To apply a solder mask on a printed circuit board, you need a so-called frame with a well-stretched stencil mesh. The process of stretching the mesh scares many people and they prefer to buy a finished frame. In fact, there is nothing complicated here, it would be a desire and a little free time.

In this article I will tell you how to properly stretch the stencil mesh on the frame.

frame frame

We cook from a square iron pipe 20 * 20 mm. frame of the desired size, we grind all the corners and sides with sandpaper so that the mesh does not tear when tensioned. We paint it from three sides (we leave the side where the mesh will be glued not painted). In this case, the frame has a working field of 210 * 300 mm, that is, A4 format.

Screen Tensioner

We take a piece of chipboard 26 mm thick. We put a frame on it and with an allowance of 5 mm from the outside, outline and cut it with a jigsaw.

Then we drill 6 mm through holes around the perimeter. On the other hand, we drill these holes to a depth of 5..6 mm. drill 10 mm.

We drive M6 nuts into the drilled holes and screw M6 bolts on the other side.

The process of stretching the mesh on the frame

We impose a frame on the side of the chipboard with nuts, degrease it and evenly with brackets, starting from the middle of each side, we fasten the screen mesh.

In this case, we used stencil grid VS-Monoprint PES 77/48 PW.

We put the chipboard with the frame on the edge, then first we tighten the bolts with our hands until they stop evenly around the entire perimeter. We take the key for 10 and stretch the grid half a turn. We twist the bolts in a checkerboard pattern, that is, evenly. As a result, the frame rises and the grid is stretched accordingly. It is not necessary to abuse the stretch here, the mesh must be sufficiently evenly stretched and not sag. A weak stretch is also not desirable. If you overtighten the mesh, the bracket may fail and the mesh may break.

We glue the stencil mesh to the frame

We breed special adhesive for stencil mesh KIWOBOND 1100, 10 ml is sufficient for this frame size. glue. We apply glue to the mesh with a brush, soaking it, it will securely stick it to the frame. You need to smear the glue immediately abundantly (if you apply a little, then it dries quickly), and of course smear it so that the diluted glue is enough for the entire frame.

After two hours, the glue will harden, remove the adhesive tape and cut the mesh around the perimeter of the frame with a paint knife.

Read articles on the site of the original source, do not support thieves.

The result of the work

The result is a frame of the right size with a high-quality stencil mesh stretched over it, for applying a solder mask to a printed circuit board. In the same way, the mesh was stretched over a smaller frame, with a working field of 110 * 170 mm., For small boards.

Stencil Frame Testing

PCB test, excellent result.

Proper solder mask application

The photo schematically shows the process of applying a solder mask. The distance between the grid and the board, the inclination of the squeegee and the grid during application.

With any factory board, the main difference will immediately catch your eye: on almost all factory boards, the tracks are covered with some kind of protective layer, only contact pads remain outside. This layer can be green, red, blue, and sometimes even black or white. So what is it, and why is it needed?

This coating is called a solder mask, and is designed to protect the tracks from oxides, accidental short circuits and overheating of the textolite during the installation of elements. In addition to this, mounting elements on a board covered with a solder mask is much more comfortable: the solder does not stretch along the tracks. If the details are sealed with a hairdryer, then this is all the more true. Yes, and the board with a mask looks much more attractive.

At the moment, three types of solder mask are available to the radio amateur:

- One-component (with UV curing).

- Two-component.

- Dry film.

The one-component mask offered by our little Chinese friends is actually a repair paint. For example, it is very convenient for her to cover up the place where the tracks are restored. No, it is also used as a mask, in this case an oven is not needed (and UV lamps are needed anyway), but in terms of strength it still loses to a two-component one. There is also a real one-component solder mask, but it is much less common.

The film mask is very similar to the photoresist both in appearance and in the principle of working with it. Yes, yes, a protective coating can also be made from photoresist, but in reality this is just a semblance that has neither chemical nor mechanical strength. It is also quite rare, it is quite expensive, and most importantly, a vacuum laminator is needed for full-fledged work (for a full fit of the mask to the board surface).

The most optimal in terms of price / quality ratio is a two-component solder mask. It is possible to purchase it by weight, which makes the mask even more affordable.

| Stores and vendors that I use. | |

|---|---|

| Online store "Everything for printed circuit boards" | Solder mask, stencil mesh (and glue for it), squeegee rubber, carbide drills were repeatedly purchased here. This is where the photoresist is purchased. There are no complaints about the store, everything is packed perfectly. There was only one feature - orders were collected and sent for a rather long time (most likely, one person was engaged in this). Now (09/13/2017) the store is changing its owner, what will happen next - time will tell. |

| Maxim (nickname: smacorp) from the RadioKot website. | Great seller and just a nice person to deal with. Here you can buy liquid tin for chemical tinning and a solder mask. All of this is of excellent quality. |

Yes, solder masking makes the PCB manufacturing process even more labor intensive, time consuming and requires new tools and materials. But after all, a real radio amateur should not stand still, acquiring new skills and knowledge is always good.

As usual, we divide the board manufacturing process into stages:

Workpiece drilling, photoresist application, exposure, development, etching. All of these steps have been discussed previously. Perhaps someone will be surprised by the fact that the first step is drilling, usually we did it almost at the very end, but in this case the holes are drilled by the CNC machine, and the order will be just that. We will talk about preparing files for the machine and making a board with it, but for now we will take it for granted.

Drilled blank, coated with photoresist.

Preparation before exposing tracks.

In the second photo, you can see that next to the track template there is another template (in fact, there is more than one). This is the template for the solder mask. According to the principle of working with it, the mask is not much different from the photoresist. This is exactly the same light-sensitive material, with slight differences: it consists of two components and it is liquid.

Mixing mask. Before applying the mask, the composite and hardener are mixed in a certain proportion, for example, for the FSR-8000 mask - 3:1. The composite has the color of the coating, and the hardener is white.

All you need.

All you need. The situation, when there was not enough mask during application, has a very depressing effect on the psyche, which means that it is necessary to calculate its quantity. In fact, everything is simple here: for 1 square decimeter of the board (10 * 10 cm), 2 grams of the mask is enough with a margin. Of course, it all depends on the consistency and method of application, but I'm talking about a situation where the mask is not diluted with anything (quite thick), and is applied through a special mesh using a squeegee. Yes, very little expense.

For example, our blank is 6.5 cm by 4.5 cm in size. We consider the area in decimeters: (6.5 cm * 4.5 cm) / 100 = 0.2925 dm². We believe that 0.3 dm², in our case it is better to round up. We consider the amount of the mask: 0.3 dm² * 2 gr. = 0.6 gr. This is the amount of the finished mask. Since we interfere in a ratio of 3 to 1, then 0.6 gr. / 4 parts \u003d 0.15 grams - the weight of one part. So 3 parts of the composite have a weight of 0.45 grams, and one part of the hardener - 0.15 grams. We interfere.

There is nothing wrong with the fact that the composite is hundredths of a gram more than it should be. But if we are talking about a situation where there is more of something, then it is very desirable that it be a composite and not a hardener. Again, in hundredths, nothing more, the proportions must be observed. Next, mix the mask very thoroughly, and leave for a few minutes. In the meantime, let's prepare the network.

Solder mask application. There are two requirements for applying the mask: the layer must be thin and necessarily uniform. Of course, you can try to cope with improvised means (usually paint rollers, spatulas for grouting and other garden tools are used here), but still the only correct way is to apply through a stencil mesh.

Stencil mesh is a material that is perfect for applying a mask. I use LM-PRINT nets (the link to the store is in the table above). In the marking of the mesh through a fraction, the number of threads per cm and the diameter of the threads in microns are indicated. For example, LM-PRINT PES 61/60 PW - 61 threads per cm, thread diameter 60 microns. The lower the number of threads, the thicker the mask on the board surface. And vice versa.

For the mesh on sale, you can find special frames on which this mesh is stretched. In my case, this is a regular 18 mm profile pipe. Glue for the mesh is special, purchased in the same place as the mesh. You can read about the tension of the mesh Racks at the corners of the mesh raise it above the workpiece by 3 mm.

The perimeter of the workpiece is glued on the grid with masking tape. Let's prepare two windows at once: for the mask and silkscreen. Squeegee rubber is also special, and purchased in the same place as the mesh.

The prepared mask is applied in an even layer on one side of the board. After that, with one confident movement, it is pulled along the workpiece with an edge of a squeegee located at an angle. The main thing is not to stop when applying. Of course, experience is needed here, and over time the result will only get better. And for training, you can use toothpaste, for example.

Soldermask drying. A very important step. The board blank during the manufacture of the solder mask has time to visit the furnace twice. The first time for pre-drying and the second time for final curing. And the only difference is temperature. If drying is carried out at a temperature of 75-85°C, then tanning at 150-160°C. Guess what happens if you exceed the pre-drying temperature? Yes, the mask will finally harden, and it will be impossible to wash it off with any developing solutions. We will get a board with a beautiful and even mask, which is completely unsuitable for soldering, since the mask layer is solid. It remains only to throw it away, and this is the whole cycle from applying the photoresist to the finished, in fact, board. It's a shame? Of course. That is why we are very careful about drying. Of course, it is better to entrust such a task to the units intended for this. I have a furnace for this, with a PID controller installed in it. Pre-drying usually takes 30-55 minutes. The main thing is that the mask should not stick after drying. Moreover, while it is hot, such an effect can be, but when it cools down, it should disappear.

Solder mask exposure. It differs from the photoresist only in the exposure time, otherwise everything is exactly the same. The mask is negative (like the photoresist, what was illuminated polymerizes), which means that we close only the contact pads. Next, we exhibit.

Solder mask development. Again, everything is like with a photoresist. Even the solution is the same, therefore, after developing the photoresist, we do not pour it out, but use it further. And even after the mask has been developed, it will come in handy, we will develop silk-screen printing with them and wash the mesh from the mask. I want to pay attention to this: if the mask is glossy, then this gloss can be easily damaged during development, therefore, ideally, you should not touch the surface of the board at all. However, if everything is done correctly, then the mask appears very easily.

Applying silkscreen. In principle, marking elements on the board is not the most necessary thing. If without a solder mask in some cases it is quite dreary, then the designation of the elements is just a convenience when assembling the device. So let's put the label on. To do this, use the same mask, just select the blue color.

note

If the marking is applied on the same side as the solder mask, it must be hardened for at least 15 minutes at the appropriate temperature. If you apply a new layer on a mask that is not tanned, the solvent included in the mask will damage the underlying layer. The mask remains on the board, but its surface cracks. Especially if the color of the screen printing mask is white, these cracks are very clearly visible in the end.

We have a marking on the reverse side, therefore it is permissible to apply without drying. In the same way, we knead the blue mask and apply it to the back of the board.

Silk screen drying. In the oven for 45 minutes at a temperature of 75-85°C.

Silk screen display. We only need the designation of the elements, which means that we use a negative template.

Silkscreen development.

Final drying. It is performed at a temperature of 150-160°C for 45-75 minutes. At this temperature, the mask acquires its final strength.

While the board is drying, you can wash the mesh from the mask. This is easily handled by a soda ash developing solution and a dish sponge.

Board cutting. Of course, it is not at all necessary to do this with the help of a machine, but since he drilled holes, then let him also cut out along the contour.

Tinning. There is also one feature here: after the furnace, the copper on the contact pads is oxidized, and it is not so easy to tin it. But this is corrected very easily, it is enough to lower the board into water for a minute, to which citric acid is added. We use it for etching, so this is not a problem. Enough half a teaspoon to half a glass of water, and the copper will become clean and shiny.

So the series of articles on the manufacture of devices has come to an end. As I promised, we have come quite a long way. Of course, manufacturing is not limited to the considered methods, this topic is very extensive. But, I hope, the general idea of the cycle allows you to draw up.

There are decades between the first and the last technology. But even this is not the main thing. Between them is a huge work of the whole world of radio amateurs. A work full of experiments, victories and mistakes, because only those who do nothing do not make mistakes. Don't be afraid to ask questions, experiment and share your experience (albeit not always successful). This experience will definitely be useful to someone else, otherwise it cannot be.

All the best.

This article is devoted to the manufacture of a home-made printed circuit board with greenery

General issues of making printed circuit boards at home are quite well covered on the Internet. I will not describe what others have already written a hundred times. Instead, I will briefly describe my little tricks and processes, especially about vias and mask (greenery).

Homemade board 8 mil tracks, 6 mil spacing, adapters and mask.

Equipment

Laser printer (Kyocera FS-1100 printer, for toner transfer), laminator, microcompressor.

materials

Everything is as usual (textolite, ferric chloride, acetone, etc.) except for stained glass paint (Pebeo Vitrea 160).

Process

Sverlovka: Since I use the CNC for drilling, the process occurs before the transfer of the toner, in this case it is easier to position the pattern.

Transferring toner to the board:

Many people use an iron, but still, the best results were achieved with the use of a laminator. We roll 10-15 times through the laminator. Paper - everyone can experiment here too, I use 130 g / m photo paper. Using photo paper seems to increase the life of the printer itself. Print mode, select the maximum toner consumption) Unfortunately, the trend is that modern printers are more and more economical (or fortunately, depending on which side you look at) and the thickness of the toner after transfer tends to decrease. This is what happened after the laminator:

Etching:

The etching process takes place in a solution of ferric chloride and is no different from the classical methods - warmer water, more iron, stir more often)

Transition holes:

Via holes are an integral part of the DIY double-sided board manufacturing process. You can consider several options for homemade transitional:

1. Use of special bushings. Difficult to find or make. The need for a sufficiently large diameter in VIA.

2. Installation of jumpers using a wire. It has one drawback - when the adapter is located under the SMD microcircuit housing. This requires some experience. (experience is needed everywhere, but making jumpers of the required length and then soldering with a minimum amount of solder is sometimes not easy)

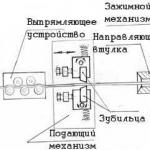

3. Pressing. This method allows you to create a high-quality transitional connection between layers. For this purpose, a special machine-press was created. Details about the press can be found in.

It would seem that the next step is to tin the board and go! But no, it's boring and ugly. We are not looking for easy ways. We make a payment with "green"

It would seem that the next step is to tin the board and go! But no, it's boring and ugly. We are not looking for easy ways. We make a payment with "green"

Mask

The mask protects the board from corrosion, creates more favorable conditions during installation, and gives the board a “branded” look. For the first time, a home-made mask was read. It is based on publicly available stained glass paint. Pebeo Vitrea 160. Water-based paint, has one feature - it requires firing (drying) in an oven at a temperature of 160 C for 40 minutes. In fact, I did not try to fry the board above 130 degrees. A temperature of 130 is quite enough for the normal polymerization of the paint.

First, we print on the same laser printer a layer to protect the pads involved in the installation. Simply put, we close the necessary areas from the mask. We impose on the board and again in the laminator:

Then we apply paint with our mini-pulverizer. I add 1 part water to 4 parts paint before applying. After application, wait 24 hours - the paint needs to dry. There is no need to rush - we will always have time to burn the fee). After that, we drive the wife out of the kitchen and occupy the stove for 40 minutes. In fact, it is better to get some kind of mini-oven or use a toaster for these purposes. But in any case, you need to carefully monitor the temperature. After 40 minutes, remove the pie from the oven:

Then we apply paint with our mini-pulverizer. I add 1 part water to 4 parts paint before applying. After application, wait 24 hours - the paint needs to dry. There is no need to rush - we will always have time to burn the fee). After that, we drive the wife out of the kitchen and occupy the stove for 40 minutes. In fact, it is better to get some kind of mini-oven or use a toaster for these purposes. But in any case, you need to carefully monitor the temperature. After 40 minutes, remove the pie from the oven:

The protective layer, consisting of toner, is removed with a solvent or acetone using a small mechanical force of the hands. Ink falls off protected areas due to poor adhesion to the toner. Now you can tin the pads and solder some SDR transceiver or other trinket. In general, the whole method is rather laborious and necessary, I believe, for very important trinkets. Well, or for real aesthetes who are not used to paying 1000 rubles for a branded double-sided card in China (if anyone is interested, write, I will give the website address where it’s really possible to order normal boards for 1000 rubles)

The protective layer, consisting of toner, is removed with a solvent or acetone using a small mechanical force of the hands. Ink falls off protected areas due to poor adhesion to the toner. Now you can tin the pads and solder some SDR transceiver or other trinket. In general, the whole method is rather laborious and necessary, I believe, for very important trinkets. Well, or for real aesthetes who are not used to paying 1000 rubles for a branded double-sided card in China (if anyone is interested, write, I will give the website address where it’s really possible to order normal boards for 1000 rubles)

15.10.2015

A solder mask (Solder Resist or Solder Mask) is a mandatory heat-resistant protective coating for the conductive pattern of printed circuit boards. Purpose: protection of individual sections of the PCB from the adverse effects of flux and solder, as well as the influence of a humid environment and mechanical stress.

Type variety

Application features

The solder mask is applied to either one () or both sides of the PCB. Mandatory isolation is required, contact areas (under the output of the microcircuit, etc.) from conductive elements - conductors or transitional holes. The result is a reduction in labor intensity/soldering time.

If it is necessary to isolate adjacent contact areas, the cutout method is used (creating an area not covered with a solder mask layer). In this case, the size of the cutouts should be 100–150 µm larger than the total size of the contact area. The distance from one edge of the solder mask to the other edge of the contact area should be within 50-75 microns. The minimum width of the jumper - the area between 2 adjacent contact areas - 75 microns.

Color - red, white, green, blue, black, yellow or super white - is chosen by the customer. The LED industry uses super white/white soldermask color, in other fields green is the most popular color. In this case, it should be taken into account that the final color saturation of the PP is created not by the base material, but by the mask coating.

The process of creating a protective layer

The mask is applied through a stencil in the form of a grid (the size of one cell is 150 μm). Wet layer thickness: 30-35 µm. Then, the product is dried. Temperature in the drying chamber: no more than 75 ˚. Dried blanks are sent to the stage of photolithography - the combination of photomasks of masks with products - and high-power UV exposure. The final stage is the manifestation of blanks in solution (substance temperature 32-34 ˚).

Restrictions

- When creating a thin jumper (less than 75 microns), it can be damaged during installation and disrupt the required adhesion to the PCB surface. As a result, the solderability properties of damaged contact areas are lost.

- Lack of possibility to apply a mask on the terminal contacts of the connectors/test points.

- When creating a protective layer on printed circuit boards with a lead-out pitch of more than 1.25 mm, it is allowed to get the solder mask on the contact areas only on one side and not more than 50 microns. And with a step of less than 1.25 mm - no more than 25 microns.

- All vias that are subject to subsequent coating with a protective solder mask must be closed (tented).

- Possible defects: the presence of areas with no protective mask - less than 0.2 mm 2 on 1 conductor and less than 2 mm 2 on polygon areas; the presence of minor delaminations (up to 0.25 mm); the occurrence of long tunnel voids.

Pros of using a protective solder mask

- high chemical resistance . The mask protects against the manifestation of aggressive environments, oxidation of copper conductors.

- Significant indicators physical stability . There is protection against scratches, mechanical impact.