 2.6 to 3 m. You can choose any length. Glass, film or polycarbonate can be used as cladding material.

Lean greenhouse adjacent to the house

The advantages of such a greenhouse:

- An excellent option for a winter garden or greenhouse when there is a transition to a private house.

- Takes up little space.

- Low consumption of materials.

If you plan to use the greenhouse all year round, you will need to connect it to a centralized heating system. This may incur additional costs.

Design disadvantages:

- It is impossible to place the product on the north side, as it will be shaded. As a result, one of the walls will be wet.

- There is much less light in a greenhouse than in a separate building. Therefore, you will need to conduct electricity and arrange powerful lighting.

The most common greenhouses are gable ones.

Capital gable greenhouse

All walls are located at right angles to the soil. The optimal roof slope is 30–40°.

Product advantages:

- Possibility to set any ridge height. The height of the roof will depend on the width of the building.

- If the shape of the house is chosen, tall plants can be grown in the greenhouse.

- It is possible to use polycarbonate for coating. Accordingly, there is no need to build a foundation.

- It is possible to install vents in the roof.

- Larger air volume with unchanged dimensions.

Flaws:

- If the product is covered with glass, then you will need to make a foundation.

- There is no possibility to redevelop the site in the future, since the weight of the structure is high due to the foundation.

- A large number of joints, which has a bad effect on the ability to retain heat. The problem can be solved by installing rubber gaskets.

- High consumption of materials when compared with arched construction.

- The need to use thick polycarbonate.

In some cases, summer residents erect an arched structure.

Arch-shaped design with polycarbonate coating

The frame has an arc shape. You can choose any length. Maximum height - 2 m.

Advantages of arched construction:

- Ease of installation.

- Possibility of increasing the length.

- Low consumption of coating material. Polycarbonate is applied as a continuous sheet.

- Minimum number of seams.

- No need to build a foundation.

- Low cost.

- Possibility of dismantling.

- High strength.

The disadvantages include:

- Limited height. If you need a greenhouse more than 2 m high, you will need to strengthen the frame.

- Low resistance to strong winds and snow.

- It is impossible to install vents in the roof.

The choice of form largely depends on the personal preferences of the summer resident.

Determining the dimensions of the structure

To draw up a drawing, you will need to determine the dimensions of the greenhouse.

What should the width be?

Width is the main indicator in the process of determining the dimensions of a structure. In a narrow building, monitoring plants is problematic. The width of the greenhouse should be such that the product is comfortable to use.

Layout of beds for a greenhouse with optimal width

In addition, this indicator will depend on how many beds need to be planted. The distance between the rows also has an impact. For example, if the beds are large, then it is quite difficult to reach the extreme point while watering the plants. If the beds are small in width, then useful area will be lost on the paths.

The practice of summer residents with extensive experience shows that the optimal option is when several beds are 80–85 cm, and the passage between them is 35–45 cm. Based on these indicators, the recommended width of the greenhouse will be 2.4–2.6 m. If you need to make not 2, but 3 beds, then the width of the product should be 3–3.4 m. In this case, the width of the bed will be 50–60 cm, and the distance between the beds will be 65–70 cm.

The minimum width of the greenhouse is 2.4 m. It is necessary to take into account the width of the door. The optimal size is 60 cm. This passage will provide comfortable movement for the summer resident. If you plan to use a wheelbarrow, you will need to make the door wider - about 90 cm.

In some cases, a building is made with several aisles and a central rack about 95 cm wide. The width of such a structure should be 3.8–4.2 m.

Determining the length of the building

This parameter does not affect anything, it can be anything. Most often, greenhouses are built so long that it is a multiple of 60 or 120 cm. In this case, it will be possible to easily attach the floor panels, which are manufactured in a standard size.

When determining the length, you need to take into account the number and size of pallets that need to be placed on the rack. Therefore, the length of the building must correspond to the length of the racks that are located on them. It is also important to take into account the area needed for the tracks along the two ends of the shelves.

Optimal building height

It is important that there is little space left between the plants that are placed in the soil or on shelves, while at the same time the summer resident has enough space to conveniently maintain them.

For example, if you plan to grow short plants in the ground, then the height of the greenhouse from the top door cornice to the ceiling will be 40–60 cm. If you want to grow plants on racks, then you need to add the dimensions of the shelves to the height.

Important: the height of the greenhouse ridge must be greater than the given value of the side walls. If the height in the ridge is 2.3–2.4 m, then in the cornice it will be 1.6–1.7 m.

The height of the door must be adjusted to the average height of the user. Most often the value is 1.8 m.

Drawing up diagrams and drawings

On the diagram you need to indicate the length, width and height that were calculated earlier.

A competent drawing is based on the shape and dimensions of the structure, and the construction diagram should be based on the requirements for this structure and the purpose of its use. It is recommended to take photos and dimensions of finished greenhouse frames as a basis or draw up a greenhouse project yourself.

An example of a competent drawing

Ready-made structures, which are manufactured at the factory, imply full compliance of the material and frame used with the main load and conditions of use. The design of a product that is built by hand should be based on similar rules.

The technology for drawing up a design diagram implies compliance with the following features:

- The frame in most cases is made of pipes or metal profiles. This is the best option for such structures.

- Lumber absorbs moisture, so it is not recommended to use it for making frames.

- If for some reason it was decided to use wood, then it is necessary to treat it with an antiseptic and apply a layer of varnish, which can extend the service life of the structure.

- The product diagram must be drawn up in accordance with the calculation of the characteristics of possible loads on the frame structure and coating. It is important to take into account the loads from wind and snow.

- If the design does not involve the manufacture of a durable frame, then the product must be cleared of snow from time to time in winter. Such a frame structure is cheaper, but it is less practical.

The frame of the building can be made of the following materials:

- aluminum;

- steel;

- wood;

- plastic.

Frame diagram of a small greenhouse

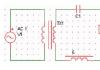

It is important to carefully consider how the heating system will be placed.

Greenhouse water heating scheme

Most often, modern greenhouses use water heating, which involves heating the plants being grown during the cold period by means of hot water that circulates in pipes.

If the greenhouse is installed near a private house, then you can connect it to the building’s heating system. In this case, the heating diagram will make it possible to correctly correlate the heating system of the greenhouse with a similar system in a private house. However, in most cases, an independent system is built for a greenhouse.

Selection of material for manufacturing

In the process of drawing up a diagram, it is necessary to take into account the material that will be used to cover the frame. The winter greenhouse must be durable and airtight, so wood or metal are suitable materials. These materials are durable, so you can choose any one. Wood is easy to work with, but metal is more reliable. Wood will not heat up at elevated temperatures.

The racks must be strong and thick, otherwise they will not be able to withstand the weight of the building and the load from snow on the roof.

Suitable materials for cladding:

- glass;

- polyethylene;

- polycarbonate

If the choice fell on film, then the frame must be sheathed in several layers. It is not recommended to use this material for arranging the entire product.

Quite often greenhouses are made with glass coverings.

Small glass greenhouse

The main advantages of this material:

- High level of transparency and durability. Unlike other coatings, the transparency of glass remains unchanged during use. You only need to wash the windows from dust and dirt from time to time.

- The material is environmentally friendly. It will not emit odors when heated.

- Glass does not interact with other elements, so if chemicals or fertilizers come into contact with it, the glass will not change its properties.

The disadvantages include:

- Fragility. If for any reason the frame structure of the greenhouse changes its geometry, the glass facing sheets will break.

- The material is heavy, and therefore the frame needs to be strengthened.

- The material is suitable exclusively for stationary structures.

- Increased thermal conductivity. The air temperature in glass products decreases quickly in frosty conditions and at night.

- High cost of material. This type of coating is the most expensive.

Another type of coating is polyethylene.

Polyethylene coated construction

Main advantages:

- Can be used for the manufacture of structures of any complexity.

- Low cost.

- Easy to install film.

The disadvantage is that the material is short-lived. A greenhouse that is covered with polyethylene is not able to withstand the weight of snow and strong winds. Therefore, summer residents need to remove the film from the frame structure in the winter. However, such actions have a positive effect on the condition of the soil.

Not long ago, a new material called agrofibre appeared on sale.

Agrofibre-coated construction

Unlike polyethylene, the material is durable and has a high level of transparency. Agrofibre can withstand heavy weight and strong gusts of wind. The material is breathable, so the greenhouse will not need to be ventilated often. Another advantage is the lightness of the product. This makes it possible to move the greenhouse from place to place.

Another material is polycarbonate.

Polycarbonate coated product

This type of coating is quite popular, as it combines the advantages of the first two types. The material is a lightweight, transparent plastic that has a high level of light transmittance. Polycarbonate also has the following advantages:

- The material is durable and can withstand significant loads.

- Low thermal conductivity. This makes it possible to save heat inside the greenhouse for a long time.

During hot weather, the temperature inside a polycarbonate structure can exceed 60°C, so the product must be ventilated. It is recommended to provide windows in the building.

You need to choose the material based on your needs.

Calculation of the amount of material

You cannot make mistakes in the process of drawing up a drawing and calculating materials - everything must be accurate to within 1 mm. Be sure to indicate the dimensions of the parts, even if they are repeated. An example of calculating the material for making a frame is shown in the figure below:

An example of calculating material for a frame

Installation of polycarbonate sheets

One standard sheet is 6 m long, and the thickness does not matter. The circumference of a standard greenhouse is also 6 m. If you decide to make a greenhouse with a house, then the formula will be as follows: H x 2 + W, where H is the height of the structure, and W is the width.

Standard sizes of polycarbonate

The sheet width is 2.1 m, which is 10 cm more than the standard span between greenhouse sections. This makes it possible to make a hermetically sealed overlap of sheets.

The end part of the structure has a width of 3 m and a height of 2.1 m. To cover 2 ends, you need 1 sheet of polycarbonate.

A sheet 6 m long needs to be cut into two parts to get 2 sections of 3 m each. The height of the sections will be 2.1 m. The elements completely repeat the dimensions of the pediment.

Accordingly, for a greenhouse 4 m long, 3 sheets of material are needed. The first sheet is attached to the end part of the structure, and the remaining 2 sheets cover the product in the upper part. If you plan to make a structure 6 m long, then you need to purchase 4 sheets of material. For a greenhouse 8 m long you will need 5 sheets of polycarbonate.

To make a greenhouse you will need the following elements:

- brush;

- dye;

- concrete mixture for preparing mortar;

- roulette;

- building level;

- sand;

- electric drill;

- frame material;

- reinforcing mesh;

- nails;

- hammer;

- coating material.

It is important to prepare tools and materials in advance so as not to stop the construction process.

Instructions for making a greenhouse

The construction of a greenhouse begins with choosing the location of the structure. It is important to consider the following factors:

- It is important to choose a place protected from the wind. If there is often strong wind in the chosen location, then you need to think about protecting the product. This will make it possible to reduce heating costs and continuously maintain the optimal temperature.

- The winter greenhouse should receive a large amount of daylight. It is recommended to position the structure lengthwise from west to east.

- Access or passage to the structure must be convenient and wide. Thanks to this, it will be convenient to use the building for its intended purpose.

To protect the greenhouse from the wind, summer residents often plant a hedge. It should be remembered that the fence must be located at a distance of at least 10 m. The distance depends on the height of the ridge.

How to make a base for a greenhouse?

The simplest method of constructing a base for a greenhouse is to tie its perimeter with slats with a section of 12x12 cm.

Wooden base for a greenhouse

Sequence of manufacturing steps:

- Dig a trench.

- Lay out the roofing felt.

- Mount the timber in several rows.

- Connect the rows with pins.

- Attach the greenhouse using construction corners.

The advantage of such a foundation is the possibility of dismantling and ease of installation. The disadvantage is that the base is subject to rot, even if protective agents are used. Accordingly, it is recommended to use the foundation exclusively as a temporary option.

If the area is damp, then a block base is suitable.

Greenhouse block foundation

You can do it this way:

- You will need to pour a 10 cm thick layer of gravel onto the prepared soil.

- Concrete must be poured on top of the fill.

- Place the starting block in the solution.

- Using a building level, the block must be leveled horizontally and vertically.

- The hollow block will need to be filled with concrete mortar and compacted.

- The base of the foundation needs to be smoothed.

- Using a construction cord, the clinker should be laid.

- After the solution has hardened, it is necessary to cover the seams.

Where the base adjoins the walls of the greenhouse, it is important to use whole bricks. The gaps between the material can be filled with small pieces.

The most reliable foundation is a brick structure on a concrete base. Manufacturing instructions:

- First of all, you will need to dig a pit 10 cm deep and 20 cm wide.

- If the soil is loose and soft, then it is recommended to make formwork from old slats.

- The container must be filled with concrete mortar.

- A building level must be mounted on a long straight plank to check the horizontalness of the concrete base.

- Anchor bolts with a diameter of 10 mm should be installed on the sides and ends. Installation must be done so that they correspond to the base of the frame structure.

- After 6–7 days, the initial row of bricks is laid. The seams between adjacent elements must be completely filled with the mixture.

Visually, the base manufacturing process can be seen in the figure:

Making a brick base

During the installation of the greenhouse, it is necessary to drill holes for the bolts in the frame structure, after which the joints are tightened with nuts. It is recommended to lay a waterproofing layer between the wooden frame and the bricks.

How to make a base, walls and frame?

One of the main processes is the construction of the base. The element is made from new brick.

Base for greenhouse

Sequencing:

Instructions for constructing the frame:

Additionally, corner supports can be provided.

How to sheathe the frame?

As mentioned earlier, it is best to use polycarbonate. It is worth knowing that the plastic coating expands in the heat and contracts when the temperature drops.

When installing the material, the following factors should be taken into account:

- Installation of polycarbonate on the frame is carried out in a certain direction. Sheets must be positioned vertically.

- The parts are mounted with the outer side facing out.

- If you plan to build an arc greenhouse, then the sheets are attached in the direction of the arcs of the frame structure.

- When constructing a pitched product, polycarbonate is attached along the vertical posts and rafters.

- Do not over-tighten the fasteners.

Polycarbonate can be fixed with various fasteners.

The rules for installing fasteners are contained in the figure:

Rules for installing self-tapping screws in polycarbonate

Step-by-step instructions for covering the frame:

- First of all, you will need to cut the sheets. They need to be placed vertically so that condensation can drain from the voids. The sheets must be cut so that the joints fall on the profile of the frame structure.

- The minimum roof overhang is 50 mm.

Small roof overhang for joining surfaces

If there is no overhang, then the junction of the inclined and vertical base must be secured with an adjustable corner profile.

- The lower end parts must be covered with a special profile, having previously been pasted over with aluminum tape. Special profiles are also produced for external corners, ridge and longitudinal joints:

Types of profiles for polycarbonate

- To fix material with a metal frame, it is recommended to use self-tapping screws with large heads and rubber gaskets.

- Large parts must be installed through a connection profile. There is no need to screw screws into the panels. The sheets are attached to the profile with a gap of several mm. The process can be seen in the figure:

Installation of large parts through a split profile

You can drill polycarbonate using standard metal drills.

Video: covering a greenhouse with polycarbonate

Finally, you will need to install the door.

Greenhouse interior design

At this stage, you need to install electricity and water into the structure. It is recommended to involve a specialist. Sequencing:

- Lighting outlets are distributed and shut-off valves are installed.

- Installation of lamps. They must be selected based on the characteristics of the plants. The best option is LED lamps.

- At the next stage, you need to choose the type of growing plants - on beds or racks.

- The soil is brought in, substrates, fertilizers and various additives are prepared.

Finally, heating is installed.

Video: instructions for installing heating in a greenhouse

It is important to choose a heating system based on your needs and capabilities.

How to heat?

The productivity of the greenhouse depends on the type of heating. Today there are many heating options: To choose, you need to consider the advantages and disadvantages of each of them:

- Electric Energy. It is possible to perform installation on an area that is located far from the house. It is allowed to use a convector, cable heating, heat pump and water heating.

- Gas. In the greenhouse you will need to install a gas heater in which combustion will take place. To prevent oxygen burnout, good ventilation must be provided.

- Bake. The option is affordable and economical. Gas, coal or wood are used as fuel. The disadvantage is the heating of the walls. It is not allowed to plant plants near the stove.

- Sun. Not suitable for winter, as the sun's rays will not be able to heat it. Can be combined with other heating sources.

You need to choose a heating system based on the local climate, planned budget and type of plants grown.

To extend the life of the greenhouse, it is important to consider the following:

- To prevent heavy snow drift, the structure should be placed at a distance of 1–2 m from buildings, fences and trees.

- After snowfalls, the greenhouse needs to be cleaned.

- To prevent the product from being torn off by the wind, metal pegs must be driven into the corners of the building.

- Polycarbonate can be cleaned with a soft cloth soaked in water.

Greenhouses do not require special attention, but periodic cleaning is recommended.

If you approach the issue of construction responsibly and follow the technology, then you can make a high-quality structure with your own hands, in which it will be possible to grow almost any plants.

Winter greenhouses are designed primarily for growing plants throughout the year. As we know, in winter, vegetables, berries and herbs are very expensive, so many summer residents build structures on their site with their own hands in order to always have fresh salads and compotes on the table. But before starting construction work, it is necessary to carefully think through the design of the future greenhouse, its heating system and make an accurate drawing.

Construction device

Today, winter greenhouses can be built from various materials. Therefore, each owner of a summer cottage can choose the most suitable and cost-effective options for himself.

Shapes and sizes of greenhouses:

The design of a winter greenhouse must withstand severe frosts, snowfalls and other atmospheric phenomena. The most durable, reliable and environmentally friendly material for constructing a greenhouse frame is wood. But such a structure can last no more than 15 years, and then it will have to be updated.

The most durable and profitable design is considered to be a greenhouse with polycarbonate cladding, since this material is of high quality, long service life and affordable price.

Any winter greenhouse must have a foundation, frame and glass roof. It is best to build such a structure from north to south. The room must have a good ventilation system to regulate heat and air conditions for the proper functioning of plants.

Ventilation can be supply or exhaust. The tightness of the greenhouse is the main condition for its effective functioning. The temperature is maintained artificially.

The greenhouse can be racked, in which the plants are placed on shelves with sides, or rackless, where the plants are planted directly into the ground. The racks in the greenhouse should be approximately at a height of about 60–80 cm from the ground, and the passage between them should be at least 70 cm. The racks are made of wooden boards, plastic or reinforced concrete, depending on the design features of the greenhouse.

Photo gallery: selection of project options

Greenhouse drawing with dimensions

Greenhouse drawing with dimensions  Scheme of a rack greenhouse

Scheme of a rack greenhouse  Winter greenhouse design option

Winter greenhouse design option

Types of structures: advantages and disadvantages

Winter greenhouses come in several types depending on their design features, type of material used, type of lighting, heating system, and foundation design.

- Capital greenhouses are built on a strip foundation. A trench is dug in the center, which is designed to “collect” cold air, which should not reach the roots of the seedlings. Thanks to this design, the inside of the greenhouse warms up quickly enough and therefore seedlings can be planted several weeks earlier than usual.

- Capital types of conventional type greenhouses are collapsible structures that can be dismantled and moved around the site. To build such a greenhouse, a metal or plastic profile, polycarbonate, and bolted connections are used. Piles serve as the foundation.

The remaining types are prefabricated structures. Only in a permanent structure can a full-fledged heating and artificial lighting system be installed.

Greenhouses may differ in such parameters as:

- Functionality. They allow you to grow not only ordinary vegetables of a given region, but also exotic ones.

- Location in relation to the ground. There can be three types: recessed, surface and arranged in the upper part of a barn, garage, closet, etc.

- Architectural solution. They can be with a single-pitched, gable, three-pitched roof, as well as arched, wall-mounted and combined.

Greenhouses also differ:

- By type of building materials. They can be built from brick, wooden beams, metal profiles or PVC pipes. Polycarbonate or glass is used as a coating. Today, combined greenhouses, in which the walls are lined with polycarbonate and the roof is made of glass, are in great demand.

- According to the type of heating system. Winter greenhouses can operate on biofuel, solar panels, and also have stove, air, gas, water or electric heating.

- By type of planting seedlings and plants. They are planted in the ground or in specially knocked down boxes placed on shelves.

Depending on the design, greenhouses are divided into the following types:

- The thermos greenhouse, or as it is called the “Patia greenhouse,” despite the complexity of its design, is one of the most popular among summer residents. Its main part is located underground, due to which the “thermos” effect is achieved. It can also be above ground, but it must be covered from the inside with any heat-insulating material. In such a greenhouse, it is recommended to install a water heating system, as it will allow warm air flows to be evenly distributed throughout the room.

- A greenhouse with a gable roof is the most common design due to its convenience and versatility. The height of the greenhouse reaches 2-.5 meters to the ridge, so a person can walk in it without bending his head. Also, in it, seedlings can be grown not only on the ground, but also in special boxes on racks. The advantage of a gable design is that snow and rainwater do not accumulate on the roof surface, but quickly flow down. Disadvantages: high cost of materials, complexity of construction and large heat losses through the northern wall. Therefore, it must be additionally insulated with various heat-insulating materials.

- An arched greenhouse is considered a complex structure, as it often causes problems with the construction of the frame and cladding. Without a special device, it is almost impossible to bend metal pipes to make a frame (but you can take PVC pipes). It is not possible to use glass to cover the frame, so all that remains is polycarbonate or various types of greenhouse films. The disadvantage of an arched greenhouse is the real danger of cracks in the polycarbonate during heavy snowfall, since if the layer is too large, the roof will not withstand the load. There is no possibility to place racks and shelves inside such a structure, so plants can only be grown on the ground.

- Greenhouse with sloping walls. The design of such a greenhouse resembles an ordinary “house” in appearance, but only with walls built at a certain angle, extending outside the room. The advantage of such a greenhouse is the possibility of construction from wood, metal, and plastic. Glass, polycarbonate, film can serve as cladding. The biggest advantage is considered to be a “self-cleaning” gable roof. The downside is the restrictions on installing racks and shelves around the perimeter of the walls due to the sloping walls.

- Greenhouse with mansard roof. A type of structure with vertical walls and a mansard roof, which copes well with mechanical loads such as snow. Thanks to the special roof, more space is created above your head, and a large number of multi-tiered racks and shelves can be placed on the walls.

- Single slope greenhouse. The design of the walls is no different from a gable roof, but here the roof is installed at a certain angle so that snow falls off it and rainwater drains without getting inside the room. Glass and polycarbonate can be used for cladding. Polyethylene film is not suitable for a winter greenhouse. Along the walls you can install shelves and racks on top of each other for multi-tiered growing of plants. It is practically devoid of disadvantages, except for the complexity of construction and installation of a strip foundation.

Preparatory work: drawings and dimensions of the structure

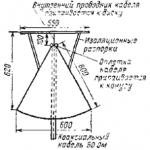

We will consider the construction of a winter greenhouse 3.34 meters wide and 4.05 meters long. The total area of the room for growing crops is 10 square meters. meters.

The greenhouse is a square room buried in the ground with shelves and a roof made of durable two-layer polycarbonate.

If there is groundwater on the site and it is close to the surface, then the greenhouse is built without deepening, and the outer sides of the structure are sprinkled with soil.

If necessary, the length of the structure can be increased by adding additional sections to the frame.

Structure of racks and their dimensions

Where the beam connects, a triangular-shaped support is built. The dimensions are shown below in the drawing.

Ridge posts are needed to support the timber at the connection point. Also, the support should not come into contact with the polycarbonate sheathing.

A strong support system will not interfere when a person moves around the greenhouse. It is necessary if the length of the greenhouse is more than 4 meters. If the length exceeds these parameters, then supports are installed every 4 meters.

Corner supports are made of 100x100 mm timber, intermediate supports are made of 50x100 mm boards.

Construction of walls and thermal insulation

The pillars will be covered with boards on both sides, and insulation will be placed in the interior space.

To save money, you can take round timber Ø 120–150 mm, hewn to 100 mm. The walls are covered with slabs.

To insulate walls, use slag, sawdust or fine expanded clay. Quicklime is added to sawdust as protection against small rodents.

When choosing timber and boards, it is necessary to take into account that this structure will be used throughout the year, so the lumber must be of high quality.

- For the construction of supports and other parts of the frame, it is recommended to purchase pine boards and timber (rounded or glued). This is the most accessible, durable and cost-effective material for the construction of greenhouses in our region.

You can also choose larch or oak, but such lumber is quite expensive and therefore it is irrational to use them in this case.

Polycarbonate has excellent heat and sound insulation characteristics. But the more complex its structure, the greater the mechanical loads it can withstand (snow and wind).

When choosing polycarbonate, you need to know its thickness.

- For cladding the walls of a greenhouse, it is best to take sheets with a thickness of 6 to 25 mm, depending on the intended design.

- For roofing, polycarbonate with a thickness of 16 to 32 mm is recommended, since this part of the greenhouse will bear the heaviest load.

Calculation of the required amount of material and tools

- Beam with a section of 100x100 mm;

- Board with a section of 50x100 mm;

- Gorbyl;

- Round timber Ø 120–150 mm;

- Boards for making shelving;

- Insulation;

- Foamed polyethylene (aluminum foil);

- Polycarbonate sheets;

- Self-tapping screws and thermal washers;

- Hardware;

- Screwdriver;

- Wood hacksaw or saw;

Step-by-step instructions for building an in-depth winter greenhouse with your own hands

We dig a pit 60 cm deep. Its length and width should be several centimeters larger than the perimeter of the future greenhouse. At the bottom we make markings for installing support pillars. We dig in the supports to a depth of about 50 cm.

At a height of one meter from the ground, stretch the construction rope and check the evenness using a level. We fill the supports with soil and compact them thoroughly.

We level the floor and cover the walls with boards outside and inside, starting from the bottom. We fill the space between them with the selected insulation. This is how we cover the opposite two walls.

After we have sheathed the walls, we need to saw off the excess ends of the boards that extend beyond the pillars. At the corners of the structure inside, we nail 50x50 mm bars onto the boards. Next, we will attach the sheathing to them on the front and back of the wall. This is how we sew up all the walls of the greenhouse. But we nail the boards to the vertical beams.

We compact the insulation inside the walls, adding the required amount of expanded clay, sawdust or slag to the top. Then we sew up the top of the walls with boards.

We also cover the inner surface of the walls with insulation made from special foil. We place the insulation so that it extends slightly at the top of the walls, and bend it so that it can cover the boards covering the upper part of the walls.

We make the roof separately from the main structure, and then install it on the greenhouse. We manufacture all other roofing elements according to the diagrams indicated in the drawing.

We connect the rafter parts into half a tree, and nail the lintel so that the distance at the bottom is 3 meters 45 centimeters. Since the jumper is temporary, we must nail it so that it can then be dismantled. The nails should not be driven in completely, but should be left 10 mm from the head so that they can be easily removed.

We assemble the rafters and nail them to the support as shown in the drawing below.

After we have nailed the rafters to the support, we remove the jumpers. We install the ridge beam under the rafters and place the front posts measuring 88 cm under it. We nail the outer rafters (20 cm) to the ridge beam. To do this, we pre-drill holes in the rafters. Then we install a jumper between the rafters, and install flashings on the side rafters, the ridge beam and on the front posts as shown in the drawing.

Reference. Strips are called wooden strips that are designed to cover various cracks.

We attach two-layer thick polycarbonate to the roof frame using self-tapping screws with thermal washers. To do this, we drill holes in the sheets larger than the diameter of the screws themselves.

After attaching the polycarbonate, we need to install a ridge corner from galvanized sheet metal. We fasten it with a gasket for insulation. We do not attach polycarbonate to the side ends of the roof until we have secured the roof to the main structure.

We install the roof on the walls and secure it with 4 metal brackets. They can be made from twenty-centimeter long nails. Then we install the side parts of the roof from polycarbonate triangles.

We install an insulated thick wooden door (thickness at least 5 cm).

After this, you can install wooden racks and shelves inside the greenhouse for future seedlings. They are installed on the sides of the walls at a distance of approximately 60 cm from the floor. A layer of earth is poured on them or boxes with soil are placed.

Heating selection

The choice of heating system depends on the size of the room. For winter greenhouses with an area of more than 15 square meters. meters, stove heating is suitable. Large areas are usually heated with biofuel, electric heaters or a water loop.

Stove heating is an affordable and economical option for a greenhouse. In this case, a stove is installed in the room, which is heated with wood, coal, briquettes, pallets or gas. But since the walls of the oven become very hot, plants should not be planted near it.

Water heating requires a water heating boiler, pipes and a tank. The pipes are buried in the ground to a depth of about 40 cm or placed immediately under the shelves.

Electric heating can be of three types: air, cable and infrared. Cable is a “warm floor” system, air is installed using fan heaters, and infrared is produced by special heating devices that are mounted under the roof of the greenhouse.

Biofuel heating is the most cost-effective heating option. Here, the indoor air is warmed due to the heat generated during the decomposition of various organic substances.

The most used biomaterials are:

- Horse manure - capable of maintaining a temperature of 33 to 38°C for 2–3 months;

- Cow dung - can keep 20°C for about 3.5 months;

- Rotted tree bark - keeps at 25°C for about 4 months;

- Sawdust - maintain 20°C for only 2 weeks;

- Straw - can maintain a temperature of 45°C for up to 10 days.

Biofuel is placed in the ground under the top layer of fertile soil. When choosing a fuel type, it is necessary to take into account its acidity level, since it significantly affects the quality of the soil. Cow dung is considered the best as its acidity level is 6-7 pH. A more acidic environment is created by bark and sawdust, and an alkaline environment is created by horse manure. Biofuel after its use can be reused as humus.

The type of heating is selected individually for each specific case, based on parameters such as the climate of the region, planned expenses and type of plants.

- Before starting construction of the greenhouse, all wooden boards and beams must be treated with antifungal and antiseptic agents.

- Before installing the supports, after treating them with protective agents, the lower parts must be tightly wrapped with roofing material and secured with a stapler.

- It is also necessary to protect the external walls by securing roofing felt to them. And only then sprinkle them with soil.

- The roof frame, after applying a protective coating and primer, is covered with white paint intended for outdoor work.

- During the operation of the greenhouse, it is necessary to choose energy-saving lamps to create artificial lighting. They help you use electricity more economically. Their number and location depend on the dimensions of the internal space of the greenhouse.

Video: how to build a winter greenhouse with your own hands

If, when constructing a winter greenhouse, you strictly observe all technical standards and follow the drawn up diagrams and drawings, then such a design will delight you and your loved ones with excellent harvests of vegetables, berries and fresh herbs for decades.

A winter greenhouse has long ceased to be something outlandish in gardening. Previously, they were built for mini-businesses or to have household help all year round, now everything is different. Many people are switching to natural products, abandoning low-quality store-bought vegetables loaded with chemicals. Buying and assembling a greenhouse today is available to almost everyone, but many prefer a capital winter greenhouse, built with their own hands according to all the rules.

A capital greenhouse, if it is made correctly, will serve for at least a decade, you just need to decide on its specialization from the very beginning. This is due to the fact that growing different plants requires a certain regime:

- light;

- watering;

- temperature;

- feeding;

- treatment against fungus and mold.

For example, you can convert an old garage for mushrooms, but growing flowers requires a lot of light. Spring seedlings do not require much heat. But without additional lighting and heating, it is impossible to grow red tomatoes, remontant strawberries and lemons in the middle of winter.

The size of the winter greenhouse also depends on various factors:

- experience in growing crops in the cold season;

- climatic conditions of the region;

- scale of greenhouse farming;

- specialization of the building and its form.

A large greenhouse structure should have 2 departments - actually, a greenhouse and a working vestibule for equipment. A process automation unit can also be located here. It assumes:

- heating boiler;

- shut-off valves for irrigation;

- electrical panel for turning on/off ventilation and lighting.

The optimal vestibule format is at least 2.5 x 2.5 m, with a hanger for work clothes and shoes. A table or other work surface will also come in handy. It will be convenient to make earthen mixtures and package fertilizers here.

Important: There is always high humidity inside the greenhouse. Therefore, all materials need to be processed, including painting and impregnation with antiseptics and fungicides against fungi.

Constructing a frame under a thick film, as in summer greenhouses for cucumbers, cannot be done here either - only a reliable covering. Glass is suitable, you can use polycarbonate or other material that transmits light well and scatters the meager rays of the sun - welcome guests in the cold season. To make the most of the influx of natural light, vary the location and shape of the building:

- Gable;

- Tent;

- Pyramidal;

- Cone-shaped;

- Spherical;

- Arched (polycarbonate).

When building a winter greenhouse with your own hands, it is important to remember about soil freezing. In the pit, excavation is carried out in different ways, but not above the level of the freezing layer. In the Russian Federation it is about 70-90 cm, depending on the region. When equipping the foundation of a permanent greenhouse, they use the same recommendations - it is poured to a depth of at least half a meter.

Varieties:

- lean-to extension to the house;

- capital greenhouse - with a foundation, glazed roof and basement walls.

The walls of the basement level, on which the translucent part of the winter building is built, are laid at a thickness of 1 brick or about 25 cm. The window level should rise above the ground level by at least 50-90 cm (depending on the region). Some greenhouse frames are equipped with easily opening transoms (windows) for ventilation, which must be opened slightly in winter and early spring - on warm sunny days. Some experts recommend a number of ready-made plastic frames with supply valves for ventilation. Only in this case can we say that the winter greenhouse was built according to all the rules.

Heating

Microclimate is the main factor that determines, even in harsh conditions where there is winter for six months, the viability of crops grown all year round. Most heated polycarbonate winter greenhouses maintain optimal temperatures, allowing even small farms to consistently grow large crops.

It all depends on the capabilities, but it is better to use combined heating, including humus and biofuel, which is the most economical. Also, in addition to gas, universal boilers can be filled with solid fuel, including agricultural waste, a mixture of sawdust and coal dust, as well as used engine oil and fuel oil. If you take care in advance about purchasing such a boiler for a winter greenhouse with heating, its heating will not be expensive.

Different types of heating are practiced:

- oven;

- water;

- gas;

- electric.

Recently, solar greenhouses and biofuel greenhouses are also gaining popularity. Steam and stove heating are appropriate for small lean-to extensions adjacent to a residential building.

Attention: Special lamps are needed to increase daylight hours. They are necessary for the development of exotic plants in winter. Phytolamps provide little heat, so you cannot count on them as additional heating. For this, there are special fan heaters and heaters using infrared rays that operate from the network.

Providing the desired microclimate from the electrical network can be organized in different ways:

- air heating;

- cable (warm floor);

- infrared rays (IR) or UFO heating devices.

Electric heating is expensive, so it is rarely used in its pure form. It makes sense when there is no other way or as a temporary measure, for example, before purchasing and installing a boiler.

Before building a winter greenhouse, it is worth considering where the pipes for steam or water heating will run. It is recommended to lay them partially under the greenhouse soil, so that heating is most complete, and partially above its surface. Pipes can also be laid along the top, especially if growing hydroponically or in containers. The heating circuit also includes a water heating boiler and a tank.

Large winter greenhouses often have cable heating, reminiscent of heating with Nexans, similar to the Norwegian know-how “warm floor”. The base is a special metal grate on a sand bed, into which the heating cable is laid in loops. It is covered with sand and fertile soil. Additionally, special fan heaters provide an influx of warm air.

Biofuel is considered the most economical way to maintain a microclimate when heating a winter greenhouse. The natural process of heat release is the result of the decomposition of organic matter:

- horse manure will give a temperature of about 33-38°C for up to 90 days;

- cow humus – up to 20°C for 90-100 days;

- rotted bark - up to 25°C for 100-120 days;

- sawdust – up to 20°C for 14-16 days;

- straw - up to 45°C for 10-12 days.

Organic matter at the stage of active decomposition is placed under the fertile layer. But to rot, manure needs enough oxygen and high air humidity - at least 70%. The acidity level of the soil for manure is up to 6-9 pH, sawdust and bark rot at a level of 5 pH.

Tip: Rotted organic matter does not need to be removed until next winter - this is an excellent natural fertilizer for greenhouse plants.

Special gas heaters are more often used for large greenhouse areas. In large farms, they are the ones who pump warm air into impressively sized winter greenhouses.

Insulation of winter greenhouses

A properly constructed greenhouse for winter growing of vegetables and flowers should be well insulated, then its maintenance will be the most economical. Insulation and type of heating are the determining factors for the temperature regime. They need to be regulated using accessible methods.

The location of the building relative to the sun also matters, although its rays provide virtually no warmth during the cold season. On the north side it makes sense to plant a hedge, which to a certain extent protects the building from gusty winds on frosty days. It should not be too close so as not to take away the heat from the walls in the turbulence zone. The size of the greenhouse, the direction in which the winds blow in a given region, and whether there are constant drafts in a given area are taken into account.

Attention: Ideally, a winter greenhouse is built from west to east, and a summer greenhouse - from north to south. This is important for the perception of the greatest amount of heat and light, which are needed for the full development of plants.

You can reduce heat loss in different ways:

- deepen the base to the level of soil freezing;

- build a frame foundation and a base of sufficient thickness;

- use double glazing or thick polycarbonate (transmits light well);

- achieve maximum tightness of joints;

- do not use freezing materials (wood is better than aluminum, frames are difficult to insulate);

- install ready-made double-glazed windows.

There are options to choose from among light-transmitting proposals, but each has its own disadvantages:

- Polyethylene film is an inexpensive base material for greenhouses, not very durable; in gusty winds, the formed plants may be left without protection. It is rational to use 2-3 layers of film, but for northern latitudes this is not entirely suitable insulation;

- Glass is a heavy and fragile coating, applicable as single and double walls for permanent attic-type greenhouses. Under mechanical stress it can easily break and damage the integrity of the building;

- Unbreakable plexiglass or organic glass is lighter than its counterpart. It can be sawed, cut, drilled. Plexiglas has some plasticity, bends under weight and deforms over time, is afraid of low temperatures, scratches remain on it, reducing permeability. This is probably why expensive material is less in demand for covering greenhouses, but it can temporarily “patch” a hole in a greenhouse;

- Transparent slate and high-permeability polymers are not the best means for preserving heat in a winter greenhouse. Today, the technology of fastening with maximum sealing has not been fully thought out so that it turns out inexpensively;

- Covering greenhouses with polycarbonate is currently considered the most suitable way to construct arched greenhouses. Experts have recognized it as the most versatile modern material. This is the optimal ratio of price and quality, durability and strength, heat retention and light transmittance.

Foam plastic is suitable for arranging a winter greenhouse and insulating the internal walls of the greenhouse. External construction and sealing of cracks are sufficient. Wood is considered the most suitable for the construction of greenhouses. This material will provide a good microclimate; it does not require additional thermal insulation. The main disadvantage is the tendency to swell from moisture and become overgrown with mold. To do this, even at the stage of preparation for construction, the boards are impregnated with fungicides and antiseptics.

Important: In some years there are severe frosts that are detrimental to heat-loving crops in winter. Therefore, for emergency cases, additional insulation of the walls and a method of pumping warm air inside the building should be provided.

Watering the greenhouse and humidifying the air

The main thing that plants protected from the cold need is normal watering. The soil near the roots should not be over-moistened to avoid rotting. But you can’t let it dry out either - this is noticeable by the dying off of the lower leaves. In order not to forget to replenish the root system with moisture, it is recommended to install automatic watering that operates on timers.

Before building a greenhouse for winter growing flowers and vegetables, it is advisable to think in advance about the water supply. You can turn to specialists who will do everything “turnkey” according to all the rules. Automatic watering and drip irrigation are very popular among experienced greenhouse owners.

Slightly heated water from the container, based on a timer signal, is pumped into the irrigation system through tubes or hoses through the irrigation system. Then it is distributed through root droppers and watering cans. Systematic watering will also ensure a sufficient level of humidity within the closed ecosystem. Some exotic plants require increased humidity, which is additionally created by sprayers.

Ventilation in the greenhouse

Humid air should not stagnate in a warm greenhouse, creating a suitable environment for fungi, mold and destructive microflora. In a room where an artificial microclimate is maintained, all indicators must be maintained at a given level, including temperature and humidity.

There are 2 types of ventilation:

- supply;

- exhaust

If there is excessive ventilation or a draft, all indicators must be restored. Therefore, the influx of fresh air must be regular, but insignificant, so that the indicators have time to recover.

Important: In the drawings of a properly designed greenhouse, there should be freely opening transoms that close hermetically after ventilation.

Lighting

Good lighting of plants is necessary for the production of chlorophyll and the full ripening of fruits. Everyone knows tasteless fresh strawberries, “starved” greenhouse tomatoes and odorless spicy greens from supermarkets in early spring. They differ noticeably in the saturation of red or green color. This is due to a lack of sunlight, which is difficult to compensate for in the cold season.

Important: Special lamps must be positioned in such a way that each plant is illuminated!

Lamps emit different light. For the full development of most representatives of the flora kingdom, you need to combine a different spectrum:

- neutral (white);

- “cold” (blue);

- “warm” (yellowish).

A combination of incandescent, halogen, neon and phytolamps is considered optimal. However, they should be located away from the plants so as not to burn them.

Helpful advice: To save electricity, install an electric meter with a “day-night” mode in your greenhouse to make payments at a reduced rate.

How to build a winter greenhouse with your own hands

A solid winter greenhouse made of polycarbonate with your own hands is eloquent proof of the master’s “golden hands”. With such a building, if properly exploited, no matter the economy or cataclysms, there will be no threat of famine. It is important to choose the right location so that it is convenient to install irrigation and electricity. You need a wide passage that is convenient for transportation, especially if the greenhouse is being built for additional income.

The scale and method of building a greenhouse depend on available finances. If you don’t have enough funds for a capital project for the winter, start small - choose a place for a pit with a foundation. In the first year, it is proposed to install a foundation and a simple frame, covering it with film. This will make it easy to set up a simple greenhouse for seedlings, lettuce, fresh herbs and cucumbers. When you have money, you can make a winter greenhouse with your own hands.

Advice: Regardless of whether it is a phased, budget or capital construction of a greenhouse for year-round cultivation of flowers and vegetables, you need to start with a project or drawing. This will help you calculate the amount of building materials and assess your strength.

For example, for the foundation you will need high-grade bricks or reinforced concrete blocks. For a wooden frame, you need timber (for supports and floors of different sections) and glass or cellular polycarbonate as a covering. However, these are only the main expenses; you will also need cement and sand, entrance doors and transoms for ventilation, sealants, insulating materials and insulation.

Modern greenhouse structures have many options, among which the most popular in households are:

- greenhouse-thermos;

- wall-mounted under glass (built against the wall of the house);

- arched under polycarbonate;

- gable and mansard buildings.

Those who have been involved in greenhouses for many years know that a small greenhouse takes a lot of effort and expense until it pays off. Therefore, they recommend immediately starting the construction of a winter greenhouse on a grand scale, like “the eyes are afraid, but the hands are doing.”

Foundation for a greenhouse

All winter greenhouses are installed with your own hands on a permanent foundation. It protects against external factors, including soil freezing and the penetration of excess groundwater. The format of the greenhouse and the characteristics of the soil determine the type of foundation, its depth and materials. Main varieties:

- point;

- tape;

- block;

- cast;

- on stilts;

- brick.

Excavation of soil when pouring the foundation is carried out to the level of soil freezing. The basement level and frame can be installed 1-2 weeks after the concrete has completely set. The laying is done to the width of 1 brick.

It is important to comply with all technological standards when building and arranging a greenhouse for growing vegetables, especially if it is a large format under a heavy glass dome.

Foam concrete walls

For the warm walls of a winter greenhouse, you can use foam concrete or aerated concrete. Lightweight porous material will create a reliable barrier against sub-zero temperatures, provided that the structure is fully heated.

The basement level should not be high - no more than 1 m, so as not to take away part of the sunlight and changeable heat during the cold season. It can be a natural continuation of the foundation, but it is better to arrange good waterproofing between the foundation and the foam concrete walls so that they do not become damp.

Greenhouse roof

The frame is attached to the basement level, according to the drawings, so these points must be marked. Metal frames are easier to assemble, cheaper and more practical, but wooden frames are more environmentally friendly and do not need to be insulated from the inside. They are less susceptible to condensation from temperature changes.

Gable and single-pitched roofing guarantees the natural drainage of precipitation and the melting of the snow cap. To do this, there must be a sufficient angle of inclination - about 25-40°. The roof is crowned with a ridge beam, which is secured with paired rafters.

Tip: If the base of the greenhouse is not insulated enough, you can install double glass or cellular polycarbonate. These are the best materials as a translucent coating. This will help save on heating in a polycarbonate greenhouse or under double glass. They are laid from bottom to top on the putty.

Upon completion of the work, external gutters for storm drainage and internal gutters for condensate drainage are also required.

Final finishing of the greenhouse

At the final stage of construction it is important:

- make the greenhouse airtight;

- insulate as much as possible (slag, sawdust, expanded clay, polystyrene foam);

- equip with systems that support microclimate;

- fill the cells for growing plants with soil mixture;

- check how the heat, light and water supply works;

- treat with fungicides and antiseptics;

- install a reliable wooden door at the entrance.

Capital construction is important, but not the main thing. Garden crops planted for the winter must fully develop in the microclimate that is organized inside a homemade greenhouse. Experienced vegetable growers share this in their video.

Video - building a winter greenhouse with your own hands

It is difficult to say which option for building a winter greenhouse is the most effective and economical. In each video, the masters share their secrets. We hope that our advice will be useful.

Today, it is not a problem to enjoy a vegetable salad in the middle of winter: there is a rich assortment of plant products in stores all year round. But, besides the fact that the price for it is not the most affordable, and the taste leaves much to be desired, the benefits are also minimal, but it is quite possible to “enrich” the body with various chemicals. Therefore, despite the abundance in stores, winter greenhouses, which provide the opportunity to grow environmentally friendly and tasty vegetables or herbs for your family, have not lost their relevance. However, compared to summer greenhouses, winter greenhouses are more complex both in terms of construction and in terms of operation of the structure, and are more demanding in terms of materials. The participants of our portal are mainly engaged in seasonal greenhouses, but they also have experience in the construction and use of year-round greenhouses.

Consider:

- Structural features of winter greenhouses.

- Arrangement of winter greenhouses.

- What to grow in winter.

What should a winter greenhouse be like?

Winter greenhouses are permanent structures built on a foundation that can withstand both wind and snow loads. These can be either free-standing buildings or extensions with one blank wall. For example, to the utility block, if the orientation of the structure allows.

Foundation

The foundation of a greenhouse can be strip or made of separate blocks; columnar and slab foundations are less common. USPs are usually not made under free-standing greenhouses, but if this is a winter garden within a permanent building, then such a foundation is quite justified. In terms of cost, a slight expansion of the building area against the general background is not critical, and the heating circuit installed when pouring the slab will simplify the further arrangement of the greenhouse.

To prevent the outflow of far from free heat through the base of the greenhouse, extruded polystyrene foam can be used when building the foundation. The most effective is comprehensive insulation of both the foundation strip and the soil under the greenhouse, on the site of future beds. The use of insulation is especially important if soil heating is planned; EPS will prevent unnecessary consumption of thermal energy for heating the lower, unused layers of the soil. You can also use insulation to protect the north side.

Frame

Like seasonal, year-round greenhouses, mainly of the frame type, the frame comes in two types:

- metal;

- wood.

These materials are comparable in strength; In addition, wood does not overheat in summer and gives off much less heat to the outside in winter. Considering that winter greenhouses are built on a foundation, and there will be no direct contact with moisture at the racks, the service life of the wooden frame is quite decent. Naturally, when calculating the parameters of all elements, the expected loads must be taken into account.

Alla Ivanova

I prefer to build only wooden winter greenhouses - cheaper, simpler, and simple - I love wood. In our steppe there are such hurricane winds - don’t worry, mother, but nothing has ever been torn down, we always do it conscientiously.

A frame made of HDPE (low-density polyethylene) pipes is increasingly in demand for seasonal greenhouses; if used for winter ones, it is in regions where heavy snowfall is very rare.

The shape of the greenhouse largely depends on the frame material, climatic conditions and personal preferences. Most often they build:

- arched;

- single-pitched;

- gable.

Due to the shape, it is problematic to make a wooden frame for arched structures; technically this is possible, but it will require much more effort and time than rectangular options. Therefore, such greenhouses are usually on a metal frame, while a wooden one is more in demand for single-pitch or gable structures. Although some still prefer to combine wood with the arch.

Sheathing

As for the frame sheathing, the era of polyethylene film in several layers is gradually disappearing; today, in most cases, cellular polycarbonate (SP) is used. Glass, also used as cladding for winter greenhouses, is significantly inferior in thermal conductivity, although it is superior in durability (if treated with care) and light transmittance. From the point of view of heat conservation, the optimal greenhouse-thermos for cold regions is considered to be double cladding with SP sheets with an air gap, similar to double-glazed windows. In this case, the thickness of the outer layer is at least 6 mm; for the inner layer, a thickness of 4 mm is acceptable. But the thicker the sheets in the layers, the lower the thermal conductivity, therefore, when creating a sealed circuit (using end caps), the lower the heat outflow. In the summer months, the effect of a thermos will help prevent overheating without the need for partial dismantling of the casing.

Anchor Plus Moderator FORUMHOUSE

Possible combinations of layers (external plus internal, distance everywhere - from 20 to 50 mm):

- 6/4 – 1.8 W/(m ⁰С);

- 10/6 – 1.61 W/(m ⁰С);

- 16/6 – 1.42 W/(m ⁰С);

- 16/10 – 1.27 W/(m ⁰С);

- 20/6 – 1.19 W/(m ⁰С).

However, you should not get too carried away with thicknesses, especially when the greenhouse is of an arched type. The thicker the sheet, the greater the minimum permissible radius with which it can be bent without loss of characteristics. Yes, and problems may arise with the purchase of components, since for sheets thicker than 16 mm they are rarely found on sale, and if they are, the price is prohibitive. While for most regions, 10 mm on the top layer is sufficient for snow loads, the main thing is to correctly calculate the pitch of the racks.

One of the portal users has a winter garden (extension), on USP, with two layers of joint venture cladding.

Arkhipov I

I plan to install a greenhouse as an extension to the boiler room on one USHP - a wooden frame, polycarbonate walls in two layers, with an air gap. Height – 2.5 m, covering – single-pitched polycarbonate roofing.

Arrangement of winter greenhouses

In order to engage in crop production when nature does not provide for it, the winter greenhouse must maintain the temperature, light and humidity conditions necessary for the crops.

Heating

Even thermos greenhouses with two layers of SP as cladding for year-round operation in regions with temperate and cold climates, first of all, need an effective one. Another thing is that a sealed circuit with minimal heat losses will save on energy. With a lot of design options and types of fuel used, the heating itself comes in several types:

- Air - warm air is supplied through air ducts at different levels or heated and maintained directly by a furnace installed in the room itself.

- Contour - a thermal contour is created along the edges, and if necessary, along the middle part, pipes and radiators are used, the boiler can be installed both in the greenhouse and remotely.

- Subsoil - in regions with a mild climate, where severe frosts are rare, a thermos greenhouse will maintain heat with minimal heating. In this case, a water heated floor circuit or electric cables/mats designed for this specific application are laid in the ground.

- Combined - they combine air or contour heating with subsoil heating for growing crops that are demanding in terms of soil temperature.

Ruslan N

Subsoil heating is not suitable for all crops; in my greenhouse I made a hydraulic system (gravity) using coal with the possibility of attaching a subsoil circuit to it (for growing cucumbers), but for other crops a good subsoil heating system is sufficient.

Or for insurance.

Alla Ivanova

The main heating is contour, pipe, the subsoil circuit is deepened by 30 cm so that it is not damaged when processed with a walk-behind tractor. If the soil is loose, it works well. But for me it’s not so important for lettuce - 14⁰C heat in the soil is enough, but other crops need higher temperatures. I have subsurface heating as an insurance policy; there are very frosty winters.

Which energy carrier to use depends on many factors - cost-effectiveness, availability, and the possibility of automating the process.

- Electricity is one of the most expensive energy sources, but with minimal heat loss it can become the basis of the system. Especially if there is a night tariff and a TA (heat accumulator).

- Mains gas is cheaper than electricity and is not inferior to electrical equipment in terms of the possibility of automating the process, but it is not available in all areas.

- Solid fuel boilers - previously the biggest problem was the need for regular loading, today there are long-lasting models, including homemade ones.

DVAL

I heat a winter greenhouse (100 m²), covered with two layers of film, with a distance of 30-40 cm, with a homemade wood-burning boiler. The set temperature (+20⁰С) is maintained automatically. Adding firewood to the boiler lasted for a day when the temperature dropped to 20-25⁰С below zero, and on “warm days” (5-10⁰С below zero) it lasted up to two days or more if the firewood was oak or acacia. The boiler heats the air - a heat generator (without a water jacket). It’s not particularly annoying, just put it on and sleep peacefully (but the signal about the boiler going out or the wood burning is sent into the house). The cost of making the boiler is insignificant, I made it from what was lying around the yard, I spent only on electrodes (10 kg) and on circles for the grinder. I tried IR gas burners - they are ineffective, they require a lot of air, and when the windows are opened frequently, the heat evaporates.

As noted DVAL, you can drown it however you like and with whatever you want, everyone chooses their own option, which they settle on as the optimal one, based on the combination of costs and returns. Here viktor50 prefers the “” boiler, and although he has a seasonal greenhouse, such experience can be adopted.

Lighting and Humidity

Winter days are short, especially – in the northern regions, therefore, even with the correct orientation of the greenhouse, for full growth, most crops require additional lighting with special lamps that generate the required spectrum. HPS (sodium arc tube lamps) or LED lamps are used. This is one of the most consumable items in winter crop production, especially on a large scale.

Alla Ivanova

Heat is only one of the conditions, the main thing is light, photosynthesis, however. In the same Novosibirsk region in winter you can only do forcing. Or lamps - for 200 m², about 40 pieces of 400 W each, that’s 18 kW/hour and for 12-16 hours a day.

Of course, when we are talking not about two hundred, but about twenty squares for personal use, the costs are much lower, and many are willing to pay for the opportunity to eat fresh herbs all year round.

Whatever they say about the variety of greenhouses, in fact, there are only two types: capital and non-capital. All others are varieties. Greenhouses also differ in their design: wall-mounted, covered with wood, large arched type and small arched type.

A winter greenhouse is not just a place for planting vegetables and flowers, but also an indicator of the skill of a gardener. Organizing and equipping a winter greenhouse is a very difficult process, requiring knowledge, special skills and training.

Types of winter greenhouses

- Capital type of greenhouse must be built with a foundation. A trench is installed in the center, a deep passage necessary for accumulating cold air, preventing it from reaching the roots of plants. The design of the greenhouse allows it to warm up quickly, which makes it possible to plant seedlings 2-3 weeks earlier.

- Conditional capital ( non-capital) the type of greenhouse makes it easy to dismantle and move the structure to any other place. To manufacture this type, polycarbonate, metal profiles, and bolted connections are used. The basis is piles. In all other respects, the entire structure is similar to the capital one, but without thermal insulation and a central trench.

All other types of greenhouses are transitional options. But only in a permanent greenhouse it is possible to organize both lighting and heating.

Winter greenhouses differ according to the following parameters:

- By functionality. You can grow not only traditional vegetables, but also exotic crops. Before building a greenhouse, it is important to decide what crops will be grown. The entire process of arranging a greenhouse, external and internal, depends on this.

- By location to the ground. All heated greenhouses are divided into 3 main types: deep into the ground, made on the surface, equipped on the top of the building (barn, garage, etc.)

- By architectural decision. Among the existing options for greenhouses, single-, double-, triple-sloped, arched, wall-mounted, and combined ones stand out.

Choosing the right option

Choice the appropriate option depends entirely on taste and financial capabilities; the size of the greenhouse will also be important. Greenhouses also differ:

- By type of building materials. For the manufacture of greenhouses, brick, wooden materials, metal or PVC frames are used. Glass and polycarbonate coatings are also often used. Combined designs are very popular.

- By heating type. There are solar greenhouses, biofuel greenhouses, greenhouses with technical heating (stove, gas, electric, water).

- For planting. Plants in a greenhouse are planted directly into the ground or into special containers placed on racks.

Choosing a location for a greenhouse

When choosing a location for a future greenhouse, 2 main factors are taken into account: