A reliable foundation is the key to a strong and durable building. The quality of the foundation plays a decisive role in the success of any construction. I must say that this applies not only to the qualities of the building itself. Strict adherence to the correct technology for creating the foundation determines the degree of safety of the building for its future inhabitants, that is, it directly affects people's lives. Of course, the durability of the building also depends on what is the basis of the building. When building a house on your own, it is necessary to pay special attention to the construction of the foundation, take into account all the features and aspects of the technology, and make every effort to comply with them. Only then will your house turn out to be really reliable, beautiful, durable and will last for decades.

We will talk about how to make a foundation for a house with our own hands in this article. Our advice will help you not to lose sight of any important details and perform all the work as efficiently and economically as possible. We bring to your attention a step-by-step description of creating various types of foundation, as well as detailed video instructions that will help you better understand all the nuances of such an important process as building a foundation for a house.

How to make a foundation for a house with your own hands: Planning

Planning is the most important stage of construction. Therefore, before proceeding with concrete work on the construction of the foundation, it is required to conduct a thoughtful serious analysis of the following aspects:

- determine the characteristics of the soil;

- correctly select and carry out the correct calculation of the required materials;

- determine the ways and methods of the device for isolating the base from moisture, and also consider thermal insulation.

In order for the foundation to turn out to be of really high quality, it is important to choose the optimal technology that strictly meets the existing conditions. Each stage of construction must be carefully thought out and coordinated, taking into account all other points. This is necessary so that no suddenly discovered nuances cause a stop to construction or its complete cessation.

For soils and climates typical of the middle zone, the most suitable and commonly used type of foundation is strip foundation. As a rule, the choice falls on him for several reasons:

- it is quite simple to make it yourself;

- it will not require large material and physical costs, as well as the use of expensive heavy equipment;

- it allows you to equip the basement;

- at the same time, its reliability is quite high due to the concrete strips that pass under all the supporting structures;

- this type has proven to be one of the most durable.

For heaving type soils with a risk of flooding, it is quite suitable. In order to determine what kind of soil is available at your chosen construction site, you can contact specialized companies where qualified personnel will perform all the necessary work and provide comprehensive data, on the basis of which the optimal type of foundation should be selected.

This data will help you not only at the foundation stage, but also in the future, when conducting water to the territory and choosing between possible options (pipeline, well, well).

The construction of the strip foundation assumes the presence of the following materials:

- cement;

- gravel;

- water;

- formwork boards;

- frame wires;

- fittings;

- spacer bars;

- brick;

- material for waterproofing device;

- nails.

Tools should also be prepared: a trowel, a shovel, a tape measure, a level, a level, a hammer.

If you are planning a large-scale construction and you need a large foundation, then it makes sense to think about buying ready-made concrete or purchasing a deep vibrator.

Marking is the first step that you should consider if you are planning how to make a foundation for a house with your own hands.

So, markup is the first task that needs to be solved when creating the base. It is carried out on the basis of design data. In accordance with them, it is necessary to determine the corner points of the planned building, and then, if necessary, intermediate points. Stakes are installed at certain points. Two pegs should be located relative to each other at a distance equal to the width of the future concrete foundation tape.

Please note that it must exceed the width of the load-bearing wall. After all the pegs have found their places, they are connected with a cord.

Do not forget to check how evenly the markup is done using a level. To do this, measure the diagonals of the rectangle, which you should have obtained as a result of connecting the peg with twine. They must be equal. If you get a different result, then you will have to perform the markup again so that all the values converge. Remember that even the slightest deviation can significantly affect the result of all further work.

When you have completed marking the outer perimeter, proceed to work with the inner one. Usually, a width of 30 or 40 cm is chosen for the tapes. Inside the area bounded by two perimeters, a trench is dug, the depth of the foundation. Make its walls even.

It is necessary to choose the depth of the foundation, focusing on groundwater. The foundation must be higher.

Familiarize yourself with the features of soil freezing, you will find a map of values on the website.

The average trench depth is 1.2-1.5 m. These values are suitable for non-rocky soils without the risk of flooding. The next stage is the creation of formwork inside the dug trench. The best material for this is boards that are connected with nails.

Next, you can move on to creating a gravel cushion at the bottom of the pit. Instead of gravel, a sand-gravel mixture can be used for this purpose. The "pillow" needs to be compacted and moistened. It is recommended to work separately with a layer of sand and with a layer of rubble, that is, tamp them in turn. First - sand, top - rubble. The height of the two layers should be 15-20 cm. Its role is to protect the foundation from negative phenomena caused by seasonal temperature changes. A dense base of the foundation will prevent the consequences of the expansion of soil layers.

Stage two: frame and moisture protection

As mentioned above, the quality of the foundation is the key to the safety of the inhabitants of the building and its durability. Therefore, when building a house on your own, do not try to make your own work easier, because all efforts will eventually pay off. The reinforcement frame is a necessary element of the strip foundation. Put bricks on the bottom of the trench, and on them - trimming reinforcement in the form of a cage. Make wire connections at the joints of the rods.

It is necessary to tie the rods carefully, so that the connection is not too tight.

The next moment, how to make the foundation for the house with your own hands correctly, is waterproofing. The material chosen for this purpose is laid on the frame. Roofing material is optimally suited, economical and well-proven in practical use. Roofing material is laid in layers with an overlap. The joints need to be connected. You can use tape for this. So you will provide reliable protection against moisture.

Stage three: concrete and pouring

Concrete can be prepared on your own or ordered ready-made from professional companies. If you decide to do everything yourself, then we advise you to stop at cement of proven high-class brands (M300, M400). You will also need crushed stone and coarse sand. Check out the component ratio table:

| Brand | Composition C:P:Sh (kg) | Composition per 10 l of cement, P:Sch (l) | Amount of concrete from 10 l of cement (l) |

| M100 | 1:4,6:7,0 | 41:61 | 78 |

| M150 | 1:3,5:5,7 | 32:50 | 64 |

| M200 | 1:2,8:4,8 | 25:42 | 54 |

| M250 | 1:2,1:3,9 | 19:34 | 43 |

| M300 | 1:1,9:3,7 | 17:32 | 41 |

| M400 | 1:1,2:2,7 | 11:24 | 31 |

| M450 | 1:1,1:2,5 | 10:22 | 29 |

The strength of the foundation grows in direct proportion to the quality of the materials you use for it. Particular attention should be paid to the process of pouring water into cement. In this case, it is necessary to strictly observe the required ratio of these components. Compliance with this moment also determines the strength of the foundation being arranged. If you are making concrete with crushed stone, be guided by the following values of the ratio of water and cement:

| 100 | 150 | 200 | 250 | 300 | 400 | |

| 300 | 0,75 | 0,65 | 0, 55 | 0,50 | 0,40 | — |

| 400 | 0,85 | 0,75 | 0,63 | 0,56 | 0,50 | 0,40 |

| 500 | — | 0,85 | 0,71 | 0,64 | 0,60 | 0,46 |

| 600 | — | 0,95 | 0,75 | 0,68 | 0,63 | 0,50 |

To determine the readiness of the solution, pick up a little mixture on the tip of a shovel. The finished mass should not flow and spread.

For the components of the fine fraction of water, more will be required. See the table below for the ratio of the required volume of water and fractions:

| gravel, mm | Crushed stone, mm | ||||||

| 10 | 20 | 40 | 80 | 10 | 20 | 40 | 80 |

| 180 | 170 | 155 | 140 | 200 | 185 | 170 | 155 |

For a solid foundation, concrete of high rigidity is required. It is she who determines the durability of the foundation and, accordingly, the entire building.

Concrete is poured in layers. Over and over again, the layers should be leveled, they need to be pierced to avoid air bubbles solidifying inside the base. You can use a deep vibrator, but there is a certain risk of violating the integrity and strength of the frame. You can significantly increase the strength of concrete if you bayonet it.

In order for the solution to become strong after pouring, it will take 4 weeks. During this period, it is necessary to ensure its protection from the influence of various negative factors. In clear and dry weather, you need to cover the structure with polyethylene and moisten from time to time. In rainy weather, you just need to cover it from excess moisture. After the expiration of the solidification period and curing, the formwork can be removed.

How to build a foundation for a house with your own hands: a video of the foundation device on poles

A pile foundation is an excellent solution for unstable soil. It is characterized by increased strength, long service life and adaptability to high loads.

The advantage of this type of construction is that during its construction there is no need to perform time-consuming work with the soil and create trenches and pits. The foundation is made in the form of piles that are driven into the ground. Piles can be purchased ready-made, but such products are not cheap. But you can also make them yourself.

For the device you will need:

- fittings;

- concrete;

- steel wire;

- ruberoid.

You can make a solution yourself from cement, sand, water. To do this, you will need an appropriate container and a deep vibrator. It is necessary to determine the location of the piles with pegs, referring to the tape measure and level. In order to make holes, you have to use a drill.

We drill wells ourselves

According to the markup, wells need to be drilled. They should be separated from each other by no more than 2.5 meters. Such work is carried out with a manual drill. When water appears in the hole, a pump will be required to pump out the liquid.

Making piles and concrete

When all holes are drilled, proceed to the formwork. It is made of roofing felt, folded in a tube, the diameter of which coincides with the section of future piles. The bundle is fixed with steel wire and inserted into the pipe.

Thus, it is necessary to equip each future pile. The roofing material will give additional rigidity to the piles and prevent the absorption of cement laitance into the soil. And also formwork is necessary to give a smooth surface to the pile. This is important because all serrated and rough substrates suffer more from frost heaving than smooth substrates. As a result, they are destroyed much faster, which negatively affects the durability of the entire building.

After completing the preparation of the piles, you can do the reinforcement frame. Take 3-4 bars of 6 mm section. They must be connected with steel wire every half a meter. Then the structure must be installed inside the wells so that they stick out 40-60 cm in height.

Now we need to prepare the solution. Be guided by the same principles that we have already described above. It is necessary to lay the mortar in portions, filling 50 cm of the pile at a time.

Do not forget to bayonet to remove air bubbles.

For bayoneting, you can use fittings. A better result can be achieved with the help of a vibration unit, but it must be used with great care to avoid damage to the reinforcement.

This design acquires final strength in 2-3 weeks. Then you can move on to the grillage device. At the same time, reliable grip of the grillage is provided by uncut upper parts of the piles.

If you are using ready-made metal piles, then to work with them you will need:

- scrap metal;

- pipes of 2 m;

- sand;

- cement;

- water;

- anti-corrosion coating.

Prepare the appropriate tools: a welding machine, a shovel, a grinder, a level, a tape measure.

As always, the first thing to do is markup. Piles should be set apart from each other by no more than 3 meters. After determining their locations, the piles must be screwed in. This type of work can be done on your own, with assistants, or contact a specialized drilling company. Of course, professional work will provide higher quality, but will also increase construction costs.

Wells should be deeper than 1.6 m. Such a depth is necessary so that the piles do not stick out due to soil deformations.

Often, during the drilling process, it is discovered that there is some kind of obstacle in the soil. In this case, it is necessary to make every effort to get rid of the interfering element so that drilling is carried out according to the planned plan. Only those piles that are driven to the required depth can guarantee the reliability of the foundation.

After all the piles are screwed in, they must be cut so that they rise above the ground at the same level. Concrete is then poured inside to protect the piles from corrosion. At the finishing stage, the heads are attached and the joints are treated with an anti-corrosion agent.

Another advantage of this type of foundation is that there is no need to wait for the concrete to harden. It is possible to carry out grillage and all other construction work without interruption.

The foundation for a private house can be made with your own hands, but it is worth remembering to follow the rules and building technology, because the foundation foundation will serve as a support for the entire building. The foundation for a country house can be of a simplified design if the building itself is of low weight, and the soils on the site have good bearing capacity. This article is all about the foundations for a house and a summer residence.

Foundation selection

Starting the construction of a small country house or a massive private cottage, especially when doing work with your own hands, it is worthwhile to carefully choose the design of the supporting base.

When choosing a base, it is imperative to take into account the weight of the future structure.

When choosing a base, it is imperative to take into account the weight of the future structure.

To determine the type of foundation, several criteria should be followed:

- The number of storeys of the building and the complex of existing loads - when choosing a foundation support, it is worth collecting all the loads that affect the base of the building, including: the weight of the building itself; the mass of people in it; weight of furniture and structures; snow loads.

- The depth of soil freezing - the depth of the foundation depends on this indicator.

- Groundwater level - several pits should be made on the site, which should be followed for some time. If the wells are filled with water, measurements should be taken, fixing the results on paper. A high level of soil year will require the use of special types of foundation for a residential or country house.

- Soil composition at the construction site - before starting construction work on laying the foundation belt, it is worth carefully studying the geology of the site. Soils with low bearing capacity that lie on the site, especially with a high level of groundwater and significant freezing of the soil in winter, will not allow the construction of a tape or column foundation under the house, which are the most popular.

Foundation structures

Most often, strip foundations are erected on a private plot for a house or summer cottage, which can be made in a monolithic version or folded from ready-made reinforced concrete blocks.

Sometimes the structures of strip foundations for buildings are erected with their own hands from rubble stone.

Any type of tape supports is allowed to be used only if the soil freezing depth on the site is up to 40 cm, groundwater is at a considerable distance from the soil surface, and the soils themselves have a high bearing capacity.

In other cases, you will need to use a foundation of a different type: pile, slab.

As for the slab foundation for residential buildings or garden houses, it is very easy to build this structure with your own hands, it is even easier to arrange a support for the building from metal screw piles, which perfectly hold buildings in wet and weak soils.

Foundation tape device technology

When starting to build strip foundations with your own hands, it is necessary to determine the total loads that will act on the supporting base, for which you need to clearly understand the dimensions of the future house.

Of no small importance are materials for the construction of walls, roofs and ceilings. In addition to the weight of building structures, it will be necessary to determine the weight of the furniture that will be placed in the rooms of the house, the mass of utilities, wind and snow loads affecting the roof of the building.

It is possible to make a strip foundation for a private house only if the bearing capacity of the soils at the construction site is high; the soil base is not subject to deep freezing and is slightly eroded by groundwater.

Selecting the type of strip foundation

If all the conditions are met, you can proceed to the choice of a strip foundation, determining what type of structure will be applied to this particular object: a monolith or a prefabricated base? Each of these options has its own advantages and disadvantages.

When constructing a monolithic base, all operations can be done by hand, even the concrete mortar can be kneaded in portions by hand directly at the construction site.

The installation of reinforced concrete blocks will require the mandatory presence of heavy lifting equipment on the construction site, which will help lay the blocks in the trench. In the conditions of a suburban area, this is not always convenient, especially if summer cottages are located on the inner territory, far from the fence. Access roads to garden plots are often not prepared for the passage of heavy equipment. In this case, you will have to use a monolithic version of the strip foundation.

If we compare the strength of a monolithic and prefabricated tape, the palm should be given to tape structures made of monolithic concrete, the strength of which is much higher.

Preparatory and earthworks

Before starting the construction of foundation structures for a private house with your own hands, you need to purchase materials, tools, and perform a set of preparatory work. The site should be cleared of construction debris, plant residues; perform work on the vertical planning of the site, filling up the pits. With the help of pegs and a rope, the perimeter of the future foundation is outlined.

A strip foundation for a summer residence, a private house is arranged in a trench, which you first need to dig with your own hands. In some cases, it is allowed to use earth-moving equipment if there are convenient entrances to the object.

Watch a video of how to dig a trench without the help of equipment.

The soil is removed from the trench and stored in two separate piles, separating the upper fertile and mainland soils. The fertile layer is used for subsequent planting, the rest is used for backfilling the sinuses after the erection of monolithic or prefabricated foundation structures.

The bottom of the trench must be leveled, a layer of waterproofing made of roofing material should be laid out, covered with a layer of coarse quartz sand, at least 10 cm thick. The sand should be carefully compacted using manual or pneumatic rammers. Crushed stone of fine fractions is poured onto a layer of sand, which is compacted with the help of rammers and water.

The finished sand and gravel cushion helps to more evenly distribute the load on the base.

Formwork and reinforcement

The strip foundation for a private house is poured into the formwork, which you can prepare yourself from boards, plywood or durable moisture-resistant fiberboard sheets. It is allowed to use reusable formwork, which should first be cleaned of smudges of concrete mix and dirt.

Formwork panels are installed with their own hands, helping to strengthen the structure with struts and supports, which are made of wooden bars. The gaps between the individual boards should be kept to a minimum to prevent the mortar from flowing through the formwork.

After completion of work on the construction of the formwork, they begin to weld or knit the reinforcing cage. It is easy to make a spatial reinforcing cage with your own hands from metal reinforcement if you have the skills to work with a welding machine. In another case, it is possible to connect the frame for reinforcing the foundation base using a knitting wire, which binds the individual bars of the reinforcement.

The frame is installed inside the formwork in such a way that the bare reinforcement does not come out to the surface of the foundation.

concreting

It is preferable to use a ready-made concrete solution prepared at the factory, but it is possible to prepare the mixture manually at the construction site using coarse sand, crushed stone, cement and water.

The concrete mixture is poured into the foundation formwork with mandatory compaction with deep vibrators. The strip foundation should be poured from both sides at once, which will help to quickly distribute the mixture in the formwork, avoiding uneven solidification.

Watch the video on how the most popular type of foundation is being built - tape.

The upper surface of the foundation tape is leveled to perfect smoothness. Concrete care consists in shelter from the sun and constant moistening of the foundation surface. It is not allowed to continue the construction process until the concrete has gained design strength. This procedure usually takes up to 28 days, but in some cases the concrete mixture dries longer, which will take a long time to set the strength of the foundation.

The finished foundation structure is sprinkled with earth, filling voids and sinuses. The laid soil is rammed as far as possible. Particularly narrow cracks can be covered with coarse sand.

prefabricated structures

A strip foundation made of prefabricated elements cannot be laid with your own hands - the structures have significant weight. A trench for laying blocks is prepared in the same way as for a monolithic tape; waterproofing and a sand and gravel pad are laid along the bottom of the prepared trench.

The side seams between the blocks are securely sealed with mortar, the side faces of the foundation blocks in contact with the ground are treated with waterproofing compounds along the entire perimeter.

Making a foundation for a house with your own hands

At the initial stage of the construction of the entire structure, the foundation is made. The strength and durability of the entire house depends on the quality and correct execution of this structural part of the building. That is why if you make the foundation with your own hands, you should know which design to prefer in this or that case, how to choose the right materials, and also make the foundation of a private house in accordance with all the rules. In our article you will find instructions and video tutorials on building different types of foundations on your own.

General provisions

For the construction of a private house, you can make one of the following types of foundations:

It is difficult to say which of them is the best, since the choice of one or another type of foundation must be made depending on the characteristics of the soil and structural features. The cheapest foundation is not always the best.

When deciding what foundation to make for a private house, you should be guided by general recommendations. It is also necessary to take into account the conditions of construction, namely:

- Before building a house, you need to conduct geological surveys in order to know the type of soil, its composition and characteristics.

- Groundwater depth. These data can also be obtained in the course of hydrogeological studies.

- For the construction of any houses and buildings, you need to know the depth of soil freezing.

- It is also necessary to know the total load from the structure in order to correctly calculate the design of the base and select suitable materials.

- It is important what kind of house you will make, with or without a basement or basement.

- You also need to take into account the materials for the manufacture of the house, as well as the material of the foundation.

- The presence or absence of underground utilities.

If you are making a foundation with your own hands, then you should be aware of common mistakes:

- It is not necessary to lay a shallow foundation for light buildings on heaving soils. In this case, the forces of frost heaving will cause deformation of the structures.

- The foundation must rest on firm ground. It would be a mistake to make the foundation of the house on uncompacted loose soil.

- Do not forget about the lateral pressure of the soil on the walls of the base, as well as the destructive effect of groundwater.

- It is important to use all measures that allow water to be diverted from foundation structures.

Let us consider in more detail the features of the device and the design of each type of foundation, which you can do yourself for a private house.

Tape base

If you decide to make a house with a basement, then the strip foundation is exactly what you need. Such a foundation is used in the construction of houses from heavy wall materials (brick, concrete, reinforced concrete and natural stone) using wooden or reinforced concrete floors. For more information on how to build such a foundation yourself, see the video tutorial offered at the end of the article.

Important: the strip foundation is made under all external walls and load-bearing structures of the building.

This is not the cheapest foundation, but its use is advisable when building a basement, garage, basement or cellar under the house. The weight of the structure is transferred to the foundation tapes. A concrete distribution pad is usually made under the tape. Its width is slightly larger than that of the tape itself. Thanks to this design, the load from the structure is evenly distributed to the ground.

According to the manufacturing method, tape bases are of two types:

- prefabricated structures are assembled from prefabricated blocks installed in trenches or a pit with a crane;

- reinforced concrete monolithic structures are made at the construction site. This option can be done without the use of construction equipment.

For a residential building, you can lay a strip foundation from the following materials:

- reinforced concrete tapes are made of concrete of a class not lower than B 15 - B 30, as well as from reinforcement with a diameter of 10-12 mm;

- rubble concrete structures should be made of concrete and coarse-grained filler (small boulders and coarse gravel);

- brick strip bases can be built from solid clay bricks.

Pile foundations

This foundation is best done if the construction will be carried out on soils with a weak bearing capacity. We can say that this is a fairly cheap foundation, because the cost of materials and the cost of earthworks are minimal. That is why it is very popular.

The entire structure is made in the form of a strip of piles, separate elements or entire pile bushes, united by a grillage or a monolithic slab. As a rule, reinforced concrete or concrete is used to make a slab or beam.

Tip: such a foundation design should be laid if there is weakened soil (loose sandy or subsidence) under the house at a great depth.

According to the type of installation, all pile foundations can be divided into the following types:

- driven (installation is carried out using special equipment);

- screw (such a foundation can be made without the use of construction equipment);

- stuffed (in this case, pipes are installed in the drilled well, into which concrete is poured).

For private houses, pile foundations can be made from the following materials:

- metal, asbestos or plastic pipes (in this case, they act as a fixed formwork, and the reinforcing cage inside the pipe, filled with concrete, serves as the supporting base);

- processed softwood logs (such designs are suitable for light small wooden houses);

- reinforced concrete piles.

Monolithic slab foundation

This is a shallow base, which is made in the form of a monolithic reinforced concrete slab. The height of the structure can be in the range of 0.3-0.8 m. For reinforcement, a rod with a diameter of 12-20 mm is used. Concrete is poured over a sand cushion, which is carried out on a compacted and leveled base of the pit.

Since the load on the foundation in this case is distributed most evenly, this type of foundation can be used:

- on soils with reduced bearing capacity;

- on soils that are subject to the forces of frost heaving;

- for houses with a height of more than two floors and buildings with a complex design.

Column bases

This version of the base can rightfully be called the most economical. It is quite easy to do it yourself. In fact, the design of the foundation is the pillars buried to a certain depth in the ground. From above, all elements are combined into one structure by means of stacked beams.

Important: columnar foundations are suitable for light houses made of timber, logs or aerated concrete blocks with a height of no more than 1-2 floors. Frame and frame-panel houses on a columnar foundation can only be built on soil that is not subject to the forces of frost heaving.

Column bases can be prefabricated and monolithic. As a material can be used:

- stone;

- clay brick;

- logs;

- concrete and reinforced concrete;

- steel pipes.

Strip foundation installation technology

For many private developers, the correct foundation is associated with a strip base, since it is this that is often used in individual construction. Therefore, we will consider the manufacturing technology of a monolithic strip foundation in more detail (it is also shown in our video tutorial at the end of the article).

For work you will need:

- gravel and sand;

- cement not lower than M 200;

- reinforcement with a diameter of 10-12 mm;

- level, plumb;

- rope, pegs;

- formwork boards;

- ruberoid;

- nails, hammer and screws;

- shovel;

- concrete mixer, trough or bucket.

We carry out work on the installation of a strip base in the following sequence:

- We prepare the construction site: remove debris, cut off unnecessary green spaces, level the site. A fertile layer of earth 20 cm thick must be carefully removed.

- We make a breakdown of the future structure on the ground. To do this, use a rope, pegs and a level. The markup sequence is as follows:

- first we find the axes of the future structure, measuring them from the edges of the site or neighboring buildings;

- the distance to the outer face is plotted from the axes (this is how we find the first corner and hammer a peg there);

- then we pull a rope or fishing line from the peg and find the remaining corners of the structure, drive in the pegs;

- then, a distance equal to the width of the foundation tape recedes from the marking along the outer edge of the foundation, the pegs are clogged again, and the cord is pulled.

- After that, you can start digging a trench under the tape or a pit, if the house is with a basement. We measure the required trench depth at the lowest point of the site. Usually, the depth of the foundation tape for a house without a basement is 20 cm below the freezing point of the soil, that is, it is approximately 1.2 m when the soil freezes by 1 m.

- The bottom of the trench or pit must be carefully leveled and compacted.

- Let's start making a sand cushion. To do this, we pour sand with a layer of 15 cm, moisten it with water and ram.

- Then we make a layer of crushed stone 10-15 cm high. It is also well rammed.

- After that, to prevent soil from absorbing moisture from concrete, a layer of roofing material or dense polyethylene is laid at the bottom of the trench.

- Now we make formwork for the foundation tape from the boards. Usually they use removable formwork made of boards or moisture-resistant plywood. The formwork structure must rise at least 300 mm above the ground. To facilitate the removal of the formwork inside, it is lined with polyethylene or roofing material, which will simultaneously perform the functions of waterproofing. Boards are fastened with nails and screws. Bars are used as a frame. There should be no gaps in the formwork through which concrete will flow.

You can find information on how to properly make a strip foundation in the proposed video tutorial:

Foundation for a private house

When laying the foundation of a house, modern builders carry out a lot of calculations that will help build the building correctly, without the risk of further deformation of the supporting structures. First, the soil is checked, the estimated load is calculated. It is worth starting the foundation for a private house by determining the type of future foundation.

Foundation types

Tape

This type of foundation is common in the construction of private houses on strong ground. According to the method of construction, it can be:

Monolithic is simple - they dig a trench for it, install formwork, make a reinforcing frame, pour concrete. When erecting a prefabricated structure, ready-made reinforced concrete blocks, rubble stone or ceramic bricks are used.

According to the depth of laying, the strip foundation can be shallow. This type is popular with private developers. This will help you save a lot of time and money. This type is used in the construction of one-story light houses on stable soils. The depth of soil freezing should be small, and groundwater should not lie high.

For the construction of houses with heavy walls, or when planning a basement (spacious cellar) under the building, a deep foundation is made. It is able to withstand heavy walls, buildings with two or more floors.

In addition, tape bases are divided into several types:

- flexible - has a transverse-longitudinal armored belt;

- monolithic - it is concreted immediately;

- intermittent - some elements of the base are located under the supporting structures;

- hard - has a longitudinal reinforcing belt.

To choose a foundation for a private house, it is worth calculating the loads and taking into account the characteristics of the site.

slab

The slab foundation is a multilayer cake. A leveling layer is made from below, then protection comes, and a concrete slab is located on top. The protective layer has a heater, hydro- and vapor barrier. The leveling layer is a gravel-sand cushion. Reinforce the structure of the slab base with reinforcement. This helps to make your home stronger and more reliable.

The mass of the slab is so great that no process that occurs in the soil under it can harm the structure. Of course, in case of a strong earthquake, the foundation may not withstand, but other types of foundation are provided for such cases.

The slab option requires a pit, the depth of which is determined taking into account whether the basement will be carried out. Detailed composition of the slab base:

- leveling layers of sand, crushed stone and gravel;

- waterproofing layer;

- concrete;

- reinforcement;

- pouring the pit with concrete;

- reinforcement;

- concrete layer.

The height of the plate sometimes reaches 1 meter. When building large buildings, such a foundation will be very expensive. One of the main advantages of such a foundation is durability - with proper installation, it will serve for more than one hundred years.

Columnar

This type of foundation is used in the construction of private structures with light walls. Usually these are wooden houses no more than two floors. It is easy to build a columnar foundation. First you need to drill a post into the ground. Concrete can also be poured into the drilled well. On top of the pillars, a strapping (grillage) of reinforced concrete beams is laid.

Possible materials for laying pillars:

- Tree. Such a foundation, made of wooden logs / beams, is used for baths, country houses.

- Stone. Often use natural material, which is applicable in the construction of heavy buildings.

- Brick. The pillars must be erected from solid bricks using a sand-cement mortar. Such a foundation is laid under the house no higher than two floors.

- Concrete. Concrete foundations are used in the construction of heavy buildings. Such a foundation is made of concrete and reinforcement.

The advantages of the columnar type of foundation are the low cost of construction, low shrinkage, and the possibility of operation on heaving soils. The disadvantages of such foundations include the mandatory implementation of the grillage, the possibility of using only for light buildings, high sensitivity to elevation changes. For the construction of cottages and small country houses, such foundations are ideal.

pile

The foundation consists of several piles connected by a single slab. The latter is most often made of concrete, reinforced with iron bars. Usually such foundations are built on sands and quicksand. The foundation can withstand heavy houses with two or more floors.

The pile foundation for a private house is made of different materials:

- Wood - used in the construction of houses from logs and timber. Such piles are often made from pine that has undergone special processing.

- Reinforced concrete - it is chosen for houses with a lot of weight.

- Metal - it is used in case of impossibility of using a reinforced concrete structure.

- Combined piles made of concrete and metal. They are used in extreme conditions, on difficult soils. They can be used even on swampy soil.

Also, piles differ in the method of manufacture:

- Depressed - they are deepened into the ground by pumps.

- Driven - are placed in the ground with hydraulic hammers. This type of pile can be used if there are no other buildings in the surrounding area. The shock wave created when driving piles can damage neighboring houses.

- Stuffed - a well is drilled for them, and then concrete is fed into it. In this case, various types of concrete can be used - at the discretion of the developer.

- Screw - this is the most expensive type of piles, but it can be used on any soil. The pile is screwed into the ground like a screw.

The pouring of the stuffed foundation for a private house is carried out independently (“home” method), without the use of special equipment. To do this, a well is drilled, and then formwork is made from roofing material according to the diameter of the well. It must be made longer than the well by 20-30 cm. Instead of such a formwork, an asbestos-cement pipe is also suitable. At the bottom of the well, it is important to place roofing material in several layers, this is necessary so that the milk that holds the composition together does not go into the soil.

Then the reinforcement cage is made. This increases the strength of the pile. Concrete is poured in 40-60 cm increments, with regular compaction. After completing these works, you need to make a grillage. Concreting should be carried out slowly, with careful tamping.

The right choice of foundation

- How deep is groundwater?

- how much the soil freezes in winter;

- Will a basement be built?

- the general condition of the soil on the site;

- the service life of the building under construction;

- materials to be used by builders;

- availability of underground communications.

Only after a qualitative and complete assessment of the soil can a solid foundation of the house be laid. In the absence of information from the company providing the land plot, all work will have to be carried out independently. First you need to drill a well and measure the depth of groundwater.

When laying the foundation, such a property of the soil as swelling in cold weather is taken into account. So that the problem does not affect the foundation, a so-called “pillow” is performed under it. It consists of crushed stone, sand and gravel. This will help distribute the lifting load evenly over the entire area. A special table will help you choose the foundation for a private house:

foundation type

Stability indicators

Labor costs

Price

Load limits

plinth

On what soils is it used

Stages of independent construction of foundations for a country house

Many private developers are constantly faced with the need to build the foundation of a country house for themselves, their friend or neighbor in the countryside. Moreover, it can be a private residential building or an outbuilding, so for each particular house, the foundation arrangement can differ significantly.

Many existing foundations can be built by yourself in a matter of days or weeks, and if everything is done correctly, then the reliability of such a foundation is practically no different from that which was built using powerful construction equipment and teams of qualified builders.

On what factors does the choice of foundation depend?

In order to build a foundation for a summer cottage, it is necessary to correctly determine the type, characteristics and purpose of the future structure, as well as adhere to a phased methodology for erecting the supporting structures of the structure. Factors affecting the choice of foundation:

- Soil type and bearing characteristics. It is necessary to take into account the height of the location of groundwater, seasonal heaving of the soil, the bearing characteristics of the soil, as well as the terrain. It is clear that no one will build a monolithic foundation or prefabricated aerated concrete structures on a strong slope, because then a huge amount of work will have to be done to level the site. But a columnar base with a grillage is ideal for such purposes.

- The mass of the future building and its overall dimensions. As a rule, country houses are rarely multi-storey, they are built one-story, less often two-story. As a building material, relatively light aerated concrete or heavier bricks are used, concrete blocks are not used here. Therefore, a private house is distinguished by its lightness and low permissible load on the ground, and it is desirable to select the type of foundation after calculations.

- financial component. Each builder of a private house is well aware that the financial component plays an important role in the construction of the foundation. It is clear that they all want to choose the right device for a private one-story house, but they immediately calculate all the permissible risks and the cost of building materials. Therefore, if there is an aerated concrete production nearby or deposits of natural building stone are found, then they will use it and the foundation will be appropriate. In addition, the foundation for a house with their own hands is often built without the use of additional labor and powerful construction equipment, as this will significantly increase the cost of the financial estimate.

- Purpose of the future building. If it is a one-story or more private residential building, then the foundation is selected as strong and reliable as possible. And if this is a small outbuilding, then the type of foundation will be completely different.

You also need to remember that the step-by-step instructions for laying the foundation differ significantly under different climatic conditions and the characteristics of a particular area, so it would be more correct to first decide and then build. An important role is played by the factor in the choice of building materials, from which the future foundation for the country house will be built.

Types of foundations for a country house

Tape. It is easy and quick to build such a foundation for a country house, and often you can use aerated concrete or brick here.

It is used in the construction of heavy one-story or more buildings, the load-bearing walls and ceilings of which will be built from heavy materials. This type of foundation is popular in suburban construction due to the ability to equip underground premises (garage, basement or technical floor).

Of course, there are several types of such bases that differ in design:

- Prefabricated. The device involves the use of ready-made factory reinforced concrete blocks, which are mounted directly on the construction site.

- Monolithic. By design, they have a single monolithic slab, load-bearing walls are erected on it. Such a slab is made of brick or rubble concrete, less often of aerated concrete. Reinforcing mesh can also be used here, such bases are already called reinforced concrete.

- Pile foundations for weak soils. The device involves the installation of finished metal or reinforced concrete piles (pillars) at the construction site. They can be of considerable length, since it is necessary to reach strong layers of soil below the freezing line.

Also, such foundations are popular because of their practicality and reliability, although it will not work to build even a one-story, but large private building on piles.

Piles are different, ranging from metal and reinforced concrete, ending with wood. The weaker the material, the less load they can withstand. Therefore, for the construction of a private large country building, it is better to immediately use reinforced concrete structures, which can be made directly at the construction site.

Only first you need to carry out the correct calculations and lay the foundation under optimal temperature conditions. Also, initially it is worth deciding what the foundation will be built from, and making a phased method for its construction.

- Universal monolithic plate. The device of such a foundation allows you to build private houses even on soft soils, because then the load is distributed evenly over the entire area of \u200b\u200bthe base.

But, the foundation is expensive due to the large amount of concrete and reinforcement, and building it from improvised weak materials is prohibited by building codes. It is better to lay such a foundation for small summer cottages, because then there will be a minimum of financial costs for land work, and the foundation can be shallow.

The main stages of laying the foundation

As a rule, laying the foundation always begins with the preparation of the construction site. But in practice, everything turns out a little differently, because it is impossible to choose and build the right foundation without preliminary calculations. Therefore, there are several key preparatory steps that you need to do before you build the foundation for the house yourself:

- First, a detailed geodetic reconnaissance of the territory is carried out, a map of soils is compiled and the depth of groundwater is specified.

- Then a map of the soil structure is developed and the depth of occurrence of strong rocks and the boundary depth of soil freezing are determined.

- The place where it is best to lay the designed private building is determined.

- The angle of inclination of the terrain is determined, minor irregularities of the construction site are eliminated.

- The maximum allowable load on the foundation is calculated taking into account building materials. Sometimes in such calculations, aerated concrete is taken as the initial parameters, which is larger in mass than bricks, but less than concrete structures.

- The optimal type of foundation is selected.

- The type of building materials that are best suited for the construction of the designed structure is selected.

Step-by-step instructions for laying a tape-type foundation for a one-story country house

How to make a foundation for a house with your own hands? In practice, it is not as difficult as it seems, but nevertheless, the advice of an experienced builder will not be superfluous, since the knowledge gained will help to avoid mistakes. The laying of any foundation consists of the following stages using the example of a tape structure:

- The construction site is marked, the surface is leveled and a loose layer of fertile soil is removed.

- Then, a trench of the estimated depth and width is dug along the perimeter of the future building, the bottom is leveled and a sand cushion is formed on it.

- A wooden formwork is mounted along the perimeter of the future foundation, inside which a reinforcing belt is provided. The design, device and characteristics of the reinforcement are selected individually for a specific type of foundation.

- After the installation of the reinforcement and its connection, the concrete pouring of the trench begins directly. This must be done evenly, delamination should not be allowed. It is possible in this case to use prefabricated structures made of concrete or aerated concrete, only then the reinforcement must be done both horizontally and vertically with longitudinal inserts.

A waterproofing layer is installed on the outer surface of the finished base, then the structure can be further strengthened with a vertical row of aerated concrete or brick.

How to build a columnar or pile foundation with your own hands

Considering that a columnar or pile foundation is more practiced for the construction of small private structures for household purposes, the financial costs for its construction are minimal.

To do this, you must first mark the territory, set marks for future pillars and drill wells to a given depth. Then sand and gravel are poured onto the bottom of the well, rammed and equipped with a vertical reinforcing belt.

After all the preparatory work, the wells are poured with concrete and left to dry for several weeks. Instead of concrete, aerated concrete can be used, only in such cases it is necessary to initially provide for good waterproofing of rectangular pillars.

Any building is based on a solid foundation. The durability of the entire building depends on the correct choice of the type of this structure. How to make a foundation for a house, taking into account all the nuances, so that it lasts for more than a dozen years?

Competent construction work involves the analysis of several factors:

1) type and structure of the soil;

2) selection and correct calculation of the required materials;

3) reliable hydro- and thermal insulation of the finished base.

Properly building a foundation for a house means choosing the right device technology, taking into account all the available conditions and thinking through important details. The process should not be interrupted due to suddenly revealed circumstances or inconsistencies.

The strip foundation is the most common design for central Russia. There are several advantages to this foundation:

- the possibility of building on their own;

- low labor and material costs;

- inside such a foundation, a basement or underground can be equipped;

- tapes passing under all load-bearing walls and places of the highest load provide a high level of strength;

- durability of operation.

Tape base in section

It is impossible to build a tape-type foundation on heaving soils prone to flooding. You can find out the features of the soil available on the site from specialized organizations conducting geological exploration.

Important: data on the depth of water will be needed not only during the construction of the foundation, but also when planning a water source on the site (well, well or centralized pipeline).

In order to build a solid foundation for a house on ribbons, you will need the following materials:

- sand-cement mixture;

- crushed stone or gravel;

- water in solution;

- unedged boards for the manufacture of formwork;

- wire for knitting a frame;

- reinforcement bars;

- bars for spacers;

- brick;

- waterproofing material;

- nails.

The master will need the following tool: a shovel, a level, a cord, a hammer, a level, a tape measure, a trowel. To prepare a concrete solution, you need a container.

Important: if the tape base must be of decent size, it is more advisable to purchase ready-made concrete with mixers or buy a deep vibrator.

Start of work: site marking and excavation

Any foundation construction begins with the marking of the site. According to the project data, the master must bring the corner and intermediate points of the future foundation to the area. The locations of the points are marked with pegs. The width between two hammered pegs is the width of the foundation strip, which must always be greater than the width of the load-bearing wall. All pegs clogged around the perimeter are connected with a cord or twine.

The accuracy of the markup is necessarily checked by a level, which measures the diagonals of the resulting rectangle. All diagonals of the future base must be equal. If there are arithmetic deviations of even a few mm, marking starts again until an accurate control measurement result is obtained.

After the external markup is done, you can move on to the internal one. The width of the tapes is usually from 30 to 40 cm. Inside the marked perimeter, you need to dig a pit to the depth of the tapes. All walls of the pit must be smooth, without protrusions and depressions.

Important: the depth of excavation for the strip foundation should always exceed the level of groundwater.

Each region of the country has its own value of the freezing point of the soil, the information is graphically depicted on the map.

Map of soil freezing in various regions of Russia

Map of soil freezing in various regions of Russia

Usually, a pit is dug to a depth of 1.2 to 1.5 m. This is quite enough for non-rocky and non-flooding soils. Next, you need to form the formwork in the direction of the tapes. For this, an unedged board and pegs are used. The boards are attached to each other with nails.

After the formation of the bottom of the foundation is completed, a pillow of sand and crushed stone (or gravel) is arranged, which is carefully compacted and wetted with water. Experts advise ramming each layer of the cushion separately: first sandy, then gravel. The optimal height of such a puff "pie" is from 15 to 20 cm. The need for a sand and gravel cushion is due to the function of frost heaving of the soil during the change of seasons. A well-compacted base under the foundation will reliably protect it from the expansion of individual soil layers.

Formation of a reinforced frame and waterproofing of the base

If the master wants to form a support for the house in accordance with all the rules, he must know that the tape structure must have a reinforced frame. The bottom of the pit is lined with bricks, on which reinforcement bars are laid. A mesh should be formed from the reinforcing bars, i.e. they are stacked crosswise. At the joints, the reinforcement is connected with a special wire.

Important: knitting reinforcement requires caution and accuracy from the master, do not overtighten the fasteners.

It is the flexibility required when knitting reinforcement that determines the manual nature of the work. The use of welding will speed up the process, but does not guarantee the strength of the future base.

After tying the reinforcing cage, it is necessary to lay a layer of waterproofing. The most commonly used roofing material, which is durable and affordable price. When laying the roofing material, the sheets are overlapped, and the places of their layering are glued with adhesive tape. This will increase the reliability of the waterproofing and prevent the penetration of groundwater.

Concrete production and foundation pouring

Concrete is made independently or purchased from specialized companies. If the master chooses the first option, it is recommended to purchase only high-quality cement (grades M300, M400). Aggregates should be coarse sand and crushed stone. The ratio table of all components is given in the table.

Table of the ratio of concrete components when using cement M400

Table of the ratio of concrete components when using cement M400

The better the materials used to prepare the solution, the stronger the finished base will be. An important point is the connection of water with cement, when a certain water-cement ratio (W / C) must be met. This indicator, along with the brand of cement used, is extremely important for the strength characteristics of the base. If concrete is made using gravel, the practical W/C values are shown in the table:

Table 1. W/C values for various grades of cements and concrete mixtures on gravel

| 0,75 | 0,65 | 0,55 | 0,50 | 0,40 | - | |

| 0,85 | 0,75 | 0,63 | 0,56 | 0,50 | 0,40 | |

| - | 0,85 | 0,71 | 0,64 | 0,60 | 0,46 | |

| - | 0,95 | 0,75 | 0,68 | 0,63 | 0,50 |

Externally, the readiness of concrete can be determined by the tubercle of the mixture at the end of the shovel. If it does not spread and does not drain, then the desired rigidity has been achieved.

Important: the lower the fraction of concrete mortar fillers, the more water will be required.

The ratio of water depending on the fractional size of the plasticizers is shown in table 2.

Table 2. Approximate values of water consumption (in l / m3) in the manufacture of concrete from materials of various fractional structures

| gravel, mm | Crushed stone, mm | ||||||

| 10 | 20 | 40 | 80 | 10 | 20 | 40 | 80 |

| 185 | 170 | 155 | 140 | 200 | 185 | 170 | 155 |

In order for the foundation under a private house to be as strong as possible, it is necessary to prepare concrete with the highest rigidity. The more rigid the solution in its parameters, the more durable the foundation of the house will be.

Concrete is poured into the formwork in layers, each layer is carefully leveled and pierced to get rid of air bubbles. An internal vibrator can be used, but it can damage the reinforcement cage. Baying concrete is an important procedure that increases the strength of the foundation being poured.

The mortar poured into the formwork gains its strength within 4 weeks. During this time, the foundation needs additional protection: if it is sunny and dry, it must be covered with polyethylene and watered regularly. If it is rainy and damp, just cover with a film or geofabric. When the tape base is completely hardened, the formwork is dismantled.

We build a foundation on pillars

Are there any rules for building a columnar foundation? First, you need to know some of the nuances: it is advisable to choose such a base on heaving soil with a deep freezing point. Tapes on moving soil will not withstand constant deformation, and support poles will last for decades to property owners.

For the device of the columnar base, the master will need the following materials:

1) pipes made of metal or asbestos cement;

2) fittings;

3) sand-cement mixture;

During the construction process, you will need a container for preparing the solution, a trowel, a shovel. To mark the area, you will need a level, tape measure, pegs and a building cord.

Implementation of marking and ground operations

The marking sequence is similar to the work on the device of the tape type foundation. In the same way, the points of location of pillars-supports are taken out onto the terrain, using the design documentation of the building. The location of the supports: at the corners of the house and in places of the highest load (bearing walls, stairs, transitions, etc.). The optimal distance between the posts is from 1.5 to 2 m.

When the marking is completed, you can come to excavation for the pillars. The diameter of each pit is equal to the cross section of the pipe. The depth should be below the freezing point of the soil. When the pits are ready, a sand cushion 10 to 15 cm high is arranged in them. It is carefully compacted and moistened.

Important: the denser the pillow under the pillars, the stronger the future foundation.

Pillar installation and concrete pouring

After completing the operations on the device of the pillow under the supports of the future base, concrete can be prepared. A solution is prepared in the same proportions as in the case of a strip foundation. The consistency of the finished concrete should resemble thick sour cream.

- an asbestos-cement or metal pipe is installed in the pit;

- a little concrete mortar is poured into the pipe;

- the pipe is raised so that the concrete is distributed over the sand cushion;

- the pipe is leveled with a level in a vertical position.

. Section of a columnar type of foundation

. Section of a columnar type of foundation

According to the algorithm described above, all pillars are installed. Next, they are reinforced. 3-5 reinforcement bars are laid inside the pipes so that they go deep into the sand cushion, and the top rises 25-30 cm above the pillars. When all the supports are reinforced, they are poured with concrete. If holes remain around the supports, they are carefully covered with soil and well compacted.

Concrete in pipe supports sets within 1-2 weeks. After this period, you can proceed to the grillage device, which will fill the space between the corner supports and increase the reliability of the foundation being built. Subsequently, load-bearing walls will be placed on the grillage.

Foundation construction on homemade piles

Is there a type of foundation for a house on unstable ground? The way out of the situation is the device of the pile foundation. The main characteristics of this design: durability and high strength, the ability to withstand high loads.

A distinctive feature of the construction is the absence of the tedious stage of excavation and the formation of a foundation pit. Such a base is attached to piles immersed in the soil. The cost of finished piles is not “affordable” for every master, so many people prefer to make these products on their own.

During the construction process, the following materials will be required:

1) fittings;

2) cement with sand;

3) steel wire;

4) roofing material;

The preparation of concrete will require a special container and vibrator. On the ground, the locations of future piles are marked with pegs using a tape measure and a level. For the production of recesses, a hand drill is required.

Well formation

Self-drilling of wells takes place already in the places of the marking placed on the site. The step from one pile to another should not exceed 2.5 meters. The required number of holes is drilled with a hand drill. If water appears in the well during drilling, it must be pumped out with a pump.

Piling and concrete production

After the formation of all the piles, a formwork made of roofing material rolled up into a tube is inserted into them. The diameter of the homemade pipe should be equal to the cross section of the future pile. Soft steel wire fixes the size of the roofing material, after which it is carefully inserted into the well.

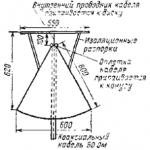

Formwork for homemade piles

In this way, blanks are made for all wells. The purpose of the formwork is to maintain the strength of home-made piles, to prevent the absorption of cement laitance by the soil. In addition, if the mortar is poured directly into the ground, the pile will have an uneven surface. All rough bases are more susceptible to the forces of frost heaving than smooth bases without flaws. A fragile foundation will begin to collapse very quickly, thereby reducing the life of the building.

After immersing the formwork into the wells, it is necessary to make a spatial reinforcing cage. For this, reinforcing bars with a section of 6 mm are used. To form one frame, 3-4 rods are required, fastened every 50 cm to each other. Having installed the structure in the well, it is necessary to see its top above the ground. Protrusion height - from 40 to 60 cm.

Next, you can move on to the production of concrete. The manufacturing technology is described in the section on the strip foundation, repetition is unnecessary. The solution should be fed into the well in batches, filling approximately 0.5 m3 each time.

Important: filling the wells with a solution must be alternated with its bayonet, removing excess air.

Bayonet is performed with a reinforcement bar. To improve the quality of work, you can use a vibration machine, but very carefully so as not to damage the reinforcing content.

Within 2-3 weeks, the concrete will gain strength, after which it will be possible to deal with the grillage. The tops of homemade piles are not cut off, they provide better adhesion of the grillage structure and piles.

Foundation construction on finished piles

What are the main points of building a foundation from ready-made, factory-made piles? The master will need the following set of materials:

- scrap metal;

- 2nd pipe;

- a mixture of sand and cement;

- metal piles;

- ready-made heads;

- anti-corrosion coating;

- water.

Of the tools and equipment, you need to have a shovel, tape measure, level, welding machine and grinder on hand.

Stages of work

Traditionally, construction begins with marking the area. The step between the piles is up to 3 m. Then they start screwing the piles. You can do this manually, involving several assistants, or you can order well drilling from a specialized company. The second option is preferable, but it costs a lot of money.

The depth of the wells should exceed 1.6 m, this prevents them from sticking out during periods of seasonal soil deformation.

Important: if an obstacle is encountered on the way of the pile, you should try to get rid of it and continue working. Only a fully installed pile 100% ensures the strength of the foundation.

The screwed piles are carefully cut to an equal protrusion from the ground, after which the products are concreted. A ready-made solution is poured inside the piles, this prevents corrosion of products in the soil. The final stage is the welding of the heads and the coating of the junction with an anti-corrosion agent.

There is no need to wait for the final hardening of concrete with this method of construction, it is fashionable to move on to the grillage device and subsequent operations.

Calculation of the strip foundation

Building a house from scratch on your own is a difficult task, but doable. Careful calculations, competent selection of building materials and high-quality implementation of each process will help to cope without the involvement of specialists. The most important stage is laying the foundation, because the durability and reliability of any building depends on the strength of the foundation. It will take about 2-3 months to make a foundation for a house with your own hands.

Do-it-yourself foundation for a house

Foundation design

For the construction of residential buildings, a strip foundation is most often used. It can be shallow, if the house is one-story and small area, or standard - laid at a depth of 1.8-2 m. The width of the base tape is usually 40 cm, but can be increased depending on the specific load of the building. When designing a house, you should immediately take into account possible extensions and arrangement of basements and semi-basements. The presence of a common base will greatly simplify the installation of a veranda or other structures that may be needed later.

Foundation design

In order not to make a mistake with the base parameters, you need to carefully calculate the total load per square meter of soil and compare it with the allowable values.

Strip foundation

When calculating the load, the following factors are taken into account:

- material for building walls;

- type of thermal insulation;

- type of roofing;

- number of floors of the house;

- type of soil on the site;

- ground water level;

- region;

- snow and wind loads.

Cross section of the strip foundation

Calculations are made using special tables, for each factor separately. After that, all loads are summed up, which determines the depth of the foundation in this area and the allowable width of the base sole.

Base marking

Foundation layout

To mark the site for the foundation, you will need pegs, a strong thin rope and a tape measure. First, everything that can interfere with the marking is removed - stones, bushes, dry stumps, and so on. They determine the line of the facade of the house relative to the site and mark it with a rope stretched between the pegs. The distance from one beacon to another should be 30-40 cm more than the width of the facade. The location of the corners of the house is marked on the rope, and 2 perpendicular lines are drawn through these points, slightly longer than the length of the side walls.

Plot marking

Now measure the distance from the corner of the facade to the corner of the back wall and mark the points on both lines, and then pull another rope, parallel to the first. The intersections of the ropes form the corners of the building, and it is from these points that you need to measure the diagonals of the resulting rectangle. If the diagonals are equal, the markup is correct. After that, the internal borders of the foundation tape are marked, stepping back from the marking lines 40 cm inside the perimeter. The pegs should be located outside the perimeter - this will allow you to more accurately indicate the corners of the base. The last to outline the internal load-bearing walls, the base for the veranda or porch.

Trench preparation

When the markup is ready, they begin to dig trenches under the foundation. This can be done with shovels or with the help of special equipment, which will be many times faster and more convenient. For a shallow foundation, the depth of the trenches is 60-70 cm, for a conventional foundation - from 1.8 m, depending on the level of soil freezing. The bottom of the trench should be at least 20 cm below this level. Depth is measured from the lowest marking point.

Trench preparation

The walls of the trenches must be leveled vertically, if the soil crumbles, props are installed. After excavation, the bottom must be checked relative to the horizontal, all irregularities are cut off with a shovel, excess soil is removed. The location and width of the trenches must be fully consistent with the project. The next stage is the installation of a sand and gravel cushion, designed to reduce the load from the building on the soil base.

The device of the sand and gravel layer has the following order:

- the bottom of the trenches around the perimeter is covered with a thin layer of coarse-grained river sand;

- spill sand with water and carefully tamp;

- pour another layer of sand and compact again;

- fine gravel is poured and leveled with a layer of 15 cm;

- tamp the surface.

For a shallow foundation, the inner surface of the trenches is lined with geotextile before filling with sand. This material protects the sand cushion from erosion by groundwater and siltation.

Formwork installation

The foundation of a residential building should rise above the ground by at least 15 cm. In flooded areas, the height of the above-ground part of the base can reach 50-70 cm. The formwork is assembled taking into account the required height, using improvised materials.

Foundation formwork installation

When installing formwork, you will need:

- edged boards with a thickness of 2 cm or plywood sheets;

- polyethylene film;

- roulette;

- screws or nails;

- hammer and screwdriver;

- bars for spacers.

Strip foundation formwork

The boards are fastened into rectangular shields, secured with transverse bars from the outside. Self-tapping screws are screwed in from the inside to make it easier to dismantle the formwork. For the same reason, it is recommended to use self-tapping screws, not nails. When assembling, you should consider the location of the sewer holes and make cutouts of the appropriate diameter in the boards. In conclusion, the shields are upholstered with a film that will not allow the tree to absorb water from the solution.

Formwork is installed in parts on both sides of the trenches, and then reinforced with transverse bars every half a meter. The shields are set strictly vertically, maintaining the same distance between opposite sides along the entire length of the perimeter. Outside, the formwork is supported with struts from a bar. There should be no gaps between the lower edge of the shields and the upper edge of the trenches, otherwise the solution will flow out.

Reinforcing frame installation

Reinforcing frame installation

The presence of a reinforcing frame in the thickness of the foundation allows you to strengthen the base and extend its service life several times. For the manufacture of the frame, steel reinforcement with a cross section of 10-16 mm is usually used. It is very important to properly tie the rods in order to distribute the load evenly over the entire area.

Strip foundation reinforcement

For work you will additionally need:

- knitting wire;

- building level;

- Bulgarian;

- cutting plastic pipes;

- roulette.

The reinforcement is cut with a grinder along the length and width of the trenches, after which a lattice with cells from 30 cm is knitted from it. To do this, 4-5 longitudinal rods are fastened with transverse segments every 30 cm.

Foundation reinforcement

It is categorically not recommended to use welding for the connection, since it weakens the attachment points and contributes to the corrosion of the rods. The frame must be voluminous, so horizontal gratings are placed at 3-4 levels, tied with vertical bars.

Additional fastenings should be made at each corner of the foundation and at the intersections of load-bearing internal walls. You can lower the frame into the trenches in parts, and already inside tie them together. To avoid corrosion as much as possible, the reinforcement cannot be laid directly on the sand: they take an old plastic pipe, cut it into rings 4-5 cm wide and put it under the grate in the corners and every 50-60 cm along the trenches. Between the side walls and the edges of the frame, you need to leave about 5 cm, the same applies to the upper edge of the reinforcement.

Reinforcing frame installation

When the grating is fixed inside the formwork, the level of concrete pouring is indicated on the inside of the shields. You can do this with the help of a fishing line: small carnations are stuffed at the ends of the formwork and a fishing line stretched strictly horizontally is fixed on them. It should be located 5 cm above the edges of the reinforcement grid and run along the entire perimeter at the same horizontal level.

Pouring concrete mortar

Pouring concrete mortar

It is recommended to pour the solution at a time, but not by the total mass, but in layers. Each layer should be no thicker than 20 cm; this will evenly distribute it between the cells of the reinforcement and reduce the number of air voids. For the manufacture of the mixture, cement M400 or M500, fine crushed stone and coarse-grained river sand are taken.

Foundation pouring

It is very important to correctly observe the proportions during mixing, otherwise the quality of the solution will be below normal. For 1 bucket of cement, 3 buckets of sifted sand and 5 buckets of crushed stone are required. Water should be taken about half of the total volume, add it in portions so as not to overdo it. The solution should not be too liquid or too thick: high-quality concrete has a uniform consistency, when the shovel is turned over, it slowly slides off with a total mass.

After pouring the first portion, the solution is leveled with a shovel and pierced along the entire length of the trenches with a piece of reinforcement to release the air that has accumulated in the solution during kneading. It is very effective to compact concrete with a vibrator, it increases the strength of the monolith several times. In the same way, the remaining layers are poured until the surface of the concrete is level with the stretched fishing line. The formwork is tapped with a hammer, after which the top of the solution is leveled with a rule or trowel.

It takes about a month to strengthen the foundation