Determining what size wire you need is only half the battle. We still need to find the required cross section. The fact is that some manufacturers, in order to increase profits, produce cables with wires of a much smaller cross-section than stated in the accompanying documents. For example, the declared cores are 4 mm 2, but in reality - 3.6 mm 2 or even less. This is a decent difference. If it is not noticed in time, the wiring may heat up and this, in turn, can lead to a fire. Therefore, we will further talk about how to find out the cross-section of a wire by diameter, because the diameter can always be measured. Next, based on the measurement results, we will find out the actual parameters of the core.

When purchasing an electrical cable or wire, to check the cross-section of the core, you need to measure its diameter. There are several ways to do this. You can use measuring instruments such as calipers or micrometers. They measure the size of the exposed part of the conductor. The device is simply attached to the core, clamped between the jaws, and the result is displayed on the scale.

How to measure the diameter of the core - take a caliper or micrometer

For private use, the measurements are quite accurate, with a small error. Especially if the devices are electronic.

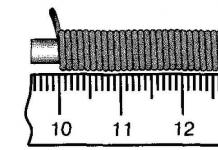

For the second method, you only need a ruler and some kind of even rod. But in this case, you still have to do calculations, albeit very simple ones. More on this method later.

Ruler+rod

If there are no measuring instruments on the farm, you can get by with a regular ruler and any rod of the same diameter. This method has a high error, but if you try it will be quite accurate.

Take a piece of wire about 10-20 cm long and remove the insulation. We wind the bare copper or aluminum wire onto a rod of the same diameter (any screwdriver, pencil, pen, etc. will do). We lay the coils carefully, close to one another. The number of turns is 5-10-15. We count the number of full turns, take a ruler and measure the distance that the wound wire occupies on the rod. Then divide this distance by the number of turns. The result is the diameter of the conductor.

As you can see, there is an error here. Firstly, you can lay the wire loosely. Secondly, it is not enough to take accurate measurements. But if you do everything carefully, the discrepancies with the actual sizes will not be so large.

How to measure the diameter of stranded wire

If you need to find out the diameter of a stranded wire, measurements are carried out with one of the wires that make it up. The process is the same: remove the insulation, remove the braiding (if any), fluff the wires, highlighting one, take measurements in any way (micrometer or wound around a rod).

Multiply the found size by the number of wires in one conductor (spread and count). That's all, you have found the diameter of the stranded conductor. It remains to find out how to find out the cross-section of a wire by diameter, because when planning wiring, it is the cross-sectional area of the wires that is used.

How to calculate using the formula

Since the cross-section of the wire is a circle, we will use the formula for the area of a circle (in the photo). As you can see, you can calculate the wire cross-section using the measured diameter or calculate the radius (divide the diameter by 2). For clarity, let's give an example. Let the measured wire size be 3.8 mm. We substitute this figure into the formula and get: 3.14 / 4 * 3.8 2 = 11.3354 mm 2. You can round the result - it will be 11.3 mm 2. Impressive cable.

The second part of the formula uses the radius. This is half the diameter. That is, to find the radius, divide the diameter by 2, we get 3.8 / 2 = 1.9 mm 2. Next, we substitute it into the formula and get: 3.14 * 1.9 2 = 11.3354 mm 2.

The numbers match, as they should. So, with a wire diameter of 3.8 mm, its cross-sectional area is 11.34 mm 2. You know how to find out the cross-section of a wire using the formula. But it is not always possible to do calculations. In this case, tables can help.

Determination of wire cross-section by diameter using tables

For cable and wire products there is a certain set of cross-sections that are specified in the standards. Knowing what cross-section you need, use the table to find the diameter of the conductor. Next, you just need to find products with the required parameters.

| Conductor cross-section | Diameter |

|---|---|

| 0.5 mm2 | 0.8 mm |

| 0.75 mm2 | 0.98 mm |

| 1.0 mm2 | 1.13 mm |

| 1.5 mm2 | 1.38 mm |

| 2.0 mm2 | 1.6 mm |

| 2.5 mm2 | 1.78 mm |

| 4.0 mm2 | 2.26 mm |

| 6.0 mm2 | 2.76 mm |

| 10.0 mm 2 | 3.57 mm |

Now a little about how to work with this table. You go for products with certain parameters. For example, you know that you need a cable with a core cross-section of 4 mm 2. Having found the corresponding value in the table, we look for the required parameters in the cable products. In this case, you will need to find wires with a diameter of 2.26 mm. If we find similar parameters in a store or market, that’s already good. It happens that the parameters indicated on the tag are too high, i.e. the actual cross-section of the conductors is smaller.

There are two ways to find what you need. The first is to look for products that meet the stated parameters. Perhaps, after spending some time, you will be able to find it. But it will take a lot of time to search. There are too few responsible producers. By the way, there is a sign by which you can navigate. This is the price. She is significantly above average. This is because more copper or aluminum is wasted. If you use this feature, it will take less time.

The second option is to look at products with a declared high denomination. In our case, we reason like this: we need a 4-square wire. The next one is 6 mm 2. It is very likely that the parameters of this cable in real life will be close to the required 4 squares. Perhaps the cross-section of the conductors will be larger, but this is good - the wiring will definitely not heat up. The disadvantage of this option is that you will spend more money, since such cables cost more.

In general, you know not only how to find out the wire cross-section by diameter, but also how to choose the right one. Even if the stated characteristics do not coincide with the real ones.

Imagine that you find an old electrical cable in your bins that you want to use. But you are faced with the problem of determining its cross section. It’s impossible to tell by eye; of course, there are no tags left on it. What to do? There are several methods based on the diameter of the core. That is, the wire diameter and cross-section are directly dependent on each other, which is confirmed by the circle formula, because the cross-sectional shape of the core is a circle. Here is the formula:

S=3.14d²/4=0.785d².

Therefore, it is necessary to first determine the diameter of the core.

Method No. 1

For this you will need a caliper. You just need to strip the core of insulation and measure the diameter. After which the resulting value is substituted into the circle formula. So much for the cross-sectional area of the wire.

Let's just say that this option is the simplest and most accurate. Therefore, it is worth keeping this measuring tool in the electrician’s arsenal.

Method No. 2

It can be used in case you don’t have a caliper at hand. This determination process is not easy and requires a certain accuracy in carrying out all its stages. So, here you will need either a pencil, or a pen, or a screwdriver, or any tube made of dense material (preferably metal). Here is the algorithm of actions:

- Twenty to thirty centimeters of insulation is removed.

- Now we wind the wire around a pencil or other object described above. The more turns are made, the more accurate the indicator. In this case, the turns must be wound so that they are pressed tightly against each other.

- The number of turns is counted.

- The length of the twisted turns is measured using a regular ruler, that is, using a pencil from the first to the last.

- Now you need to carry out one mathematical operation - divide the length of the turns by their number. This will be the diameter of the wire.

Of course, it is not the most accurate, because everything will depend on how the cable core was wound. Here, as mentioned above, the density of turns is of primary importance. Now you can substitute the value of the wire diameter into the formula for the area of a circle.

Method No. 3

This method concerns determining the cross-section of a wire based on the diameter of a stranded core. In fact, all of the above methods are suitable for this option, with only one condition. It is necessary to fluff up the vein, so to speak. Select one wire and measure its diameter with a caliper or use a pencil. Then the resulting value must be multiplied by the number of delays, which will not be difficult to calculate. This is the diameter of the core, which is substituted into the section formula.

Method No. 4

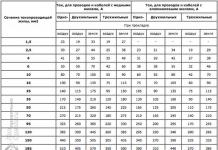

This is the so-called tabular method, that is, to determine the cable area you will need a table that shows the main parameters of the product. Such a table is also available on the Internet, so you shouldn’t have any problems finding it. You can refer to the PUE tables, which also describe the parameters and indicators of electrical cables.

Why do you need to know the wire cross-section?

Everyone knows that the thicker the wire, the more current loads it can withstand, the more power household appliances can be connected to it. Therefore, the cable cross-section is the main characteristic that will help avoid unpleasant moments associated with overheating of the electrical wiring, and, accordingly, the occurrence of fires.

There are certain standards that stipulate what cross-section (diameter) of the wire should be installed for the required current loads. These standards are determined by the electrical installation control rules (EPR), which contain tables. They clearly define positions related to area, material from which the wires are made, and current load or power consumption.

But there is one very subtle point that the buyer should know. There are electrical wires that are manufactured according to technical specifications (TU), and there are those manufactured according to state standards (GOST). Their differences lie in the fact that products manufactured according to specifications sometimes have a smaller core diameter (ten to thirty percent), and, accordingly, a reduced cross-section. And this is the reason for the reduction in the current load that the cable can pass through itself. Plus, the insulation is made in a thinner layer. You can probably guess what this could lead to.

Therefore, a recommendation: if you choose electrical wiring manufactured according to technical specifications, then it is recommended to choose its cross-section an order of magnitude higher. For example, according to your calculations, you need a 1.5 mm² cable, then it is better to choose 2.5 mm². In reality, this figure will be an area of 1.8-2.0 mm².

How can I find out what standards the wire was made to?

- Firstly, this must be indicated in the product quality certificate.

- Secondly, you can check the insulation. If it is soft and quickly removed from the core, then this is definitely a material made according to specifications.

- Third, measure the diameter of the wire with a caliper. And then, using the circle formula, calculate the area of the core. In principle, this can be done on a cell phone calculator, that is, right in the store. If the calculated value corresponds to the nominal value, then this is a GOST material. If the value is lower, then this is a wire manufactured according to specifications.

Conclusion on the topic

As you can see, there are several ways to find out and determine the cross-section of a wire based on the diameter of the core. The simplest one is number one. But in this case you will need a caliper. If you have the Internet at hand, you can use the World Wide Web. That is, everyone chooses what is convenient for them at a certain point in time.

You can often find electrical products in supermarkets without tags or identification marks. Among it there could easily be a coil of wire or cable. How do you know if the wire size is appropriate for your specific situation? The answer is simple - measure it or consult the seller.

Anyone who sells cables and wires can tell you what load they can withstand. In addition, inscriptions (numbers) are stamped on the wires, characterizing the cross-section and number of cores. But in real practice, not everything is as simple as it seems. The quality of cable products has recently deteriorated noticeably.

Problems with the quality of manufactured wires

Many manufacturers of cable and wire products, trying to make more money, artificially reduce the thickness of the insulation and increase the diameter of the cable. By specifying a larger wire cross-section than in reality, the manufacturer saves a very large amount. For example, to produce thousands of meters of copper wire with a cross-section of 2.5 mm2, 22.3 kg of copper is required, and to produce a wire of 2.1 mm2, only 18.8 kg is required. This results in a saving of 3.5 kg of copper.

Another way to reduce the cost of products is to manufacture a conductor from low-quality raw materials. When adding cheap impurities, the current conductivity decreases, therefore, cable length calculations must be changed.

Why do you need to calculate the cable load?

This question often arises when installing wiring in an apartment or home. First, all planned loads are considered, and then the required wire cross-section is determined. Then the necessary material is purchased from the store and electrical wiring is installed in the house.

As a result of using new wiring, the circuit breaker on the electrical panel first “knocks out”, and then damage to the wire is discovered. Moreover, it often turns out to be completely melted, as a result of which a short circuit occurs. It turns out that the calculations were made incorrectly, and how can you find out the minimum permissible value of the wire cross-section in this case?

To avoid serious overloads, it is necessary to calculate how many electrical appliances in the apartment will be used simultaneously. Among the most powerful household appliances that are usually used at home when preparing food and creating our comfort are:

- electric stove;

- air conditioner;

- microwave;

- electric kettle;

- iron;

- washing machine and dishwasher;

- coffee grinder;

- vacuum cleaner.

The power consumption of these household appliances ranges from 1 to 2 kilowatts (with the exception of electric stoves).

Important! If the cross-section of the wire is indicated incorrectly (underestimated), then when using it, it is natural for large overloads to occur, which lead to a fire in the wiring.

How to calculate?

Experienced electricians can “by eye” determine the wire cross-section with great accuracy. This is much more difficult for an ordinary person to do. Therefore, it is best to calculate the cable cross-section by diameter right in the store. At least it will be much cheaper than eliminating the consequences of a short circuit due to an overload in the electrical network.

Let's try to do this with specific examples using arithmetic formulas in school mathematics.

Everyone roughly understands what a wire cross-section is. If you bite it across with wire cutters, you can see the round cross-section of a copper or aluminum core. It is measured using a standard mathematical formula: as the area of a circle. Where r is the radius of the circle, squared and multiplied by the constant “pi” (π=3.14).

The larger the diameter of the cable/wire, the more current can pass in a certain amount of time. And, accordingly, the more energy consumed by electrical appliances, the larger the cross-section of the wire should be.

From the simplified formula Scr = 0.785d2 it is clear that to calculate the cross-sectional area you need to know the exact diameter of the wire. To do this, it is necessary to remove the insulation from the core.

Calculation for stranded wire

Stranded wire (stranded) consists of single-core wires twisted together. Anyone who is even a little familiar with mathematics understands perfectly well that it is necessary to count the number of these wires in a stranded wire. After this, the cross-section of one thin wire is measured and multiplied by their total number. Let's consider the following options.

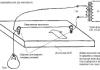

Calculation using a caliper

The measurement is carried out with a caliper with a conventional scale (or micrometer). Experienced craftsmen always have this tool at hand, but not everyone is a professional electrician.

To do this, using the VVGng cable as an example, cut the thick sheath with a knife and spread the wires in different directions.

Then select one core and strip it with a knife or scissors. Next, measure this core. The size should be 1.8 mm. Please refer to the calculations to prove the measurement is correct.

The figure 2.54 mm2 obtained as a result of the calculation is the actual cross-section of the core.

Measuring with a pen or pencil

If you don’t have a caliper at hand, you can use improvised methods using a pencil and ruler. First, take the wire to be measured, strip it and wind it around a pencil or pen so that the turns lie close to each other. The more turns, the better. Now let's count the number of wound turns and measure their total length.

For example, we got 10 turns with a total winding length of 18 mm. It is easy to calculate the diameter of one turn; to do this, divide the total length by the number of turns.

As a result of all the calculations made using the formula, you will obtain the required diameter of the core. In this case it is 1.8 mm. Since the diameter of one core is known, it is not difficult to calculate the cross-section of the entire VVGng wire using the already known formula.

You can see that the results were equal.

Using tables

How can you find out and measure the cable cross-section if you don’t have a caliper, a ruler, or a micrometer at hand? Instead of racking your brains over complex mathematical formulas, just remember that there are ready-made tables of values for measuring cable cross-section. There are, of course, very complex tables with many parameters, but, in principle, to begin with it is enough to use the simplest of the two columns. The diameter of the conductor is entered in the first column, and the ready-made values of the wire cross-section are given in the second column.

Wiring cross-section table for closed wiring

Wiring cross-section table for closed wiring There is another “approximate” method that does not require measuring the thickness of individual wires. You can simply measure the cross-section (diameter) of the entire thick scroll. This method is usually used by experienced electricians. They can find out the cable cross-section both “by eye” and with the help of tools.

The outer diameter of the cable determines the choice of cable support structures, since the space in which the cable will be laid may be limited. Previously, designers had to look for this data in a table of sections and diameters of wires/cables. However, this procedure was time-consuming, given that several types of cable can be laid in one cable duct.

Online cable diameter calculator

Using this service, you can get a diameter calculation in a matter of seconds.

For example, to determine the diameter of the VVGng cable, write the brand in the search bar, indicate the number and cross-section of the cores. The result of your request will be displayed on your screen.

You can also find out the outer diameter of the wire by markings.

The service information is for reference and informational purposes only and is based on manufacturer data. There may be a minimum calculation error allowed by the manufacturer himself.

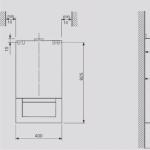

What is the outer diameter of the cable:

In the figure we see a cross section of the VVGng cable, which consists of 5 cores, insulation and sheath.

D is the outer diameter of the VVGng cable.

Cable diameter table:

Example of a table for calculating the diameter of a VVGng and VVGng(A)-LS cable

| 5.0 | 5.4 |

| 6.0 | 6.3 |

Often, before purchasing cable products, there is a need to independently measure its cross-section in order to avoid deception on the part of manufacturers, who, due to savings and setting a competitive price, may slightly underestimate this parameter.

It is also necessary to know how the cable cross-section is determined, for example, when adding a new energy-consuming point in rooms with old electrical wiring that does not have any technical information. Accordingly, the question of how to find out the cross-section of conductors always remains relevant.

General information about cable and wire

When working with conductors, it is necessary to understand their designation. There are wires and cables that differ from each other in their internal structure and technical characteristics. However, many people often confuse these concepts.

A wire is a conductor that has in its design one wire or a group of wires woven together and a thin common insulating layer. A cable is a core or a group of cores that has both its own insulation and a common insulating layer (sheath).

Each type of conductor will have its own methods for determining cross sections, which are almost similar.

Conductor materials

The amount of energy that a conductor transmits depends on a number of factors, the main one of which is the material of the current-carrying conductors. The following non-ferrous metals can be used as the core material of wires and cables:

- Aluminum. Cheap and lightweight conductors, which is their advantage. They are characterized by such negative qualities as low electrical conductivity, a tendency to mechanical damage, high transient electrical resistance of oxidized surfaces;

- Copper. The most popular conductors, which have a high cost compared to other options. However, they are characterized by low electrical and transition resistance at the contacts, fairly high elasticity and strength, and ease of soldering and welding;

- Aluminum copper. Cable products with aluminum cores coated with copper. They are characterized by slightly lower electrical conductivity than their copper counterparts. They are also characterized by lightness, average resistance and relative cheapness.

Important! Some methods for determining the cross-section of cables and wires will depend specifically on the material of their conductor component, which directly affects the throughput power and current strength (method of determining the cross-section of conductors by power and current).

Measuring the cross-section of conductors by diameter

There are several ways to determine the cross-section of a cable or wire. The difference in determining the cross-sectional area of wires and cables will be that in cable products it is necessary to measure each core separately and summarize the indicators.

For information. When measuring the parameter under consideration with instrumentation, it is necessary to initially measure the diameters of the conductive elements, preferably removing the insulating layer.

Instruments and measurement process

The measuring instruments can be a caliper or a micrometer. Mechanical devices are usually used, but electronic analogues with a digital screen can also be used.

Basically, the diameter of wires and cables is measured using a caliper, since it is found in almost every household. It can also measure the diameter of wires in a working network, for example, a socket or panel device.

The diameter of the wire cross-section is determined using the following formula:

S = (3.14/4)*D2, where D is the diameter of the wire.

If the cable contains more than one core, then it is necessary to measure the diameter and calculate the cross-section using the above formula for each of them, then combine the result obtained using the formula:

Stotal= S1 + S2 +…+Sn, where:

- Stotal – total cross-sectional area;

- S1, S2, …, Sn – cross sections of each core.

On a note. To ensure the accuracy of the results obtained, it is recommended to take measurements at least three times, turning the conductor in different directions. The result will be the average.

In the absence of a caliper or micrometer, the diameter of the conductor can be determined using a regular ruler. To do this, you need to perform the following manipulations:

- Clean the insulating layer of the core;

- Wind the turns around the pencil tightly to each other (there should be at least 15-17 pieces);

- Measure the winding length;

- Divide the resulting value by the number of turns.

Important! If the turns are not laid evenly on the pencil with gaps, then the accuracy of the obtained results of measuring the cable cross-section by diameter will be in doubt. To increase the accuracy of measurements, it is recommended to take measurements from different sides. It will be difficult to wind thick wires onto a simple pencil, so it is better to resort to a caliper.

After measuring the diameter, the cross-sectional area of the wire is calculated using the formula described above or determined using a special table, where each diameter corresponds to the cross-sectional area.

It is better to measure the diameter of the wire, which contains ultra-thin cores, with a micrometer, since a caliper can easily break it.

The easiest way to determine the cable cross-section by diameter is using the table below.

Table of correspondence between wire diameter and wire cross-section

| Diameter of conductor element, mm | Cross-sectional area of the conductor element, mm2 |

|---|---|

| 0,8 | 0,5 |

| 0,9 | 0,63 |

| 1 | 0,75 |

| 1,1 | 0,95 |

| 1,2 | 1,13 |

| 1,3 | 1,33 |

| 1,4 | 1,53 |

| 1,5 | 1,77 |

| 1,6 | 2 |

| 1,8 | 2,54 |

| 2 | 3,14 |

| 2,2 | 3,8 |

| 2,3 | 4,15 |

| 2,5 | 4,91 |

| 2,6 | 5,31 |

| 2,8 | 6,15 |

| 3 | 7,06 |

| 3,2 | 7,99 |

| 3,4 | 9,02 |

| 3,6 | 10,11 |

| 4 | 12,48 |

| 4,5 | 15,79 |

Segment cable cross-section

Cable products with a cross-section of up to 10 mm2 are almost always produced in a round shape. Such conductors are quite sufficient to meet the domestic needs of houses and apartments. However, with a larger cross-section of the cable, the input cores from the external electrical network can be made in segment (sector) form, and it will be quite difficult to determine the cross-section of the wire by diameter.

In such cases, it is necessary to resort to a table where the size (height, width) of the cable takes the corresponding value of the cross-sectional area. Initially, it is necessary to measure the height and width of the required segment with a ruler, after which the required parameter can be calculated by correlating the obtained data.

Table for calculating the area of an electric cable core sector

| Cable type | Sectional area of the segment, mm2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| S | 35 | 50 | 70 | 95 | 120 | 150 | 185 | 240 | |

| Four-core segment | V | - | 7 | 8,2 | 9,6 | 10,8 | 12 | 13,2 | - |

| w | - | 10 | 12 | 14,1 | 16 | 18 | 18 | - | |

| Three-core segmental stranded, 6(10) | V | 6 | 7 | 9 | 10 | 11 | 12 | 13,2 | 15,2 |

| w | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | |

| Three-core segmented single-wire, 6(10) | V | 5,5 | 6,4 | 7,6 | 9 | 10,1 | 11,3 | 12,5 | 14,4 |

| w | 9,2 | 10,5 | 12,5 | 15 | 16,6 | 18,4 | 20,7 | 23,8 | |

Dependence of current, power and core cross-section

It is not enough to measure and calculate the cross-sectional area of the cable based on the diameter of the core. Before installing wiring or other types of electrical networks, it is also necessary to know the capacity of the cable products.

When choosing a cable, you must be guided by several criteria:

- the strength of the electric current that the cable will pass;

- power consumed by energy sources;

Power

The most important parameter during electrical installation work (in particular, cable laying) is throughput. The maximum power of electricity transmitted through it depends on the cross-section of the conductor. Therefore, it is extremely important to know the total power of the energy consumption sources that will be connected to the wire.

Typically, manufacturers of household appliances, appliances and other electrical products indicate on the label and in the documentation accompanying them the maximum and average power consumption. For example, a washing machine can consume electricity ranging from tens of W/h during rinsing mode to 2.7 kW/h when heating water. Accordingly, a wire with a cross-section that is sufficient to transmit electricity of maximum power must be connected to it. If two or more consumers are connected to the cable, then the total power is determined by adding the limit values of each of them.

The average power of all electrical appliances and lighting devices in an apartment rarely exceeds 7500 W for a single-phase network. Accordingly, the cable cross-sections in the electrical wiring must be selected to this value.

So, for a total power of 7.5 kW, it is necessary to use a copper cable with a core cross-section of 4 mm2, which is capable of transmitting about 8.3 kW. The cross-section of the conductor with an aluminum core in this case must be at least 6 mm2, passing a current power of 7.9 kW.

In individual residential buildings, a three-phase power supply system of 380 V is often used. However, most equipment is not designed for such electrical voltage. A voltage of 220 V is created by connecting them to the network through a neutral cable with an even distribution of the current load across all phases.

Electric current

Often the power of electrical equipment and equipment may not be known to the owner due to the absence of this characteristic in the documentation or completely lost documents and labels. There is only one way out in such a situation - to calculate using the formula yourself.

Power is determined by the formula:

P = U*I, where:

- P – power, measured in watts (W);

- I – electric current strength, measured in amperes (A);

- U is the applied electrical voltage, measured in volts (V).

When the strength of the electric current is unknown, it can be measured with control and measuring instruments: an ammeter, a multimeter, and a clamp meter.

After determining the power consumption and electric current, you can use the table below to find out the required cable cross-section.

Calculation of the cross-section of cable products based on current load must be carried out to further protect them from overheating. When too much electric current passes through conductors for their cross-section, destruction and melting of the insulating layer can occur.

The maximum permissible long-term current load is the quantitative value of the electric current that can pass the cable for a long time without overheating. To determine this indicator, it is initially necessary to sum up the powers of all energy consumers. After this, calculate the load using the formulas:

- I = P∑*Ki/U (single-phase network),

- I = P∑*Kи/(√3*U) (three-phase network), where:

- P∑ – total power of energy consumers;

- Ki – coefficient equal to 0.75;

- U – electrical voltage in the network.

Tablitz for matching the cross-sectional area of copper conductorsconductor products current and power *

| Section of cable and wire products | Electrical voltage 220 V | Electrical voltage 380 V | ||

|---|---|---|---|---|

| Current strength, A | power, kWt | Current strength, A | power, kWt | |

| 2,5 | 27 | 5,9 | 25 | 16,5 |

| 4 | 38 | 8,3 | 30 | 19,8 |

| 6 | 50 | 11 | 40 | 26,4 |

| 10 | 70 | 15,4 | 50 | 33 |

| 16 | 90 | 19,8 | 75 | 49,5 |

| 25 | 115 | 25,3 | 90 | 59,4 |

| 35 | 140 | 30,8 | 115 | 75,9 |

| 50 | 175 | 38,5 | 145 | 95,7 |

| 70 | 215 | 47,3 | 180 | 118,8 |

| 95 | 260 | 57,2 | 220 | 145,2 |

| 120 | 300 | 66 | 260 | 171,6 |

*Important! Conductors with aluminum conductors have different values.

Determining the cross-section of a cable product is a particularly important process in which miscalculations are unacceptable. You need to take into account all factors, parameters and rules, trusting only your calculations. The measurements taken must coincide with the tables described above - if they do not contain specific values, they can be found in the tables of many electrical engineering reference books.

Video