The household electrical network has a voltage of 220 volts, which most electrical appliances are designed for. In this case, it often becomes necessary to power individual consumers - low-voltage heaters, halogen lamps and power other devices (LED strips, etc.) designed for alternating current. This is provided by a transformer, which is small in size and has a one-piece housing.

The device can be picked up and purchased in retail chains, and, if necessary, made by hand. A standard step down transformer consists of 2 windings (primary and secondary) wound around a ferromagnetic core with copper wire. The primary is connected to the network, and the secondary to the load. Principle of operation such a device is as follows:

A standard step down transformer consists of 2 windings (primary and secondary) wound around a ferromagnetic core with copper wire. The primary is connected to the network, and the secondary to the load. Principle of operation such a device is as follows:

- The voltage applied to the primary winding generates an alternating field around the core.

- Magnetic induction, when connected to a load, creates voltage in the turns of the secondary winding, and energy will be supplied from the primary winding, which will be transferred to the secondary circuit.

The value of the output voltage is affected by the ratio and the number of turns of each winding. By adjusting this indicator, you can achieve any current value on the secondary winding, and get both step-down and. In this case, it must be borne in mind that the device connected to a 220 V household network will give out an alternating voltage, which, if necessary, can then be converted by a rectifier.

At present, electronic-type step-down devices are widely used, made based on semiconductors, the work of which is complemented by an integrated circuit. They have certain advantages in the form of small size, high efficiency, low weight, lack of heating and noise, the possibility of adjusting the current, short circuit protection. But the traditional transformer continues to be actively used because of the reliability and simplicity of design.Choice of ready-made solution, criteria

Electrical and electronics stores offer ready-made household transformers for various needs. Choosing the right device should be guided by the following criteria:

- Input voltage parameters. The case of the device must be marked with 220 or 380 V. In this case, a household version for a 220 volt network is required.

- The input voltage parameters, which must correspond to 12 V.

- Power. To do this, pre-calculate the total load that will be powered through the transformer. This indicator of the device must exceed the calculated value by at least 20%.

In the video, a story about the purchase of a turnkey solution

The name of the word "transformer" comes from the Latin "transformare", which means "to transform". The scientific definition for it is as follows: a transformer is a device capable of converting, using the properties of electromagnetic induction, voltage values of one magnitude into values of another without changing the frequency.

The device has found wide application in various fields of energy, electronics and radio engineering. The most commonly used transformers in electrical networks and in power supplies all kinds of electronic devices.

General device and principle of operation

A transformer is an electrical device that reduces or increases an alternating electrical voltage. Such transformers are called step-down or step-up. It should be noted that there are also such devices that leave the value of the alternating voltage unchanged, they are called galvanic.

Any transformer consists of the following main parts:

The transformer has in its design two or more windings interconnected by inductance. They can be either wire or tape type and are always covered with an insulating layer. Windings are wound on a magnetic circuit made of soft ferromagnetic material. The primary winding is connected to a voltage source, and the secondary winding is connected to a load.

The general principle of operation of the device, regardless of its type and purpose, is as follows. An alternating voltage is applied to the primary winding of the device, this leads to the appearance of an alternating current in it. This current, in turn, leads to the creation of an alternating magnetic field in the core, under the influence of which an alternating electromotive force (EMF) appears in the windings. When the secondary winding is connected to the load, an alternating current begins to flow through it. The winding to which electricity is supplied is called the primary winding. Second, connected to the load and consuming current, is called secondary.

Depending on the design of the device, there are:

- autotransformer;

- impulse;

- separating;

- peak transformers.

According to the method of cooling, transformers are air-cooled and liquid-cooled. In addition, devices are produced with combined cooling, liquid-air.

The main technical characteristics of the devices include:

The main indicator of the device is the rated power, the unit of which is volt-ampere (VA). It is customary to consider low-power devices that transmit tens of volt-amperes, medium power - hundreds, and large - up to several thousand volt-amperes.

Separately, I would like to dwell on an important parameter, such as the transformation ratio. This value indicates the magnitude of the ratio between the input and output voltage and is directly proportional to the ratio of the number of turns of the respective windings.

step down transformer from 220 to 12 volts

Transformers of this type are widely used in everyday life and in production. Their main purpose is to power low-voltage devices, such as lighting devices, designed powered by 12 volts, or application in power supplies.

Transformers of this type are widely used in everyday life and in production. Their main purpose is to power low-voltage devices, such as lighting devices, designed powered by 12 volts, or application in power supplies.

At the same time, manufacturers are increasingly adding protection against short circuits and overvoltages during production, which has a positive effect on the life of both the entire device and the load connected to it. True, it should be understood that in this case, a transformer is no longer understood as one electronic element, but as a certain combination.

The need to use sources with a voltage of 12 volts

There are places where low voltage is preferred. These are objects with high humidity, increased safety requirements. And in damp and fire hazardous rooms, the use of a 220-volt network is generally prohibited by the rules of the rules for the installation of electrical installations (PUE).

A power grid using a step-down transformer does not require expensive protective materials and is considered relatively safe for human life and health. Using 12 volt bulbs in the lighting network is not only cheaper than their counterparts, but also more profitable in the sense that their service life is several times higher, since they are additionally protected by a step-down transformer from voltage surges and noise.

Application for light sources

Increasingly, halogen and LED lamps are used as light sources in apartments and offices, as well as when creating interior lighting. Due to their design, they have a high brightness of the glow and a service life.

Increasingly, halogen and LED lamps are used as light sources in apartments and offices, as well as when creating interior lighting. Due to their design, they have a high brightness of the glow and a service life.

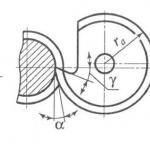

The small size of such light sources allows them to be used in diverse places, and the light weight of the luminaires does not weigh down the entire structure, which gives freedom of action when mounting them both single and in a chandelier. Halogen lamps are made with different operating voltages, it is 6, 12, 24 volts. Two types of step-down transformers are used to power halogen lamps - toroidal and pulse.

In a toroidal converter, a ring-type magnetic circuit is used as a basis, which is a geometric figure torus. This type of magnetic circuit is practical and has the highest efficiency. But there are also disadvantages. First of all, these are their dimensions and weight, and secondly, increased heating during operation.

Smaller sizes, the possibility of a smooth start, and the presence of stabilization are possessed by electronic transformers that are used in digital power supplies. The principle of operation of these devices differs from toroidal models, since, in addition to the transformer, additional electronic parts are used here. Participating in the conversion of electricity, it practically does not heat up. Often such a device is made with built-in protection, which brings additional convenience in use and extends the service life. The only drawback of a pulse transformer is its price.

Power supply for halogen lamps 12 volts

In order to use an electronic transformer as a power source, a number of electronic parts must be connected to it. In general terms, the circuit of such a power supply will work as follows.

In order to use an electronic transformer as a power source, a number of electronic parts must be connected to it. In general terms, the circuit of such a power supply will work as follows.

The mains voltage of 220 V passes through the filters to a special part of the circuit called the driver. The current, passing through the key transistor and the primary winding, saturates the core, forming an EMF on the signal turns.

The current that appears charges the capacitor of the self-oscillating circuit, the voltage on the capacitor plates rises until the transistor closes. The potential difference on the signal winding disappears, and the capacitor is discharged through it, while the transistor switch opens again. The whole process occurs anew, its frequency is about tens of thousands of hertz. To obtain a constant voltage of 12 V, a diode bridge with a smoothing electrolytic capacitor is connected to the output of the device.

Calculation and selection of transformers

At various points of sale, you can purchase devices with different capacities and parameters. Before proceeding with the installation, it is necessary to calculate the power of the connected load.

At various points of sale, you can purchase devices with different capacities and parameters. Before proceeding with the installation, it is necessary to calculate the power of the connected load.

Consider an example for halogen lamps. Suppose that we have ten spot halogen bulbs with a power of 30 W and a voltage of 12 volts installed in our house. The power of all lighting fixtures will be 300 W, for comfortable work it is necessary to add 15 percent to this power. It turns out that it is necessary to consider the purchase of a device with a parameter of at least 345 watts with a voltage of 12 volts. In this way, the calculation is carried out for any device, whether it be a halogen spotlight or an LED strip. Of the manufacturers, you should pay attention to Philips, Feron, OSRAM.

When connecting, it is important to consider one of the properties of buck converters. It lies in the fact that the lower the voltage, the more current is consumed at a constant power, and hence the greater the voltage drop on the wires. Therefore, when mounting low-voltage lighting lines, it is necessary to ensure that the length of the lines from the transformer to each light bulb is approximately equal. In this case, the glow of all sources will be the same.

In order to use a 12V buck converter for more than one halogen lamp, two methods are possible:

- Parallel connection.

- Creation of separate groups.

In the first method, all lamps are connected in parallel to each other. To do this, a distribution block is connected to the output of the transformer, on which the connection is mounted. For the second case, all wiring is divided into groups containing an equal number of light sources. With this type of connection, you will have to use a transformer for each line. The convenience is that in case of failures on one line, the second group continues to work, as well as in the use of devices with less power.

In the first method, all lamps are connected in parallel to each other. To do this, a distribution block is connected to the output of the transformer, on which the connection is mounted. For the second case, all wiring is divided into groups containing an equal number of light sources. With this type of connection, you will have to use a transformer for each line. The convenience is that in case of failures on one line, the second group continues to work, as well as in the use of devices with less power.

For our above example, we can divide the connection into two groups. Each group will include five light sources. Since the power of the lines will decrease, it will be enough for us to purchase two step-down converters of 170 watts each.

Switching wires with the device itself should not cause difficulties. Typically, terminals on devices are labeled Input and Output, respectively, input and output. If there is a constant voltage at the output of the device, then a + sign is put on the positive terminal or this terminal is colored red.

It is also important to note that if you want to replace the halogen bulbs in the chandelier with LED ones, then by simply unscrewing one and installing the other, you will most likely get all kinds of flickering at the output. The fact is that transformers for 12 volt LED lamps must be stabilized, while there is no such requirement for halogen lamps. And the second case that you may encounter: the chandelier will not turn on at all. This is due to the fact that pulse transformers are protected and automatically turn off when a load with low power is connected to them. There is only one way out in this case - replacing the power supply with a suitable one.

Even a novice radio amateur can independently make a transformer from 220 to 12 Volts. This device belongs to AC machines, the principle of operation is vaguely reminiscent of an asynchronous motor. Of course, you can buy a ready-made transformer, but why spend money, especially in cases where there is enough steel for the core and wire for the coils on hand? It remains only to study a little theory and you can start manufacturing the device.

How to choose materials

In the manufacture of a step-down transformer from 220 to 12 volts, it is important to use high-quality materials - this will ensure high reliability of the device, which you will subsequently assemble on it. It should be noted that the transformer allows you to make an isolation from the network, so it can be installed to power incandescent lamps and other devices that are in rooms with high humidity (showers, basements, etc.). When making the coil frame yourself, you need to use durable cardboard or textolite.

It is recommended to use domestic wires, they are much stronger than Chinese counterparts, they have better insulation. You can use wire from old transformers, as long as there is no damage to the insulation. To isolate the layers from each other, you can use both plain paper (preferably thin) and FUM tape, which is used in plumbing. But for the insulation of the windings, it is recommended to use a fabric impregnated with varnish. It is imperative to apply insulation over the windings - lacquer fabric or cable paper.

How to carry out the calculation?

Now that all the materials are ready, you can calculate the transformer from 220 to 12 volts (for a lamp or any other household appliance). In order to calculate the number of turns of the primary winding, you need to use the formula:

N = (40..60) / S.

S is the cross-sectional area of the magnetic circuit, the unit of measurement is sq. see In the numerator there is a constant - it depends on the quality of the core metal. Its value can range from 40 to 60.

Example calculation

Let's say we have the following settings:

- The window is 53 mm high and 19 mm wide.

- The framework is made of textolite.

- Upper and lower cheeks: 50 mm, frame 17.5 mm, therefore, the window has a size of 50 x 17.5 mm.

Next, you need to calculate the diameter of the wires. Let's say you want the power to be 170 watts. In this case, the current on the network winding will be equal to 0.78 A (we divide the power by the voltage). In the design, the current density turns out to be 2 A/sq. mm. With these data, you can calculate that you need to use a wire with a diameter of 0.72 mm. It is also allowed to use 0.5 mm, 0.35 mm, but the current will be less.

From this we can conclude that to power radio equipment on lamps, for example, you need to wind 950-1000 turns for a high-voltage winding. For glow - 11-15 turns (the wire only needs to be used with a larger diameter, depending on the number of lamps). But all these parameters can be found empirically, which will be discussed later.

Calculation of the primary winding

When making a transformer from 220 to 12 Volts with your own hands, you need to correctly calculate the primary (network) winding. And only after that you can start doing the rest. If you incorrectly make the calculation of the primary, then the device will start to warm up, buzz strongly, it will be inconvenient to use it, and even dangerous. Let's say a wire with a cross section of 0.35 mm is used for winding. One layer will fit 115 turns (50 / (0.9 x 0.39)). The number of layers is also easy to calculate. To do this, it is enough to divide the total number of turns by how much fits in one layer: 1000/115 = 8.69.

Now you can calculate the height of the frame along with the windings. The primary one has eight full layers, plus insulation (0.1 mm thick): 8 x (0.1 + 0.74) = 6.7 mm. To prevent high-frequency interference, the network winding is shielded from the rest. For the screen, you can use a simple wire - wind one layer, insulate it and connect the ends to the body. It is also allowed to use foil (of course, it must be strong). In general, the primary winding of our transformer will take 7.22 mm.

A simple way to calculate secondary windings

And now about how to calculate the secondary windings, if the primary is already available or ready. You can use such a transformer 220 to 12 volts for LED strips, just be sure to install a voltage stabilizer. Otherwise, the brightness will be inconsistent. So what do you need to calculate? A few meters of wire and only wind a certain number of turns over the primary winding. Let's say you wound 10 (and you don't need more, that's enough).

Next, you need to assemble the transformer and connect the primary winding to the network through a circuit breaker (for safety reasons). Connect a voltmeter to the secondary winding and click the machine. See what voltage value the device shows (for example, it showed 5 V). Therefore, each turn produces exactly 0.5 V. And now you just focus on what voltage you need to get (in our case it is 12 V). Two turns is 1 volt of voltage. And 12 V is 24 turns. But it is recommended to take a small margin - about 25% (which is 6 turns). Nobody canceled the voltage loss, so the 12 V secondary winding should contain 30 turns of wire.

How to make a coil frame

It is extremely important in the manufacture of the frame to achieve a complete absence of sharp corners, otherwise the wire may be damaged, an interturn short circuit will appear. On the cheeks, you need to take away the places to which the output contacts from the windings will be attached. After the final assembly of the frame, it is necessary to round off all sharp edges with a needle file.

Plates made of transformer steel should fit into the holes as tightly as possible, free play is not allowed. For winding thin wires, you can use a special device with a manual or electric drive. And thick wires need to be wound exclusively by hand without additional devices.

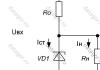

Rectifier block

By itself, a 220 to 12 volt transformer will not produce direct current; additional devices must be used. This is a rectifier, filter and stabilizer. The first is performed on one or more diodes. The most popular scheme is the bridge. It has a lot of advantages, among the main ones are minimal voltage losses and high quality of the output current. But it is allowed to use other rectifier circuits.

As filters, a conventional electrolytic capacitor is used, which allows you to get rid of the remnants of the variable component of the output current. A zener diode installed at the output allows you to keep the voltage at the same level. In this case, even if there are ripples in the 220 V network and in the secondary winding, the voltage at the rectifier output will always have the same value. This is good for the devices that connect to it.

Without this electrical device, consumers of electricity would not be able to charge car batteries, connect energy-saving light sources. An electrical product lowers the stationary voltage to the required level. The device is made on the basis of electromagnetic induction. Sold in specialized stationary trade enterprises, online stores.

General device and principle of operation

A step-down transformer from 220 to 12 volts is bought by drivers, summer residents, owners of country houses, cottages for building an in-house low-voltage lighting network. At times, the use of 220 volt electrical power in the home is not economically rational.

The product consists of four main parts: two core rods and two coils of copper wire of the required section and length. They are called windings containing an unequal number of turns. Core rods are made of special steel used in the electrical industry. The transformer 220 is supplied with the current of the stationary electrical network.

In the primary winding, an intensive movement of electrons begins, an electromotive force is created. A magnetic field is formed, crossed by the second winding. Electric potentials appear in it, since the magnetic field of the first coil causes self-induction (the movement of electrons) into the second one. There is a difference in electrical levels, tending to equalize the potential values to zero.

The transfer of electrons from a high potential to a final zero creates an electric current. The voltage in the secondary winding depends on how many times it has fewer turns than in the first. It should be remembered that a step-down electrical device generates an alternating voltage in the terminal winding with a polarity change of 50 times per second. They also receive direct current by connecting a rectifier to the system in order to have 12 volts of direct current at the output.

There is a wide range of electronic step-down products that do not contain cores, coils.

Step-down devices are microscopic electronic circuits coupled with capacitors, resistors, and other important elements. They have undeniable advantages over traditional current converters, which are:

- in compactness;

- in weight;

- in manual undervoltage control;

- in silent operation;

- in high efficiency.

The buyer can choose the transformer he needs. This is his right.

It is recommended to operate a self-made transformer by hiding it behind the walls of a metal or wooden case with natural ventilation.

How to choose a step down transformer

Imported electrical appliances powered by 110 volts appeared on sale. Domestic electrical networks supply current with a voltage of 220 volts. It is problematic to use a foreign household or other device. But there is a way out. You can purchase a 220 transformer with 110 volt step-down terminals.

![]()

When choosing a step-down product, it is important to calculate the maximum load for which it is designed. The result is obtained by the following method. Multiply volts by current to get power. The formula looks like this: V x A=W. A powerful consumer of electrical energy is selected, the peak load is calculated using the formula, and 20% is added to its value.

Let's take an example. A housewife purchased an imported food processor powered by a 110 volt network, designed for a current of 3 A. We multiply the indicators. We get the power of 330 W. This is the standard power at which the combine operates. But during the preparation of a dressing, for example, for borscht, a bone got into the combine, which the device must grind. In a second, the power will jump to 1400 W. The manufacturer of electrical appliances in the technical data sheet indicates the maximum power.

A device that lowers the current is easy to make yourself. The algorithm of actions is as follows: the number of turns of metal wire on the coils is counted. The calculation of the primary begins with a winding of 220 volts. After calculations, the number of turns is determined. 2200 turns are obtained with a wire cross section of 0.3 mm and a rod area of 6 square meters. cm.

After that, the number of turns for a 12 volt coil is calculated. The second coil, producing a voltage of 12 volts, will have 120 turns with a wire cross section of 1 mm. The number of turns of one winding should not be equal to the other. Ideally, they can, if the copper wire is of different sections.

A voltage of twelve volts is used to power LED strips, lamps, and halogen lighting. Halogen lamps require little power. An important point is the manufacture of the core. The power of the transformer depends on its quality.

If there is no special electrical steel at hand, metal containers from beer, bread kvass, and other liquid products are used. Strips 3 dm long and 0.2 dm wide are cut from cans. The workpieces are fired, after which scale deposits are removed. Lacquered, wrapped with paper on one side.

The second winding is filled with wires with a cross section of 1 mm. The reel base is made of high strength cardboard material. Wrap the cardboard blank with paraffin-impregnated paper. Wire is wound on the prepared cores, not forgetting to separate the wound turns with paper. Ready-to-use windings are fixed on a compact wooden or metal frame. Fix with staples or other fasteners.

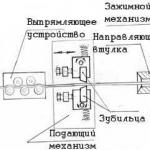

Step-down transformer connection diagram

How to connect a 220 to 12 volt transformer is of interest to many. Everything is done simply. Suggests the algorithm of actions marking at the connection points. The output terminals on the connection panel with the contact wires of the consumer device are marked in Latin letters. The terminals to which the neutral wire is connected are marked with the symbols N or 0. The power phase is designated L or 220. The output terminals are marked with the numbers 12 or 110. It remains not to confuse the terminals and answer the question of how to connect a step-down transformer 220 with practical actions.

![]()

The factory marking of the terminals ensures safe connection by a person who is not familiar with such actions. Imported transformers pass domestic certification control and do not pose a danger during operation. Connect the product to 12 volts according to the principle described above.

![]()

Now it’s clear how a factory-made step-down transformer is connected. It is more difficult to decide on a homemade device. Difficulties arise when, during the installation of the device, they forget to mark the terminals. To make the connection without error, it is important to learn how to visually determine the thickness of the wires. The primary coil is made of wire of a smaller section than the end-action winding. The connection scheme is simple.

It is necessary to learn the rule according to which it is possible to obtain a step-up electrical voltage, the device is connected in the reverse order (mirror version).

The principle of operation of a step-down transformer is easy to understand. It has been empirically and theoretically established that the coupling at the level of electrons in both coils should be estimated as the difference between the magnetic flux effect that creates contact with both coils and the electron flux that occurs in a winding with a smaller number of turns. By connecting the terminal coil, it is found that a current appears in the circuit. That is, they receive electricity.

And here there is an electrical collision. It is calculated that the energy supplied from the generator to the primary coil is equal to the energy directed into the created circuit. And this happens when there is no metal, galvanic contact between the windings. Energy is transferred by creating a powerful magnetic flux with variable characteristics.

In electrical engineering there is a term "dissipation". The magnetic flux along the route loses power. And that's bad. The design feature of the transformer device corrects the situation. The created designs of metal magnetic paths do not allow the dispersion of the magnetic flux along the circuit. As a result, the magnetic fluxes of the first coil are equal to the values of the second or almost equal.

In order to ensure uninterrupted power supply to a high-rise building, a summer cottage or a detached building at a distance from the transformer substation, it is necessary to install a step-down transformer. What kind of device is this, what are its features and how to connect on your own?

Step-down transformer - what is it and how is it used

By itself, this is an electromagnetic unit, the function of which is to convert alternating current of one voltage into current with a different voltage. This device is required when the mains voltage is higher or, conversely, lower than required to power one or another. When connecting, it is important to use exactly the winding that is intended for this - depending on this, the device will become step-down or step-up. In case of incorrect connection to the winding of the wrong type, the transformer will quickly fail. Therefore, when mounting it, it is extremely important not to confuse anything.

What will be needed?

To carry out all the work yourself you will need:

- directly transformer;

- voltmeter;

- power cable (for example, this http://provod-kabel.kiev.ua/);

- Appropriate tools.

Naturally, you also need to have some knowledge and skills in order to avoid mistakes.

Step-by-step instructions for connecting a step-down transformer

As mentioned above, the key point is to choose the right winding.

1. If it is absolutely known that the transformer is only step-down, it is advisable to choose the winding that has the largest number of turns and resistance.

2. Anode-filament devices have windings of both types. To highlight the primary winding, pay attention to its conclusions - they are usually placed at a distance from the rest. Sometimes the winding is wound in a completely different section of the frame, in which case it is quite easy to distinguish it.

3. If, however, you are still not sure, take a picture of the device and post it on the thematic forum, specifying the brand of the device. More knowledgeable people will definitely tell you where which conclusion is located in this case.

4. Be sure to check the voltage and frequency of the unit - they must correspond to 220 V and 50 Hz.

5. Sometimes the winding has three terminals, one of which is suitable for connection to a 110 or 127 V network. Your goal is to choose a combination of terminals in which the resistance is maximum. It is on them that you can start up a voltage of 220 V.

6. If the input is not three, but four, it is assumed that there are two windings. They must be connected in series and in phase to supply the appropriate voltage from the mains.

7. To perform this operation, you must first make a serial connection. Then connect the windings to a voltmeter with a maximum voltage of 500 V. Now a small voltage of several volts should be applied to one of the secondary ones. In this case, it is impossible to touch the conclusions of the primary ones.

8. Record the voltmeter reading. Now turn it off, swap the leads of any of the primary windings and repeat the procedure. You need to choose the option that showed the highest value.

9. If one winding is selected, it must be connected through a fuse to the network. The rated current is determined depending on the power of the transformer - no more than 0.05 A per 10 W. If there are two windings, they should be connected to the network in series and in phase.

10. After that, very carefully, so as not to touch the terminals, measure the alternating voltage generated by the transformer device with a voltmeter.

11. For transformation into direct alternating voltage it is necessary to connect a rectifier with a filter. It is important not to reverse the polarity when connecting to an electrolytic capacitor. Remember: at the output of the filter, the voltage will increase by almost one and a half times compared to the voltage on the secondary winding.

Before making the necessary soldering, the transformer must be de-energized. If the rectifiers are high voltage, the filter capacitors should also be discharged before touching them. It is impossible to exceed not only the maximum current of each individual winding, but also the permissible power from the transformer as a whole.

What to do if your gas lawn mower won't start

What to do if your gas lawn mower won't start  lumber. What to look for when buying

lumber. What to look for when buying  How to install and connect a washing machine.

How to install and connect a washing machine.