The wiring arrangement in a private house may, in some respects, differ significantly from the wiring in an apartment. There may be large electrical receivers in the form of pumps, electric heaters and even machine tools.

In addition, a private house can be made of flammable materials, which also places a huge responsibility on you. At the same time, in your home you have a wider choice of cable laying and installation methods, especially if this is only the stage of building a house.

Any electrical network in a private home begins with its connection to the electrical network. To do this, you must obtain technical specifications from Energonadzor.

In most cases, they also carry out the connection to the electrical network. The result of their work in 90% of cases is an input circuit breaker, the outputs of which are connected to the meter. Usually Energonadzor also requires connecting a cable to the meter terminals, which will go directly to our distribution panel. Our task is to prepare this cable.

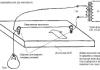

Input of power supply to the house through the wall

The most common way to enter the power cable into the house is through the wall (see). It is quite simple to carry out, but there are several requirements that should be taken into account at the installation stage.

So:

- First of all, it should be taken into account that, according to clause 2.1.79 of the PUE, the entrance to the house must be located at a height of at least 2.75 meters. In this case, the distance from the edge of the roof slope to the wire should not be less than 20 cm.

Note! If the height of your house does not allow entry into the house through the wall at a height of 2.5 meters, then in this case entry through the roof is possible. But maintaining a height of 2.75 meters is mandatory.

- It should also be taken into account that the PUE standards require the possibility of replacing the wire. For this, special sleeves are used. Usually this is a steel pipe.

Note! This stand pipe must be made in such a way as to prevent the possibility of moisture entering and accumulating in it. To do this, it should be tilted outward and bent.

- The cable for electrical wiring in a private house cannot be laid directly over building structures if they are made of combustible material. Therefore, the cable should be placed in a fireproof sheath. This could be a metal corrugation or tray. In addition, it is possible to line the wire and the wall with fireproof material. It could be asbestos sheeting.

- Another point to consider is the location of the input itself. According to clause 2.1.75 of the PUE, it must be located at least a meter from the window or balcony. If you have a second floor, then the distance from the wire to the window located above should also be at least 1 meter.

Input of power supply to the house underground

Although this method is used much less frequently in many respects, it is even more reliable. It just needs to be provided for at the stage of building the foundation, and this is often forgotten to do.

And among some energy supply companies, such home delivery causes a stormy protest. Nevertheless, it has a right to exist and is very successful in many respects.

So:

- According to clause 12.1 of VSN 59 - 88, pipes into which the electricity is then drawn. cable should lie at a depth of 0.5 to 2 meters.

- These pipes should also be inclined towards the street in order to exclude the possibility of water accumulating in them and entering the room.

- After laying the cable in the pipe, they must be tightly sealed in order to completely eliminate the possibility of moisture entering the room.

- When laying cables along the combustible foundation of a house, the same rules and regulations should be followed as when introducing power through the wall.

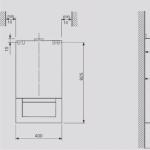

Before making electrical wiring in a private house, you should correctly place the distribution board. There are a number of restrictions here that are quite logical and easily explainable.

- First of all, according to clause 11.1 of VSN 59 - 88, distribution boards should be located in places convenient for maintenance. They must have lighting and be located in places that prevent them from flooding. The latter is especially true when the panels are located in the basement.

- There should be no piping of liquid fuel boilers or gas pipes in the room where the switchboard is located.

- Heating, water supply and sewerage pipes running indoors should not have flanges, valves or other drainage or safety fittings. The same applies to ventilation and air conditioning systems.

- Also, our instructions do not recommend placing shields under bathrooms, restrooms, steam rooms and other rooms in which there is a high risk of flooding.

- When attaching panels to combustible bases, a fireproof surface should be provided between it and the wall. Usually this role is played by a sheet of iron. In addition, all distribution boards must be closed with a locking device.

Choosing the type of wiring in a private house

Electrical wiring in a private house can be done in two ways - open and hidden. Choosing the right option for your home depends on what material it is made of and your wishes.

We will present only the basic requirements for each type of wiring, and you can choose the most suitable one for your home construction.

Hidden wiring

Hidden electrical wiring has found the most widespread use. It reliably hides all utility networks from prying eyes, does not steal free space and ensures the mechanical integrity of the wire.

At the same time, the price of installing such wiring is somewhat higher due to its labor intensity, and the possibilities for its repair and replacement are limited.

So:

- Hidden electrical wiring in a private house, according to table. 2.1.2 and 2.1.3 PUE, for fireproof bases (brick, concrete, etc.) can be carried out directly over structural elements in special furrows. After installation, they must be plastered with alabaster or plaster with a thickness of at least 10 mm.

- When installing in combustible structures (wooden houses), everything is a little more complicated (see). In this case, the wire must be laid with a lining of fireproof materials (for example, asbestos sheet) followed by plastering.

Note! In all cases, the lining of fireproof materials must be done in such a way that there is a margin of 1 cm on each side of the wire.

- Another possible option for arranging hidden wiring in a wooden house is installation in plastic boxes or corrugation. But in this case, the boxes and corrugation must be plastered after installation. And under the corrugation or box itself it is necessary to place fireproof materials.

- The easiest way to carry out hidden wiring in a wooden house is by laying it in a steel pipe or corrugation. In this case, no additional conditions are required.

Open wiring

Open wiring in a private house places higher demands. Despite this, its installation is simpler, installation speed is higher, and there are more repair and maintenance capabilities.

At the same time, it “steals” the free space of the room, open wiring does not fit well into almost any modern room design, and the cost of installation robots for fireproof surfaces is much higher.

- Using the same PUE tables, you can see that for installation on fireproof structures, the option of using insulators is possible. This retro option is now particularly popular, and even decorative wiring of this type has appeared. But the safety of this method is not at the highest level.

- Much more often, open wiring on fireproof structures is laid in plastic boxes and corrugation. This method allows you to protect the wiring from mechanical damage and also visually brightens it up.

- It is also possible to conduct wiring in combustible structures using the open method, only with a lining of non-combustible materials. Only cables in a special sheath made of fireproof or fire-resistant materials can be laid directly over the elements of such structures. But the aesthetic appearance of such wiring causes a lot of negative emotions.

- More often, in an open manner, wiring on combustible structures is laid in steel or copper pipes, or steel corrugation. This wire protection allows you to mount wires directly on structural elements, without the use of additional pads.

Conclusion

In our article, we presented the main points that are worth paying attention to when designing an electrical network in a private home.

There is no difference in the calculation and distribution of lighting groups and methods of powering various consumers between an apartment and your own home. Therefore, numerous videos and articles on the pages of our website will help you with this.

Electricity is a serious and responsible matter. If you are going to do all the work yourself, you need to do everything very carefully and diligently. Proper wiring in a private home is a guarantee of safety, because according to statistics, 70% of fires occur due to electrical faults. If you are not confident in your abilities, it is better to entrust the work to proven specialists.

Action plan

Electrical wiring in a private house is done before finishing work begins. The frame of the house is out, the walls and roof are ready - it's time to start work. The sequence of actions is as follows:

- Determination of input type - single-phase (220 V) or three-phase (380 V).

- Development of a scheme, calculation of the capacity of the planned equipment, submission of documents and receipt of the project. Here it must be said that the technical specifications will not always determine your declared power; most likely they will allocate no more than 5 kW.

- Selection of components and components, purchase of meters, machines, cables, etc.

- Input of electrics from the pole into the house. Performed by a specialized organization, you need to decide on the type - overhead or underground, install an input machine and a counter in the right place.

- Install the panel, bring electricity into the house.

- Laying cables inside the house, connecting sockets and switches.

- Ground loop design and its connection.

- Testing the system and obtaining a certificate.

- Electrical connection and operation.

This is only a general plan; each case has its own nuances and features, but you need to start by obtaining the technical conditions for connecting to the electrical network and the project. To do this, you need to decide on the type of input and the planned power consumption. It must be remembered that the preparation of documents can take six months, so it is better to submit them even before the start of construction: two years are given to fulfill the technical conditions. During this time, you will probably be able to build a wall on which you can put a machine and a counter.

How many phases

A private house can be supplied with single-phase voltage (220 V) or three-phase (380 V). According to energy consumption standards for a private house, the maximum consumption per house for a single-phase network can be 10-15 kW, for a three-phase network - 15 kW.

Three-phase input is needed only when you need to connect powerful equipment operating from a 380 V network

Three-phase input is needed only when you need to connect powerful equipment operating from a 380 V network So what's the difference? The fact is that powerful electrical appliances can be directly connected to a three-phase network - electric stoves or heating boilers, ovens and similar equipment. However, the input requirements and wiring of the 380V network are much stricter: higher voltage, greater chance of serious injury. Therefore, if your house is no more than 100 square meters, and you do not think of heating it with electricity, you are better off using 220 V.

Making a plan and receiving a project

Having decided on the type of input, you can begin to develop a plan for electrifying your home. Take a scale plan of the house, and draw where the equipment will be located, figure out where to place the sockets and switches. In this case, you need to take into account where any large-sized furniture will be located, and where it can be rearranged, so that sockets and switches are not placed in these areas.

All lighting fixtures will need to be drawn on the plan: chandeliers, sconces, floor lamps, lamps. Some of them will need switches, some will need sockets. Then you will need to figure out which devices in each room will need to be turned on.

For example, in the kitchen there is a lot of equipment that works constantly. It definitely needs sockets. There is also equipment that turns on periodically. All this is plotted on the plan, and the optimal location of the switching points is determined. The same approach applies to each of the rooms.

The result of designing electrical wiring in a private house. You should also get a similar diagram.

The result of designing electrical wiring in a private house. You should also get a similar diagram. Determination of total power

Having decided approximately what equipment will be installed in your home, add up its power. The average power can be taken from the table: there is probably no technology yet. Moreover, where there are, take into account starting loads (they are much higher). Add about 20% of the reserve to the found amount. The result will be the required power.

You indicate it in papers submitted to obtain permission to connect electricity to the site. If you are given the stated power, you will be very lucky, but you should not hope for it. Most likely you will have to invest in the standard 5 kW - the most common electricity limit for a private home.

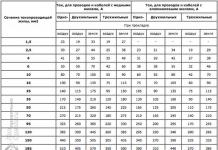

Average power values of devices for calculating the total load on the electrical wiring of a private house with your own hands

Average power values of devices for calculating the total load on the electrical wiring of a private house with your own hands Breakdown of consumers into groups

All these consumers (this is the term of professionals) - lamps, spotlights, switches, sockets - are divided into groups. A separate branch runs electrics to lighting fixtures. Usually one is enough, but this is not a rule; it may be more convenient or expedient to make two branches - for each wing of the house or for each floor - depending on the type and configuration of the building. The lighting of the basement, utility rooms, as well as the light on the street stands out in a separate group.

Then the sockets are divided into groups. How much you can “put” on one wire depends on the diameter of the wire used, but not very much - three to five, no more. It is better to allocate a separate power supply line for connecting each powerful device: this is more reliable from the point of view of fire safety, and will contribute to a longer operation of the devices.

As a result, you may have three to seven lines running into the kitchen - this is where the equipment is most abundant and powerful too: for an electric boiler and electric stove, separate lines are absolutely needed. It is better to “plant” the refrigerator, microwave, electric oven, and washing machine separately. Not so powerful blender, food processor, etc. can be included in one line.

Designing electrical wiring in a private house: counting the number of groups and planning what to connect where

Designing electrical wiring in a private house: counting the number of groups and planning what to connect where There are usually two to four lines going into the rooms: in a modern home and in any room there is something to plug into the electrical network. One line will go to lighting. On the second there will be sockets into which you will need to plug in your computer, router, TV, and phone charger. All of them are not very powerful and can be combined into one group. If you intend to install an air conditioner or turn on an electric heater, you will need separate lines.

If a private house is small - a dacha, for example, then there may be two or three groups: one for all lighting fixtures, the second for the street and the third for all internal sockets. In general, the number of groups is an individual matter and depends most of all on the size of the house and the amount of electrical equipment in it.

The wiring plan can be quite small if the house is small

The wiring plan can be quite small if the house is small Based on the number of groups received, the number of machines on the distribution panel in the house is determined: to the received number of groups, add two to four for development (suddenly you forgot something important, or you need to turn on something new powerful, divide a group that is too large or far apart into two, etc.).

The distribution panel and the number of machines in it are selected based on the number of groups: there is a separate machine for each group. If a private house is large - on several floors, it makes sense to install more powerful machines on each floor, and connect group machines to them.

Where to put the shield

The installation location of the shield is not regulated by regulations. There are only restrictions regarding the distance from pipelines; it must be at a distance of at least 1 meter. Any pipes are taken into account: water supply, heating, sewerage, internal drains, gas pipelines and even gas meters.

There are no restrictions on premises. Many people install a panel in the boiler room: since it’s a technical room, it makes sense to collect all communications here. The receiving authorities do not make any claims. Sometimes it is more convenient to place the shield near the front door. If the protection class meets the requirements, there should be no claims.

Selection of cables and components

Today's standard wiring diagram for a private house includes two circuit breakers. One - input - is installed before the meter, usually on the street. It and the meter are sealed upon commissioning. The second RCD machine is placed in the house in front of the panel.

The operation (shutdown) current of these devices is selected so that the circuit breaker installed in the house is turned off first (its current value is slightly less). Then, in the event of an emergency, you will not need to crawl under the roof.

Typical wiring diagram for a private house: there can be many different groups

Typical wiring diagram for a private house: there can be many different groups If the design load is less than 15 kW, the input circuit breaker is set to 25 A. The meter is selected accordingly. For higher power consumption, it will be necessary to install a transformer; its parameters and the parameters of all equipment will be indicated in the project.

Recently, when connecting a private house to the power grid, they are required to install a meter and a machine on the street. This requirement is not supported by law; it is simply easier for the electricity service to control consumption. If you want, you can fight, if not, choose a meter and machine in a case with increased dust and moisture protection - a protection class of at least IP-55. For installation inside a building, the protection must be less - IP-44, and accordingly the price will be lower.

Cable selection

For electrical wiring in a private home, it is better to use cables rather than wires. Their insulation is at least twice as good, therefore the laying requirements are not so stringent, and they are safer to use. All internal wiring in a private home must be made with protective grounding. Previously, there were no such requirements, but now many electrical appliances have three-pin plugs and require grounding for safe operation. Therefore, the cable must be three-core.

In electrical cables, the cores are made of copper or aluminum. Although aluminum is cheaper, it is used less often: it is rigid, more likely to break, and more difficult to work with. If you install electrical wiring in a private home yourself and lack experience, this can become a problem. In addition, it cannot be used inside wooden houses at all.

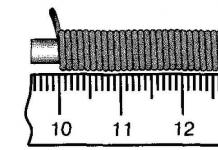

Determination of core cross-section

Once you have decided on the material, you can select the diameter of the cable cores. This is done depending on the planned load on the line according to the table.

Calculation of electrical wiring - the selection of the cross-section of the cable cores is carried out according to this table

Calculation of electrical wiring - the selection of the cross-section of the cable cores is carried out according to this table The cross-section of the core is selected according to the current or power of all consumers connected to one circuit breaker. This is where your home electrification plan, where you have outlined consumer groups, will come in handy once again. You calculate the sum of the currents or powers of all devices and select the desired cross-section of the cores according to the table.

How to use the table? If you decide to lay copper wires, the input voltage is 220 V, then the left part, the corresponding column, is suitable for internal wiring. The found power of all consumers connected to the group will be compared (it is easier to find and calculate).

In the part where we are talking about copper wires laid in trays, voids, channels, in the “220 V” column, find the nearest higher value. Follow this line to the right to the column “Section, sq. mm". The number indicated here will be the required core size. From conductors of this diameter it will be necessary to make electrical wiring from the machine to sockets or switches.

In order not to get confused when counting and laying, designate wires of the same diameter on the plan with a certain color (write it down so as not to forget what color you designated what). After the diameter has been determined for all consumer groups, the length of the required cables for each size is calculated, and a margin of 20-25% is added to the found figures. You have calculated the wiring for your home.

Shell type selection

There are certain requirements for the type of sheath only when laying electrical wiring in wooden houses: it is recommended to use triple (NYM) or double (VVG) cable insulation. In houses of less flammable materials, any insulation can be used.

The main thing is that it is intact, without cracks, sagging or other damage. If you want to play it safe, you can use conductors with enhanced protection. This makes sense in rooms with high humidity (kitchen, bathroom, swimming pool, bathhouse, etc.).

Selection of sockets and switches

For some powerful devices, sockets are selected according to the maximum (starting) current. For other low-power consumers they are standard. You need to know that they exist:

- External - when the body sticks out from the wall. They are easier to install: a backing is attached to the wall, and a socket is attached to it on top. But few people use such models now, even at their dachas. The reason is aesthetic: not the most attractive sight.

- Internal. A recess is made in the wall for the electrical part, and an installation box is installed and walled up in it. The electrical part of the socket or switch is inserted inside this box.

It is indoor electrical sockets and switches that are most often used today. They are decorated in different styles and painted in different colors. They are selected mainly to match the finish, and if this is not possible, they are installed in white.

DIY wiring

Modern construction trends provide for hidden wiring. It can be laid in specially made grooves in the walls - grooves. After laying and securing the cables, they are covered with putty, comparing them with the surface of the rest of the wall.

If the erected walls will then be lined with sheet materials - plasterboard, gypsum plasterboard, etc., then grooves are not needed. The cables are laid in the gap between the wall and the finish, but in this case - only in corrugated sleeves. The shell with laid cables is attached with clamps to the structural elements.

How should internal wiring be laid? In a private home, when installing it yourself, you must follow all the rules

How should internal wiring be laid? In a private home, when installing it yourself, you must follow all the rules When installing, you need to remember that the internal electrical wiring of a private house is done according to all the rules and recommendations. This is the only way to guarantee safety. The basic rules are:

- laying wiring only vertically and horizontally, no rounded corners or beveled routes;

- all connections must be made in installation junction boxes;

- horizontal transitions must be at a height of at least 2.5 meters, from which the cable runs down to the socket or switch.

A detailed route plan, similar to the one in the photo above, must be saved. It will come in handy during repairs or wiring upgrades. You will need to check with him if somewhere nearby you need to ditch or make a hole or hammer a nail. The main task is not to get into the cable.

Wire connection methods

A large percentage of electrical wiring problems come from poor wire connections. They can be done in several ways:

- Twisting. Only metals that are homogeneous or do not enter into a chemical reaction can combine in this way. It is strictly forbidden to twist copper and aluminum. In other cases, the length of bare conductors must be at least 40 mm. The two wires are connected to each other as tightly as possible, the turns are laid one next to the other. The connection is wrapped on top with electrical tape and/or packed with heat-shrink tubing. If you want the contact to be 100% and losses to be minimal, do not be too lazy to solder the twist. In general, according to modern standards, this type of wire connection is considered unreliable.

- Connection via terminal box with screw terminals. The housing is made of heat-resistant plastic and contains metal terminals that are tightened with screws. The conductor, stripped of insulation, is inserted into the socket and secured with a screw or a screwdriver. This type of connection is the most reliable.

- Connecting blocks with springs. In these devices, contact is provided by a spring. A bare conductor is inserted into the socket and clamped by a spring. Still, the most reliable connection methods are welding and soldering. If it is possible to make the connection like this, you can assume that you will not have problems. At least with connections.

- Installing electrical wiring in a house with your own hands requires careful fulfillment of all requirements. This is a guarantee of your private security and the safety of your private property. After the wires from the machine to the connection point of the socket or switch are laid, they are checked for integrity with a tester - the wires are connected to each other, checking the integrity of the conductors, and each individually to the ground - checking The insulation is not damaged anywhere. If the cable is not damaged, proceed with the installation of the socket or switch. Once connected, everything is checked again with a tester. Then they can be started on the appropriate machine. Moreover, it is advisable to sign the machine immediately: it will be easier to navigate. After finishing the electrical wiring throughout the house and checking everything yourself, they call electrical laboratory specialists. They check the condition of the conductors and insulation, measure grounding and zero, and based on the results they give you a test report (protocol). Without it you will not be given permission to put into operation.

Recently, capital and dacha construction has become very popular. Many homeowners prefer to create their dream home themselves, without resorting to the services of companies.

Without electricity, the life of a modern person is unthinkable. Therefore, power supply to the home is the homeowner’s first priority.

People who decide to build a house with their own hands are faced with the need to electrify it. It also happens that in existing housing the electrical wiring is in very poor condition and needs to be replaced.

We will consider all the nuances of connecting your home to the electrical network, installing different types of electrical wiring, and study in detail common mistakes in order to avoid them in practice. The article will also contain instructions for commissioning wiring and recommendations on popular issues.

Regardless of whether you want to connect a new house to the network, or restore power supply in an old one (for example, when completely changing the wiring), you will have to undergo a lot of bureaucratic procedures. To obtain a permit you need:

Drawing up a wiring diagram

The best way to start installing wiring in a private house with your own hands is with basic electrical wiring. This will greatly facilitate further calculations of consumables and determination of installation locations for power elements.

The wiring diagram must include the following elements:

- Supply from the nearest support to the incoming electrical panel

- Introductory /

- Internal electrical panel with consumer groups:

- Rosette group

- Lighting

- Power group (high-current household appliances (boiler, washing machine, machine tools)

- Outbuilding (garage, basement)

A diagram of how to properly conduct and make electrical wiring in a private house with your own hands:

Separate RCDs/automatic circuit breakers are installed for each of these groups.

Also, when drawing up a diagram, you need to have a general plan of the house, on which to mark the direction of laying the cables and the installation locations of sockets and switches.

It would be good if the wiring had two separate circuits. Then it will be possible to turn off one for repairs, and from the second to power the necessary lighting or soldering equipment.

Based on these data, a schematic diagram is constructed, the total cable length required in each case, the placement of power elements, metering devices, and the point of entry of power cables are calculated.

What you need

Let's try to figure out how to make and install electrical wiring in a private house yourself. In order to install high-quality electrical wiring in your house that complies with all SNIPs and safety standards, you will need the following materials and tools.

Consumables

Required Tools

- (grinder with diamond discs)

- Assembly chisel

- Hammer

- Cable scissors

- Putty knife

- Emery grater

- Pliers

- Roulette

- Screwdriver

Selected based on the total load. On average, this is 0.5-0.9 square millimeters per 1 kW of power. It is best to use copper stranded wire. He is better twistable, elastic, stable to short-term loads.

The number of sockets, switches and other elements is calculated when drawing up a circuit diagram. It is better to take boxes and boxes from self-extinguishing or non-combustible materials.

Hidden wiring is best done under the baseboard, and not in the groove. This position of the cable prevents it from being hit by a drill or nail during repair work; it is accessible and can be checked or reconnected.

Video on how to properly make and conduct electrical wiring in a private house with your own hands:

Step-by-step installation instructions

Different homes recommend different types of wiring. In wooden buildings it is most often done, and in concrete buildings with many technological voids it is done hidden. Let's consider the nuances of installing and conducting electrical wiring in a private house with your own hands.

Open (external)

Often used in country wooden houses. It can be made both in special boxes, under baseboards, and in, from a special cable and on porcelain insulators-mounts that fix vertical elements.

To conduct open electrical wiring in the house, you need:

Closed

Installation is a little more difficult. To hide cables in walls, you need:

- Mark the walls using a marking line

- Using a grinder, cut 2x2 cm grooves in the walls

- Use a wall chaser to cut out spaces for installing distribution boxes, switches and sockets

- Install boxes and socket boxes. Secure them with asbestos or screws and dowels

- Prime the grooves

- Place the cable in them. It must first be cut into pieces of the required length.

- Secure it in the groove with plaster. Mounting pitch – about 40 cm

- After 20-25 hours, when the plaster is completely dry, clean it

- Install switches and sockets

That's all the simple steps required to electrify your home yourself.

Step-by-step video instructions on how to do electrical wiring in a private house with your own hands:

Installation of accessories

In the now fashionable open-type retro wiring, the fittings can be very diverse. In addition to switches and sockets, porcelain insulating rollers are used there. Each piece of fittings should be fastened at the following distance:

- Insulating rollers: 10-12 centimeters apart

- Single-core twisted wire - 1 centimeter from the wall

- Sockets: no lower than 35-40 centimeters from the floor and no lower than 15 cm from the kitchen table

- Switches - from 50 to 150 centimeters from the floor

Switches and sockets must not be installed at the same level. This rule also applies to hidden electrical wiring.

Safety rules, mistakes and ways to avoid them

Sometimes homeowners neglect certain nuances or make careless mistakes that can seriously affect fire safety. We will look at the most common of these mistakes and ways to avoid them.

- Aluminum wires. They must not be used under any circumstances. They are fragile and can break off when replacing an outlet or switch. It's better to pay more, but take copper ones.

- It is prohibited to use stranded wires in hidden wiring.. The terminal does not hold such a cable very well, so a constant heating point is created. This can lead to both damage to the socket/switch and a fire.

- Do not connect wires of different metals directly to each other.. To avoid oxides, do this only through the terminal to eliminate possible metal-to-metal contact.

- Waterproofing. It should not be neglected in rooms with high humidity: bathrooms, kitchens, pantries, terraces. Failure to do so may result in electric shock.

- Mark the wire length with maximum accuracy. Placing twists on straight sections, especially if 10-15 centimeters are missing, is strictly prohibited!

- Strobe under the groove. Its depth should be 2-2.5 centimeters. There is no point in running the cable deeper, and a shallower groove is difficult to plaster.

- . They should be located almost under the ceiling. This is done for ease of wiring maintenance and to avoid confusion between cables for various purposes.

- Wire cuts. They must be strictly vertical or horizontal. Possible cable savings when laying diagonally can lead to a drill or nail getting into it during repair or finishing work in the house.

- Wire size. It shouldn't be too thin. Thin wires cannot withstand the increased load and burn out. The optimal cross-section for the socket group is 2-2.5 mm, for the lighting group – 1.3-1.5 mm.

And a little about safety precautions. Work with home electrics only when the plugs are off. Electric shock can lead to the most tragic consequences.

Testing and commissioning

After complete installation of electrical wiring, you need install all planned machines, RCDs and electrical appliances. After this, feel free to invite a specialist from the energy supervision department to check and commission the electrical equipment of your home.

Acceptance testing of your facility must result in the issuance of a positive conclusion on the safety of the electrical installation carried out, the possibility of further use of the equipment. You must contact the energy supply organization with the “Connection Permit Certificate”. On this basis, she must connect your facility to the support and draw up a contract for the provision of services.

You should not skimp on consumables and tools - after all, in the future, quality work done will be the key to your peace of mind and comfort.

Do the electrical wiring in the house yourself - It’s not a difficult task, but it requires care and scrupulousness.. If you approach this matter responsibly, the wiring will serve you for many years and is guaranteed to be safe.

Installing new electrical wiring yourself requires a competent approach and accuracy. Before starting direct installation, a wiring diagram is drawn. In a private home, this is especially important, since installation errors can lead to a fire hazard. A drawn power supply diagram will help you quickly and accurately eliminate damage that may occur in the future or upgrade your home network.

Requirements for wiring in a private house

Electrical wiring is carried out in the form of a combination of wires and cables, as well as their fastenings and associated protective elements. It can be installed in both open and closed types. Open type wiring is laid along the surface of walls, ceilings or floors using: cables, rollers, hoses. Hidden electrical wiring is laid in the middle of various elements of the house: under the floor, in walls, suspended ceilings or in other monolithic objects.

Installing electrical wiring in a private house with your own hands is not difficult at all if there is a clear circuit diagram. At the same time, all work goes much faster and the likelihood of mistakes is less. Before you begin planning and drawing up a diagram, you need to know what the installation requirements are.

The list of requirements is established by special rules of the PES (rules for the operation of electrical installations), which are mandatory. Here's the main list:

Electrical wiring steps

Compliance with all requirements will ensure that the electrical wiring in the house is done correctly with your own hands. The step-by-step scheme for drawing up a plan can be represented in the form of the following operations:

- choice of material and its quantity;

- installation diagram drawing;

- laying and installation of all parts of electrical wiring;

- performance check.

It is not difficult to complete the steps yourself. But before you properly conduct the wiring in the house, you will need to complete the preparatory stage. It includes determining the places where connection points for electrical appliances and lamps will be located, and their number.

Selection of materials and installation method

The utility company supplies electricity through installed lines using poles and poles or through power cables buried in the ground. The cable branches off from the common line to an electrical panel located on private property. The branch is made with a two-wire or three-wire wire. Accordingly, a two-phase or three-phase line is used. More often, a cable containing a phase and a neutral is removed. An electricity meter is installed at the end of this line. It is important to know that the line to the meter belongs entirely to the energy supply company, and it is prohibited to perform any operations with it.

The utility company supplies electricity through installed lines using poles and poles or through power cables buried in the ground. The cable branches off from the common line to an electrical panel located on private property. The branch is made with a two-wire or three-wire wire. Accordingly, a two-phase or three-phase line is used. More often, a cable containing a phase and a neutral is removed. An electricity meter is installed at the end of this line. It is important to know that the line to the meter belongs entirely to the energy supply company, and it is prohibited to perform any operations with it.

Further laying of the line is carried out by the owner of the household himself or by an electrician. The line itself can be laid open or hidden.

Open type wiring is carried out on the surface in a visible form, which is both a disadvantage and an advantage. The advantage is ease of installation, free access to any part of the electrical network, but the disadvantage is poor protection from mechanical damage. The cable, laid along the surface, is attached through insulators that resemble a fungus. In this case, the design of sockets, switches, and distribution boxes is of an overhead type. To protect against damage and ensure electrical safety, plastic boxes are used. They form a channel into which the cable is laid.

Hidden wiring is located in the completed, and after laying the cable, plastered grooves. Hidden in a floor screed or behind false panels. Electrical accessories are used internally. The wire itself, if not laid in a concrete or brick wall, is laid in a metal hose. The disadvantage is that if the wire is damaged, it will have to be removed from the monolithic structures. It is possible to use a combined method, making some areas hidden and others external. The required parts of the electrical wiring in the house will be:

- Switch box.

- Circuit breaker.

- Electrical appliance connection point.

- Switch.

- Junction box.

- Cable.

The electrical panel is installed in such a size that all input elements fit into it. The circuit breaker is designed to quickly break the wire in the event of an emergency on the line. Its main characteristic is the value of the rated current. How many amperes a machine will need in a house is calculated by summing the power of the entire planned load that can be connected simultaneously to the circuit.

When selecting a machine, not only the power of the connected devices is taken into account, but also the quality and cross-section of the installed electrical wiring. A mismatch in the cross-section of the cable that will be used for wiring electricity can lead to overheating, resulting in a short circuit and fire.

The cross-section of a wire is characterized by the amount of current that it passes through itself without deteriorating its electrical properties. For example, a copper wire with a cross-section of 1.5 mm/2 can withstand a continuous current load of 19 amperes. Therefore, it is impossible to use a 20 A circuit breaker with such a cross-section; you will need one for 16 A.

The distribution box has the form of a plastic container with a lid, on the sides of which there are holes for cable entry. Its main characteristics are the size and quality of the material it is made of. Switches and sockets are designed for a current that does not exceed the value of the devices connected to them.

Building a circuit

After selecting materials and locating connection points for electrical appliances, a drawing of the electrical circuit is made. It is best to use a ready-made house plan, which depicts all the elements involved in building an electrical network.

To simplify wiring, consumers are divided into groups; this will also help distribute the load and save materials. If a private house has many rooms, then the drawing shows separately the outlet circuits and lighting. The diagram indicates the following:

The cable leaving the meter exits and is switched at the distribution panel. A series of automatic protection systems are installed in it, consisting of an input circuit breaker and single-pole switches. Ideally, each electrical point is equipped with its own automatic machine, but this is not unprofitable in terms of costs. Therefore, groups are created, each of which has its own fuse.

In the middle of the group, disconnection occurs in the following way. The power wire coming out of the machine branches in the distribution box to each electrical point. Such a point represents the place to which the electrical device is switched. In this case, a wire with two or three cores is supplied to the socket, and it is connected in parallel. The switch is installed in series in the break of the power wire.

A wire with three cores implies grounding through one of the three wires. The presence of grounding is important, since there is a potential difference on the metal cases of electrical appliances, for example, on a refrigerator, kettle, heating boiler, etc. This voltage can be life-threatening in the event of an insulation breakdown. Performed grounding eliminates this problem. For this purpose, the socket is equipped with a grounding contact. In fact, this is a continuous connection between the metal parts of electrical appliances and the ground.

Grounding is carried out using a circuit in the form of a triangle, welded from thick metal with equal sides. The grounding loop is located at a distance of no more than 1 meter from the foundation of the house. A large-section wire is screwed to the triangle using a bolt, the other end of which is connected to the grounding strip in the panel.

Cable laying and installation of elements

After drawing up the diagram and purchasing materials, installation occurs. The main thing is to observe safety precautions and strictly follow the drawn diagram. First, lines are drawn along the surfaces of the walls and ceilings corresponding to the laying of the wire. Then the locations of the electrical accessories are marked. For hidden wiring, the following is done: gating, preparation of recesses for sockets, switches, and space for the panel. For external versions, cable holders are attached at equal distances and holes are made for fastening overhead fittings.

After drawing up the diagram and purchasing materials, installation occurs. The main thing is to observe safety precautions and strictly follow the drawn diagram. First, lines are drawn along the surfaces of the walls and ceilings corresponding to the laying of the wire. Then the locations of the electrical accessories are marked. For hidden wiring, the following is done: gating, preparation of recesses for sockets, switches, and space for the panel. For external versions, cable holders are attached at equal distances and holes are made for fastening overhead fittings.

After laying and securing the cable, the shield is assembled. To do this, an input circuit breaker is installed on the DIN rail and automatic switches are installed on each group of lines. If necessary, an RCD is added or a differential circuit breaker is installed instead of the input one. This is a type of switch that simultaneously combines the functions of a circuit breaker and an RCD. A grounding and neutral strip is also installed in the shield.

After installing all the elements in the panel, the wires are connected. It is generally accepted to use brown for the phase wire, blue for neutral and yellow-white for grounding. All connections are made using device clamps. In the distribution box, the wires are connected by twisting with further insulation or using clamps in sockets and switches according to their design.

Functionality check

After wiring in the house is done with your own hands or with the help of a specialist, it needs to be checked. To do this, use a multimeter in the continuity mode to check the integrity of the wiring, the absence of short circuits in sockets and switches, and the functionality of the machines.

Only after a successful test is the input machine connected to the meter terminals to supply electricity to the system. If possible, be sure to turn off the machine in front of the meter when connecting. It should be remembered that 220 volt voltage is dangerous to life and working with it requires clearance and knowledge of protection, so at the final stage it is better to invite an electrician.

The need to conduct electrical wiring in a house may arise in some situations - during renovation, construction of a new home, or replacement of outdated electrical equipment. The main requirement for installation is experience in working with electrical networks and the tools used.

Ignoring safety precautions and negligence in handling electrical appliances and equipment can lead to serious consequences. Particular attention should be paid to fire safety techniques when working in wooden houses.

Where to start installing electrical wiring?

apartment wiring diagram

apartment wiring diagram  house wiring diagram

house wiring diagram For a more accurate location of wiring throughout the house, you need to draw up a detailed diagram, or preferably two. One is electrical, to determine all types of electrical devices, their power, connection methods, and the second is installation, in which you indicate the location of the electrical cable outlets for each device throughout the house.

When drawing up a diagram, you should adhere to some rules:

- Every line must have a separate cable and come from the distribution panel.

- Where lines branch boxes are installed.

- Every light fixture and sockets, are broken down by type of power and wiring cross-section.

- In each type group, total power - 4.6 kW, for wiring with a cross-section of 2.5 mm, and power of 3.3 kW - with a cross-section of 1.5 mm. If the wiring power is greater than permissible, then it is divided into subgroups.

- In the shield a separate circuit breaker is allocated for each group, for lighting with a power of 16 A, for sockets and groups of sockets, respectively, 25 A or 40 A.

- Sockets grounded devices are installed for devices with increased power and connected to a separate circuit breaker; they cannot be combined into groups.

- For particularly powerful devices(washing machines and dishwashers, kettles, electric water heaters, microwave ovens and more) copper wiring with a cross-section of 1 mm square is installed for every 1.5 kW of power, minimum.

- Ground wire must be continuous; it is not allowed to install sockets on it using the “loop” method.

- In dry rooms switches are mounted in a break in the phase wire (they are not installed in a neutral wire), and in wet ones - in breaks in the neutral and phase lines.

- If the house has two floors, then the devices are divided into groups and subgroups by floor.

Healthy! The cross-section of the wires can be safely increased by 50%, this will only increase its ability to bear additional load. At the same time, the cost of purchasing this type of wiring will increase slightly. It is important not to purchase wires with a cross-section lower than the calculated one; this will most likely lead to overheating of the wire and a fire.

Features of installing wiring in the house

Before you start installing wiring in the house with your own hands, you need to familiarize yourself with the rules for installing the equipment and follow the installation conditions:

Before you start installing wiring in the house with your own hands, you need to familiarize yourself with the rules for installing the equipment and follow the installation conditions:

- Provide free access to all electrical equipment - sockets, switches and metering equipment.

- Equipment installation performed at a distance of 60–150 cm from the floor.

- Doors and other interior or furniture parts should not block access.

- Cables are laid only in the upper part of the room.

- Sockets are mounted at a distance of 50-80 cm from the floor, wires are supplied from below, the minimum distance to an electric or gas stove is 50 cm, as well as to pipes and heating radiators.

- Sockets are mounted in the amount of 1 piece. for 6 sq. meters, with the exception of the kitchen - here sockets are installed according to the number of appliances. A separate voltage reduction system must be provided for the bathroom.

- Laying the wire, maintaining clear horizontal or vertical lines without bends or creases.

- Horizontally lay the wire with a minimum distance of 5 - 10 cm from the eaves or ceiling, as well as 15 cm from the floor and ceiling. Vertically - 10 cm from the edge of doorways or windows, 40 cm away from gas pipes.

- Do not allow wires to touch and metal structures of the building.

- and copper wires are excluded, reliably insulate each connection, use boxes when routing cables and connecting them.

Installation methods

The wiring is mounted in two installation methods - open and hidden:

Open wiring

Open installation of cables is carried out on the outer surfaces of walls or ceilings. The advantages are good repair data and quick installation. Externally, such a network is not aesthetically pleasing; it is used mainly in country houses and outbuildings, wooden houses without finishing.

But this type of wiring has a number of advantages:

- It is possible to use cables and wires with a minimum cross-section to create the same load.

- Open wiring control much easier to carry out than hidden.

- Allowed to be installed in wooden houses, or having a wooden finish.

Open wiring happens:

- Stationary.

- Mobile.

- Portable.

Hidden wiring

Hidden electrical wiring is installed inside the walls or ceilings of the house, under decorative cladding. Such wiring is safer due to protection from mechanical damage and open fire. But it requires additional effort during installation.

To install such a network, it is better to use copper wires with 2,3,4 cores, with a cross-section of at least 1 mm square per 1.5 kW load. Two-wire wires are used for devices without mandatory grounding, three-wire wires are installed when connecting equipment with required grounding or several switches in a row, four-wire wires are used for boilers and similar devices connected to three phases.

Healthy! In the installation of hidden wiring, only the wire is used, and the cable is used in the open method of installing the electrical network.

Preparing for wiring

Before you begin installing electrical wiring, you must:

Before you begin installing electrical wiring, you must:

- Prepare material.

- Make markings.

- Prepare the walls for wiring installation.

The next step is to perform a number of works:

- Apply markings to the walls of the premises, so to speak, a draft of the entire wiring diagram, indicate the place where the wires enter the house, where sockets, lighting fixtures and switches will be located.

- Transfer the electrical lines diagram on the plane of the room, indicate where the electrical wiring will go and the space allocated for the electrical panel, installed at a height of 1.5 m from the floor.

- You need to start laying the line of the main bundle of wires, indicating the places of turns. Upon completion, it would be useful to make a copy on paper; it will help with further reconstruction or repair of the wiring.

Tools needed when replacing wiring in a house:

- Bulgarian;

- disc on concrete or stone;

- hammer drill;

- drill;

- screwdriver with LED;

- cord;

- construction level;

- putty knife;

- insulating tape;

- putty or other fixing material;

Materials required for work:

- copper or aluminum wires;

- sockets;

- switches;

- distribution boxes;

- installation boxes for sockets;

After completing all the preparations, you need to prepare the tools for installing the line:

- Bulgarian. It must have a diamond disc for cutting concrete; such a disc can work on any surface, not necessarily concrete.

- Chisel for installation and hammer. They are used on soft materials - plaster, foam block. Using such “gentle” tools, there will be less dust than using an angle grinder.

- Using existing tools, you can lay a groove (furrow) in the wall, a cable or wire is inserted into it. The depth of such a recess is from 2 to 3 cm, and the width is 2 cm.

- Cut cables or wires, adding 15-15 cm to their required length for allowance for twisting together. This must be taken into account when calculating materials.

- Place a cable of the appropriate length into the prepared groove, and fix it with a building mixture similar to that used to finish the wall. At the same time, level the mixture with the plane of the walls so that the area with the wiring does not stand out on the wall. To do this, prepare the mixture according to the instructions in a small volume, and apply it with a spatula to the laid cable in some places, wait until it dries completely, and smooth out the unevenness with a foam float.

Installation rules and safety precautions

junction box

junction box Before you begin installing the electrical network indoors, you need to familiarize yourself with the installation rules:

- Install distribution boxes at the points where wires branch to switches and sockets.

- The switch is located at the entrance, preferably on the side where the door handle is located, so that when opening it does not touch the door.

- Safety precautions It is prohibited to mount the socket close to metal grounding devices (gas and electric stoves, sinks, etc.), or maintain a distance of 50 cm between the socket and the device.

- Forbidden Installation of sockets should be carried out in rooms with high humidity. In the shower room, bath, or sauna it is only allowed to maintain a distance of at least 2.4 meters from water sources.

To begin installation of the electrical network, you must familiarize yourself with the safety rules:

- Before starting work, familiarize yourself with the old line laying diagrams to avoid damaging them.

- Work is performed in daylight, since when replacing electrical wiring, the house is de-energized.

- When performing electrical installation work It is recommended to use special tools with insulated handles.

- Before, how to touch the connected wires in the circuit, they should be checked with a screwdriver with an indicator to see if there is voltage flowing through the wires.

Careless behavior with electricity can lead to irreversible consequences and serious trouble.

Healthy! If the wire is marked “NG”, this means that fire-resistant plastic was used in its manufacture, and this will eliminate the source of the fire if the wiring catches fire.

Operational control

When using electrical equipment in the home, you should follow the recommendations from the following manuals:

- "Rules for the use of electricity."

- “Rules for technical operation of electrical installations by consumers.”

- “Safety rules for the operation of electrical installations by consumers.”

Compliance with these instructions is mandatory. Responsibility for the condition of the entire network and operational safety lies entirely with the owner. Monitoring compliance with safety precautions and operating rules falls entirely on the energy supply organization with which the corresponding contract is concluded.

This organization conducts systematic checks of the condition of the electrical network, its operating rules and compliance with all rules for using the network.

Electrical wiring cost calculation

In order to find out the exact cost of wiring in the house, you must first calculate the amount of cable. There are 2 calculation methods:

In order to find out the exact cost of wiring in the house, you must first calculate the amount of cable. There are 2 calculation methods:

- Calculation according to the electrical network diagram.

- Based on the total area of the room.

Calculation based on an electrical wiring diagram involves drawing up a detailed diagram. It should include specific information:

- Specify, how many sockets, switches, distribution boxes will be needed, as well as the height, fasteners and methods of connecting to the network.

- Determine the location of each lighting fixture(chandeliers, spotlights, etc.), ceiling height - will it go down or not?

- Choose. For lighting devices, take a wire with a cross-section of 3.0 * 1.5 mm sq., for a socket 3.0 * 2.5 mm sq., for partings with increased power - 3.0 * 4.0 mm sq.

Using the prepared project, you can easily calculate the length of the wire, the number of sockets and switches. Alternatively, you can transfer the diagram to the walls and measure it with a tape measure, which will be more accurate.

The second option is simplified; you need to multiply the total area of the room by 2. This will give you the required footage. But there are a number of nuances in this method:

- Only 1 line is defined this way, lighting or power.

- The calculation is carried out in a ratio of 1:1.5. Where 1.0 equals the lighting line, and 1.5 equals the power line. That is, for a room of 50 square meters. m. consumption of the power line is 50 x 1.5 = 75 m. and for the lighting line - 50 x 1 = 50 m.

- Corridor– 1 socket (50 RUR).

- Kitchen– 2 sockets (100 RUR).

- Rooms– 9 sockets (450 RUR).

- Switches for the whole house– 7 pieces (60 rubles).

- Additional socket for washing machine– 1 piece (50 rubles).

- Copper wire– on average 135 m (6075 rubles/meter).

- Lighting(cartridges for incandescent lamps) – 7 pieces (210 RUR).

- Installation boxes for sockets– 13 pieces (65 rubles).

- Distribution boxes– 5 pieces (250 RUR).

- Distribution panel– 1 piece (130 RUR).

So, let’s sum up the costs of all materials and components - 7,390 rubles is the minimum cost of installing a network yourself, without involving professionals.

If you don’t have the skills to work with electrical equipment, then all you have to do is turn to professional electricians. The exact price will depend on the complexity of the scheme.

Prices for installation work on the electrical network in a three-room house of 60 sq.m.:

- Wall chipping(60 m) – 13200 rub.

- Installation of sockets(13 pieces) – 3900 rub.

- Installation of distribution boxes(5 pieces) – 1500 rub.

- Installation of distribution panel(1 piece) – 1000 rub.

- Wire laying(135 m) – 4050 rub.

Total: installation work 23650 rub. To this amount it remains to add the cost of the material 7390 rubles.

Network connection

The final stage is connecting the electrical wiring to the general electrical network. This connection is usually carried out by housing and communal services electricians. But before contacting them, you must obtain permission from the electricity supply organization. This issue can be resolved quite quickly, provided that all installation rules and regulations are observed, as well as the operation of the electrical network.

This completes the process of installing electrical wiring in the house. There is nothing impossible or difficult about carrying out such work. But you should not treat the installation of electrical networks with neglect, this can lead to a fire hazard and will damage the entire system.