Almost every land owner, sooner or later, thinks about building a bath. After all, a bath is not just a room for washing, but also an important element of summer vacation. The construction of a turnkey bath can be ordered from professionals for a tidy sum, or you can try to build a bath with your own hands.

After reading this article, you will be able to choose a project, find out the sequence of the construction process, get acquainted with the models of boilers and find the best bath option for your dacha.

Before starting construction, it is necessary to develop a bath project. To do this, it is not necessary to contact an architect, you can develop a simple project yourself, especially since now there are many computer programs for designing.

Think about what size bath will be optimal for your family. What rooms will be located inside the bath. From what materials to make the foundation, walls and roof, do not forget also about the decoration of the bath. An important point in the design is the location of the boiler and the method of its combustion.

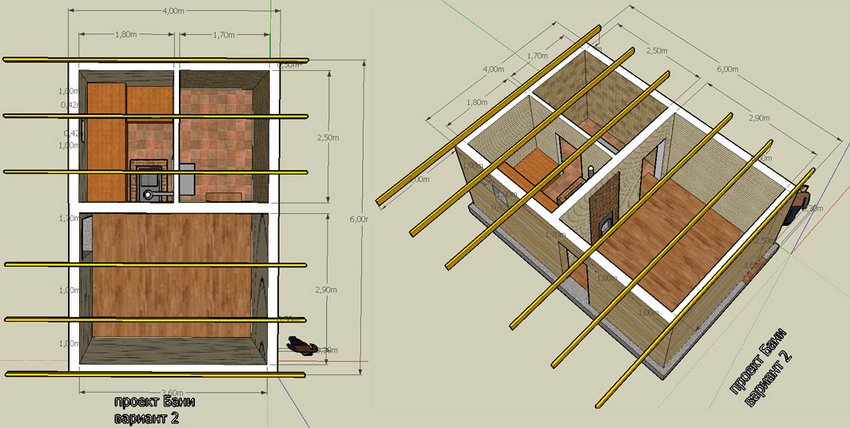

Below you can see the popular projects of baths:

- The bath project is 4x4 meters in size.

- Bath project - 4x6 meters.

- Bath project - 5x6 meters.

- Bath project - 6x3 meters.

- Bath project - 3x3 meters.

After you have decided on the size and materials for the bath, you need to draw up a cost estimate.

Foundation

For the construction of a bath, several types of foundation are used. Depending on the weight of the walls and the characteristics of the soil, the following types of foundations are made:

- Slab foundation.

- Column foundation for light walls.

- Pile foundation.

- Concrete strip foundation.

As practice has shown, the most reliable foundation for almost all types of soil is a concrete strip foundation reinforced with reinforcement.

To make a strip reinforced foundation for a bath, you will need:

- Cement.

- Sand.

- Gravel.

- Fittings.

- Formwork.

- Ruberoid.

- Wire.

- Shovels.

- Concrete mixer.

- Harness.

- Stakes.

- Tools (pliers, hammer, tape measure and others).

In the place chosen for the construction of the bath, mark the trench for the future foundation. For marking, use a tourniquet stretched between the pegs. The width of the trenches is made based on the weight of the material for the walls. For a one-story bath made of wood or brick, it is enough to make a trench 30-40 centimeters wide. After installing the markup, do the following:

- Based on the markings, dig a trench 50-80 centimeters deep.

- Tamp the bottom of the trench and fill it with water to shrink the soil.

- Cover the bottom of the trenches with roofing paper for waterproofing.

- Fill the trench with gravel to a third of its depth.

- Install the formwork along the edges of the trench.

- Make a frame reinforcing the foundation, from reinforcement rods interconnected by wire.

- Install the reinforcement cage into the formwork.

- Using a concrete mixer, make a cement mortar in the proportion of one part cement to one part sand and two parts gravel.

- Pour the cement into the formwork, being careful not to allow air pockets.

- After the concrete has dried, remove the formwork.

The foundation for the bath is ready!

Walls

For the construction of walls use the following materials:

- Wooden bar.

- Logs.

- Boards.

- Brick.

- Blocks from various building mixtures (cinder block, aerated concrete, wood concrete, and so on).

Since the construction of a bath from logs or bricks has already been quite widely described on the Internet, let's consider the option of building a frame bath from a bar of 15x15 and 5x10 centimeters and boards with a section of 2x15 centimeters:

- Make the lower trim, for this, take the bars with a section of 15x15 cm and install them on the foundation, connecting them with special metal plates and corners. There is another way to connect the bars, by cutting spikes, grooves at their ends and then fastening them with screws or nails. When tying, do not forget to put waterproofing under the bars.

- Install vertical racks from a 5x10 cm beam. The distance between the racks is usually 50-60 centimeters. First of all, determine the position of window and door openings and install the racks framing them.

- In the process of work, fix the already installed racks with temporary strips so that they do not warp.

- Make the top harness by attaching it to the ends of the uprights.

- When making the final fastening of the upper trim, carefully monitor the position of the vertical racks, checking their evenness with a level.

- Be sure to reinforce all corner joints with diagonal posts, this will help to avoid warping the frame.

- Make a ceiling sheathing.

- After making the frame, make the outer cladding of the walls of the bath with a board with a section of 2x15 centimeters. If you do not want gaps between the boards, then make the sheathing - "overlap", laying the bottom edge of the board on the nailed board. In appearance, this method resembles wall siding.

- Having sheathed the bath from the outside, proceed to the installation of insulation. Sheets of foam or mineral wool are installed along the vertical racks of the frame.

- On top of the insulation, it is necessary to install a layer of vapor barrier, which is attached to vertical racks using thin rails.

- After installing the vapor barrier, make the inner lining of the bath with clapboard or slats.

- Insulate the ceiling by laying vapor barrier sheets on the inner lining, then insulation. Sheathe the ceiling from the outside with plywood sheets.

Please note that the manufacture and insulation of the ceiling can also be done after the installation of the roof.

Roof

The roof for the bath is of three types:

- Shed.

- Gable.

- Complex - consisting of four or more slopes.

Usually, the first two options are used for a bath. Let's look at the option of a gable roof covered with metal tiles:

The manufacture of the roof begins with the installation - Mauerlat. In the case of frame walls, the role of the Mauerlat is performed by the upper stroke.

- Install the uprights on the bench.

- Connect the racks with girders and puffs.

- Install the rafter legs by attaching them to the Mauerlat, run and connecting the upper ends to each other. The distance between the rafters should be 50-60 centimeters.

- Install sheets of metal.

- Sheathe the gables with wooden slats or sheet iron.

For a more visual acquaintance with the roof fastening, the following figure is shown:

All sizes of roof elements are listed:

Keep in mind that the smaller you make the slope of the roof, the more snow load will fall on it in winter. Also, a small slope of the roof can lead to poor drainage and leaks.

floors

The design of the floor depends on the type of room. In the rest room, ordinary wooden floors are made. In the washing and steam rooms, the floors are made of two levels:

- The first level is made of concrete, has a slope towards the drain hole.

- The second level is a finished floor made of boards with gaps for draining water.

If you want to make a floor of porcelain stoneware or tiles, then they simply fit on the first level, sloping towards the drain hole.

In order to make a concrete floor and drain in the bath you need:

- In the center of the steam room and washroom, install plastic pipes with a diameter of 5-10 centimeters with a bell at the end. Pipes must go through the foundation to the street and connect to the sewerage system.

- Lay down a layer of waterproofing material.

- Spread a layer of gravel 10-15 centimeters thick over the entire area of \u200b\u200bthe rooms.

- Make a cement mortar and pour the floor with a slope to the hole installed on the drain socket pipe.

- Install a grate on the drain hole to prevent debris from entering the sewer.

At the second stage, wooden floors are made:

- Install wooden logs in all rooms of the bath. Make the distance between the lags 30-40 centimeters. As a log, you can use bars with a section of 3x5 cm or 4x6 cm.

- Nail boards with a section of 2x15 cm or 5x20 cm onto the logs.

- In rooms where water is supposed to be drained, leave gaps of 0.5-1 cm between the boards.

Do not forget, before starting the installation of wooden floors, treat all parts with wood impregnation. When making floors, keep in mind that they should be above, or at the level of the top edge of the foundation.

Boiler

The model of the boiler for the bath will largely depend on your financial capabilities and the fuel that you will use for heating. If you know how to use welding, then you can make a simple boiler yourself, from thick sheet iron. If you prefer more advanced colas on gas or electricity, then they can be purchased from specialized companies.

The boiler in the steam room is installed in such a way that the combustion chamber is loaded with fuel either from the street or from the rest room (dressing room). The boiler itself, for fire safety purposes, is located 10-15 centimeters from the nearest walls. Walls to the height of the boiler, covered with sheets of iron. A good solution would be to overlay the boiler with bricks, thereby reducing its cooling time and protecting the walls from fire.

When arranging a chimney for a boiler, pay special attention to the place where the pipe is in contact with the ceiling. The hole for the chimney should be insulated with a refractory material. Also, pay attention to the place where the chimney pipe exits through the roof. Usually, this place is prone to leakage, so it should be carefully sealed. Below are the options for boilers for the bath:

- Homemade boiler from sheets of metal.

- Gas boiler.

- Electric boiler.

- Solid fuel boiler.

Bath arrangement

After the bath is built, it is necessary to equip it:

- Bring to the bath all the communications available on the site - electricity, sewerage, water supply.

- Place inside the sink, shower, light sources, furniture for relaxation.

- Decorate the walls of the steam room with curly slats and make stepped shelves.

- Buy wooden tubs, buckets, buckets and brooms.

After the arrangement, you can safely invite guests to take a steam bath in your personal bath!

You can also see the instructions for assembling a mini-bath for giving without a foundation in the video:

Variants of beautiful and unusual baths

In addition to traditional materials and design for a bath, there are many alternative solutions. Below we give photos of the most unusual baths:

- A mobile bath from a "lining", built on a car trailer.

- Sauna in a huge wine barrel.

- Bath from plastic bottles.

- Bath dugout, built right in the ground.

- Bath housed in an iron container.

- Forest bath from raw logs.

- A beautiful bath from a gun carriage.

- Bath from unedged boards.

At the end of the article, I would like to remind you that heating the bath is associated with fire and high temperatures. Therefore, when building a bath from bricks, logs, cinder blocks or boards, pay great attention to fire safety. This warning also applies to the electrical wiring device, since the rooms inside the bath have high air humidity and the risk of a power outage due to condensate is very high.

We hope that reading our article will encourage you to build a bath yourself!

Everyone perceives the dacha in different ways, for some it is a way to relax after a working day in the garden, for others it is an occasion to gather with friends, for others it is just a Saturday tradition. But in any case, a bath in the country is a real miracle that every summer resident dreams of. Therefore, this article is devoted to how to make this dream come true, i.e. build your own bathroom.

Bath design

The first step towards the realization of this dream is the creation of a bath project. It depends on him what the bath will be, so it is necessary to approach this stage very responsibly.

The project must contain the following information:

- Building dimensions;

- layout;

- Location of doors and windows;

- Structural features of the structure;

- What materials will the building be built from?

If you can build a bath with your own hands, then it is better to entrust the implementation of the project to professionals. True, you can use a ready-made project that best suits your wishes.

You can find some of these projects on our building portal. However, before giving preference to any of them, you should think in advance what kind of bath you want to see on your site. It can be a small building with a washing room, a dressing room and a steam room for one or two people, or vice versa, a whole bath complex in the country, which may include, etc.

Design nuances

To avoid mistakes during the design of the bath, the following points must be considered:

- In order for the steam room to be convenient and comfortable, you need to plan it correctly. According to experts, the area of a steam room for 2-3 people should be about 10 square meters.

- The height of the steam room should be 2-2.2 m. A lower ceiling is inconvenient, and a higher one leads to wasted energy and longer heating of the room.

- Windows and doors should preferably be small. In addition, a high threshold should be set, although this will create some inconvenience, it will seriously reduce heat loss.

- When performing the interior decoration of the steam room, resinous wood should not be used.

Advice!

If you bought a plot for a summer residence without buildings, then this does not mean that it will not come to the construction of a bath soon.

Country houses from block containers are a great way to equip the site.

After installing such a house, which happens very quickly, you can take your time and do it.

Place for a bath

Also at the design stage, before you make a bath in the country, you should carefully consider its location on the site. The best option would be to build it near the reservoir, which will allow you to plunge after the steam room in cool water.

In addition, it is desirable that the bath is not visible from neighboring areas or the street. If it is impossible to withstand such a condition, then it is possible to artificially make a green fence from shrubs and trees.

materials

Any building materials are suitable for the construction of a bath, however, a bath built of timber or logs is considered traditional. I must say that the choice largely depends on the budget of the project, since the price of different materials can vary significantly.

Since the process of building a wooden building is fundamentally different from building a brick, we will further consider both options.

Construction of a bath from a bar

Foundation

As with any other construction, the construction of a bath from a bar begins with a foundation. Since the structure will be relatively light, the foundation can be made columnar, provided that the ground is solid.

The foundation is done as follows:

- The first step is to prepare the construction site for further work. To do this, remove debris and remove the top layer of soil.

- Then markings are applied to the soil surface in accordance with the project. All dimensions of the future structure must be double-checked several times in order to avoid mistakes.

In the photo - a columnar foundation

- Further, at the corners of the building and at the junction of the inner walls with the outer ones, holes should be dug to a depth of about 30 cm. The diameter should correspond to the size of concrete blocks or flat stones that will be used as pillars.

- After that, the same pits are made for the posts, on which the lags will rest.

- Then the bottom of the pits should be covered with a layer of sand about 10 cm thick and carefully compacted.

- Next, blocks or stones are laid, which should rise 25-30 cm above the soil surface. It is important to ensure the correct location of the pillars - the foundation surface should be located in the same horizontal plane.

- At the end of the work, the surface of the blocks is covered with waterproofing material. Most often, ruberoid is used for these purposes.

erection of the box

After the foundation is ready, you can start building walls.

The instructions for doing this work are as follows:

- The erection of walls begins with the laying of the first crown of timber 20x20 cm. Before laying it, the beam must be treated with an antiseptic and resin, which will ensure its safety for a long time. Before fixing the beam, you should make sure that its location is horizontal.

- To fasten the timber, it is necessary to make a tenon-groove connection, which can be made with a conventional saw, as shown in the diagram. In addition, metal corners and self-tapping screws can be used to strengthen the structure.

- After laying the first crown, the floor lag is installed. The traditional option is to insert them into the beam of the first crown, however, this significantly complicates their replacement, which will be needed sooner or later. Therefore, it is more expedient to attach the logs to the first crown using metal corners and self-tapping screws.

- Internal wall beams can be cut into external walls using a tenon-and-groove connection.

- Next, heat-insulating material (tow) is laid on the first crown and the second row is mounted from a bar 150x150 mm, also treated with an antiseptic. The connection of the crowns with each other is carried out with the help of spikes (dowels). To do this, a hole is drilled through the upper crown to the middle of the lower crown and a spike is inserted. Installation of dowels is carried out in a checkerboard pattern at a distance of 1-1.5 meters from each other.

- After the walls are erected, window and door openings are cut with a chainsaw.

- After that, the floor beams are laid, and the truss system is installed in accordance with the building project.

- The final stage is the installation of roofing material and laying the floor.. After that, the arrangement of the bath in the country is carried out, which we will discuss below.

This completes the main stage of work.

Construction of a bath from bricks or blocks

Foundation

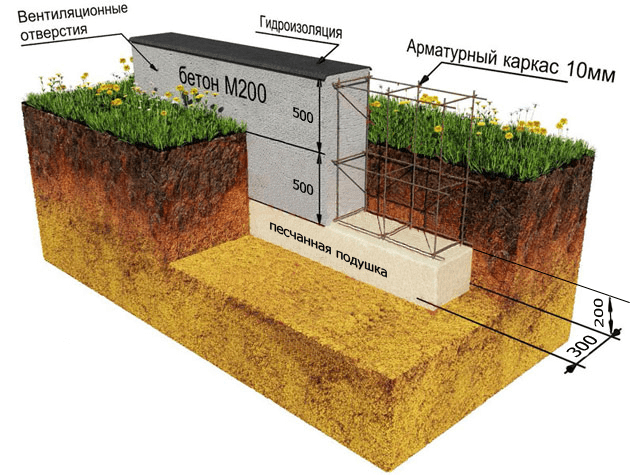

The construction of a brick bath in a country house also begins with the construction of a foundation. Since the building will be heavy, the foundation must be solid.

You can execute it like this:

- As in the first case, you first need to prepare and mark the site.

- Further along the perimeter of the outer walls, trenches are dug to a depth below the level of soil freezing. The width of the trenches depends on the thickness of the walls.

- Further, a sand cushion 15 cm thick is laid on the bottom.

- After that, the formwork is installed and reinforcement with steel bars is performed. As a rule, reinforcement is a metal frame made of reinforcement, fastened together with wire.

- After that, the formwork is poured with concrete. At this stage, it is necessary to ensure the horizontal level of the foundation.

An important point in the construction of the foundation is the preparation of concrete, since the strength of the structure depends on it. To prepare high-quality concrete, you will need the following ingredients:

All components must be thoroughly mixed until a homogeneous mass is obtained.

erection of the box

After 28 days, when the concrete has gained strength, you can continue to build a bath in the country.

The work is done in the following order:

- As in the first case, before the walls are erected, the foundation is waterproofed with a roofing material.

- Next, bricks or blocks are laid on a cement-sand mortar. When laying each row, it is necessary to check the horizontal position of its location using the building level.

- In accordance with the project, at the stage of erecting walls, it is necessary to provide window and door openings. A jumper must be laid over each opening. As a rule, concrete beams are used for this.

- After the walls are erected, floor beams are laid and the roof truss system is performed.

On that, the construction of the box is completed.

Bath arrangement

So, the building is ready, now it remains to figure out how to equip a bath in the country. Of course, doors and windows should be installed first. Then you need to pay attention to the steam room.

Arrangement is carried out as follows:

- First of all, logs are laid and a wooden floor made of resin-free wood is laid.

- Next, insulation is performed, especially if the building is built of brick or blocks. To do this, slats are nailed to the walls, between which mineral mats are fixed, after which foil insulation is mounted. Then the walls are sewn up with linden clapboard.

- The next step is to make shelves from linden or abash. Shelves are stuffed from hotel rails, between which there should be a distance of several millimeters.

- The final stage of work is the implementation of lighting. For the steam room it is necessary to use special hermetic lighting fixtures. In this case, the switches must be located outside it.

Advice!

If there is no electricity in the country house, then renting a diesel generator for the country house will help solve the problem of power supply.

After the steam room is ready, you should purchase equipment for a bath in the country. The most important element is the stove-heater. Of course, it can be laid out of brick, but this is quite a difficult job, so it's easier and safer to buy a finished product.

As for the arrangement of the rest of the premises, the interior of the bath in the country depends on individual preferences. Most often, the bath is decorated in the Russian style, however, you can use more modern options.

Conclusion

A bath in the country is available to almost every summer resident, so it is quite possible to build it yourself. The most important thing in this case is to strictly observe the technology at each stage of construction in order to avoid mistakes. The result of such work will be a comfortable and safe steam room that will delight its owners for many years.

Having fruitfully spent the whole day in the summer cottage, it is appropriate to start your vacation with a visit to the bathhouse, where you can take a steam bath and in this way relieve the accumulated fatigue. Needless to say about the benefits of such procedures for the human body, this has long been a proven fact. The point is small - to determine where the bath should be located in the country and build it with your own hands. How to do it right, you will learn from our article with step-by-step instructions for the construction of this popular structure among the people.

Construction stages

To make a bath yourself, you need to outline a clear procedure:

- Choose a suitable place to build.

- Design a bath building and determine its dimensions in accordance with the needs, wishes and possibilities.

- Select building materials and calculate their quantity according to the developed project.

- Prepare the site and make the foundation.

- Build walls, partitions and roofs.

- Perform internal arrangement - conduct communications, install a sauna stove and organize ventilation.

The best option for a bath is a separate building, an extension to the house is economical, but inconvenient. There are no strict requirements for the placement of the building, except for one - compliance with fire safety standards. Based on them and taking into account the common wishes of the owners of cottages, we will give the following recommendations for choosing a place:

- plan the construction site somewhere in the backyard, in a quiet place and at the maximum distance from the neighbors;

- the optimal distance to the country house is 8-10 m;

- excellent location - next to the home pool or on the shore of the reservoir;

- think over the question of how to inexpensively bring water supply, sewerage and electricity to the bath;

- outbuildings from which unpleasant odors can be heard (garage, barn, stable) should be as far as possible from the designed building.

Site plan with the location of the bath

Note. If you decide to start building a bathhouse near a pond, then you need to foresee the likelihood of flooding and take measures in advance, for example, raise the level of the clean floor higher.

Step one - choosing a project

Unlike similar structures being built next to private houses, 2 main requirements are put forward for a summer cottage:

- A bathhouse for a summer residence should be designed for daily washing after a hard day and quick heating. If the heating of the steam room lasts for half a day, then it is easier and more convenient to use a summer shower.

- The design is provided as simple and cheap as possible. We do not take cases when the country house is a two-story cottage and the sauna should look like it.

Reference. For those who do not want to engage in construction in principle, there are options for ready-made mini-baths. For example, a mobile bath in the form of a trailer for a car or a finished product in the form of a barrel, shown in the photo.

In order for the steam room to be quickly heated, its size must be optimized for the number of people who constantly live in the country and take bath procedures. This will not create any special problems for guests who can take turns washing. The drawing below shows a plan for a mini-bath 3 x 3 m, designed for the simultaneous stay of two people:

As you can see, the small house is divided into only 2 rooms - a rest room and a steam room combined with a shower. Since this is a budget option for a sauna, the ceiling height is also small - up to 2.7 m. If you need to divide the rooms and increase the size, you can take as a basis the layout of the building 5 x 3 m, shown in the following drawing.

Note. The terrace is shown in the picture conditionally and is built according to your desire and size.

For comfortable bathing and relaxation of 4 people, the total area of all bathhouse rooms should be 20 m², 5 m² for each. Then a 5 x 4 m building scheme with a large open terrace will suit you:

Stage two - selection of materials

In general, baths are usually made from various building materials - bricks, blocks and even sandwich panels. But the best option is a tree, and here's why:

- wood is a natural eco-friendly material;

- it is easy to handle with a minimum of tools;

- lumber is affordable;

- wooden structures are lightweight and do not require a powerful foundation (an exception is log cabins).

Bath, built on frame technology

When building a bath, the ecological purity of the constituent elements plays a special role. It's all about the high temperature, due to which building materials that are harmless under normal conditions begin to release compounds that adversely affect the health of those who wash. Therefore, it is highly undesirable to use any artificial heaters in the bath house - mineral wool and polymers. What to use:

- dried timber with a section of 15 x 15 or 10 x 15 cm;

- edged boards 150 x 50 or 150 x 40 mm;

- finishing lining;

- materials for caulking - jute, moss, flax;

- natural heaters - expanded clay, sawdust, clay and so on.

log bath

Note. For the device of vapor and waterproofing, it is allowed to use polyethylene films and special membranes that allow moisture to pass in one direction.

A few words about how best to build a bath from lumber, more precisely, about the construction of the walls. There are 3 ways to choose from:

- Installation on frame technology.

- Prefabricated timber structure.

- Walls made of logs (log house).

The preferred option is a do-it-yourself bathhouse made of timber, shown below in the photo. It meets all the requirements and will cost relatively inexpensively. Yes, a frame building is cheaper, but it uses basalt wool for insulation, which releases carcinogenic substances when heated. A chopped house is suitable for environmental friendliness, but it requires a strip foundation, and this is an increase in the cost of the project. In addition, the logs must be able to connect correctly so that the structure turns out to be beautiful and warm.

Advice. If you want your bath to look like a log house, nothing prevents you from building it from a bar, and then finishing it with a block house that imitates a log.

We build a turnkey cottage

Before starting construction work, it is necessary to prepare the selected site. Remove unnecessary objects, stones and vegetation from it in order to calmly proceed with marking. If the site has a slight slope, then it is desirable to level the site.

With the help of pegs, rope and measuring instruments, mark up, outlining the contours of the future building. Make sure that the indents from other buildings correspond to your calculations, and then mark the installation points for the foundation supports. Usually they are placed like this: 4 corner posts, and between them - intermediate supports with an interval of no more than 1.5 m. For the installation of internal partitions and a log in the middle, several more rows of posts are planned.

Base device

As a basis, we took the foundation of the columnar type as the simplest and cheapest in execution. It makes no sense to pour a concrete tape under a small country bath, except that it is built from a log and therefore has a decent weight. The work algorithm is as follows:

- In the places marked with pegs, dig holes 0.7-1.2 m deep, depending on the location of the stable layer of soil. Make the dimensions of the recesses 20 cm larger than the dimensions of future columns so that they are convenient to lay out.

- Tamp the bases and sprinkle them with sand to a height of 10-15 cm, and on top make the so-called footing 40 mm thick from a cement-sand mortar.

- Lay brick or cinder block pillars to the required height. Inside each, insert reinforcing bars with a diameter of 12-14 mm to fasten the beams.

- After the mortar has hardened, treat the masonry with bituminous mastic, which provides waterproofing, and lay the usual roofing material on top (2 layers are needed).

- Fill the recesses around the supports with soil and compact it.

If the soil in the country house is oversaturated with moisture and is prone to frost heaving, then the columnar and strip foundation will not last long. In winter, the freezing soil will push it outward and the structure will warp. Since the depth of the unstable horizon sometimes reaches 3 m, the pile-screw foundation shown in the photograph will serve as a reliable foundation here. Laying so much concrete is simply unrealistic, and pointless.

The essence of the idea is to screw piles with blades into the ground to the required depth so that they reach dense soil that does not give subsidence. Wet soil will not be able to push them back - the blades will interfere. Details about the device of the pile-screw foundation are described in the video:

Construction guide

The crucial moment is the installation of the first crown. The bars are laid on supports, aligned horizontally and at the corners, and then fixed. If you need to connect 2 beams to increase the length, then docking is performed on one of the foundation pillars by cutting into half a tree.

Attention! Before erecting the wooden structures of the bath, all elements should be impregnated with an antiseptic.

Connect the bars at the corners in the simplest way - "in the paw". To speed up the process, make a template for sawing the ends shown in the diagram:

Before combining the sawn beams, lay the joint with a caulk - jute or flax fiber. Repeat the same action before laying subsequent crowns so that there are no gaps between the elements. Connect every 3 rows of bars with steel brackets - dowels, as the scheme prescribes:

To cut internal partitions into external walls, it is necessary to cut each beam to get a connection in half a tree, as shown in the figure. Other ways of cutting are also shown there, but it is more difficult for a novice carpenter to implement them.

Note. Using the presented connection scheme, you can assemble walls with cuts, as is done in log houses. But keep in mind that the consumption of timber will increase.

During installation, check the vertical and, if necessary, correct the position of the elements before placing the dowel. Having reached the design height, lay the boards around the perimeter (in technical language - Mauerlat) and proceed to the assembly of the gable roof truss system, whose design is shown in the photo:

The installation order is as follows:

- Attach the cross beams to the Mauerlat in increments of 0.5-0.6 mm.

- Install a vertical post in the center of each crossbar. Rafters are attached to it, resting on the Mauerlat with the other end.

- To support the rafters, put 2 slanting jumpers on each beam. Nail the batten boards on top.

- Cover the crate with sheets of a diffusion membrane and nail it with planks. Mount the roofing from slate, corrugated board or metal tiles.

- Knock the ceiling beams from the bottom with a clapboard. Sew the gables with the same material.

Thermal insulation of ceilings with sawdust

To prevent heat from escaping through the roof, be sure to insulate the ceiling. Use sawdust mixed with clay, vermiculite or expanded clay. Do not lay floors until you carry out communications in the building - water supply and sewerage. Very detailed and accessible about the construction of a bath from a bar is described in the video:

Interior arrangement

The organization of water supply and wastewater disposal begins at the stage of foundation construction. While the mortar of the brickwork of the pillars is solidifying, trenches for communications should be dug, as is done in the example in the diagram:

To complete the equipment of the bath in the country, you need to perform the following work:

- Lay water and sewer pipes along the trenches (the first should lie above the second) with a conclusion at the intended points. At the entrance to the building, insulate these communications.

- Pour at least 30 cm of expanded clay on the ground so that it forms a gutter under the steam room and washing room. Run a sewer pipe into the gutter and fill it with cement screed, as shown in the diagram below. After that, you can sew up the floors with boards.

- Install plumbing fixtures and connect them to the supply pipes. Install sinks and siphons.

- Make lighting by connecting it to the mains through the RCD. Use lamps and switches that are not afraid of moisture, and hide the wires inside special corrugated sleeves.

- Organize ventilation by building adjustable wooden dampers into the outer walls.

- Put together wooden shelves and put them in the steam room.

The device of the inclined subfloor in the steam room

A separate issue is the installation of a bath stove. Brick building is not necessary, it is too long and expensive. It is better to put a metal one (you can make it yourself) with a firebox placed in the dressing room. For the installation of the chimney, the recommendation is this: take insulated sandwich pipes and try to immediately bring the channel out into the street so that you do not have to go through the attic and roof. The wooden walls of the steam room must be protected from the stove with steel sheets - this is a fire safety requirement.

Installation of a sauna stove and crossing wooden floors with a chimney

Conclusion

From the foregoing, the conclusion suggests itself: to build even a simple bathhouse in the country, you will need to make a lot of effort. But don’t let that bother you, imagine that you hired a team of builders to do all the work, who will give you an impressive bill. Add to this the time spent supervising the construction and an unknown number of mistakes made by workers. Here it is worth remembering a proverb adapted to the occasion: if you want to make a bath well, build it yourself.

Structural engineer with over 8 years experience in construction.

Graduated from East Ukrainian National University. Vladimir Dal with a degree in Electronic Industry Equipment in 2011.

Related posts:

- This is a difficult, but quite feasible undertaking. First of all, the owner must choose the right material for the construction of the bath.

Choosing a place to build a bath

Start by choosing a suitable location for the building. The following recommendations will help you with this:

Before starting any construction activities, prepare a bath project.

Determine the optimal size of the structure. One vacationer should account for at least 5 m2 of the total building area. For example, if you are building a bathhouse for 4 people, its area must be at least 20 m2.

The standard bath consists of a steam room, a washing department, a dressing room and a rest room. Set the dimensions and features of the spatial placement of the listed premises that are convenient for you.

Prepare the following drawings:

You can make all these drawings yourself or find them in an open source. In general, the projects of log baths remain almost the same. If you have the desire and sufficient budget, order the preparation of drawings by a professional.

Materials for building a bath

To build a bath from a bar, you will need a whole set of different materials and devices, namely:

- beam. Traditionally, a material with a section of 150x150 mm is used;

- floor boards. The best option is a four-meter edged board 15x5 cm;

- ceiling boards. Usually used lining with a width of 10 cm and a thickness of 2 cm;

- materials for interior decoration. Lining is perfect;

- vapor barrier material. The best option is modern vapor barrier films;

- waterproofing material. If possible, use penofol. Polyethylene film is also suitable;

- ceiling heater. Mineral wool materials are well suited;

- sheet asbestos. With it, you isolate the wooden elements of the building from high temperatures. Insulation sheets must be fixed to the walls near the sauna stove. Also, wooden elements installed in close proximity to the chimney need insulation;

- bulk materials for arrangement. The set is standard: cement, sand and gravel;

- material for finishing the roof. Focus on your preferences. The main thing is that the roof of the bath looks good surrounded by the roofs of other buildings on the site;

- insulation for interventional space. Use jute. Tow and moss are also suitable.

The construction of a bath is best to start in the spring, because. after the completion of the main activities, the wood will need to be left for a six-month "wintering". During this time, the material will dry and give the required shrinkage.

Buy cement immediately before construction begins.

Bath construction guide

The work is carried out in stages - from preparing the construction site to equipping the bath with various accessories.

First stage - Site preparation

Clear the construction site of all sorts of debris, shrubs, large roots and, in general, everything that can interfere with the foundation construction stage.

The second stage - Pouring the foundation

Attach the batten boards to the rafters. Lay hydro, heat and vapor barrier materials, the insulation of the bath is one of the most important elements of its construction, the quality of the built bath will directly depend on this. Install your chosen roof finish.

Prices for various types of timber

Fourth stage - Interior fittings

Start by arranging the necessary communications.

You should take care of the installation even at the stage of creating the foundation. To do this, create a pit or drainage well outside the bathhouse, connected to the bathhouse by a pipe laid with a slope.

After completing the arrangement of the sewer, make the floor. It can be concrete or wood. Concrete floors are usually tiled. This coating is more durable.

The wooden floor is traditionally made leaky. The technology is extremely simple: logs are installed, floor boards are nailed to them with some clearance. You can also create a small hatch for drains and close it with a perforated grate. The floor in this case should be made with some slope. As a result, moisture from the floor will enter the hatch, and from there it will be discharged through a pipe into a drainage well or pit.

In order for the wood to last as long as possible, carefully ventilate the bath after each visit.

Insulate the ceiling and walls of the building using suitable moisture, heat and vapor barrier materials. Install doors and windows. Connect plumbing and electricity to the bath. Install the necessary electrical appliances.

Prices for thermal insulation materials

Thermal insulation materials

Fifth stage - Furnace and shelves

Choose the design of the shelves at your discretion. They are built in the same order: first, a support frame is mounted from a strong beam, after which boards are nailed to the supports.

The oven is also up to you. You can lay out a traditional one, install a convenient metal unit or a modern electric heater.

Heavy furnaces require the mandatory arrangement of an individual foundation. At this point, everything is also determined in a separate order, taking into account the characteristics of a particular furnace.

Prices for various types of stones for furnaces

Stones for stoves

Step Six - Optional Accessories

In conclusion, you will only have to supplement your country bath with various kinds of accessories, namely:

- brooms;

- wooden mug for adding water;

- buckets;

- various kinds of wooden gratings, etc.

The internal arrangement of the additional premises of the bath is at your discretion.

Successful work!

Prices for bath and sauna accessories

Bath and sauna accessories

Video - Do-it-yourself bathhouse in the country

Hello, dear site visitors! We continue the series of articles from our readers In this article, the author shares his personal experience in building a log bath with his own hands. Construction is not finished yet, so we wish him success! If you have recommendations and questions for the author, you are welcome in the comments.

Part 1. Foundation

For the construction of the bath, I chose a relatively flat area with a slope of 20 cm on a six-meter segment. First of all, after preliminary marking, he made a cut of the fertile layer over the entire area of the future foundation. This is required to exclude the processes of decay of plant residues and other organic matter in the basement.

The site is dominated by sandy soil, so the best option would be a height of 50 cm from the base and a width of 40 cm. The outline of the foundation is marked with ropes that are attached to improvised corners of the inner and outer perimeter. To mark the perimeter, I took cuttings of boards about 70 cm long and drove them into the ground, screwed horizontal shelves with protruding screws for attaching the rope from above with self-tapping screws. It is better to choose a rope that is not prone to stretching, it will be easier to work with this.

In addition to the lengths of the sides of the future foundation, the diagonals between the angles must be verified, which must be equal to each other with a tolerance of plus / minus 3-4 cm. You can read more about how to mark the foundation in this article. We continue to remove the fertile layer and dig a trench to create a sand cushion.

As a result, we get a fully prepared "pit", where the bottom of the trenches is almost horizontal (we check with the building level). The depth of the trenches is 20 cm, from the soil level at the highest point of the site 40 cm, at the lowest - 30 cm.

The dimensions of the foundation are determined by the center of the intersection of the logs of the log house. This will be the center line. If the diameter of the logs is about 20-22 cm, then we retreat on both sides of the center line, respectively, by 15-20 cm. This will be required to obtain "shelves" for attaching floor logs and rain tides. In addition, an error is practically eliminated when the logs, due to miscalculations of the foundation, fall outward or inward “hanging” in the air.

The bath is connected to the strip foundation in order to exclude multidirectional shifts of the bath and the furnace. The size of the furnace platform was chosen as 120 * 120 cm, as the average for installing metal furnaces under brick lining.

We start laying sand in the trenches. At the same time, we moisten and compact the sand. We pour water until puddles appear, after the moisture is absorbed, we begin to tamp. The process is repeated 3-4 times until your shoes leave no marks on the compacted surface of the sand.

A day later, after the completion of work, we once again pass the entire base under the foundation with a rammer. Of course, you can use a simpler option and connect a tamping machine to work, this will not speed up the process much. I have the simplest option: a beam of 100 mm, a sole of 20x20 mm and a handle. The appearance of the finished base and manual rammer is shown below.

On top of the prepared site under the foundation, we pour a sand cushion to level the horizon and raise the site above the level of the site in order to prevent water from entering under the foundation.

If you hire a concrete truck, then take care of additional strengthening of the formwork with diagonal stops outside and inside the proposed foundation. The pressure that is created when the mixture is supplied can demolish an insufficiently strong structure. The same applies to pouring the mixture from a concrete mixer. Only in this case, you need to strengthen the place where you will drain or simply move the concrete mixer around the perimeter.

It is better to pour the entire volume of concrete at one time, so as not to get the effect of a layered cake. We cover the top of the foundation with a film that keeps our foundation moist in order to avoid cracks in the concrete. The foundation is periodically watered with water, not allowing it to dry out.

After 7-10 days, we remove the formwork, unscrewing the self-tapping screws, which will also go into work at subsequent stages. The finished foundation looks like this. Layout: 2x6 meters - veranda; 4x4 meters - rest room; 2x2 meters - washing room; 2x2 meters - steam room. The location of the ventilation holes is approximately 20 cm from the ground level, if necessary, you can buy plugs to close the holes in the winter.

The approximate quantity and price of materials used in the construction of the foundation are shown in the table below.

Part 2. Installation of a log house and a roof

For dressing a log house 6x4 meters and a chopped veranda, you will need 25 bags of moss. When buying, make sure that the weight of a bag of compacted moss is approximately 20 kg. Moss must be elastic, that is, have optimal moisture content.

We use “cuckoo flax”, which we collect in late autumn, when all living creatures go to “wintering” in the soil and there is no risk of grabbing a snake with a bunch of moss. A small amount of sphagnum moss is allowed, which is shorter and crumbles when dry. If only sphagnum is fully used, then after a while it will simply fall out of the grooves.

The length of the strands of moss should be at least 30 cm, so that when caulking it is possible to twist the ends and ensure the sealing of the grooves. When drying, we sort the material, choosing twigs, foreign plants and cones from it. By the way, if the bump falls into the groove, then at a certain humidity it opens with such an effort that is enough to lift the log and arrange a “cold bridge”. This is how log house installers did in the old days, and even now this situation is not uncommon if the owner “offends” with money.

We install rolling logs. I have a small gap between the foundation and the log house, so I used half a log on one side and a 100 mm beam on the other.

We punch the place of contact of the log with the roofing material with moss.

Errors were revealed that caused the unwillingness of the cutters to do their work efficiently. The grooves were cut with a chainsaw, which made the gaps in the logs very large. Look, the edges of the grooves fit snugly against the body of the log, but in fact there is a void inside. Because of this, the amount of moss that will go to the caulk increases greatly. And this is if you do the caulking yourself, and the "shabashniks" only do the external processing, no one will break through the insides.

| Material | Volume/quantity | Price |

|---|---|---|

| Edged fence board "inch" on the crate, 300 mm | 1 m 3 | 4500 rubles |

| Wood screws 50 mm | 2 kg | 300 rubles |

| Moss | 25 bags | 6250 rubles |

| log house | 1 piece | 72000 rubles |

| Board 50 * 150 six meters | 14 pieces | 3600 rubles |

| Metal tile, thickness 0.5 mm, length 4.2 meters (additional ridge and wind protection) | 12 sheets | 31000 rubles |

| Steam-Wind-insulation | 1 roll | 800 rubles |

| Grooved board 20 mm | 1 m 3 | 8500 rubles |

| "Belinka" base | 2.5 liters | 400 rubles |

| "Belinka" glazing composition | 2.5 liters | 600 rubles |

| Total: | 127950 rubles | |

Part 3

The most simple, but tedious work on caulking a log house. We use a mallet, iron and wooden caulks. An iron one with a blade thickness of 3 mm and a width of 50 mm, a wooden one is made of hardwood (I have dry birch) and is a consumable.

The original view of the groove.

We fill the moss into the groove with a construction trowel. Previously used a spatula, but it quickly failed and was not as elastic. Feel free to hammer the groove completely. There is an opinion among the inhabitants that there is no need to make the seams dense and uniform, they say, the temperature in the bath is enough to compensate for the losses. But judge for yourself, drafts in the steam room and washing room will not add comfort and firewood consumption will be 2-3 times higher.

We hammer the resulting roller with a wooden caulk.

If necessary, if the groove is not tight enough, we make another roller of moss and punch it until we feel the hardness of the wood when struck with an iron caulk.

The final view of the caulked groove.

To prevent birds from dragging moss and for aesthetics, we close the groove with a 100 mm wide jute tape, which will subsequently be treated with impregnation and glazing composition to match the color of the log. Special "craftsmen" put logs on only one jute or linen, but this is unacceptable for a bath. If we have constant humidity in the house, then vaporization is welcome in the bath. Flax and jute absorb moisture, but do not dry out for a long time, the grooves rot and become moldy.

We get logs prepared for grinding.

We especially carefully caulk the corners to prevent cold air from entering the bathhouse. Work, if you do not hire specialists, will cost nothing. When attracting "shabashniki" - from 70 to 150 rubles per linear meter.

Part 4. Sanding logs

So, the caulking is completed, the moss is filled and compacted in the grooves, we proceed to prepare the log house for painting. At present, the logs look very unpresentable - traces of a planer, chips and pulled out wood chips. In addition, the logs are strongly "tanned" in the sun and under the influence of slanting rains, and some of the knots require sampling and sealing with mastic.

The ends of the logs, which were damaged during storage and transportation, also require processing. Here the most loose wood, respectively, a high probability of decay and further destruction of the log.

Logging tools:

- Bulgarian;

- petal emery wheel;

- soft brush from a mop;

- putty knife.

Bulgarian used the cheapest - 1200 rubles, made in China. It is worth noting that it withstood all the tests with honor and remained operational even after passing 70 square meters of walls (we add to this the semicircular profile of the log). The only inconvenience is cleaning the stator, rotor and the inside of the grinder from wood dust. Of course, you can put a stocking on the instrument, but the incoming air is not enough for cooling. By the way, the work is very dusty and immediately stock up on glasses, closed on all sides, and respiratory protection equipment - a respirator is enough. Working with a grinder requires utmost attention. High speeds and a removed protection cover can play a trick on you. One has only to lose vigilance, intercept too quickly to the grinding wheel, and you are guaranteed an injury. I twice went through the same place on my arm - the glove to shreds and the skin torn to the meat.

The grinding wheel was used with grain 80. Through testing and selection, I settled on this value - grain 60 leaves too noticeable marks, and grain 100 clogs very quickly. The approximate consumption of petal circles is 1 piece per 3 square meters. You can use the circle further, but the pace of work slows down, and you just get tired.

Attention bonus! I accidentally found that if a circle clogged with dust and tar is passed over the concrete of the foundation, then the sandpaper is cleaned and the circle is ready for work again.

With no skill and when working with all caution, you can sand 6-10 squares of a wall in a day. The prices of "shabashniki" fluctuate between 400-500 rubles per square, and plus they do not stand on ceremony with consumables. Pay attention to resin pockets. If you expose such an area, then treat it with a solvent, otherwise this resin will then come out even through a layer of paint.

I started working from the smallest wall, the logs are changing before our eyes. Faced with the problem that when processing grooves, the edge of the grinding wheel leaves cuts on the lower log. But with further processing, the cuts grind well, and no traces remain.

Especially a lot of fuss with the corners, the high speed of the grinder and tightness slow down the process. Where the circle does not reach, you will have to switch to a slower processing method - a chisel.

When the grinding wheel is almost "sat down", we pass the ends of the logs. It is irrational to use a new circle for the ends - you will have to throw it out after a dozen logs.

We seal the ends with mastic on wood. At first I used the color “pine”, but then I realized that it was more economical to use white, since there would be painting under it.

After grinding, an interesting structure of the tree appears, intricate patterns run throughout the log. The knots and irregularities of the log add a certain fundamentality to the log bath, and I was even glad when there were especially knotty specimens.

To get an idea of how the wall would look after painting, I stopped and prepared the logs. According to all the aggregate features (quality and price), I chose the composition under the Belinka brand. Pre-treated with Base, the drying time of which is 24 hours, and passed over the polished surface with the first layer of glazing composition No. 24 (rosewood). Agree, charming beauty! If you want to get a surface that is smooth to the touch, then after the first layer of the composition and its drying, go over the log manually with a “zero” sandpaper. This is true on the railings and on the front of the bath, where guests love to run their hands along the wall and appreciate the work of the master.

The drying time of the first layer is 12 hours, to be sure, I survived the day and covered with the second layer. A dark noble matte sheen appeared. Another trick - after using the glazing composition, a little pigment remains at the bottom of the jar. We dilute it with a solvent to a very pale appearance and pass through the second layer of the dried coating. You can do the procedure at any time after the coating. As a result, we get a surface that resembles a log additionally impregnated with wax. Very pretty.

Along the way, the ends were processed with a glazing composition No. 11 (white), which favorably sets off the work already done.

The result completely satisfied me, we continue the polishing that we started. Since you will do all the work yourself, the quality will be at the highest level. If the hired workers can ignore flaws, then the master himself will torment himself for even the smallest oversight. For example, I, knowing that somewhere at the bottom of the log I missed a cut, like a criminal returning to the scene of the crime, again and again examined his “jamb”. Until it was corrected.

The log cabin is getting more and more beautiful. Do not forget to clean the logs from dust with a brush after work.

In the next photo, the logs processed by the Base, and the ends sealed with white mastic.

Having appreciated the color and texture of the painted logs, I realized that inside the veranda it would look a little dark, and I experimented with coloring the log with composition No. 11 (white).

White paint retains the texture of the sanded log, and I decided to completely paint the veranda. Through the first layer, a slight yellowness of pine appears, and there is no shine. Very similar to just bleached wood. But the second layer works wonders. There is brilliance and a certain completeness. By the way, buy "Belinka Azure", as the white "Belinka Top Azure" is designed for window frames and costs much more.

Now the bath, with the exception of one wall, is covered in one layer and looks like a house with a Khokhloma painting negative. Pleased with the upper cross beam - a knotty Christmas tree, which gives the structure a look of conformity with the natural style.

We continue the construction of the bath and proceed to the stage of flooring on the veranda. There is a roof over the room, but the absence of a pediment (for the airiness of the building) does not prevent drops of slanting rains from entering. In winter, snow blowing and its subsequent melting during a thaw is not ruled out. Therefore, we will pay special attention to the conservation of boards and logs, as well as to making the surface of the floors water-repellent along with a good appearance.

Part 5. Floor of the veranda

Boards 50 * 150 set on edge will serve as lags. According to the universal formula, the thickness of the board is multiplied by a factor of 20, and we get the step between the lags in my case 1000 mm. But I decided to somewhat strengthen the structure and placed the logs in 600 mm increments. It turned out like this.

On the veranda (conditionally 2 meters by 6 meters) I bought 16 six-meter boards, taking into account the lag and a margin of one board. It cost me 4300 rubles and 500 rubles for shipping. Some boards showed blue and mold, which is easily removed by sanding and bleaching. Worst of all, several boards are affected by the woodworm. Its larvae made several through holes, which I then sealed with mastic. Upon inspection, I didn’t find more living creatures and calmed down on that - after drying, the wood attracts them little, and treatment with an antiseptic and biocide will discourage the beetle from any desire to approach my veranda. I laid a vapor-permeable film on the ground inside the foundation so that no plant would get a chance to germinate inside the veranda. The boards were marked and sawn in accordance with their location.

After that, I removed the boards, numbering them according to their location, and started processing the logs. I used a vigorous antiseptic of Yaroslavl production. I am a little familiar with the preparation of antiseptics and the composition of the purchased products inspired confidence in me. Preservation of wood is declared at 45 years old, subject to the impregnation technology. It is required to use 500 grams of solution per square meter, i.e. We apply the first layer, and after 1-2 hours the second. The antiseptic is yellow, so the coating is clearly visible. When dry it becomes dark brown.

Next came the turn of the boards. Previously, on the surface located below and on the sides of the boards, I passed with a petal emery wheel, fixed on a grinder to remove the pile. So we provide better absorption of the antiseptic. Then we grind the front surface with a circle with a grain of 100. I also used my long-suffering grinder of the lowest price category. If you are afraid to make potholes and holes, then try grinding part of the board with a clogged circle to gain a little experience. Don't forget to chamfer the edges of the board.

Attention bonus! To make the floor surface perfect to the touch and pleasant to the feet, walk along the sanded board with a mild soapy solution. Apply with a brush or roller. When dried, the risen residual pile will become hard and it is easy to knock it down with a sandpaper even in manual mode.

The boards are laid on logs with a gap of 4 mm. As a "standard" we take an ordinary nail, which we put vertically between the boards.

Since my boards are of natural humidity, they can be somewhat drier, that is, they are likely to warp during the drying process. That is why I decided to use not self-tapping screws for fastening, but screw nails. A self-tapping screw is a weaker fastener for transverse loads and can simply burst. The head of the nail, so that there is no rust and its spread to the boards, is covered with mastic on wood.

See the nail? And he is here!

In the process of laying the boards, I begin processing them. I had the choice of using Alpina outdoor terrace oil or Belinka glazing as a coating. I liked the second option better. Firstly, that the oil that the Belinka Base penetrates deep into the tree and protects it from moisture. Secondly, the oil tinting and Belinka No. 24 are almost similar. Thirdly, oil and glazing composition, which does not have high resistance to abrasion, should be renewed every two years. And fourthly, Belinka is cheaper. A large flow of visitors is not planned on the veranda and the maximum load is walking in slippers or barefoot.

After the first layer of the Base has dried (24 hours), apply the second layer and let it dry for another day. And the culminating moment comes - coating with Belinka No. 24 glazing compound. If you want more effect and shine of the floor, then get Top Azure.

–––––– Half a year has passed ––––––

It has been quite a while since my last story in the past, and the construction of the bathhouse has been moving forward little by little. Little by little, because you have to do everything yourself. I don't trust scammers. I contacted them twice (assembling the log house and installing the roof) and was very dissatisfied with the result.

I looked at the bath from the side and decided that another pediment was needed to protect the veranda space from rain. He laid the lining in different directions, leaving something like a window. There will be a stained glass window - polycarbonate with a pattern applied with special stained glass paints.

The fit of the boards to the pediment turned out to be quite tight, so I will do without an additional plinth, I will leave it as it is.

The pediment is painted in the same color as the bath, a side board with a claim for carving is installed. The cost of the work was: lining - 2500 rubles; self-tapping screws - 200 rubles; paint - 200 rubles; wind carved board - 800 rubles. I think that it is quite inexpensive for such a result.

Last year, I didn’t have time to paint the roof lining, I just covered it with a base coat, the temperatures started to drop below zero. Just the other day, having chosen a period without rain, I walked with two layers of white Belinka. I liked the result, but I think to fix it with a third layer.

And so, the new bath construction season has opened. In autumn, I managed to capture a few fine days with a positive temperature, which finally made it possible to make a window and a door. The technology for preparing openings is standard. We mark and cut out with the formation of a spike on the log. For the window opening, I used a bar 100 * 200, and for the door frame, a bar 100 * 250. At the sawmill, they met me halfway and made two six-meter blanks on special order. They took quite ridiculous money - about 2500 rubles with delivery.

On the spot, the beam was sawn into the required segments. The window opening turned out to be clean 50 * 50 centimeters, the door clean 70 * 160. So we really realize the old commandment - bow to the bathhouse when you enter. The upper level of the threshold will be 15 centimeters from the floor to keep warm in winter. I sawed a groove on the beam according to the size of the spike on the log, plus a centimeter in width in each direction. I fixed a rolled insulation 20 centimeters wide on the spike, it seems linen, I don’t remember what I bought. The vertical beam went to the stretch, and horizontal segments were used as struts. The gap from the top pigtail to the log is about 3 cm, filled with moss. There is also moss under the threshold and window sill, which, after installing all the components, was compacted to the state of almost a log.

A quarter is selected on the window for the convenience of installing plastic. Spacers are placed in the door, since during the natural drying of the timber, deformation is possible.

What is planned. Plastic window with imitation of division into smaller windows. The photo shows my hooliganism, so to speak - instead of a window, I inserted foam plastic and made markings for the future product with insulating tape.

The door is metal with a heater on a cloth and jambs. In the company where the doors are made, the director is my good friend, we discussed all the details and, I hope, a good product will turn out. On the door leaf there will be a wooden lining 1.5 centimeters thick. According to the overlay, I will perform aging of wood, I will make an imitation of forged hinges and wooden cross bars. But this is in the future, and now he is engaged in the improvement of the veranda.

We have one craftsman who makes tables and benches of fairly good quality and quite inexpensively. This headset cost me only 7.5 thousand rubles. By tradition, I covered it with the Belinka base, Rosewood glazing compound and deck varnish from the same company.

Somewhere on the hundredth or two hundredth jump from the level of the veranda, I realized that I needed a porch. The plans were to make some kind of forged product with wooden steps, but for now I decided to limit myself to a temporary hut. Although the makeshift turned out to be quite nice and will still serve me until I get bored. On the sidewalls I used logs that remained from cutting out openings, on the steps a board 50 * 150. On the base he laid stones from a nearby quarry.

And now about the pressing. Firstly, I spend the caulk inside the log house. The logs have already settled down in place. What is possible - dried up, what is needed - led what it wanted - settled in its permanent place. Accordingly, gaps appeared inside that require careful sealing.

External examination confirmed the good quality of the caulk. Nothing has fallen out, the birds haven't messed up, and the moss is lying as planned. When sawing openings, the moss was packed into one dense and hard strip, it was even difficult to make out, but it is good to fill cracks with such strips. I made another birch caulk. The shoulder blade turned out to be wider and larger, a two-kilogram sledgehammer perfectly suited it. Moss flies into the cracks with a whistle, and where the log lay too tightly I use birch wedges. The process is lengthy, but mandatory if you do not want to bathe in felt boots in winter. Secondly, I conducted an audit of the foundation. There are light chips on the outside, but these are sagging during pouring and do not affect the quality. However, if I have free time, I will plaster and cover with facade paint. Manufacturer and color not yet chosen. Last year I installed low tides, which performed well even with a serious snow load. And, thirdly, I will count the snow holders. When last year a crust formed on the roof after a freezing rain, and 50-60 centimeters of snow fell on it, it was a good surprise in the form of a huge dense snowdrift near the bathhouse after the first thaw.

