Recently, the demand for all types of construction work has increased significantly. The reason for this is the constant desire for change. Some acquire new housing, others create a unique design. Construction and installation work, which will be discussed in the article, includes a huge range of activities. We will talk about them today.

Types of jobs

First of all, construction and installation works are divided into actions related to general construction and special manipulations. General processes include the following types:

- earthen;

- concrete or reinforced concrete;

- stone;

- finishing;

- carpentry;

- roofing.

Special events include:

The volume of construction work directly depends on the purpose and expected result. The more global the construction, the greater the volume will be.

Depending on how many processes are performed by machines, there are:

- fully mechanized work,

- partially mechanized,

- manual labor.

Types of construction work can also differ in the complexity of their implementation. Simple are those that can be carried out by one person or a small group of builders. At the same time, the processes are logically connected with each other according to the specifics of execution. Difficult consider those works in which a large number of people are involved, as well as various construction equipment. However, there are cases when a complex of simple manipulations is performed in the same way.

Home construction

If you are planning to build a house, then you will have to master all types of construction work. This happens in stages.

- The first thing it all starts with is the earthen processes, during which the foundation is being built, walls are being erected, and the basement floor is being made.

- The second stage of construction is work already above the ground, namely: installation of structures, laying walls from the selected material, construction of openings, manipulations with wood and roof.

- The third and final stage is the decoration of the house. At the same time, you are working with wiring and all electrical equipment in the room.

Overhaul

Repair and construction works are divided into two categories: capital and current. What is meant by these concepts? The need for a major overhaul of the building, first of all, is indicated by its appearance. It's not just scuffs and minor problems. As a rule, this is global destruction, collapses and strong faults.

Works that are classified as major repairs:

- restoration of the destroyed parts of the building, house, apartment;

- global restructuring and replacement of the main structures;

- strengthening of the elements that have become unusable.

Maintenance

The current repair is also a repair and construction work, but in terms of volume, such processes are much smaller and do not cover much of the area involved. Moreover, such orders are cheaper. It is worth saying that the prices for construction work completely depend on the volume and complexity of the process being performed.

The need to carry out maintenance appears much more often than the need for capital work. A person's need to live in comfortable conditions tells him when it's time to make an upgrade.

Types of construction work that are classified as current repairs:

- partial replacement of elements of the floor, walls, roof and other places;

- wall correction;

- door repair;

- change of wallpaper, parquet, linoleum;

- painting walls, floors, ceilings;

- work to eliminate cracks, cracks, leaks.

building materials

The quality of construction work largely depends on the qualifications of the master. However, the final result, that is, the external beauty and reliability of the structure, depends on the choice of material. In the modern market of construction products, there is a huge number of various companies offering their services. Sometimes it is difficult to choose high-quality material on your own, so trust the advice of experts. It is best if the choice is made directly by the executor of the order. This way you can file a claim at the end of the process. Otherwise, it will be difficult to do so.

Let us give an example of the choice of material for housing construction. For example, if you decide to build a house out of wood, then at your service:

Each of the materials has its own advantages and disadvantages. And the choice should be made by someone who knows all the features of the process and the purpose of construction. But these types of bricks are available for those who build a stone house:

- ceramic;

- silicate;

- facing;

- facade;

- furnace.

Already by the name it becomes clear for what purpose the brick was made, but still there are nuances in terms of manufacturer and quality. It happens that the same material from different manufacturers is fundamentally different from each other. Be careful when choosing such products, because this is half the success in construction.

Finishing

Construction and finishing work is the creation of a kind of "soul" of the room. It is at this stage that it acquires its final form. In some cases, all the work, including finishing the premises, is performed by the same contractor, but sometimes it becomes necessary to find another contractor. In the course of finishing, the flooring is being manipulated, wallpaper is being pasted, walls are being painted, work is being done with stone and wood. Using high-quality material, you guarantee yourself a unique look of housing. In addition, you need to think about its strength and safety.

Design

Describing the types of construction work, we sooner or later approach the design of the premises. This is a special science, accessible to not many people. The presence of finances and desire does not mean the presence of taste. Therefore, when developing a room design, we recommend that you seek advice from specialists if you are not sure of a good result. A professional will carefully analyze all the features of your premises and develop the option that will look best for you.

There are many design secrets. One of them is the process of selecting the color scheme of the room. Shades are of great importance in design. They show or hide flaws. Here are some examples:

- in a room that is constantly in the sun, it is better to use cold tones: blue, blue-green, blue-violet;

- on the north side, it is better to give preference to warm tones: red, yellow, orange;

- white, gray, black colors are considered neutral, so they can be used in any room;

- it is important to maintain color - colors that combine with each other, otherwise the room will look awkward;

- when combining colors, you can follow two directions: contrast and nuance. The first is acceptable for the kitchen, living room, hallway, and the second, more calm, suitable for bedrooms, nursery.

The mood of the people living in it depends on what design of the room you choose. This has been proven by scientists.

Style

When discussing construction and finishing works, one cannot ignore such a topic as the style of construction. After all, when a person plans to build a house, the first thing he imagines is how his housing will look like. What are the current styles of houses?

In many ways, the style of the building depends on the financial capabilities of the customer.

Rates

Construction work rates vary depending on the contractor and the complexity of the process. Each company has a price list with prices. Before placing an order, read all the documents and clarify the details. It is very important to find out the reasons for which the prices for the performance of certain works may be increased. It is best if the cost of the entire order is indicated initially. Then at the end of construction you will not expect an unpleasant surprise.

And lastly, work only with trusted companies. Nowadays, there are a lot of scammers or simply unskilled workers. The ideal option would be if you act on the recommendation.

Speaking about the construction of buildings, roads and repair of facilities, we mean the implementation of a whole range of activities and actions that lead to the desired result, namely, a new building or a repaired road. Construction and installation works (hereinafter referred to as construction and installation works) are just that main part of the construction industry, without which it is impossible to carry out a major overhaul of premises, or to erect new buildings.

Decryption of construction and installation works

A fairly broad definition is understood as a variety of works that differ from each other in the direction of action and means of execution. If we give a general definition of the concept, then the decoding of construction and installation works will look like this - this is a set of actions for the construction of new facilities (buildings, structures), their repair and reconstruction, as well as the installation and installation of equipment. One company simply cannot do all the work, since the scale of the tasks set for it will be simply enormous. Therefore, in the construction market there are organizations whose activities have a narrower specialization. For example, there are companies engaged only in the construction and repair of roads, or firms building industrial facilities.

Types of construction and installation works

There are several main types of such work:

- general construction;

- transport and handling (delivery of materials, devices and equipment);

- special (with a special type of material).

The most diverse is the construction activity. It consists of:

- excavation (digging holes, trenches, pits), pile (driving, installation of pile foundations) and stone works (building walls, laying stone, etc.);

- roofing (arrangement of attic spaces, roofs), plastering (painting, pasting) and insulating;

- devices of floors, and communications;

- works on the installation of wooden, concrete and reinforced concrete, light enclosing structures;

- arrangement of the territory;

- work on the installation of technological equipment;

- and etc.

In order to finally understand what decoding of construction and installation works is, you need to understand what all types of the above works include.

Features of construction and installation works

Each area of activity has a number of features and nuances. For construction and installation works, the most important criterion is quality, which completely depends on the professionalism of employees, the competent organization of the process and the interaction of the system links with each other. At the beginning of work, the set goals and objectives, planning and control are of great importance, and the end result is the competent and high-quality production of construction and installation works. After all, the safety of people depends on this.

Getting the desired result is greatly influenced by the correct preparation and organization of the process. Making mistakes or miscalculations can be costly for the contractor company in the literal and figurative sense of the word. Correcting defects in construction can cost a human life. Plus, it's always quite expensive. It should also be understood that when calculating construction and installation works, the use of unverified or low-quality materials, as well as unreasonable savings on mandatory cost items, is not allowed. In order to take into account all the features of construction, it is necessary to carry out all the work in stages.

Order of conduct

Deciphering construction and installation works will include the competent and consistent implementation of all stages of construction activities.

For example, before the construction of new facilities, it is first necessary to carry out geological studies of the soil of the site. It is possible that before construction begins, it will be necessary to drain the swamp or carry out drainage work to avoid flooding.

After that, you can start drawing the outline of the foundation. This is usually done with wire, wooden pegs and rope. Next, you need to dig a trench to lay the foundation of the future building. After you can proceed to the construction of walls. If a wooden building is planned, then the drafted project should be strictly adhered to. Stone walls have their own rules - for example, laying the stone strictly horizontally, dressing the seams and pouring with mortar.

After that, attic floors are laid out, windows, attics and rafters are mounted, it all depends on the number of floors of the building and the complexity of the construction. Next, the roof fronts are closed and the roofing material is laid. The next step is the finishing work (external and internal), then the installation of equipment (plumbing, heating systems, etc.)

The volume of construction and installation works largely depends on the tasks set. For example, one company can be directly involved in the construction of an object, but they trust another organization or do it on their own.

Organization of construction and installation works

Various subjects are necessarily involved in the process of erecting buildings and structures: designers, surveyors, equipment suppliers and customers. In order for the construction and installation process to be systematic, special attention should be paid to the organization of work.

It is better to clarify all questions on construction technology with representatives of construction and installation organizations and specialized trusts that prepare projects.

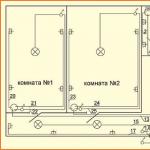

Usually the project contains a schedule of works, a general construction plan, according to which the terms of the work of the performers are calculated and all the volumes of construction and installation work are shown. In addition, this document indicates the location of the building under construction and construction sites, water and energy supply schemes, as well as the amount of materials, products and construction machines used. For complex buildings, technological maps are used, which prescribe special safety requirements, main stages, construction technologies, etc.

The organization of production of construction and installation works is very important, because it depends on it in what rhythm assembly, carpentry and other types of work will be carried out.

What is an estimated cost?

The level of quality of ongoing construction activities largely depends on the amount of the allocated budget for construction. Therefore, such a concept as "estimated cost of construction and installation works" plays a decisive role in the workflow. It is the official confirmation of project funding. It reflects all the final figures.

Calculation of construction and installation works

Jobs are fairly easy to calculate. It is necessary to add up all direct costs (the cost of materials, wages of workers, etc.), overhead costs (administrative and economic, etc.) and planned savings. The last component is otherwise called the estimated or standard profit of the construction organization.

Construction and installation works are the most important stage of construction. Only with competent and qualified planning and organization of construction and installation works, it is possible to achieve the desired result with minimal effort, money and time.

TO Category:

Pipelay Cranes

-

The main types of construction and installation works and methods for their implementation

General information. The main types of construction and installation works in the construction of the linear part of the main pipelines are preparatory, loading and unloading and transport, welding and installation, earthworks, insulation and laying and ballast works, as well as the construction of crossings through natural and artificial obstacles, cleaning the cavity and testing pipelines. These types of work are performed by mechanized methods.

The main mechanisms for performing linear construction and installation works, with the exception of preparatory work, are pipelayers.

Preparatory work on the route of the pipeline under construction is carried out in advance, significantly ahead of other types of construction and installation work.

The preparatory works include the following: restoration and fixing of geodetic signs; clearing the construction strip from forests and shrubs; lane layout; arrangement of temporary roads and access roads to the highway; installation of drainage structures for draining the construction strip.

During the construction of pipelines in mountainous conditions, the preparatory work also includes the removal of overhanging stones and rocks, protective anti-landslide and anti-landslide measures, overburden work, the installation of "shelves", cutting steep slopes, the installation of anchoring machines, the arrangement of entrances to the pipeline route at the locations of "shelves", tunnels, installation sites, the installation of culverts and other works.

In winter, in addition, measures are taken to ensure minimal (in the zone of trench digging) or maximum (in the zone of passage of mechanisms) soil freezing, construction of winter roads and ice crossings across rivers and watercourses.

Preparatory work begins with the restoration and fixing of geodetic signs that determine the position of the axis of the pipeline and temporary structures. This is necessary for transferring to the area from the technical design the dimensions of the width of the construction strip, the location of the shut-off valves, etc., as well as for the production of layout work. Geodetic signs are fixed with outrigger poles or stakes, which are located outside the construction strip in order to preserve them for the entire period of construction.

After the restoration and fixing of geodesic signs in the forested areas, they begin clearing the construction strip, which includes the following operations: felling trees and cutting branches, forming a cart and hauling whips to stacks, crosscutting, picking branches, uprooting stumps, backfilling holes and leveling irregularities. The clearing of the construction strip is started after receiving a logging ticket (order). Work on clearing the forest is carried out by integrated teams. Trees are felled with gasoline-powered saws or logging machines, stumps are uprooted by rooters, and pits are filled in and the terrain is leveled with bulldozers. The construction strip is cleared of bushes and undergrowth with bulldozers, brush cutters and feller bunchers.

Temporary roads are constructed for the passage of construction vehicles and vehicles during the construction of main pipelines in swamps, wetlands, on fine, highly moistened soils and in areas with permafrost and subsidence soils.

The main structures of temporary roads are plank and winter. Lay roads are a flooring of logs with a diameter of 14...20 cm, which is laid on longitudinal logs (beds) with a diameter of 18...25 cm and a length of 6...8 m, placed at a distance of 1...1.5 m from one another. Along the edges of the roadway, clamping logs are laid, which are fastened to the beds with a wire twist. A layer of peat 5–10 cm thick and draining soil at least 20 cm thick are poured on top of the flooring. A layer of poured peat and soil protects the log flooring from destruction by tractor tracks.

Winter roads are arranged along the route in the first winter months with the onset of frost. The winter road is a strip cleared of forest vegetation and leveled with compacted snow cover and frozen ice cover. When winter roads cross rivers and streams, ice crossings are arranged.

Temporary roads are built by specialized teams equipped with bulldozers, truck cranes, single-bucket excavators, flatbed trucks, dump trucks, motor graders, rollers and watering machines.

To divert surface water from the construction strip on watered sections of the route and lower the groundwater level, longitudinal ditches are torn off, to which, depending on the degree of watering of the area and the inflow of groundwater, transverse drainage ditches are laid to discharge water into the underlying water intakes (rivers, lakes). With difficult terrain, in areas with significant slopes, upland ditches are arranged. Drainage and upland ditches usually tear off a trapezoidal profile with a depth of 0.8 ... 1.2 m (after soil settlement) depending on the intensity of water inflow and a bottom width of up to 0.5 m.

At the intersections of pipelines being laid with roads, streams, small rivers, irrigation canals, culverts are arranged in the form of reinforced concrete trays or pipes.

To drain the bottom of the trenches with a small influx of groundwater, an open drainage system is used, i.e., water is pumped out by self-propelled drainage installations immediately before the pipeline is laid in the trench and backfilled.

They plan a construction strip for the unhindered movement of construction equipment and vehicles. When planning, the microrelief is leveled, longitudinal and transverse slopes are cut, low-lying places are poured. The layout of the microrelief is carried out on the construction strip in the area of trench digging by rotary trench excavators. This is necessary to level the bottom of the trench and eliminate additional stresses in the pipeline, since the bottom of the trench dug by a rotary trencher copies the surface topography. The microrelief is planned by bulldozers 2 (see Fig. 1) with longitudinal passages along the axis of the construction strip.

The layout of the construction strip in conditions of rugged terrain includes cutting longitudinal and transverse slopes, as well as backfilling low-lying places. At the same time, the soil cut from local elevations is moved, if necessary, to lower places. Deep lowlands with a shortage of cut soil are sprinkled with soil developed from the lateral reserve.

On slopes with a transverse slope steepness of more than 8 °, in order to enable construction work and the passage of construction equipment, a working strip (“shelf”) is arranged, the width of which depends on the transverse dimensions of the pipelayers as the most overall of the construction machines and the diameter of the pipeline, but not less than 8 m, including the bulk part. When arranging "shelves", the soil is developed by bulldozers and single-bucket excavators. Rocky soils are preliminarily loosened in an explosive way.

Loading and unloading and transport works. After preparing the route for construction and constructing temporary roads, they begin to transport pipes and building materials from the points of their receipt to pipe welding bases, construction sites, temporary warehouses and work sites.

Pipes arriving at the railway station are stored in a transshipment warehouse during unloading, in piles, or loaded directly onto pipe trucks.

Pipes are stacked in stacks with a height of no more than 8 m on a planned horizontal platform. The lower row of pipes is placed on linings of round wood with a diameter of at least 200 mm. Stops are made at the ends of the linings so that the pipes do not roll out.

Pipes are unloaded from wagons by truck cranes into stacks. Pipes from stacks are loaded with the same cranes onto pipe trucks for transportation to pipe welding bases. For transportation of pipes, pipe carriers based on off-road vehicles are used.

At pipe welding depots, pipes are unloaded from pipe carriers by pipelayers, who take one or more pipes at one time, depending on the mass of the pipes and the load capacity of the pipelayer.

In the northern regions of the country, pipes and other building materials are delivered to the construction site by water - on cargo ships, river barges, dry-cargo platform barges, and also on deck barges made of universal pontoons. Special piers are built for unloading pipes and cargoes. Pipes and cargo are unloaded using floating cranes, truck cranes or pipelayers.

Welding and installation work. At the construction of main pipelines, the basic scheme for the production of welding and installation works is used. According to this scheme, pipes with a length of 10.5 to 12 m entering the pipe welding bases are unloaded by a pipe layer and subjected to pre-assembly on mechanized lines.

The pipe welding base consists of an assembly rack with centering conductors and internal centralizers, a welding bench with a rotator and welding equipment. At these plants, pipes are welded in sections 24–36 m long, which are then transported to the route by lash trucks and laid out by pipelayers along the future trench for welding into a continuous pipeline string.

On the route, pipe sections are welded together mainly by manual arc welding. The electric current for welding on the track is generated by a welding generator.

Welding on the track is carried out by two methods: elementary and in-line.

With the first method, the team of welders is divided into two links: one of them welds the first (root) layer, the other - the subsequent ones. This method is most often used in the construction of pipelines with a diameter of up to 530 mm.

The flow method is used when laying main pipelines with a diameter of 1020 ... 1420 mm. This welding method is divided into flow-group to flow-dissected. When using the flow-group method, construction and installation work is performed by a team, the units of which unload and prepare pipe sections for assembly; carry out heating and welding of the first and second seams, as well as filling and facing layers. The flow-dissected method provides further dissection of the process of welding pipe joints into separate technological operations. Each link welds one (certain) section of each joint. With the flow-dissected method, the team is completed from the following units: unloading pipe sections and laying out along the route; preparing them for welding and preheating; assembly performed together with welding of the root layer; hot pass;, welding of filling and facing layers.

The team that performs welding and installation work on the highway is equipped with pipelayers, bulldozers, welding machines, an internal centralizer, a propane heater, tongs, and a gas cutting machine.

When welding a pipeline, much attention is paid to quality control of welding and installation work, which consists of periodic checks of the condition and quality of welding materials; systematic step-by-step control during the assembly process » welding of pipes in sections at the pipe-welding base and welding of sections into a pipeline string on the route; external inspection and measurement of the geometric parameters of welded joints and preparation of their surface for control by physical methods of flaw detection; periodic verification of the qualifications of welders; quality control of welded joints by physical methods of flaw detection.

To control welded joints, non-destructive control methods are widely used by scanning the joints with gamma rays. A beam of gamma rays, penetrating the controlled joint, makes it possible to detect hidden defects (for example, cracks, lack of penetration, gas pores, slag inclusions). Recently, X-rays have been used to control joints on the route. When checking the quality of the welded pipe joint, it is exposed to transillumination along the entire circumference. The internal state of the welded joint during transillumination is photographed on a photosensitive film and, if there are defects in the joint, they are displayed on the film. All welded joints, rejected according to the results of the control, are cut out and repaired in accordance with the requirements of the Building Code to the rules (SNiP Sh-42-80).

Welding and installation work is carried out with the help of pipelayers. Pipelayers at the pipe-welding base reload pipes from the pipe truck to the assembly and welding line or stack them, the welded pipe sections are removed from the welding stand and loaded onto a lash truck or stacked. In addition, they are involved in all operations for lifting, supporting and moving pipes while straightening and cleaning their ends.

After welding, two- and three-pipe sections are loaded by pipelayers onto a lash carrier by dragging. At the same time, the pipelayer makes a detour of the whip truck along the contour of its trailer.

On the route, pipelayers participate in the assembly and welding of fixed joints: they lift (with one or two pipelayers) a section and a pipeline string and, supporting it, create conditions for docking, centering and welding the next section with a previously welded pipeline string. Moreover, when performing these operations, particularly precise work of the pipelayer operator is required. After welding the next section, the pipelayer lays it along the trench on the ground on wooden benches.

When welding overlaps, welding valves or coils, the pipelayer performs the same operations as when welding fixed joints on the route, only particularly precise movements of the load hook and boom are required.

Earthworks - digging and backfilling trenches, reclamation of fertile lands, etc. Trenches for pipelines are dug mainly by rotary trench excavators (see Fig. 1). Only on curved sections of the route with a radius of 50 ... 60 m when working in soft unstable soils, as well as with the inclusion of boulders and rock fragments, trenches are developed by single-bucket excavators with buckets with a capacity of 0.5 ... 1.6 m3. Frozen and rocky soils are previously loosened by explosion or mechanically using powerful bulldozers-rippers. In wet and swampy soils, trenches are dug with single-bucket swamp excavators or conventional excavators using portable decks, as well as special floating swamp excavators.

The trenches are backfilled with bulldozers or trench fillers immediately after the pipeline is laid. After backfilling and compaction of the soil, the thickness of its layer above the pipeline should be at least 0.8 m.

When laying a pipeline on fertile lands, they are recultivated: the fertile layer is removed before construction begins, it is stored in dumps and returned to its place after construction is completed. In sandy-desert areas, after completion of work, the strip adjacent to the pipeline is fixed by planting drought-resistant plants.

When laying pipelines on the ground, the complex of earthworks consists of laying foundations for it from well-draining low-moisture soils (pebble, gravel and sandy rocks), embankment of the foundation and construction of drainage and fire ditches.

If the pipeline is laid on pile supports (as a rule, on permafrost soils), wells are drilled in advance and pile supports are installed. The technology of these works and the types of mechanisms are prescribed depending on the structure and temperature regime of permafrost soils.

Insulation and laying works (cleaning the outer surface of the pipeline from dirt, rust, scale, applying a primer and an insulating coating on it; quality control of the coating; laying the pipeline in a trench) is carried out by a mechanized column equipped with specialized machines: a group of pipelayers I, one pipe cleaning and one pipe insulation machines.

Insulating and laying work is carried out in three ways: combined, separate and with the laying of pre-insulated pipes.

The combined method is used when laying pipelines on flat terrain in dense soils, on swampy sections of the route without deep swamps and bogs, as well as on rough terrain with a slope or rise of up to 3%. With this method, cleaning the outer surface of the pipeline, applying a primer and an insulating coating, as well as laying the pipeline into a trench is performed simultaneously - directly on the route in a single process flow.

The separate method is used when laying pipelines in soils with a weak bearing capacity. In this case, the pipelayers supporting the pipeline by weight, due to the possibility of collapse of the trench walls, move at a considerable distance from the edge of the trench. The separate method is also used when laying pipelines on areas with large slopes, swampy and watered sections of the route, etc. With the separate method, work on cleaning and isolating the outer surface of the pipeline is performed in the same way as with the combined method: directly on the route, but at the same time they are technologically separated from the work of laying the pipeline in a trench. In this case, after cleaning and insulation, the pipeline is first lowered by pipe layers onto wooden beds installed on the trench berm, and then, when the pipe layers pass again, into the trench.

During the construction of pipelines from pipes with insulation applied to them in advance, cleaning and insulation of pipes is carried out on semi-stationary or stationary bases. At the same time, before insulation, the pipes are welded in sections 24 ... 36 m long, then they are isolated and transported to the route. On the track, the sections are welded together in a continuous thread, which is laid on wooden benches parallel to the axis of the trench. After that, the insulating-laying column team restores the damaged insulation, cleans the welded joints, applies a primer and an insulating coating on them, and then the pipeline is lowered by pipelayers into the trench, just as with a separate laying method.

To protect the outer surface of pipelines from corrosion, bitumen-rubber mastics or polymer (polyethylene and polyvinyl chloride) film coatings are used. Bitumen-rubber mastic, as it is applied to the pipeline, is reinforced with a non-woven fiberglass canvas, which is applied with an overlap of 20 ... 25 mm.

When laying pipelines in stony and rocky soils, in "hot" areas where the product will be transported with a temperature above 55 ° C, at crossings through roads and railways, as well as through water areas, bitumen-rubber mastics and polymer film coatings are protected with wrapping material to protect them from mechanical damage.

The wrapping material is applied to the surface to be insulated in one or two layers with an overlap of 3.. .4 cm immediately after the application of the anti-corrosion coating.

Bitumen-rubber mastic is poured onto the surface of pipes using pipe-insulating machines. Mastic is prepared in bitumen-melting boilers installed at construction sites near the column base. Ready-made mastic from boilers to pipe-insulating machines is delivered by bitumen trucks to the chassis of cars.

Polymeric tapes are applied by pipe-insulating machines, as well as combined machines, which simultaneously clean the pipeline and insulate it with polymeric tapes.

The main machines in the production of insulation and laying works are pipelayers. The number of pipelayers in the column and their power are set depending on the diameter and wall thickness of the pipes, the terrain and the nature of the soil.

Pipelayers in the production of insulation and laying works perform the following operations: they lift the pipeline from the edge of the trench to a height of 0.8 ... 1.8 m and support it with pipe cleaning and pipe insulation machines installed on it. When performing these operations, pipelayers simultaneously move along the pipeline under construction, manipulate booms with different reach, shift the insulated pipeline from the edge to the trench axis, finally align the pipeline axis with the trench axis and lower the pipeline into the trench.

When conducting insulation and laying works, step-by-step quality control of cleaning, priming, insulation and laying of the pipeline into the trench is carried out. To control the quality of cleaning and insulation, instruments are used to check the cleanliness of cleaning, the continuity of the insulation and its adhesion (adhesion) to the surface of the pipeline. The quality of the pipeline laying is checked visually.

Ballasting works. Pipelines of large diameters, laid in flooded areas, swamps or in floodplains, are buoyant. To give the pipeline negative buoyancy, it is loaded with reinforced concrete (Fig. 118, a) or cast-iron weighting agents weighing 4 tons each, or attached to the bottom of the trench with anchors (Fig. 118, b). Ballasting with anchors is used if the bearing part of the anchor can be immersed in mineral soil.

Construction of transitions. Pipelines cross various natural and artificial obstacles (for example, railways and roads, ravines, rivers). Depending on the type of obstacles, pipeline crossings are divided into underground and underwater.

Underground include pipeline crossings constructed by roads and railways. These crossings are built mainly in a trenchless way, i.e. without opening the subgrade and the top cover or structures of the road and therefore without stopping traffic on the road. When crossing roads, pipelines are laid in protective casings. Horizontal drilling installations are used for laying casings.

When crossing large rivers and lakes, crossings are carried out mainly under water (siphons). Works on the arrangement of crossings through water barriers are carried out according to individual design solutions. During the construction of crossings on navigable, rafting tracks and reservoirs, the project for the production of work is coordinated with the shipping inspection, with the organization conducting the rafting of the timber, or with the basin administrations.

Rice. 118. Pipeline ballasting:

a - weighting agents, b - anchors; 1 - pipeline, 2 - weighting agent, 3 - power belt, 4 - lining mat, 5 - anchor rod, 6 - anchor

The construction of underwater crossings consists of the following operations: preparatory work; welding, hydraulic testing, insulation and lining of pipelines; development of coastal and underwater trenches; devices of the descent path when laying by the way of dragging; pipeline ballasting; laying pipelines in a trench; secondary test; trench backfilling; coast protection works.

Underwater crossings are built by specialized units.

The preparatory work includes: checking hydrogeological and cryological conditions (if construction is carried out in winter), measuring depths to clarify the actual bottom profile at the crossing site and its compliance with the project.

Welding and insulation work is carried out in the same way as for the linear part of the pipeline. As an insulating coating, polymer tapes are used, which are protected from mechanical damage by wrapping material and a lining made of wooden laths.

Underwater trenches are developed using dredgers, dredgers, scrapers, excavators installed on floating facilities, special mechanisms adapted for deepening the laid underwater pipelines, or using an explosive method.

The most responsible type of work in the construction of underwater crossings of main pipelines is laying them on the bottom of the water barrier. The following main methods of laying pipelines are used: dragging along the bottom of a water barrier; free immersion with the gulf of water in the pipeline or its loading; lowering using floating cranes or supports equipped with lifting devices; laying from pipe-laying barges with successive extension of pipe sections; laying with towing sections (lashes) and welding of intersection joints afloat.

When constructing underwater crossings, pipelayers are used in the process of performing welding, installation and insulation work, as well as when unloading individual pipes and sections. In some cases, pipelayers are used as traction mechanisms when pulling siphons.

Cleaning the cavity and testing the pipeline for strength and tightness. The pipeline laid in the trench is tested for strength and tightness. It is preliminarily cleaned of scale, burr and soil, water and various objects that have fallen into it. The pipeline is cleaned by blowing through cleaning pistons or elastic separators, as well as by flushing with water, skipping elastic separators. Purges are made with compressed air, sometimes with natural gas. Aboveground gas pipelines are cleaned in accordance with special rules. After cleaning, inventory plugs are installed at the open ends of the pipeline.

The main pipelines before putting them into operation are subjected to a pressure test for strength and tightness with air, water or the product for which they are intended. The procedure and test parameters are determined by SNiPs.

When cleaning the cavity and testing pipelines, remote instrumentation is used, as well as special equipment and a set of filling and pressure testing units. To clean the cavity and test the pipeline, a flow chart and instructions are drawn up.

Estimated cost of the object calculated according to the technological composition of cap. investments:

C total \u003d KV \u003d C str. + C mont. + With rev. + With pr.z., Where

From p.- estimated cost of construction work;

With mont.- estimated cost of installation work;

Cathedral.- Estimated equipment, furniture, inventory;

From pr.z.- estimated cost of other capital works and costs.

Estimated cost of construction and installation works calculated: C smr \u003d PZ + HP + SP.

Direct costs of PP – main production costs for the implementation of construction and installation works, the physical volume of which is determined by the project, and the cost value - according to the estimated norms:

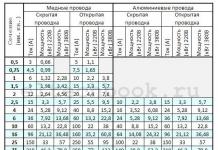

PZ \u003d C mat + C ozp + C emm, Where

C mat- the cost of materials, parts and structures;

With ozp- funds for the remuneration of construction workers (installers), i.е. workers employed in the production of construction and installation works (basic wages);

With umm - the cost of operating machines and mechanisms (including the remuneration of workers-machinists - With zp. mash.).

Workers wage fund: FOT slave \u003d C ozp + C zp. mash.

HP Overhead - indirect costs associated with ensuring the conditions for the production of construction and installation works and the activities of the HMO.

The following types of HP are taken into account:

administrative expenses;

employee service costs;

expenses for the organization of work;

other overhead costs.

The amount of overhead costs is determined according to MDS 81-33.2004:

HP \u003d H HP FOT slave / 100, Where

H nr- overhead costs (in %) are accepted either by type of construction and installation work or by type of construction. Since 2005, a reduction factor of 0.94 has been applied to the HP standards.

Estimated profit of the joint venture - profit of the contractor (accumulation area), the amount of funds necessary for the development of the material and technical base and incentives for HMO employees, determined according to MDS 81-25.2001:

SP \u003d N SP FOT slave / 100, Where

H cn- JV standards (in %) are adopted either by type of construction and installation work, or industry-wide (50% - repair work, 65% - everything else).

For construction projects financed from non-budgetary sources, it is allowed:

SP \u003d N cn (PZ + NR) / 100, where the Gosstroy of the Russian Federation recommended the standard of estimated profit from the estimated cost H cn \u003d 12%.

3. Pricing and cost estimate system construction cost

A set of rules, regulations, norms, prices, and other materials necessary to determine the cost of construction products (complex No. 81 of regulatory documents of the Gosstroy of the Russian Federation - the Ministry of Regional Development of the Russian Federation).

The foundation of the system State elemental estimated norms (GESN), which determine the consumption of resources in natural meters (labor costs of workers, machine operating time, material consumption) per unit of construction and installation works, which are the basis for the transition to cost indicators (Federal unit prices (FER), Territorial unit prices (TER), Industry unit prices (OER), aggregated cost indicators by type of work, etc.).

| The system of pricing and estimated rationing in construction (TsiSN System) | ||||||||||||

| Methodology for determining the cost of construction products on the territory of the Russian Federation (MDS 81-35.2004) | Estimate-normative (estimate-information) base | Auxiliary budget documents (VSD) - methodical. and hands. dock you | ||||||||||

| Federal level | Industry Level | Territorial level | Brand Level | |||||||||

| State estimated standards (GSN) | Industry estimated standards (OSN) | Territorial estimated standards (TSN) | Company estimate standards (FSN) | |||||||||

Collections of GESN contain the technical part (general instructions, rules for determining the scope of work, correction factors for the norms) and tables of elemental estimated norms, in which, for each work, the following is given:

number, name, gauge and composition of the work;

labor costs of construction workers in man-hours per work meter;

average grade of work;

labor costs of machinists in man-hours per work meter;

list and time of operation of machines and mechanisms in machine-hours per work meter;

list and consumption of materials, products, structures, energy carriers in physical. units of measure per work meter.

Collections FER (TER) contain those. part (general instructions, rules for determining the scope of work, correction factors for prices) and tables with unit prices (EP), which, for each work, provide:

number, name and measure of work (coincides with GESN);

unit price (direct costs for the work meter) in rubles. as of 01.01.2000 - in total and with allocation by parts of the PZ (the cost of materials, parts and structures, funds for the wages of construction workers (installers), the cost of operating machines and mechanisms, including the wages of machinists as part of the latter);

consumption of materials not included in the price, in natural units of measurement per work meter;

labor costs of construction workers or assemblers (in man-hours per work meter).

Prices in FER (TER) collections can be closed and open :

1) B closed rates the cost of all elements of direct costs is taken into account.

2) B open rates the estimated cost of basic materials is not taken into account. They are given in the EP in separate lines indicating their name and consumption per price meter. FERM (TERM) – all open: unaccounted materials are given in the introductory notes.

The bulk of large and medium-sized projects, one way or another, is connected with the construction of industrial and agricultural facilities, housing, bridges, roads, etc. The buildings being erected are either in themselves the goal of the plan, or are its integral part, without which the continuation of the project is impossible. As a rule, the largest volume of financial and material resources expended falls on construction and installation work. Accordingly, the regulation of this activity in the legislation occupies a special place.

What does SMR mean and how are they regulated

Construction as such includes a wide range of concepts. This is not only the erection of new buildings and buildings, but also their repair (current and capital), restoration, reconstruction and renovation. The process itself is multifaceted and consists of the following stages:

- organizational (market research, development of the project concept, selection of the customer and contractor);

- survey (geodesic, geological, environmental, geotechnical, hydrometeorological);

- design (preparation of design and working documentation);

- phase of material support (procurement of necessary products and raw materials, their transportation to the sites);

- construction and assembly (preparatory, basic and finishing);

- commissioning (control measures and carrying out the necessary tests).

There are several interpretations of the term "construction and installation work", depending on the dictionary, reference book or legislative act where this term is mentioned. At the same time, they all agree that construction and installation works in construction is a certain list of operations aimed at the construction of new buildings, premises and the installation (installation) of the necessary equipment in them (ventilation, heating, gas and water systems, sewerage, etc.). For abbreviation in technical documentation, the abbreviation CMP is more often used, rather than the full name.

The main document regulating all construction and installation activities in Russia is SNiP, which stands for Construction Norms and Rules.

It includes five sections:

- General questions, classification and terminology. Management, organization and economics.

- Requirements and standards for the design of structures, foundations and equipment.

- Preparation, execution and acceptance of performed operations. Recommendations for SMR.

- Standards for the preparation of estimates for all types of operations with explanations.

- Norms of labor and material costs, prices for manipulations.

Also, the production of building materials, structures and products is regulated by GOST (State Standards), developed by government agencies and scientists. GOSTs are approved by Gosstandart and Gosstroy of the Russian Federation. For certain technologies and materials, especially new ones, manufacturers develop specifications (technical specifications) that are agreed with state institutions. With the development of best practices and new technologies, the entire regulatory framework is regularly reviewed and amended.

Existing species

The construction of a new building or its deep reconstruction requires a huge number of actions of different directions and intensity using the whole variety of materials and specialized equipment. Construction can be carried out in several different ways:

The construction of a new building or its deep reconstruction requires a huge number of actions of different directions and intensity using the whole variety of materials and specialized equipment. Construction can be carried out in several different ways:

- contractor(the most common in Russia), when all operations are performed by specialized organizations in accordance with the agreement concluded with the customer;

- economic when the entire volume of construction and installation works is carried out by the forces of the enterprise's own divisions;

- mixed when one part of the operations is carried out independently, and contractors are invited for the other.

Based on the focus and expected result, the following main types of construction and installation works are distinguished:

- general construction;

- transport;

- unloading and loading;

- special.

Usually, installation or construction work is distinguished depending on which operations prevail at a particular stage. Assembly are activities using ready-made parts or parts, for example, installation of power wiring and other cables, reinforced concrete and metal structures, various equipment (pumping, energy, transport, technological), painting and insulation of pipelines.

General construction actions, based on the processed materials and the erected structural elements, are divided into the following types:

Some of these actions are combined into the term "zero cycle" familiar to every builder. It represents the initial phase of construction and includes the preparation of the construction site and access roads to it, excavation, laying the foundation. The zero cycle ends when the underground part of the building is erected and engineering networks are carried out. After it, the above-ground and finishing cycles follow.

Special actions include actions performed in a special way or with special materials that require specific knowledge and skills. These include, for example, the installation of complex devices and systems, elevators, telephone lines, the lining of units with refractory or acid-resistant masonry, and the installation of mine shafts.

Loading and unloading and transport manipulations involve the delivery to the workplace of structural elements and parts of various sizes, tools and necessary equipment. Due to the variety of transported goods, specialized equipment is used, such as panel carriers, trailers, dump trucks, conveyors, loaders, excavators, cranes.

Sometimes procurement operations are also distinguished, consisting in the manufacture of semi-finished products (concrete mix, reinforcing cage, mortar, prefabricated structures, including SKDs). Depending on the required volumes and the complexity of manufacturing, they can be produced both by specialized enterprises (such as a plant for reinforced concrete products) and directly at the construction site.

In addition to the erection of buildings, the list of construction operations also includes landscaping and gardening, land reclamation, dredging, the creation of environmental structures (anti-landslide, anti-erosion, anti-mudflow), bank protection, drilling, pumping water, etc.

Contractual relationship

Considering the complexity and variety of activities carried out during the implementation of a project, especially a large one (construction of an industrial complex, military or agricultural facility), it is necessary to hire contractors to perform all the necessary actions.  Some of them cover most of the general construction processes, others specialize in certain areas that require special equipment and trained professional personnel.

Some of them cover most of the general construction processes, others specialize in certain areas that require special equipment and trained professional personnel.

Accordingly, the most common type of agreement is a work contract that has two contracting parties:

- the customer, authorized by the investor, who sets the parameters for carrying out certain processes, accepts the results and pays for them;

- a contractor who fulfills the requirements of the customer within the agreed time frame.

The parties to the agreement may be legal entities, individuals or third parties acting on behalf and in the interests of the customer. Contractors are usually construction organizations or licensed individual entrepreneurs.

If the contractor is not able to fully fulfill the entire scope of his obligations on his own, then he has the right (if this is not prohibited by the agreement) to conclude a subcontract within the approved budget, that is, to attract other organizations to perform certain processes.

Often, for the implementation of the entire construction complex, a general contractor is appointed, which ensures and guarantees the entire construction process, fulfilling the order partly on its own, partly with the participation of subcontractors. The general contractor is responsible for all defects of subcontractors.

In addition to general provisions, such as the names of the parties, the date and place of signing, details, legal addresses and signatures of the parties, the standard contract includes the following main sections:

In addition, the contract as an integral part has a number of applications, the list of which is indicated in the main body of the agreement. These include:

- calendar plan;

- lists of necessary equipment and materials;

- a copy of the customer's title documents for the land plot;

- a copy of the customer's permit for construction;

- a copy of the contractor's license;

- acts of acceptance and transfer of technical documentation, materials and equipment;

- a copy of the insurance policy;

- work schedule;

- budget documentation;

- act of acceptance.

If necessary, the parties may conclude additional agreements on certain issues within the framework of the execution of the general agreement. Problems arising in the production process are displayed in the protocols of disagreements and agreement of disagreements.

Depending on the scope of the activities performed and the scale of the project, the contract may have different content.

Thus, an agreement for the construction of a small residential building and a large plant can differ dramatically from each other, both in terms of volume and in detailing all the actions performed.

A construction contract imposes a great responsibility on the contractor, since poor quality of workmanship, the use of low-quality materials and non-compliance with approved standards can cause destruction of structures, large financial losses or death of people. Therefore, the quality of construction and installation works at each phase of construction is of particular importance.

The quality of construction products affects the cost and performance of the structure, their durability and efficiency. If an object is built from untested materials or in violation of technical regulations, this leads to an increase in the cost of all processes due to the need to constantly correct identified shortcomings, increase operating costs to maintain the object in working order, and reduce the level of comfort for residents.

Control is carried out by checking the compliance of product indicators with approved requirements, fixed in technical conditions, standards, projects, supply contracts, product passports. The main task is to prevent marriage and defects, to maintain the proper quality of products. There are two forms of quality control:

- production (internal) control system;

- external control.

Internal control is carried out directly by employees of enterprises (design, industrial) that produce the necessary products. Plants and factories that produce building materials issue passports for their products, confirming that the state standard was maintained during their manufacture. The presence of such a passport when delivering products is mandatory.

Internal control has several areas that differ in their characteristics and focus.

By implementation time:

- Input. This is the study (external inspection) of materials, structures and products arriving at the construction site, as well as accompanying and technical documentation. The registration method is mainly used (analysis of passports, invoices, certificates), sometimes the measuring method.

- Operating. It is carried out during the processes or immediately after their completion, has the form of a measurement or technical inspection, its results must be recorded in special journals. The main figures at this stage are foremen, superintendents, and site managers.

- Acceptance. It is carried out after the completion of a certain type of operation (stone, facing), representatives of the customer or designer often join the verification, so it has an element of external control. As a result, a decision is made on the degree of suitability of the object and the possibility of continuing construction.

By scope of checks:

- Solid. All structural elements or units of production (piles, metal structures, etc.) are inspected.

- Selective. A certain part of the product, selected at random, is studied, its volumes are determined by SNiP (Building Norms and Rules).

By frequency:

- Constant. Information about the state of the parameter being monitored is supplied continuously.

- Periodic. The parameter is monitored at certain intervals.

- Volatile. Checking occasionally (at any time) is used when there is no need for deeper forms of control.

By methods of conducting:

By methods of conducting:

- Visual. Its basis is GOST 16501-81.

- Measuring. It is carried out using the necessary measuring instruments, if necessary, a laboratory analysis is carried out using the appropriate equipment. A variety of methods can be used: mechanical (destructive), pulsed (acoustic, vibration) and radiation.

- Registration. This is an analysis of data that is recorded in various documents (journals, certificates, certificates of examination). It is used in cases where, for technical reasons, access to the control object is impossible.

To ensure the appropriate quality of products, specialized services are created at large enterprises, which are usually subordinate to the chief engineer (technical inspection, construction laboratory, geodetic service).

Analysis of the data obtained as a result of instrumental research and their comparison with the current legal and design documentation is called construction expertise. It can be extrajudicial and judicial. All identified violations, deviations and defects are recorded in the expert opinion, which also includes photographs of the detected shortcomings. Based on the results of the examination, the following are determined:

- assessment of the wear of elements, engineering networks and structures during operation;

- determination of the amount of damage from emergency situations (fire, flood);

- compliance with the project, GOST or SNiP;

- testing of materials and structures used;

- study of load-bearing elements in preparation for reconstruction or redevelopment.

International practice of quality control suggests a slightly different approach to this issue, which is based on:

- material interest and responsibility of each performer for the proper execution of all manipulations, which is regulated by internal management - this is a kind of standard established at the enterprise;

- clear instructions for each work process;

- availability of highly qualified personnel;

- equipping with modern high-tech equipment.

External quality control includes inspections carried out by organizations that have the right to supervise and are independent of the contracting organization. Its main forms are:

- technical supervision of the customer;

- architectural supervision of the design organization;

- state architectural and construction supervision;

- control upon acceptance into operation of the facility by various acceptance commissions: fire, sanitary and epidemiological, industrial and mining supervision, labor inspection.

Technical supervision by the customer. It is carried out continuously during the entire period of construction and installation work. The representative of the customer participates in the examination of all covert actions carried out, acceptance committees, intermediate acceptances of the most important structural elements. If there is no customer approval, then no further operations are carried out. Representatives of technical supervision are empowered to make a decision to suspend construction and refuse to pay for processes performed with violations of design calculations and technology. If the quality turns out to be insufficient in the end, then the employees of the technical supervision of the customer are responsible along with the contractors.

Architectural supervision by the designer is also ongoing. Its main difference from the control functions of the GASN and the technical supervision of the customer is that a separate contract is concluded for its implementation between the customer and the designer with the appropriate payment. Architectural supervision consists in monitoring the strict adherence of all actions of the contracting organization to regulatory documents and the approved project.

All changes in the project, rationalization proposals must be agreed with the representative of architectural supervision. He is also present at intermediate acceptances and surveys, resolves issues related to design and estimate documentation, points out shortcomings and monitors their elimination. All comments of architectural supervision are recorded in a special journal, which is then transferred to the customer.

State Architectural and Construction Supervision carries out general control at all phases (survey, project development, construction). Its representatives must check the pre-project documents, issue a building permit and check its implementation at any time. They have the right to suspend construction, fine and initiate criminal proceedings.

Certification and licensing as components of quality control

With the rapid development of new technologies, the development of innovative building materials and methods of their fastening, the question arose of the compliance of these developments with approved standards and quality indicators. Therefore, in recent decades, great importance has been attached to the certification of manufactured products and the licensing of design, survey and construction activities.

- this is an activity aimed at establishing the compliance of product quality indicators with the requirements of approved norms and standards. It is aimed at protecting the rights of consumers and the environment, as well as for the safety of health, life and property of people. The objects of certification in construction can be:

- design products;

- industrial products manufactured by enterprises of the construction industry and building materials;

- erected structures and buildings;

- relevant services and works;

- imported elements.

Certification comes in its form:

- Voluntary, based on the initiative of a product manufacturer who wants to demonstrate the conformity of their products to potential customers.

- Mandatory, used for a separate legally approved range of goods, which, in case of poor quality, can be dangerous to human health and the safety of their property (balcony doors, windows, structures for private houses, locks, sealants).

In general terms, certification of any type of product occurs as follows:

- the applicant submits a declaration for certification;

- the scheme of carrying out and the methodology for conducting tests, as well as the testing laboratory are determined;

- sampling and identification of samples, examination of products and study of the state of production;

- analysis of the obtained results;

- execution, registration and issuance of a certificate of conformity.

Licensing is an examination of the applicant (legal or natural person) and the documents submitted by him regarding their readiness to perform the types of activities specified in the application. A special commission checks the availability of the necessary technical base and legislative acts, the implementation of the declared technological processes and the level of control over them, the qualifications and work experience of personnel, and feedback from the applicant's clients.

The regulation on licensing stipulates that the applicant must have at least half of the staff of specialists and managers in the field of design and construction with experience in the specialty from 3 to 5 years. In addition, on the property rights (or on other legal grounds), the candidate must have the necessary objects, tools and means of production (special equipment, manual or automatic tools, transport, power plants, measuring instruments).

The list of actions and necessary equipment is clearly defined in the classifier of design and construction and installation works. Actions for the construction of objects for various purposes (functional and sectoral), for example, roads, aerospace or agricultural facilities, are summarized together. Not only directly construction and installation works are licensed, but also the functions of the general contractor and developer.

As a rule, the license period after the first application is set to be short (1 year), if during this time the analysis did not show any violations on the part of the applicant, then the next license can be valid for 5 years, when applying again, the entire procedure is completely repeated. For violation by the organization of the norms of the current legislation, the license may be revoked.

Organization of construction and installation works

In the process of erecting large objects, such as multi-storey buildings, bridges, roads, factories, as a rule, various specialized and general construction organizations take part. In order to ensure the continuity of processes and the planned phased commissioning of the completed parts of the facility, a system of continuous planning and execution of work is needed.

In practice, there are three main methods for organizing the production of construction and installation works:

- Consistent. When it is applied, individual activities are carried out one after another, that is, the next one begins no earlier than the end of the previous one. This approach is poorly applicable to large-scale projects, since it requires a lot of time, but it is suitable for the construction of single buildings, since a small number of workers can be dispensed with.

- Parallel. It is based on the maximum possible combination of various processes (assembly and construction) in a single period of time. It makes it possible to build several buildings at the same time, but requires a significant amount of labor and equipment.

- inline. It consists in the division of complex processes, combined in time, into a number of simple operations performed sequentially. All actions are divided into streams that are executed within a clearly defined time frame. In each facility that is included in the flow, construction and installation works are carried out by complex teams moving from one building to another. This ensures an even load on the staff and the rhythmic delivery of objects included in the flow.

The projects for the production of works (PPR) include the main decisions on the organization of construction and installation work. The PPR is developed by specialized trusts or other organizations and consists of:

- a calendar plan, in which all the works of different performers are marked, linked to deadlines;

- master plan indicating the location of the facility itself, auxiliary sites, mechanized installations, warehouses, heat and power supply networks, access roads;

- schedule of requirements for the receipt of products, materials, structures, special equipment, workers.

For processes carried out according to new methods and high complexity, the PPR contains technological maps.

They indicate economic and technical indicators, requirements for the necessary safety precautions, schedules and recommendations on the methods of organizing the work of workers, the need for resources (parts, inventory, equipment), and calculations of labor costs.

They indicate economic and technical indicators, requirements for the necessary safety precautions, schedules and recommendations on the methods of organizing the work of workers, the need for resources (parts, inventory, equipment), and calculations of labor costs.

Often, a number of unrelated works are carried out simultaneously on the site, for example, electrical installation, plumbing, carpentry, and cladding. The rhythm of the workflow requires the delivery of certain materials at the right time in sufficient quantities and in the correct technological sequence. In order to prevent downtime, taking into account the opinion of contractors, hourly schedules are developed, guided by which the manufacturer ships, and the auto plant delivers the required elements to the site.

In order to link the supply of parts and their installation, transport and installation schedules are drawn up. Based on the technological sequence of the installation of the building and the standard time for the installation of each element, the time of arrival of vehicles at the site and the range of goods delivered by each flight are clearly indicated. Weekly, daily and hourly schedules are compiled, thanks to which different departments can see the big picture and act in concert. This allows you to plan the time of completion of each type of work and approximately calculate the deadline for the completion of the object.

In order to more fully cover the entire complex of ongoing processes, scheduling is used when working on all types of objects. It gives a general understanding of the sequence of actions in different time periods (from a day to several months), although plans regularly require adjustments depending on emerging circumstances. The duration of construction is calculated according to the norms of SNiP and varies greatly from the complexity of the structure. Reducing or increasing the duration of the work should always be justified, since with an increase in the duration, the deadlines for delivery can be disrupted and the customer suffers losses, and an unreasonable reduction often causes non-compliance with the standards for performing technological operations.

Depending on the scale of the project, the following types of planning can be used:

- simplified methods;

- calendar line charts;

- network charts.

Simplified methods are used when performing current tasks, usually for the next few weeks or days. Such schemes only indicate the types of actions performed and the deadlines for their completion, they are not sufficiently clear and not optimized. Also, planning in the most generalized monetary form can be attributed to simplified forms.

A calendar line chart, otherwise known as a Ganga chart, is a scale with marked horizontal lines of varying lengths that represent the duration of each task. In order to fully and efficiently compose it, you need to take into account the following points:

- draw up a list of necessary work;

- determine their volumes and methods of production;

- calculate their labor intensity, based on the norms and previous experience;

- make a preliminary schedule with approximate deadlines for the execution of each case;

- optimize it taking into account the real possibilities of distribution of labor force, equipment and other conditions.

In order to correctly calculate the amount of work and the time spent on it, one should, in addition to the prescribed norms, take into account other significant factors, for example, local weather conditions or terrain features. If at the initial stage there is a time delay due to incorrect calculations, then it will be almost impossible to compensate for it, since it is very difficult to correct the linear graph.

The network diagram is compiled according to a more modern graph technique (maps, maze, networks). Drawn on a sheet of paper or displayed on a computer monitor, such a scheme looks like a set of vertices connected by segments (non-directional and directional). The circles on the beginning and end of the segment indicate the beginning and end of work. In this kind of planning, there can be a number of different paths between the start and end events. The longest path is called the critical path, and it determines the total duration of the project. Accordingly, in other ways there are temporary reserves and the ability to vary the speed of execution of processes.

The strength of such planning is the ability to adjust it along the way.

If the construction does not meet the agreed deadlines, then there is an opportunity to reduce the time of the critical path by redistributing labor and material resources from the stages of the non-critical path, attracting reserves or changing the sequence of processes (if this is technologically feasible). A number of computer programs have been developed to facilitate the compilation of schedules and their refinement.

Estimated cost calculation

An integral part of the project documentation is the estimate, that is, the estimated cost of construction and installation works. Correct financial calculations contribute to the rhythmic and uninterrupted construction stages. If inaccuracies were made, then this can lead to losses, missed deadlines, debts, or the need to attract additional financial resources, often credit.

An integral part of the project documentation is the estimate, that is, the estimated cost of construction and installation works. Correct financial calculations contribute to the rhythmic and uninterrupted construction stages. If inaccuracies were made, then this can lead to losses, missed deadlines, debts, or the need to attract additional financial resources, often credit.

The estimated cost usually includes several components and is calculated according to the following formula: Ssmr \u003d PrZ + NR + PN (Spr), where Ssmr is the estimated cost of all work, PrZ is the total amount of direct costs, PN (Spr) - planned savings, or estimated profit. To better understand how the calculations are made, you should dwell on each of the components in more detail.

The sum of all direct costs is calculated taking into account the total amount of work (in physical units) and the currently applied prices per unit of measurement in accordance with the estimated standards. Direct costs typically range from 65% to 80% of the total cost and consist of:

- employee salaries who are directly involved in construction and installation work (10-15%);

- cost of all building materials, which are used in the construction of structures (50-55%);

- operating costs of the vehicles used, special equipment, mechanisms and machines, including the salary of specialists managing them (5-10%).

Overhead costs include the reimbursement of the contractor or subcontractor for all costs associated with the organization and maintenance of appropriate living and production conditions at the construction site. The amount of overhead costs is set depending on the wage fund and strongly depends on the scale of the facility being built, the method of production, and the type of construction. Typically, this figure varies between 13-20%. For their calculation, norms are used taking into account the peculiarities of production. It is not allowed to use a multiplier for overhead costs.

Overhead costs include:

- Expenses for administrative and economic needs. It takes into account the payment of business trips, the cost of stationery, mail and telephone communications, the maintenance and service of passenger vehicles, the purchase of the necessary specialized literature (regulatory, technical, economic), subscription to the required periodicals.

- Labor costs. These are the training and retraining of managers and specialists, the creation of proper living and sanitary and hygienic conditions, and labor protection. This also includes additional payments to employees (length of service, additional leave for seniority), social insurance.