The term "thermal conductivity" is applied to the properties of materials to transmit thermal energy from hot to cold areas. Thermal conductivity is based on the movement of particles inside substances and materials. The ability to transfer heat energy in quantitative terms is the coefficient of thermal conductivity. The cycle of thermal energy transfer, or heat exchange, can take place in any substances with unequal placement of different temperature sections, but the thermal conductivity depends on the pressure and temperature in the material itself, as well as on its state - gaseous, liquid or solid.

Physically, the thermal conductivity of materials is equal to the amount of heat that flows through a homogeneous object of established dimensions and area for a certain time period at a specified temperature difference (1 K). In the SI system, a single indicator that has a thermal conductivity coefficient is usually measured in W / (m K).

How to Calculate Thermal Conductivity Using Fourier's Law

In a given thermal regime, the flux density during heat transfer is directly proportional to the maximum temperature increase vector, the parameters of which change from one section to another, and modulo with the same temperature increase rate in the direction of the vector:

q → = − ϰ x grad x (T), where:

- q → - the direction of the density of the object that transfers heat, or the volume of heat flow that flows through the site for a given time unit through a certain area, perpendicular to all axes;

- ϰ is the specific coefficient of thermal conductivity of the material;

- T is the temperature of the material.

When applying the Fourier law, the inertia of the flow of thermal energy is not taken into account, which means that the instantaneous transfer of heat from any point to any distance is meant. Therefore, the formula cannot be used to calculate heat transfer during processes with a high repetition rate. This is ultrasonic radiation, the transfer of thermal energy by shock or impulse waves, etc. There is a Fourier law solution with a relaxation term:

τ x ∂ q / ∂ t = − (q + ϰ x ∇T) .

If the relaxation τ is instantaneous, then the formula turns into the Fourier law.

Approximate table of thermal conductivity of materials:

| The basis | Thermal conductivity value, W/(m K) |

| hard graphene | 4840 + / – 440 – 5300 + / – 480 |

| Diamond | 1001-2600 |

| Graphite | 278,4-2435 |

| Boron arsenide | 200-2000 |

| SiC | 490 |

| Ag | 430 |

| Cu | 401 |

| BeO | 370 |

| Au | 320 |

| Al | 202-236 |

| AlN | 200 |

| BN | 180 |

| Si | 150 |

| Cu 3 Zn 2 | 97-111 |

| Cr | 107 |

| Fe | 92 |

| Pt | 70 |

| sn | 67 |

| ZnO | 54 |

| black steel | 47-58 |

| Pb | 35,3 |

| stainless steel | Thermal conductivity of steel - 15 |

| SiO2 | 8 |

| High quality heat resistant pastes | 5-12 |

| Granite (consists of SiO 2 68-73%; Al 2 O 3 12.0-15.5%; Na 2 O 3.0-6.0%; CaO 1.5-4.0%; FeO 0.5- 3.0%; Fe 2 O 3 0.5-2.5%; K 2 O 0.5-3.0%; MgO 0.1-1.5%; TiO 2 0.1-0.6% ) | 2,4 |

| Concrete mortar without aggregates | 1,75 |

| Concrete mortar with crushed stone or gravel | 1,51 |

| Basalt (consists of SiO 2 - 47-52%, TiO 2 - 1-2.5%, Al2O 3 - 14-18%, Fe 2 O 3 - 2-5%, FeO - 6-10%, MnO - 0, 1-0.2%, MgO - 5-7%, CaO - 6-12%, Na 2 O - 1.5-3%, K 2 O - 0.1-1.5%, P 2 O 5 - 0.2-0.5%) | 1,3 |

| Glass (consists of SiO 2 , B 2 O 3 , P 2 O 5 , TeO 2 , GeO 2 , AlF 3 etc.) | 1-1,15 |

| Heat-resistant paste KPT-8 | 0,7 |

| Concrete mortar filled with sand, without crushed stone or gravel | 0,7 |

| The water is clean | 0,6 |

| Silicate or red brick | 0,2-0,7 |

| Oils based on silicone | 0,16 |

| foam concrete | 0,05-0,3 |

| aerated concrete | 0,1-0,3 |

| Wood | Thermal conductivity of wood - 0.15 |

| Oils oil based | 0,125 |

| Snow | 0,10-0,15 |

| PP with flammability group G1 | 0,039-0,051 |

| EPPU with flammability group G3, G4 | 0,03-0,033 |

| glass wool | 0,032-0,041 |

| Cotton wool stone | 0,035-0,04 |

| Air atmosphere (300 K, 100 kPa) | 0,022 |

| Gel air based | 0,017 |

| Argon (Ar) | 0,017 |

| vacuum environment | 0 |

The given table of thermal conductivity takes into account heat transfer by thermal radiation and heat exchange of particles. Since a vacuum does not transfer heat, it flows with the help of solar radiation or other type of heat generation. In a gas or liquid medium, layers with different temperatures are mixed artificially or naturally.

When calculating the thermal conductivity of a wall, it must be taken into account that heat transfer through wall surfaces varies from the fact that the temperature in the building and on the street is always different, and depends on the area of \u200b\u200ball surfaces of the house and on the thermal conductivity of building materials.

To quantify the thermal conductivity, a value such as the coefficient of thermal conductivity of materials was introduced. It shows how a particular material is able to transfer heat. The higher this value, for example, the thermal conductivity of steel, the more efficiently the steel will conduct heat.

- When insulating a house made of wood, it is recommended to choose building materials with a low coefficient.

- If the wall is brick, then with a coefficient value of 0.67 W / (m2 K) and a wall thickness of 1 m, with an area of \u200b\u200bit 1 m 2, with a difference between the outside and inside temperatures of 1 0 C, the brick will transmit 0.67 W of energy. With a temperature difference of 10 0 C, the brick will transmit 6.7 W, etc.

The standard value of the thermal conductivity coefficient of thermal insulation and other building materials is valid for a wall thickness of 1 m. To calculate the thermal conductivity of a surface of a different thickness, the coefficient should be divided by the selected wall thickness value (meters).

In SNiP and when carrying out calculations, the term “thermal resistance of the material” appears, it means reverse thermal conductivity. That is, with a thermal conductivity of a foam sheet of 10 cm and its thermal conductivity of 0.35 W / (m 2 K), the thermal resistance of the sheet is 1 / 0.35 W / (m 2 K) \u003d 2.85 (m 2 K) / W.

Below is a table of thermal conductivity for popular building materials and heat insulators:

| building materials | Thermal conductivity coefficient, W / (m 2 K) |

| Alabaster slabs | 0,47 |

| Al | 230 |

| Asbestos-cement slate | 0,35 |

| Asbestos (fiber, fabric) | 0,15 |

| asbestos cement | 1,76 |

| Asbestos cement products | 0,35 |

| Asphalt | 0,73 |

| Asphalt for flooring | 0,84 |

| Bakelite | 0,24 |

| Crushed concrete | 1,3 |

| Sand-filled concrete | 0,7 |

| Porous concrete - foam and aerated concrete | 1,4 |

| solid concrete | 1,75 |

| Thermal insulating concrete | 0,18 |

| bituminous mass | 0,47 |

| paper materials | 0,14 |

| Loose mineral wool | 0,046 |

| Heavy mineral wool | 0,05 |

| Cotton wool - a heat insulator based on cotton | 0,05 |

| Vermiculite in slabs or sheets | 0,1 |

| Felt | 0,046 |

| Gypsum | 0,35 |

| Alumina | 2,33 |

| gravel aggregate | 0,93 |

| Granite or basalt aggregate | 3,5 |

| Wet soil, 10% | 1,75 |

| Wet soil, 20% | 2,1 |

| Sandstones | 1,16 |

| dry soil | 0,4 |

| compacted soil | 1,05 |

| Tar mass | 0,3 |

| Building board | 0,15 |

| plywood sheets | 0,15 |

| hard wood | 0,2 |

| Chipboard | 0,2 |

| Duralumin products | 160 |

| Reinforced concrete products | 1,72 |

| Ash | 0,15 |

| limestone blocks | 1,71 |

| Mortar on sand and lime | 0,87 |

| Resin foamed | 0,037 |

| Natural stone | 1,4 |

| Cardboard sheets from several layers | 0,14 |

| Rubber porous | 0,035 |

| Rubber | 0,042 |

| Rubber with fluorine | 0,053 |

| Expanded clay blocks | 0,22 |

| Red brick | 0,13 |

| hollow brick | 0,44 |

| solid brick | 0,81 |

| solid brick | 0,67 |

| cinder brick | 0,58 |

| Silica based boards | 0,07 |

| brass products | 110 |

| Ice at a temperature of 0 0 С | 2,21 |

| Ice at -20 0 C | 2,44 |

| Deciduous wood at 15% humidity | 0,15 |

| copper products | 380 |

| Mypora | 0,086 |

| Sawdust for backfill | 0,096 |

| Dry sawdust | 0,064 |

| PVC | 0,19 |

| foam concrete | 0,3 |

| Styrofoam brand PS-1 | 0,036 |

| Styrofoam brand PS-4 | 0,04 |

| Polyfoam brand PKhV-1 | 0,05 |

| Styrofoam brand FRP | 0,044 |

| PPU brand PS-B | 0,04 |

| PPU brand PS-BS | 0,04 |

| Polyurethane foam sheet | 0,034 |

| PU foam panel | 0,024 |

| Lightweight foam glass | 0,06 |

| Heavy foam glass | 0,08 |

| glassine products | 0,16 |

| Perlite products | 0,051 |

| Slabs on cement and perlite | 0,085 |

| Wet sand 0% | 0,33 |

| Wet sand 0% | 0,97 |

| Wet sand 20% | 1,33 |

| burnt stone | 1,52 |

| Ceramic tile | 1,03 |

| Tiles brand PMTB-2 | 0,035 |

| Polystyrene | 0,081 |

| Foam rubber | 0,04 |

| Cement-based mortar without sand | 0,47 |

| Natural cork board | 0,042 |

| Light sheets of natural cork | 0,034 |

| Heavy sheets of natural cork | 0,05 |

| Rubber products | 0,15 |

| Ruberoid | 0,17 |

| Slate | 2,100 |

| Snow | 1,5 |

| Softwood with a moisture content of 15% | 0,15 |

| Coniferous resinous wood with a moisture content of 15% | 0,23 |

| Steel products | 52 |

| glass products | 1,15 |

| Glass wool insulation | 0,05 |

| Fiberglass insulation | 0,034 |

| Glass fiber products | 0,31 |

| Shavings | 0,13 |

| Teflon coating | 0,26 |

| Tol | 0,24 |

| Cement based slab | 1,93 |

| Cement-sand mortar | 1,24 |

| Cast iron products | 57 |

| Slag in granules | 0,14 |

| Ash slag | 0,3 |

| Cinder blocks | 0,65 |

| Dry plaster mixes | 0,22 |

| Cement-based plaster | 0,95 |

| ebonite products | 0,15 |

In addition, it is necessary to take into account the thermal conductivity of heaters due to their jet heat flows. In a dense medium, it is possible to “transfer” quasiparticles from one heated building material to another, colder or warmer, through submicron pores, which helps to spread sound and heat, even if there is an absolute vacuum in these pores.

Whatever the scale of construction, the first step is to develop a project. The drawings reflect not only the geometry of the structure, but also the calculation of the main thermal characteristics. To do this, you need to know the thermal conductivity of building materials. The main goal of construction is to build durable structures, durable structures that are comfortable without excessive heating costs. In this regard, it is extremely important to know the thermal conductivity coefficients of materials.

Brick has the best thermal conductivity

Characteristics of the indicator

The term thermal conductivity refers to the transfer of thermal energy from hotter objects to cooler ones. The exchange continues until temperature equilibrium is reached.

Heat transfer is determined by the length of time during which the temperature in the premises is in accordance with the ambient temperature. The smaller this interval, the greater the thermal conductivity of the building material.

To characterize the conductivity of heat, the concept of the thermal conductivity coefficient is used, which shows how much heat passes through such and such a surface area in such and such time. The higher this figure, the greater the heat transfer, and the building cools down much faster. Thus, when erecting structures, it is recommended to use building materials with minimal heat conductivity.

In this video you will learn about the thermal conductivity of building materials:

How to determine heat loss

The main elements of the building through which heat escapes:

- doors (5-20%);

- gender (10-20%);

- roof (15-25%);

- walls (15-35%);

- windows (5-15%).

The level of heat loss is determined using a thermal imager. Red indicates the most difficult areas, yellow and green indicate less heat loss. Zones with the least losses are highlighted in blue. The value of thermal conductivity is determined in the laboratory, and the material is issued a quality certificate.

The value of heat conductivity depends on the following parameters:

- Porosity. The pores indicate the heterogeneity of the structure. When heat passes through them, cooling will be minimal.

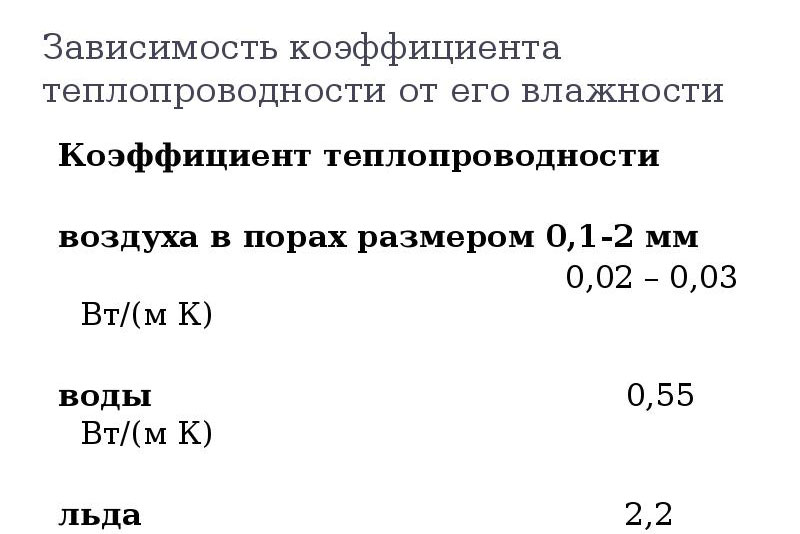

- Humidity. A high level of humidity provokes the displacement of dry air by liquid droplets from the pores, due to which the value increases many times over.

- Density. Higher density promotes more active interaction of particles. As a result, heat transfer and temperature balancing proceeds faster.

Coefficient of thermal conductivity

In the house, heat loss is inevitable, and they occur when the temperature outside the window is lower than in the rooms. The intensity is a variable and depends on many factors, the main of which are the following:

- Surface area involved in heat transfer.

- An indicator of thermal conductivity of building materials and building elements.

- temperature difference.

The Greek letter λ is used to designate the thermal conductivity of building materials. The unit of measurement is W/(m×°C). The calculation is made for 1 m² of a meter-thick wall. A temperature difference of 1°C is assumed here.

Case Study

Conventionally, materials are divided into heat-insulating and structural. The latter have the highest thermal conductivity; walls, ceilings, and other fences are built from them. According to the table of materials, when building reinforced concrete walls, to ensure low heat exchange with the environment, their thickness should be approximately 6 m. But then the building will be bulky and expensive.

In the event of an incorrect calculation of thermal conductivity during the design, the residents of the future house will be content with only 10% of the heat from energy sources. Therefore, houses made of standard building materials are recommended to be insulated additionally.

When performing the correct waterproofing of the insulation, high humidity does not affect the quality of the thermal insulation, and the resistance of the building to heat transfer will become much higher.

The best option is to use a heater

The most common option is a combination of a supporting structure made of high-strength materials with additional thermal insulation. For example:

- Frame house. Insulation is placed between the posts. Sometimes, with a slight decrease in heat transfer, additional insulation is required outside the main frame.

- Construction of standard materials. When the walls are brick or cinder block, insulation is done from the outside.

Building materials for exterior walls

Walls today are built from different materials, but the most popular remain: wood, brick and building blocks. The main difference is the density and heat conductivity of building materials. Comparative analysis allows you to find the golden mean in the ratio between these parameters. The greater the density, the greater the bearing capacity of the material, and hence the entire structure. But the thermal resistance becomes smaller, that is, energy costs increase. Usually at lower density there is porosity.

Thermal conductivity coefficient and its density.

Wall insulation

Heaters are used when there is not enough thermal resistance of the outer walls. Usually, to create a comfortable microclimate in the premises, a thickness of 5-10 cm is sufficient.

The value of the coefficient λ is given in the following table.

Thermal conductivity measures the ability of a material to conduct heat through itself. It strongly depends on the composition and structure. Dense materials such as metals and stone are good heat conductors, while low density materials such as gas and porous insulation are poor conductors.

Methodological material for self-calculation of the thickness of the walls of the house with examples and a theoretical part.

Part 1. Heat transfer resistance - the primary criterion for determining the thickness of the wall

To determine the thickness of the wall, which is necessary to comply with energy efficiency standards, the heat transfer resistance of the designed structure is calculated in accordance with section 9 "Methodology for designing thermal protection of buildings" SP 23-101-2004.

Heat transfer resistance is a property of a material that indicates how heat is retained by a given material. This is a specific value that shows how slowly heat is lost in watts when a heat flux passes through a unit volume with a temperature difference on the walls of 1°C. The higher the value of this coefficient, the “warmer” the material.

All walls (non-translucent enclosing structures) are considered for thermal resistance according to the formula:

R \u003d δ / λ (m 2 ° C / W), where:

δ is the thickness of the material, m;

λ - specific thermal conductivity, W / (m · ° С) (can be taken from the passport data of the material or from tables).

The resulting value of Rtotal is compared with the tabular value in SP 23-101-2004.

To focus on the regulatory document, it is necessary to calculate the amount of heat required to heat the building. It is performed according to SP 23-101-2004, the resulting value is "degree day". The rules recommend the following ratios.

| wall material | Heat transfer resistance (m 2 °C / W) / application area (°C day) |

||||

| structural | heat-insulating | Double-layer with external thermal insulation | Three-layer with insulation in the middle | With non-ventilated atmospheric layer | With ventilated atmospheric layer |

| Brickwork | Styrofoam | ||||

| Mineral wool | |||||

| Expanded clay concrete (flexible links, dowels) | Styrofoam | ||||

| Mineral wool | |||||

| Aerated concrete blocks with brick cladding | Cellular concrete | ||||

| Note. In the numerator (before the line) - the approximate values of the reduced resistance to heat transfer of the outer wall, in the denominator (behind the line) - the limiting values of the degree-days of the heating period, at which this wall design can be applied. |

|||||

The results obtained must be verified with the norms of clause 5. SNiP 23-02-2003 "Thermal protection of buildings".

You should also take into account the climatic conditions of the zone where the building is being built: different regions have different requirements due to different temperature and humidity conditions. Those. the thickness of the gas block wall should not be the same for the coastal region, central Russia and the far north. In the first case, it will be necessary to correct the thermal conductivity taking into account the humidity (upward: increased humidity reduces the thermal resistance), in the second case, you can leave it “as is”, in the third case, be sure to take into account that the thermal conductivity of the material will increase due to a larger temperature difference.

Part 2. Thermal conductivity of wall materials

The coefficient of thermal conductivity of wall materials is this value, which shows the specific thermal conductivity of the wall material, i.e. how much heat is lost when a heat flux passes through a conditional unit volume with a temperature difference on its opposite surfaces of 1°C. The lower the value of the coefficient of thermal conductivity of the walls - the warmer the building will turn out, the higher the value - the more power will have to be put into the heating system.

In fact, this is the reciprocal of the thermal resistance discussed in part 1 of this article. But this applies only to specific values for ideal conditions. The real thermal conductivity coefficient for a particular material is affected by a number of conditions: temperature difference on the walls of the material, internal heterogeneous structure, humidity level (which increases the density level of the material, and, accordingly, increases its thermal conductivity) and many other factors. As a rule, tabular thermal conductivity must be reduced by at least 24% to obtain an optimal design for temperate climates.

Part 3. The minimum allowable value of wall resistance for various climatic zones.

The minimum allowable thermal resistance is calculated to analyze the thermal properties of the designed wall for various climatic zones. This is a normalized (basic) value, which shows what the thermal resistance of the wall should be, depending on the region. First, you choose the material for the structure, calculate the thermal resistance of your wall (part 1), and then compare it with the tabular data contained in SNiP 23-02-2003. If the value obtained turns out to be less than that established by the rules, then it is necessary either to increase the thickness of the wall, or to insulate the wall with a heat-insulating layer (for example, mineral wool).

According to paragraph 9.1.2 of SP 23-101-2004, the minimum allowable heat transfer resistance R o (m 2 ° C / W) of the enclosing structure is calculated as

R o \u003d R 1 + R 2 + R 3, where:

R 1 \u003d 1 / α ext, where α ext is the heat transfer coefficient of the inner surface of the enclosing structures, W / (m 2 × ° С), taken according to table 7 of SNiP 23-02-2003;

R 2 \u003d 1 / α ext, where α ext is the heat transfer coefficient of the outer surface of the enclosing structure for the conditions of the cold period, W / (m 2 × ° С), taken according to table 8 of SP 23-101-2004;

R 3 - total thermal resistance, the calculation of which is described in part 1 of this article.

If there is a layer in the enclosing structure ventilated by outside air, the layers of the structure located between the air layer and the outer surface are not taken into account in this calculation. And on the surface of the structure facing towards the layer ventilated from the outside, the heat transfer coefficient α external should be taken equal to 10.8 W / (m 2 · ° С).

Table 2. Normalized values of thermal resistance for walls according to SNiP 23-02-2003.

The updated values of the degree-days of the heating period are indicated in Table 4.1 of the reference manual to SNiP 23-01-99 * Moscow, 2006.

Part 4. Calculation of the minimum allowable wall thickness on the example of aerated concrete for the Moscow region.

When calculating the thickness of the wall structure, we take the same data as indicated in Part 1 of this article, but rebuild the basic formula: δ = λ R, where δ is the wall thickness, λ is the thermal conductivity of the material, and R is the heat resistance norm according to SNiP.

Calculation example the minimum wall thickness of aerated concrete with a thermal conductivity of 0.12 W / m ° C in the Moscow region with an average temperature inside the house during the heating season + 22 ° C.

- We take the normalized thermal resistance for walls in the Moscow region for a temperature of + 22 ° C: R req \u003d 0.00035 5400 + 1.4 \u003d 3.29 m 2 ° C / W

- The coefficient of thermal conductivity λ for aerated concrete grade D400 (dimensions 625x400x250 mm) at a humidity of 5% = 0.147 W/m∙°C.

- Minimum wall thickness of aerated concrete stone D400: R λ = 3.29 0.147 W/m∙°С=0.48 m.

Conclusion: for Moscow and the region, for the construction of walls with a given thermal resistance parameter, an aerated concrete block with a width of at least 500 mm is needed, or a block with a width of 400 mm and subsequent insulation (mineral wool + plastering, for example), to ensure the characteristics and requirements of SNiP in terms of energy efficiency of wall structures.

Table 3. The minimum thickness of walls erected from various materials that meet the standards of thermal resistance according to SNiP.

| Material | Wall thickness, m | conductivity, | |

| Expanded clay blocks | For the construction of load-bearing walls, a grade of at least D400 is used. |

||

| cinder blocks | |||

| silicate brick | |||

| Gas silicate blocks d500 | I use a brand from D400 and higher for housing construction |

||

| Foam block | frame construction only |

||

| Cellular concrete | The thermal conductivity of cellular concrete is directly proportional to its density: the “warmer” the stone, the less durable it is. |

||

| Minimum wall size for frame structures |

|||

| Solid ceramic brick | |||

| Sand-concrete blocks | At 2400 kg/m³ under conditions of normal temperature and air humidity. |

Part 5. The principle of determining the value of heat transfer resistance in a multilayer wall.

If you plan to build a wall from several types of material (for example, building stone + mineral insulation + plaster), then R is calculated for each type of material separately (using the same formula), and then summed up:

R total \u003d R 1 + R 2 + ... + R n + R a.l where:

R 1 -R n - thermal resistance of various layers

R a.l - resistance of a closed air gap, if it is present in the structure (table values are taken in SP 23-101-2004, p. 9, table 7)

An example of calculating the thickness of a mineral wool insulation for a multilayer wall (cinder block - 400 mm, mineral wool - ? mm, facing brick - 120 mm) with a heat transfer resistance value of 3.4 m 2 * Deg C / W (Orenburg).

R \u003d R cinder block + R brick + R wool \u003d 3.4

R cinder block \u003d δ / λ \u003d 0.4 / 0.45 \u003d 0.89 m 2 × ° C / W

Rbrick \u003d δ / λ \u003d 0.12 / 0.6 \u003d 0.2 m 2 × ° C / W

R cinder block + R brick \u003d 0.89 + 0.2 \u003d 1.09 m 2 × ° C / W (<3,4).

Rwool \u003d R- (R cinder block + R brick) \u003d 3.4-1.09 \u003d 2.31 m 2 × ° C / W

δwool = Rwool λ = 2.31 * 0.045 = 0.1 m = 100 mm (we take λ = 0.045 W / (m × ° C) - the average value of thermal conductivity for mineral wool of various types).

Conclusion: in order to comply with the requirements for heat transfer resistance, expanded clay concrete blocks can be used as the main structure with ceramic brick lining and a layer of mineral wool with a thermal conductivity of at least 0.45 and a thickness of 100 mm.

Questions and answers on the topic

No questions have been asked for the material yet, you have the opportunity to be the first to do soMany building materials are available for sale that are used to improve the properties of the structure to retain heat - heaters. In the construction of a house, it can be used in almost every part of it: from the foundation to the attic. Next, we will talk about the main properties of materials that can provide the necessary level of thermal conductivity of objects for various purposes, and they will also be compared, which will help the table.

The main characteristics of heaters

When choosing heaters, you need to pay attention to various factors: the type of structure, the presence of exposure to high temperatures, open fire, the characteristic level of humidity. Only after determining the conditions of use, as well as the level of thermal conductivity of the materials used for the construction of a certain part of the structure, you need to look at the characteristics of a particular insulation:

- Thermal conductivity. The quality of the insulation process carried out, as well as the required amount of material to ensure the desired result, directly depends on this indicator. The lower the thermal conductivity, the more efficient the use of insulation.

- Moisture absorption. The indicator is especially important when insulating the external parts of the structure, which can be periodically affected by moisture. For example, when warming the foundation in soils with high water or an increased level of water content in its structure.

- Thickness. The use of thin insulation allows you to save the interior space of a residential building, and also directly affects the quality of insulation.

- Flammability. This property of materials is especially important when used to reduce the thermal conductivity of the ground parts of the construction of residential buildings, as well as buildings for special purposes. Quality products are self-extinguishing, do not emit toxic substances when ignited.

- Thermal stability. The material must withstand critical temperatures. For example, low temperatures for outdoor use.

- Environmental friendliness. It is necessary to resort to the use of materials that are safe for humans. The requirements for this factor may vary depending on the future purpose of the structure.

- Soundproofing. This additional property of heaters in some situations allows you to achieve a good level of protection of the room from noise, as well as extraneous sounds.

When a material with low thermal conductivity is used in the construction of a certain part of the structure, then you can buy the cheapest insulation (if preliminary calculations allow).

When a material with low thermal conductivity is used in the construction of a certain part of the structure, then you can buy the cheapest insulation (if preliminary calculations allow).

The importance of a particular characteristic directly depends on the conditions of use and the allocated budget.

Comparison of popular heaters

Let's look at a few materials used to improve the energy efficiency of buildings:

- Mineral wool. Made from natural materials. It is resistant to fire and is environmentally friendly, as well as low thermal conductivity. But the inability to resist the effects of water reduces the possibilities of use.

- Styrofoam. Lightweight material with excellent insulation properties. Affordable, easy to install and moisture resistant. Disadvantages: good flammability and emission of harmful substances during combustion. It is recommended to use it in non-residential premises.

- Balsa wool. The material is almost identical to mineral wool, only differs in improved moisture resistance. During manufacture, it is not compacted, which significantly extends the service life.

- Penoplex. The insulation resists moisture, high temperatures, fire, rotting, decomposition well. It has excellent thermal conductivity, easy to install and durable. It can be used in places with maximum requirements for the ability of the material to withstand various influences.

- Penofol. Multilayer insulation of natural origin. Consists of polyethylene, pre-foamed before production. May have different porosity and width. Often the surface is covered with foil, due to which a reflective effect is achieved. Differs in ease, simplicity of installation, high energy efficiency, moisture resistance, small weight.

When choosing a material for use in close proximity to a person, it is necessary to pay special attention to its environmental and fire safety characteristics. Also, in some situations, it is rational to buy a more expensive insulation, which will have additional properties of moisture protection or sound insulation, which ultimately saves money.

Table Comparison

| N | Name | Density | Thermal conductivity | Price, euro per cubic meter | Energy costs for | ||

| kg/cu.m. | min | Max | European Union | Russia | kW*h/cub. m. | ||

| 1 | cellulose wadding | 30-70 | 0,038 | 0,045 | 48-96 | 15-30 | 6 |

| 2 | fibreboard | 150-230 | 0,039 | 0,052 | 150 | 800-1400 | |

| 3 | wood fiber | 30-50 | 0,037 | 0,05 | 200-250 | 13-50 | |

| 4 | flax fiber whales | 30 | 0,037 | 0,04 | 150-200 | 210 | 30 |

| 5 | foam glass | 100-150 | 0.05 | 0,07 | 135-168 | 1600 | |

| 6 | perlite | 100-150 | 0,05 | 0.062 | 200-400 | 25-30 | 230 |

| 7 | cork | 100-250 | 0,039 | 0,05 | 300 | 80 | |

| 8 | hemp, hemp | 35-40 | 0,04 | 0.041 | 150 | 55 | |

| 9 | cotton wool | 25-30 | 0,04 | 0,041 | 200 | 50 | |

| 10 | sheep's wool | 15-35 | 0,035 | 0,045 | 150 | 55 | |

| 11 | duck down | 25-35 | 0,035 | 0,045 | 150-200 | ||

| 12 | straw | 300-400 | 0,08 | 0,12 | 165 | ||

| 13 | mineral (stone) wool | 20-80 | 0.038 | 0,047 | 50-100 | 30-50 | 150-180 |

| 14 | fiberglass wool | 15-65 | 0,035 | 0,05 | 50-100 | 28-45 | 180-250 |

| 15 | expanded polystyrene (non-pressed) | 15-30 | 0.035 | 0.047 | 50 | 28-75 | 450 |

| 16 | expanded polystyrene extrusion | 25-40 | 0,035 | 0,042 | 188 | 75-90 | 850 |

| 17 | polyurethane foam | 27-35 | 0,03 | 0,035 | 250 | 220-350 | 1100 |

The indicator of heat-conducting properties is the main criterion when choosing an insulating material. It remains only to compare the pricing policies of different suppliers and determine the required quantity.

Insulation is one of the main ways to get a building with the necessary energy efficiency. Before making the final choice, determine the exact conditions of use and, armed with the table below, make the right choice.

1. Heat loss at home

The choice of thermal insulation, wall finishing options for most customers - developers is a difficult task. Too many conflicting problems need to be solved at the same time. This page will help you figure it all out.

At present, the heat saving of energy resources has become of great importance. According to SNiP II-3-79* "Construction Heat Engineering", heat transfer resistance is determined based on:

- sanitary and hygienic and comfortable conditions (first condition),

- conditions for energy saving (second condition).

For Moscow and its region, the required thermal resistance of the wall according to the first condition is 1.1 °C m. sq. / W, and according to the second condition:

- for a permanent home 3.33 °C m. sq. / W,

- for a house of seasonal residence 2.16 ° С m. sq. / W.

1.1 Table of thicknesses and thermal resistance of materials for the conditions of Moscow and its region.

| Wall material name | Wall thickness and corresponding thermal resistance | Required thickness according to the first condition (R=1.1 °С sq.m. / W) and the second condition (R=3.33 °С sq.m. / W) |

|---|---|---|

| Solid ceramic brick | 510 mm, R=1.1 °С m. sq. /W | 510 mm 1550 mm |

| Expanded clay concrete (density 1200 kg / m3) | 300 mm, R=0.8 °С m. sq. /W | 415 mm 1250 mm |

| wooden beam | 150 mm, R=1.0 °C m. sq. /W | 165 mm 500 mm |

| Wooden panel filled with mineral wool M 100 | 100 mm, R=1.33 °С m. sq. /W | 85 mm 250 mm |

1.2 Table of the minimum reduced resistance to heat transfer of external structures in houses in the Moscow region.

These tables show that the majority of suburban housing in the Moscow region does not meet the requirements for heat saving, while even the first condition is not met in many newly built buildings.

Therefore, by selecting a boiler or heaters only according to the ability to heat a certain area indicated in their documentation, you assert that your house was built with strict consideration of the requirements of SNiP II-3-79 *.

The conclusion follows from the above material. For the correct choice of the power of the boiler and heating devices, it is necessary to calculate the actual heat loss of the premises of your house.

Below we will show a simple method for calculating the heat loss of your home.

The house loses heat through the wall, roof, strong heat emissions go through the windows, heat also goes into the ground, significant heat losses can occur through ventilation.

Heat losses mainly depend on:

- temperature difference in the house and on the street (the greater the difference, the higher the losses),

- heat-shielding properties of walls, windows, ceilings, coatings (or, as they say, enclosing structures).

Enclosing structures resist heat leakage, so their heat-shielding properties are evaluated by a value called heat transfer resistance.

The heat transfer resistance shows how much heat will go through a square meter of the building envelope at a given temperature difference. It can be said, and vice versa, what temperature difference will occur when a certain amount of heat passes through a square meter of fences.

R = ∆T/q

where q is the amount of heat that a square meter of enclosing surface loses. It is measured in watts per square meter (W/m2); ΔT is the difference between the temperature in the street and in the room (°C) and, R is the heat transfer resistance (°C / W / m2 or °C m2 / W).

When it comes to multi-layer construction, the resistance of the layers simply add up. For example, the resistance of a wall made of wood lined with bricks is the sum of three resistances: a brick and wooden wall and an air gap between them:

R(sum)= R(wood) + R(cart) + R(brick).

1.3 Temperature distribution and boundary layers of air during heat transfer through a wall

Calculation of heat loss is carried out for the most unfavorable period, which is the most frosty and windy week of the year.

Building guides usually indicate the thermal resistance of materials based on this condition and the climatic area (or outside temperature) where your house is located.

1.3 Table- Heat transfer resistance of various materials at ΔT = 50 °C (T out = -30 °C, T int = 20 °C.)

| Wall material and thickness | Heat transfer resistance R m , |

|---|---|

| Brick wall 3 bricks thick (79 cm) 2.5 bricks thick (67 cm) 2 bricks thick (54 cm) 1 brick thick (25 cm) |

0,592 0,502 0,405 0,187 |

| Log cabin Ø 25 Ø 20 |

0,550 0,440 |

| Log cabin 20 cm thick 10 cm thick |

0,806 0,353 |

| Frame wall (board + mineral wool + board) 20 cm |

0,703 |

| Foam concrete wall 20 cm 30 cm |

0,476 0,709 |

| Plastering on brick, concrete, foam concrete (2-3 cm) |

0,035 |

| Ceiling (attic) ceiling | 1,43 |

| wooden floors | 1,85 |

| Double wooden doors | 0,21 |

1.4 Table - Heat losses of windows of various designs

at ΔT = 50 °С (T external = -30 °С, Т internal = 20 °С.)

Note |

As can be seen from the previous table, modern double-glazed windows can reduce window heat loss by almost half. For example, for ten windows measuring 1.0 m x 1.6 m, the savings will reach a kilowatt, which gives 720 kilowatt-hours per month.

For the correct choice of materials and thicknesses of enclosing structures, we apply this information to a specific example.

In the calculation of heat losses per square. meter involved two quantities:

- temperature difference ΔT,

- heat transfer resistance R.

We define the indoor temperature as 20 °C, and take the outside temperature as -30 °C. Then the temperature difference ΔT will be equal to 50 °С. The walls are made of timber 20 cm thick, then R = 0.806 ° C m. sq. / W.

Heat losses will be 50 / 0.806 = 62 (W / sq.m.).

To simplify the calculations of heat losses in building reference books, heat losses of various types of walls, ceilings, etc. are given. for some values of winter air temperature. In particular, different figures are given for corner rooms (where the swirl of air flowing through the house is affected) and non-corner rooms, and different thermal patterns are taken into account for rooms on the first and upper floors.

1.5 Table - Specific heat loss of building fencing elements

(per 1 sq. m. along the inner contour of the walls) depending on the average temperature of the coldest week of the year.

Note |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1.6 Table - Specific heat loss of building fencing elements

(per 1 sq. m. along the inner contour) depending on the average temperature of the coldest week of the year.

2. Consider an example of calculation

heat loss of two different rooms of the same area using tables. Example 1

2.1 Corner room (first floor)

Room characteristics:

- first floor,

- room area - 16 sq. m. (5x3.2),

- ceiling height - 2.75 m,

- outer walls - two,

- material and thickness of the outer walls - timber 18 cm thick, sheathed with plasterboard and covered with wallpaper,

- windows - two (height 1.6 m, width 1.0 m) with double glazing,

- floors - wooden insulated, basement below,

- higher attic floor,

- design outside temperature –30 °С,

- the required temperature in the room is +20 °C.

Calculate the area of heat transfer surfaces.

External wall area excluding windows:

S walls (5 + 3.2) x2.7-2x1.0x1.6 = 18.94 sq. m.

window area:

S windows \u003d 2x1.0x1.6 \u003d 3.2 square meters. m.

Floor area:

S floor \u003d 5x3.2 \u003d 16 square meters. m.

Ceiling area:

S ceiling \u003d 5x3.2 \u003d 16 square meters. m.

The area of the internal partitions is not included in the calculation, since heat does not escape through them - after all, the temperature is the same on both sides of the partition. The same applies to the inner door.

Now we calculate the heat loss of each of the surfaces:

Q total = 3094 watts.

Note that more heat escapes through walls than through windows, floors and ceilings.

The result of the calculation shows the heat loss of the room in the most frosty (T out. = -30 ° C) days of the year. Naturally, the warmer it is outside, the less heat will leave the room.

2.2 Room under the roof (attic)

Room characteristics:

- top floor,

- area 16 sq. m. (3.8x4.2),

- ceiling height 2.4 m,

- exterior walls; two roof slopes (slate, solid lathing, 10 cm mineral wool, lining), gables (10 cm thick timber, sheathed with lining) and side partitions (frame wall with expanded clay filling 10 cm),

- windows - four (two on each gable), 1.6 m high and 1.0 m wide with double glazing,

- design outside temperature –30°С,

- required room temperature +20°C.

2.3 Calculate the areas of heat-releasing surfaces.

The area of the end external walls minus the windows:

S walls \u003d 2x (2.4x3.8-0.9x0.6-2x1.6x0.8) \u003d 12 square meters. m.

The area of the roof slopes that bound the room:

S rays. walls \u003d 2x1.0x4.2 \u003d 8.4 square meters. m.

The area of the side partitions:

S side burnout \u003d 2x1.5x4.2 \u003d 12.6 square meters. m.

window area:

S windows \u003d 4x1.6x1.0 \u003d 6.4 square meters. m.

Ceiling area:

S ceiling \u003d 2.6x4.2 \u003d 10.92 square meters. m.

2.4 Now we calculate the heat losses of these surfaces, while taking into account that heat does not escape through the floor (there is a warm room). We consider heat losses for walls and ceilings as for corner rooms, and for the ceiling and side partitions we introduce a 70% coefficient, since unheated rooms are located behind them.

The total heat loss of the room will be:

Q total = 4504 watts.

As you can see, a warm room on the first floor loses (or consumes) much less heat than an attic room with thin walls and a large glass area.

In order to make such a room suitable for winter living, it is first necessary to insulate the walls, side partitions and windows.

Any enclosing structure can be represented as a multilayer wall, each layer of which has its own thermal resistance and its own resistance to the passage of air. Adding the thermal resistance of all layers, we get the thermal resistance of the entire wall. Also summing up the resistance to the passage of air of all layers, we will understand how the wall breathes. An ideal timber wall should be equivalent to a 15 - 20 cm thick timber wall. The table below will help you with this.

2.5 Table- Resistance to heat transfer and air passage

various materials ΔT=40 °С (T external =–20 °С, Т internal =20 °С.)

wall layer |

Thickness layer walls |

Resistance heat transfer wall layer |

Resist. air passage permeability equivalent to timber wall thick (cm) |

|

|---|---|---|---|---|

| Ro, | Equivalent brick masonry thick (cm) |

|||

| Brickwork from ordinary clay brick thickness: 12 cm 25 cm 50 cm 75 cm |

12 25 50 75 |

0,15 0,3 0,65 1,0 |

12 25 50 75 |

6 12 24 36 |

| Claydite-concrete block masonry 39 cm thick with density: 1000 kg / m3 1400 kg / m3 1800 kg / m3 |

39 | 1,0 0,65 0,45 |

75 50 34 |

17 23 26 |

| Foam aerated concrete 30 cm thick density: 300 kg / m3 500 kg / m3 800 kg / m3 |

30 | 2,5 1,5 0,9 |

190 110 70 |

7 10 13 |

| Brusoval wall thick (pine) 10 cm 15 cm 20 cm |

10 15 20 |

0,6 0,9 1,2 |

45 68 90 |

10 15 20 |

- Heat loss through the contact of the foundation with frozen ground usually takes 15% of the heat loss through the walls of the first floor (taking into account the complexity of the calculation).

- Heat loss associated with ventilation. These losses are calculated taking into account building codes (SNiP). For a residential building, about one air exchange per hour is required, that is, during this time it is necessary to supply the same volume of fresh air. Thus, the losses associated with ventilation are slightly less than the sum of heat losses attributable to the building envelope. It turns out that heat loss through walls and glazing is only 40%, and heat loss for ventilation is 50%. In European norms for ventilation and wall insulation, the ratio of heat losses is 30% and 60%.

- If the wall "breathes", like a wall made of timber or logs 15 - 20 cm thick, then heat is returned. This allows you to reduce heat losses by 30%, therefore, the value of the thermal resistance of the wall obtained during the calculation should be multiplied by 1.3 (or, accordingly, heat losses should be reduced).

3. Conclusions:

Summing up all the heat losses at home, you will determine what power the heat generator (boiler) and heaters are needed for comfortable heating of the house on the coldest and windiest days. Also, calculations of this kind will show where the “weak link” is and how to eliminate it with the help of additional insulation.

You can also calculate the heat consumption by aggregated indicators. So, in one- and two-story houses that are not heavily insulated at an outside temperature of -25 ° C, 213 W are required per square meter of total area, and at -30 ° C - 230 W. For well-insulated houses, this is: at -25 ° C - 173 W per sq. m. of the total area, and at -30 ° С - 177 W. Conclusions and recommendations

- The cost of thermal insulation relative to the cost of the entire house is significantly low, but during the operation of the building, the main costs are for heating. In no case can you save on thermal insulation, especially with comfortable living in large areas. Energy prices around the world are constantly rising.

- Modern building materials have a higher thermal resistance than traditional materials. This allows you to make the walls thinner, which means cheaper and lighter. All this is good, but thin walls have less heat capacity, that is, they store heat worse. You have to heat constantly - the walls heat up quickly and cool down quickly. In old houses with thick walls it is cool on a hot summer day, the walls that have cooled down during the night have “accumulated cold”.

- Insulation must be considered in conjunction with the air permeability of the walls. If an increase in the thermal resistance of the walls is associated with a significant decrease in air permeability, then it should not be used. An ideal wall in terms of air permeability is equivalent to a wall made of timber with a thickness of 15 ... 20 cm.

- Very often, improper use of vapor barrier leads to a deterioration in the sanitary and hygienic properties of housing. With properly organized ventilation and “breathing” walls, it is unnecessary, and with poorly breathable walls, this is unnecessary. Its main purpose is to prevent wall infiltration and protect insulation from wind.

- Wall insulation from the outside is much more effective than internal insulation.

- Do not endlessly insulate walls. The effectiveness of this approach to energy saving is not high.

- Ventilation - these are the main reserves of energy saving.

- Using modern glazing systems (double-glazed windows, heat-shielding glass, etc.), low-temperature heating systems, effective thermal insulation of enclosing structures, it is possible to reduce heating costs by 3 times.