Well, I’ll tell you what I do to keep my bath warm and dry. A month ago I bought a metal stove from Izistim for 58,000 rubles. I chose for a long time, tediously, I read all the reviews and realized that this is what I need. Its parameters can be found on the official website of the company, where a detailed description is given. While the furnace is standing on the street in front of the bathhouse, 130 kg of metal still needs to be thought out how to carefully drag it, especially since I still have no floors and 600 pieces of bricks are stacked on the ground. It turned out that these ovens are made literally at my side, so I had the honor to communicate directly with the manufacturers, who really helped with advice and recommendations. The pipe is planned to be adjacent to the stainless sleeve. The structure will be about 5 meters. I ordered a stainless pipe with a wall thickness of 1 mm in the same place, in the Izistim company. Just a week later I received the order. Laser welding, high quality and reasonable price. In terms of money, the pleasure amounted to 11,500 full-weight rubles for a set of pipes of 5 meters. CRAFT company.

The complete kit includes a tee, a plug for cleaning the pipe from soot and removing condensate, and a type of adapter with a platform that will allow you to firmly fix the chimney in a brick pipe. The design on the right in the photo is a horizontal pipe section from the stove to the chimney. Heat-resistant stainless steel 4 mm thick, made in EasySteam for 4300 rubles.

Naturally, I didn’t go shopping and bought convection doors without leaving the cash register. Convenient locks, normal appearance and additional metal sheets for fixing products in brick.

I bought Kostroma clay brick of grade 150, which is enough for lining the furnace. The geometry of the brick is normal, if necessary, the edges can be rounded to give the products a more interesting shape. If you want a more beautiful brick, then buy Vitebsk brand 200. Each brick cost me 25 rubles apiece.

I didn’t bother with clay, which needs to be mined and prepared somewhere else, since I don’t have any special skills. I bought a ready-made mix "Makarov's Furnace House" produced by Kostroma, Gzhel color. They also have a white clay mix for aesthetes. Pechnikov could not be found - everyone is busy. The cost for the masters starts from 40 rubles for a brick for lining and 60 rubles for a brick on a pipe. You can calculate the cost yourself. I will do it myself, although the work will be delayed.

Part 6. Furnace

“And the battle begins again” - we continue the construction of the bathhouse and the improvement of the internal space. The heart of the bath is the oven. My wishes for the climate of the future steam room and other rooms are extremely simple and unpretentious. Firstly, the legs and ears should be warm even in winter, and not bathe with a hard plus in the head area and at the same time in felt boots so that the legs do not freeze. Secondly, the inertia of the sauna stove must be present in order to be able to stop the heating and take a steam bath without running around for firewood while constantly maintaining the desired temperature. It is desirable that the heat in the bath was two or three days to dry the premises. And, thirdly, hot water should not boil in the steam room, but is located in the washing compartment in the remote tank.

As I already wrote, the Sochi stove from the Izistim company was chosen with a hinged heat exchanger for heating water.

The heat exchanger is equipped with inlet and outlet pipes with a diameter of one inch. The design is intended for lining with brick, which will simultaneously become a screen from hard infrared radiation emanating from metal and a heat accumulator. Before installation, it is required to heat the oven on the street in a gentle mode to burn the factory paint and eliminate the smell of burning when operating directly in the bath. A heat-resistant cord is laid on the door and blower, which is necessary for sealing. Previously, this was not the case, but the company's managers listen to the recommendations of consumers through communication on the forum and make the necessary changes.

A cast-iron grate is installed inside the combustion chamber. Additional sheets of metal are welded on the sides and at the end of the chamber to reduce the effect of the flame on the walls of the furnace in order to avoid deformation.

For relative thrust, he installed a meter-long pipe and conducted the first tests of a metal sauna stove. The draft even with such a pipe stub is quite good, only there is a slight flow of smoke from the door when it is opened and, accordingly, a small amount of soot on the glass.

The foundation for the furnace is connected with the foundation of the bathhouse, reinforcement was carried out during pouring. To start laying, I leveled the surface with cement mortar so as not to damage the waterproofing. I laid a roofing material on the pedestal in two layers, on which I will begin to lay out the brick.

To rise above the floor level, and from the foundation it will be about 18-19 centimeters, we lay out the base under the oven three bricks high. There is a little trick. To save mortar and bricks, we lay out a “well”, and inside we simply place the worst brick and fill the remaining space with sand.

The sand will need to be slightly moistened and compacted so that it does not settle, but this is not necessary, the filling will not go anywhere.

Brick made by Kostroma, worth 24 rubles apiece. The geometry is normal, there are chips at the corners and edges, so you have to choose on the front side of the furnace. It pricks badly, it is better to cut with a grinder. For the solution, the furnace mixture "Makarov's Oven House" is used. The solution sets quickly, holds the brick perfectly, and is easy to use. Bags of 25 kg, the cost is about 400 rubles per piece. One bag is designed for laying 60 bricks. The solution must be mixed with a powerful drill with a nozzle, it is unlikely that it will be possible to make a homogeneous mass with your hands. The mixture is well dried and water has to be added quite a lot.

I “sealed” the upper row of bricks on the base of the furnace with mortar, I wanted to install the structure on metal nickels - the legs of the furnace, as it seemed to me, would push through the brick. But it turned out that in this case the neck with the door rises and a gap appears. Therefore, then he cleaned the solution, refused the lining.

I immediately tried on convection doors that will draw air from the rest room to the steam room for exchange. But, as it turned out later, they cannot be installed in this place, the decorative screen around the firebox will interfere.

The most difficult thing was to drag the stove into the bathhouse and not demolish anything along the way. The design of 130 kg commanded respect, and I had to order two stronger loaders. If for the first time a loader from the category of “legs and a cap” helped me to drag the stove to the bathhouse, then the masters really arrived. They pushed me away and in 10 minutes they hoisted the “piece of iron” to the place of operation.

I put a T-shaped outlet on the furnace to determine the root pipe. The picture shows a rear view, where the “lambs” are located for removing the roof and then cleaning the pipe from soot, although the manufacturers assured me of its absence.

The root pipe will run to the left of the furnace and also stand on a foundation connected to a common belt. We continue laying with the formation of a pipe.

The pipe will be functional only after the entrance of the T-shaped segment, so we make its sides one and a half bricks, and we also fill the internal space with sand.

Inside the steam room in the furnace screen, we install two more convection doors, but of a large size. This is necessary to quickly warm up the room. We do not lay the top of the furnace with bricks, we leave space for stones. With the convection doors open, air is taken from the floor, passes near the furnace body and exits through the stones already heated. The air flow can be adjusted with a damper. Doors are hung from the side convenient for you.

I bought the doors from the Izistim company, they modernized the design by adding a stainless steel box along the width of the brick. Now it has become convenient to install the doors, without additional wire fastening. Small gaps are left along the perimeter (except for the bottom) of the doors, which compensate for the thermal expansion of the metal.

The root pipe, so that it passes between the rafters and does not take up much space, is located in line with the “face” of the stove screen. The T-shaped adapter goes a little to the side. In "Izistim" it was made for me with a margin. But, as it turned out, the size was the most suitable, as they say, do not subtract, do not add. A 4 mm stainless steel product cost 4,500 rubles.

It's time to hang the heat exchanger. I bought galvanized corners, spurs and couplings per inch, attached to the general structure, wrapping the threads with flax treated with a heat-resistant sealant (red in the picture).

Brickwork reached the top of the firebox. We install a support corner of 50 * 50 mm with an approach to a brick of 8-10 cm. Around the firebox there is a thermal gap of about 2 cm.

The front side is almost finished, the convection doors are set higher than planned, but for air exchange it is even more convenient, the air coming from the rest room to the steam room will not overheat. Contact with the heated oven is minimal.