An optocoupler is an electronic device consisting of a light source and a photodetector. The role of the light source is performed by an infrared LED with a wavelength in the range of 0.9 ... 1.2 microns, and the receiver is phototransistors, photodiodes, photothyristors, etc., connected by an optical channel and combined into one housing. The principle of operation of an optocoupler is to convert an electrical signal into light, and then transmit it through an optical channel and convert it into an electrical signal. If the role of a photodetector is performed by a photoresistor, then its light resistance becomes thousands of times less than the original dark one, if it is a phototransistor, then the impact on its base creates a similar effect as when current is applied to the base of a conventional transistor, and it opens. Usually optocouplers and optocouplers are used for the purpose of galvanic isolation.

This probe is designed to test a large number of types of optocouplers: optotransistors, optothyristors, optotriacs, optoresistors, as well as the NE555 timer chip, the domestic analogue of which is

Modified version of the probe for checking optocouplers

The signal from the third output of the 555 microcircuit, through the resistor R9, is fed to one input of the VDS1 diode bridge, provided that a working optocoupler radiating element is connected to the Anode and Cathode contacts, in which case current will flow through the diode bridge and the HL3 LED will flash, provided that the photodetector is working, VT1 will open and HL3 will light up, which will conduct current, while HL4 will blink

This principle can be used to test almost any optocoupler:

The multimeter should show about 570 miles of volts if the optocoupler is working in the diode continuity mode, because in this mode about 2 volts come from the tester probes, but this voltage is not enough to open the transistor, but as soon as we apply power to the LED, it will open and we will see on the display the voltage that drops across the open transistor.

The device described below will show not only the health of such popular optocouplers as PC817, 4N3x, 6N135, 6N136 and 6N137, but also their response speed. The basis of the circuit is the microcontroller of the ATMEGA48 or ATMEGA88 series. The components under test can be connected and disconnected directly into the device when it is turned on. The result of the test will be shown by the LEDs. So the ERROR element glows in the absence of connected optocouplers or their inoperability. If the element is OK, the OK LED will light up. Simultaneously with it, one or more TIME LEDs will light up, corresponding to the response speed. So, for the slowest optocoupler, PC817, only one LED will light up - TIME PC817, corresponding to its speed. For fast 6N137s, all four LEDs will be lit. If this is not the case, then the optocoupler does not correspond to this parameter. The speed scale values PC817 - 4N3x - 6N135 - 6N137 are related as 1:10:100:900.

Microcontroller fuses for firmware: EXT = $FF, HIGH = $ CD, LOW = $ E2.

The printed circuit board and firmware can be downloaded from the link above.

I recently had to fiddle with various electronic ballasts and, in their composition, with a DB3 dinistor, optocouplers and zener diodes from other devices. Therefore, in order to quickly test these components, a specialized tester had to be developed and manufactured. Additionally, in addition to dinistors and optocouplers, in order not to create testers for such components, the tester can check zener diodes, LEDs, diodes, transistor junctions. It uses light and sound indication and an additional digital voltage meter to assess the level of operation of dinistors and the voltage drop at the junction of the tested zener diodes, diodes, LEDs, transistors.

Note: All rights to the scheme and design belong to me, Anatoly Belyaev.

2017-03-04Circuit Description

The tester circuit is shown below in Pic 1.

Note: For a detailed view of the image, click on it.

Pic 1. Diagram of the DB3 tester (dinistors), optocouplers, zener diodes, diodes, LEDs and transistor junctions

The basis of the tester is a high-voltage pulse generator, which is assembled on a transistor VT1 according to the principle of a DC-DC converter, that is, high-voltage self-induction pulses enter the storage capacitor C1 through a high-frequency diode VD2. The generator transformer is wound on a ferrite ring taken from an electronic ballast (any suitable one can be used). The number of turns is about 30 for each winding (not critical and winding can be done simultaneously with two wires at once). The resistor R1 achieves the maximum voltage across the capacitor C1. I got about +73.2 V. The output voltage is supplied through R2, BF1, HL1 to the contacts of the XS1 socket, into which the tested components are inserted.

A digital voltmeter PV1 is connected to pins 15, 16 of the XS1 socket. Bought on Aliexpress for 60 R. When checking dinistors, the voltmeter shows the opening voltage of the dinistor. If LEDs, diodes, zener diodes, transistor junctions are connected to these XS1 contacts, then the voltmeter PV1 shows the voltage at their junction.

When checking dinistors, the HL1 indicator LED and the BF1 sound emitter operate in a pulsed mode - indicating that the dinistor is in good condition. If the dinistor is broken, then the LED will glow constantly and the voltage on the voltmeter will be about 0 V. If the dinistor is open, then the voltage on the voltmeter will be about 70 V, and the HL1 LED will not light. Optocouplers are checked in the same way, only the indicator LED for them is HL2. In order for the operation of the LED to be pulsed, a serviceable dinistor DB3 (KN102) is inserted into the XS1 contacts. With a good optocoupler, the glow of the indicator LED is pulsed. Optocouplers are designed in DIP4, DIP6 packages and must be installed in the corresponding XS1 pins. For DIP4 it is XS1 and for DIP6 it is XS1.

If you check the zener diodes, then connect them to XS1. The voltmeter will show either the stabilization voltage if the zener diode cathode is connected to pin 16, or the voltage at the zener diode junction in the forward direction if the anode is connected to pin 16.

The voltage from the capacitor C1 is directly output to the XS1 contacts. Sometimes it is necessary to light a powerful LED or use the full output voltage of a high voltage generator.

Power is supplied to the tester only during component testing, when the SB1 button is pressed. Button SB2 is designed to control the supply voltage of the tester. With the simultaneous pressing of the buttons SB1 and SB2, the voltmeter PV1 shows the voltage on the batteries. I did this so that I could change the batteries in a timely manner when they run out, although I think that it will not be soon, since the work of the tester is short-term and the loss of battery energy is more likely due to their self-discharge than due to the operation of the tester itself when checking components. The tester is powered by two AAA batteries.

For the operation of a digital voltmeter, I used a purchased DC-DC converter. At its output, I installed +4.5 V - the voltage supplied to both the power supply of the voltmeter and the HL2 LED circuit - control of the operation of the output stage of the optocouplers.

I used a 1GW planar transistor in the tester, but you can use any suitable and not only planar one, which will provide a voltage on the capacitor C1 of more than 40 V. You can even try using a domestic KT315 or an imported 2N2222.

Photo review on the manufacture of the tester

Pic 2. Tester circuit board. Panel side view.

Pic 2. Tester circuit board. Panel side view. On this side of the board, a socket, a sound emitter, a transformer, indicator LEDs and control buttons are installed.

Pic 3. Tester circuit board. View from the printed conductors.

Pic 3. Tester circuit board. View from the printed conductors. On this side of the board, planar components and large-sized parts are installed - capacitors C1 and C2, trimmer resistor R1. The printed circuit board was made by a simplified method - cutting grooves between the conductors, although etching can be done. The PCB layout file can be downloaded at the bottom of the page.

Pic 4. Internal contents of the tester.

Pic 4. Internal contents of the tester. The body of the tester consists of two parts: upper and lower. A voltmeter and a tester board are installed in the upper part. A DC-DC converter is installed in the lower part to power the voltmeter and a container for batteries. Both parts of the body are connected by latches. