Hi all!

Lately I have often been asked the following questions: at what temperature should moonshine be distilled? Or, how to distill moonshine using a thermometer installed in a distillation cube? And the like.

Indeed, such questions arise in most novice distillers. Today I will try to answer these questions and tell you whether a thermometer is generally needed in a moonshine still and what it gives us.

First of all, I would like to draw your attention to the fact that this article is devoted to working on a classic moonshine still, consisting of a tank and a cooler. Or else steamer between the tank and the distiller. The thermometer is installed in the distillation cube.

For more complex equipment, different rules apply. For example, to work on a film column I have separate article.

What does a thermometer do in a moonshine still?

Now I will briefly list the advantages of this device, and in the next section I will explain how to implement them in practice.

- The ability to accurately determine the start of distillation, therefore saving on water by turning on its supply only when necessary.

- Determine the initial strength of the mash.

- Determine the current strength of moonshine at the outlet of the refrigerator, therefore eliminating the need to use hydrometers during distillation.

- Switch from body selection to tail selection in a timely manner.

- Complete the selection of tailings and all distillation in a timely manner.

- Calculate the remaining alcohol in the cube.

How to control the distillation process by temperature

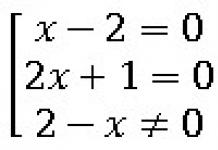

As you know, ethyl alcohol boils at a temperature of 78.4 °C (at an atmospheric pressure of 760 mmHg). But mash or raw alcohol is a water-alcohol solution ( impurities neglected), and therefore the boiling point of this solution is different and depends on the ethanol content in it. Moreover, a certain amount of alcohol in the mash corresponds to a certain amount of alcohol in the vapor entering the cooler.

Below is a table of the dependence of the boiling temperature of mash (or raw mash) on the alcohol content in it.

The tablet is simple, but I will still explain how to use it.

- When distilling mash

- Let's say you poured 10 liters of mash.

- The mash boiled and the selection began at 92 degrees, therefore the strength of the liquid is approximately 12%. Just you need to focus not on the very first drops, but when a cheerful trickle begins and the temperature stabilizes. Yesterday my first drops appeared at 88-89 degrees, but the temperature very quickly reached 93 and then began to rise very slowly - by 0.1 degrees. This is the number you need to focus on.

- We drive the moonshine to 98-99 °C, depending on your greed and patience. I usually drive it up to 98. I still don’t recommend going up to 100 degrees - the loss of product will be insignificant, but you’ll waste a lot of time and at the same time collect a lot of unnecessary impurities.

- When distilling raw alcohol

- We filled in, say, 20% sorting.

- Using the table, we determine that the boiling point of the mixture is 88-89 degrees. Therefore, there is no need to turn on the water before 80 °C and you can save it.

- In most methods, and in mine too article about distillation, it is recommended to take up to 40% of the body in the stream (or while it is burning). This corresponds to a temperature of 95-96 °C. Those. With such heating, you can proceed to the selection of tailings. Looking ahead, I want to say that according to my latest data, it is better to move on to the tails at 93-94 °C. Yes, this way we send a large amount of alcohol to the tailings, but from these tailings it will then be possible to squeeze out a decent amount of good quality moonshine. I will tell you why it is necessary to complete the selection of the body at 93 °C in one of the following articles, when I organize the information received.

- We select tails to 98-99 degrees.

Thanks to the special structure of the distillation column, it becomes possible to almost completely clean the final drink from fusel oils and impurities. Unlike distillation, the quality of the raw materials itself does not have such a key role, since there is practically no organoleptic quality in the final drink. The result is alcohol with a strength of up to 96.6% with poor organoleptic properties, but pure. It can be used to produce vodka and various liqueurs.

Let's consider the principle of the distillation column and what parts it consists of.

Distillation column, drawing

Distillation column, operating principle

Rectification is the separation of binary or multicomponent mixtures due to countercurrent mass and heat exchange between steam and liquid. The parts of the distillation column provide a sequential process:

- Evaporation cube - storage and heating of still liquid

- Column - heat and mass transfer inside the column itself due to the nozzle

- Dephlegmator - condensation of vapors, formation of reflux

- Selection unit - selection of reflux and rectified water

Let's look at the operation of each part separately.

Evaporation cube

This is a container in which mash or distillate is stored and heated. It is also called bottom liquid. When heated, the liquid evaporates, and the steam rises up the column, where it is divided into fractions. At the same time, the cube serves as the base for the column. The cube can be heated on regular or. Induction is faster and safer.

Also used as a heat source in some models.

Usually, the mash is distilled first to obtain raw alcohol. The column must be switched to distiller mode, that is, open the selection valve as much as possible. After this, the raw alcohol is distilled again, this time slowly and with the selection of the food fraction.

A thermometer is located on the cube to monitor the temperature of the still liquid. When the cube reaches 60-70°C, it is necessary to supply coolant so that the vapors can condense. When reaching 70°C, the power of the heating element must be reduced and left at this value until rectification is completed.

Tsarga

The drawer is the body of the column, its central part. Heat and mass transfer, which is the operating principle of the distillation column, occurs here. It is this that makes the rectification process possible:

- The liquid in the cube evaporates and steam rises up the column

- At the top there is a reflux condenser (refrigerator), in which the steam is condensed

- The distillate flows down the reflux condenser and along the walls of the column

- The liquid comes into contact with the steam on the walls of the nozzle with which the column is filled

- As a result of heat and mass transfer, the lowest boiling fraction accumulates in the upper part of the column

- The low-boiling fraction condenses in the refrigerator and enters the selection channel.

A column can be assembled from several frames. The higher the column, the more intense the heat and mass transfer, and the cleaner the liquid is separated into fractions. Inside the column is filled with a nozzle: SPN or RPN. Without a nozzle, heat and mass transfer is impossible.

To speed up the rectification process, you can use. The walls of the column are heated, so phlegm, which is not in contact with the nozzle, evaporates from the walls. As a result, the process is accelerated and the degree of purification increases.

Additionally, they can be used with a column. On its surface, heat and mass exchange also occurs between hot steam and cold phlegm. The degree of purification is increasing.

Rectification attachment

The rectification nozzle is a universal tool that consists of a selection unit and a refrigerator. In the refrigerator, condensation of alcohol vapor occurs, which returns down in the form of phlegm. The selection unit allows you to control the amount of alcohol that comes out of the column. By controlling this volume, you can change the quality of the alcohol, that is, the degree of its purification. The slower the process, the purer the alcohol turns out.

The nozzle can be purchased ready-made or separately.

Alcohol selection unit

Used to improve cleaning quality

Automation for distillation column

Rectification requires constant monitoring to ensure that the head and tail fractions do not end up in the food part. This process can be facilitated using BUR - a rectification control unit. The block will limit the selection of rectified product in accordance with a given program so that the tail part does not mix with the food product. This way you can move away from the column without fear that the tails will end up in the clean rectified material.

BUR is an optional part of the distillation column, but it is much more convenient to work with it.

What's next

The resulting rectified alcohol will have a harsh taste. The alcohol must be diluted, filtered and allowed to brew. You can use alcohol to clean it, it's called. As a result of carbonization, the alcohol acquires a milder taste, the coal binds the remains of fusel oils, which in small quantities penetrate into the drink even during fractional selection in the distillation column. This is how classic Russian vodka is prepared.

After sorting (diluting) and charcoaling, the alcohol needs to rest in a glass container for several days.

Read more about the design and operation of the distillation column in the corresponding product card.

Instructions on how to clean moonshine as much as possible from harmful impurities, that is, do fractional distillation - separate the “heads,” “body,” or “heart,” and “tails.”

The body is the same drinking fraction, the purer you select it, the higher the quality of the final product.

Heads are the lightest-boiling non-potable fraction (the boiling point of acetone is from 50 degrees Celsius), you cannot drink it (consists mainly of acetones, methanols, ethyl acetates)

Tails are popularly known as fusel, also not a tasty and smelly fraction, we try to prevent it from getting into our final product. In some cases, moonshiners deliberately allow the tails to enter the body, this is done to increase the aromatic properties. But to do this, you need to understand all the processes in more depth.

How to select these fractions in practice?

Reflux is a selection product in a rectification unit or distiller. In moonshine, it is an alcohol-containing liquid.

1. Place the device on the stove (it is best to use (if the device is suitable) or gas), turn on the heating at maximum power. from the outlet of the refrigerator we direct it into the receiving container.

2. When the tank temperature reaches 75 degrees Celsius, turn on the cooling water flow. We check that water flows through the cooling jackets of refrigerators and is drained freely into the sewer.

IMPORTANT: The supply of coolant to any refrigerator must proceed from the bottom up to avoid the effect of airing!

3. Use a thermometer to monitor the increase in temperature in the cube. Braga boils at a temperature of about 85 C, water-alcohol solutions - at 78-90 C, depending on the alcohol content in them. When the temperature approaches the boiling point, it is necessary to reduce the heating to select the head fractions.

Distillate - here: a water-alcohol mixture, a product of distillation of mash or other alcohol-containing liquid in a distillation (moonshine) still. It could be 1st, 2nd, etc. distillate. distillation.

4. After reflux begins to drip into the receiving container (preferably with a narrow neck to reduce the evaporation of high-alcohol reflux), you need to adjust the heating power input and the flow of cooling water through the refrigerator. It is necessary to ensure that the head fraction comes out at a low speed, approximately 1 drop per second.

5. We select the head fraction in an amount corresponding to approximately 10% of absolute alcohol from its total amount in the cube.

Absolute alcohol = 100% alcohol in reflux. (Important! During the first distillation, it is not necessary to select the head fraction!)

EXAMPLE: a cube contains 15 liters of mash with an alcohol content of 10%, i.e. the total amount of absolute alcohol is 1.5 liters. Calculation 1500 ml / 100 X 10 = 150 ml. Although absolute alcohol cannot be achieved at home, the calculation of the selection of the head fraction is made from it. Therefore, it is important to use high-precision measurement equipment, we advise.

6. We change the receiving container and begin the selection of the middle fraction of the distillate (“body”). The power of the heater can be increased, and the flow of water through the refrigerator can be selected based on the power of the refrigerator itself; the phlegm should come out cold. The refrigerator itself should not choke, i.e. The liquid in it should not boil.

We periodically measure the strength of the distillate using a hydrometer.

13. Next, we select the “body” according to point 6. For devices with a “steam tank” intermediate cleaning system, we keep the temperature on the thermometer at the upper point of steam evaporation during selection in the range of close to 90-96 C and monitor the strength of the selection. Below 50% selection should be stopped. Towards the end of the body selection, slowly reduce the heating power, the temperature may return to normal, in which case the selection can still be continued. But the selection rate will also decrease.

14. We complete the work by selecting the body according to point 8. If you have a device with a steam chamber, then it is not advisable to select the body of the second distillation below 50% alcohol content in reflux. If you have a device with precooling, a strengthening column, then the alcohol content of the phlegm in this case will be higher than in a device with a steam chamber, here you need to navigate by the lower thermometer, 96-97 degrees - this is a signal that you need to stop. If a device with precooling or a reinforcing column does not have a lower thermometer, then look at the upper thermometer, it should not read more than 90-95 degrees!

Total: We got three factions - “heads”, “body”, “tails”.

16. THE DRINK IS READY!

FOLLOW TECHNOLOGY AND YOU WILL UNDERSTAND WHAT REAL QUALITY IS!

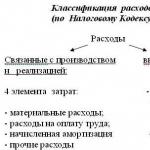

Along with water and alcohol, mash contains other substances, many of which are harmful to the body. Fortunately, their boiling point is higher or lower than that of ethyl alcohol, so using fractional distillation (separation into fractions) you can prevent most dangerous impurities from entering the finished product. We will look at methods that allow you to select the correct number of tails and heads of moonshine, which will have a positive effect on the quality of the distillate.

Attention! The information is relevant only for a conventional moonshine still, consisting of a distillation cube and a coil-shaped refrigerator; it is also possible to have a steamer. For devices with reflux condensers and other devices that simulate the operation of a distillation column, the parameters for selecting tails and heads may differ from those set out here. I advise you to clarify this point with the circuit designers, manufacturers or equipment sellers. I do not advise on commercial models of devices.

The amount of harmful impurities depends on the raw materials, water, yeast, temperature, duration of fermentation, design of the moonshine still and distillation technology. Even in mash according to the same recipe, the concentration of harmful substances can change every time, but at home, analyzing the composition of mash is impossible, so you have to take approximate values as a basis.

"Head" of moonshine(also called “pervach” or “pervak”) - the initial fraction with a sharp unpleasant odor. Contains the most dangerous impurities: methyl alcohol (a lot in grain and fruit mashes), acetone, acetaldehyde and others. Due to the fact that the boiling point of harmful substances is lower than that of ethyl alcohol, during distillation they come out first, therefore, they can be prevented from getting into the main product.

In everyday life, pervach is considered the highest quality moonshine, since it is strong and quickly intoxicates. In fact, it is poison in its pure form; its consumption causes toxic poisoning, which is often confused with intoxication.

Heads are the strongest

Heads are the strongest The moonshine head should not be drunk or used for rubbing. This fraction can be used exclusively for technical needs, but due to the unpleasant odor, in most cases it is simply thrown away.

"Body"– the drinking part, the main goal of the moonshiner (the second name is “heart”). In theory, it contains only ethyl alcohol and water, but in practice there are always other impurities in the “body”, since during distillation it is physically impossible to divide the yield into clear fractions; to one degree or another, different substances with similar boiling points are always mixed, the yield is “ lubricated."

For complete decomposition into fractions, rectification is needed, thanks to which pure ethyl alcohol can be obtained. The disadvantage of this method is that, along with harmful impurities, substances responsible for the organoleptic properties of the drink are removed.

This means that after rectification, the taste and smell of moonshine made from different raw materials (sugar, grain and fruit) will be the same, since only ethyl alcohol will remain in the drink.

It should be remembered that the harm and benefits of many substances in the distillate are relative. For example, fusel oils cause the liver to become active before alcohol begins to act, this protects the body from the harmful effects of alcohol.

A study by Vladimir Pavlovich, professor of the Research Institute of Narcology of the Ministry of Health of the Russian Federation, proved that rectified alcohol (vodka) causes alcohol addiction many times faster than distillates - whiskey, cognac, tequila, etc. About 70% of addicted people are vodka alcoholics. The purer the poison (in our case, ethyl alcohol), the faster the addiction develops.

Correct division of moonshine into fractions during distillation on a classic moonshine still allows you to remove almost all harmful substances, but leave those that are responsible for the aroma and taste of the drink, which cannot be done with rectification.

"Tail" of moonshine– the third fraction, in addition to ethyl alcohol, contains fusel oils, which give an unpleasant odor, taste and cloudy color. The boiling point of fusel milk is higher than that of ethyl alcohol, so in order to separate the tail of moonshine, it is enough to stop collecting the main product - the “body” - in time.

Although after distillation a lot of ethyl alcohol remains in the “tails” (up to 40%), the ingress of other substances with it spoils the quality of the moonshine, which is why it is so important to complete the distillation on time.

Tailings can be recycled, but it's usually not worth the energy.

Tailings can be recycled, but it's usually not worth the energy. Unlike the “heads,” the “tails” are recyclable; they can be added to a new batch of mash (immediately before distillation) or purified in a distillation column. It is useless to distill the “tails” a second time in a moonshine still; it will not improve the quality!

The question of how many “heads” and “tails” to select is a compromise between the quantity and quality of moonshine. Further we will use the “golden mean” - parameters tested by more than one generation of moonshiners. You can change them at your discretion in one direction or the other. Further I will pay attention not to specific numbers, but to methods of calculation.

How to take the head of moonshine

First, the mash is brought to a boil. When the first drops appear, the power is reduced to a minimum, then the heating is gradually increased again so that the device reaches operating mode. Performance depends on the design and power of the stove; there are no average parameters here. It is considered normal when the moonshine comes out cold (the temperature is approximately equal to the temperature of the cooling water). This is what we need to strive for.

Head separation methods:

1. On sugar. The simplest, but at the same time effective method. Suitable if the sugar content of the mash or the amount of added sugar is known. In fruit or grain mash, sugar content is determined by a special device - a vinometer (hydrometer-saccharometer) before adding yeast.

For example, there are 5 liters of mash with a sugar content of 20%, this means that the total sugar content is 1 kg (5 * 0.2 = 1). The calculation assumes that 1 liter of solution is equal in weight to 1 kilogram, in practice this is not the case, but the error itself has little effect on the result, and it simplifies the calculation significantly, so I advise you not to “bother.”

From 1 kg of sugar, 60-100 ml of heads are taken. It is advisable to divide this amount into two distillations, taking 30-50 ml of the yield during the first distillation and the same amount during the second.

2. For pure alcohol. It is not always possible to determine the sugar content before fermentation begins. In this case, the first distillation is done without cutting off the “heads”, then the amount of absolute alcohol is measured. For example, if you get 6 liters of distillate with a total strength of 63%, then it contains 3.78 liters of pure alcohol (6*0.63=3.78). To simplify the calculations, we take the strength of ethyl as 100%, although absolute alcohol can only be obtained in laboratory conditions.

During the second distillation, the head fraction is cut off at the rate of 8-15% of the amount of pure alcohol. In our example, this is 0.567 liters (3.78*0.15=0.567).

One of the variations of this method is the selection of 1% of heads from the volume of mash, but for various reasons related to fermentation and sugar concentration, this method cannot be considered accurate; it is better to focus on absolute ethyl.

3. By smell. Suitable for experienced distillers who can identify moonshine heads by their unpleasant smell.

The distillate coming out of the apparatus is periodically sniffed, rubbing a couple of drops in the palms, when the pungent smell disappears, they begin to select the “body”. This is a good way to check the accuracy of calculations based on sugar or alcohol.

4. By temperature. Due to the design features of moonshine stills and the different composition of impurities, this method does not always work well in practice. I recommend using it only as a last resort. I bring it here for your reference.

The evaporation temperature of the “heads” is 65-68°C. During distillation, when the temperature reaches 63°C (the thermometer should be at the entrance to the refrigerator), the heating power is sharply reduced in order to smoothly reach the above temperature range. Next, the “heads” are selected while drops flow from the apparatus. When the output stops, raise the temperature to 78°C and take the “body” to a temperature of 85°C. The values are approximate and may differ depending on the device!

How to separate tails in moonshine

Evidence of the appearance of tails is a drop in strength in the stream to 30-45 degrees. In order not to miss this moment, it is advisable to collect the moonshine coming out of the still into a flask or small jar near the end of the distillation, in which you can simply take a measurement with an alcohol meter (the liquid temperature must be 20°C). If the strength is high enough, pour the distillate into a common container and place the jar again.

During the first distillation (especially fruit and grain mashes), you can collect the “body” until the distillate degree drops below 30%. At the same time, the moonshine sometimes becomes cloudy, but it’s okay; a second distillation, in which the beginning of the tails is considered to be 40% strength, will correct the problem.

Most moonshiners prefer to consider anything that has a strength below 40 degrees to be moonshine tails. If there is no alcohol meter, the moonshine is taken until it burns in the spoon.

When the yield strength drops below the minimum, distillation is stopped by stopping the heating, or tailings are continued to be collected up to 15-20%, but this wastes energy and time, which in most cases is not worth it.

1 of 13

Presentation on the topic: Thermal movement. Temperature

Slide no. 1

Slide description:

Slide no. 2

Slide description:

Thermal movement. Temperature We begin this academic year by studying a new section of physics devoted to thermal phenomena. Thermal phenomena include heating and cooling of various bodies, melting, evaporation, boiling, melting of substances, etc. The words “warm”, “cold” have long been familiar to us. , “hot” mean the thermal states of bodies. The quantity characterizing the thermal state of bodies is temperature.

Slide no. 3

Slide description:

Features of the movement of particles that make up bodies Repetition. Answer the questions: The main provisions of MCT (and their experimental confirmation) What is diffusion? How does the diffusion process occur? What explains the increase in the rate of diffusion with increasing temperature?

Slide no. 4

Slide description:

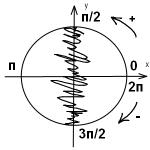

Thermal movement. Temperature Thermal motion is the random movement of the molecules of a substance. In liquids and gases, molecules move randomly, colliding with each other. In solids, thermal motion consists of oscillations of particles around an equilibrium position. Body temperature depends on the speed of movement of molecules. The faster the molecules move, the higher the body temperature. Let us pay attention to the fact that thermal motion differs from mechanical motion in that a lot of particles are involved in it and each one moves randomly.

Slide no. 5

Slide description:

Source of information about temperature From life experience we know that different bodies can be heated to different degrees. However, the sensation of heat and cold is a subjective factor. Let's check this experimentally. ! ? ! Conclusion: it is impossible to judge temperature using sensations!

Slide no. 6

Slide description:

Thermometer So, we have a problem: we need to find such a sign or such a property of bodies that would clearly indicate how the body is heated. Such a sign may be the expansion of bodies when heated. The hotter the body, the larger its volume, the more intense the chaotic movement of molecules and atoms. A device that uses this property of bodies is a thermometer. From the Greek “therme” - heat and “metreo” - I measure. A liquid thermometer is a device whose operating principle is based on the use of the thermal expansion property of a liquid. Depending on the temperature region, the liquid thermometer is filled with mercury, ethyl alcohol and other liquids. Any thermometer shows its own temperature. To determine the temperature of a medium, the thermometer must be placed in this medium and wait until the temperature of the device stops changing, taking a value equal to the temperature of the medium.

Slide no. 7

Slide description:

Celsius temperature scale The Celsius temperature scale was proposed in 1742 by the Swedish scientist A. Celsius and named after him. The melting temperature of ice is taken as zero degrees Celsius, and the boiling temperature of water at normal atmospheric pressure (760 mm Hg) is taken as 100 degrees. The interval between these temperatures is divided into 100 equal parts of 1 degree Celsius (1°C).

Slide no. 8

Slide description:

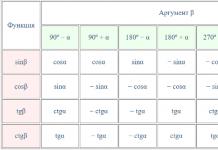

Temperature scales Other temperature scales are used in practice, such as the Kelvin scale and the Fahrenheit scale. The relationship between the Celsius scale and the Kelvin scale can be seen in the figure. To measure temperature, various substances (mercury, alcohol) are used, which change their volume with changes in temperature.

Slide description:

The physical meaning of temperature In a body with a higher temperature, molecules move faster on average. The temperature of a substance is determined not only by the average speed of movement of molecules, but also by their mass. Temperature is a measure of the average kinetic energy of the particles of a body.

Slide no. 11

Slide description:

Laboratory work: “Measuring body temperature” Purpose of the work: establishing a connection between body temperature and an increase in the kinetic energy of molecules. Equipment: thermometer. Progress of work1. Hold the thermometer in your fist so that you can see the temperature value on the scale.2. Observe the rise in the column of mercury (alcohol). Answer the questions in writing: 1. Why does the column of mercury (alcohol) rise up?2. When will the column of mercury (alcohol) stop?3. What does a thermometer measure?4. Is it possible to remove a thermometer from the environment whose temperature is being measured? Why?5. What can be said about the magnitude of the kinetic energy of mercury (alcohol) molecules when the column rises?6. What device did you use to determine body temperature?7. What is the division price of this device?8. What minimum (maximum) temperature can be measured with this device?

Slide no. 12

Slide description:

This is interesting to know * Various mammals have a normal temperature from 35 to 40.5 ° C; * The temperature of birds is 39.5 - 44 ° C; The highest air temperature on Earth is 58 ° C, the lowest is - 88.3 ° C; Temperature the surface of the Sun is about 6000°C; At a temperature of 42°C, the blood does not absorb oxygen from the air, and a person dies from oxygen deficiency. The natural temperature of a person’s body cannot be lower than 34°C. It is sometimes artificially lowered to 26°C and then the body falls into a state of suspended animation. Life processes in it slow down. Instead of 16 breaths per minute, a person takes only 4, the pulse drops from 70 to 25 beats per minute. Bears, badgers and many other animals are in a state of suspended animation in winter.

Slide no. 13

Slide description: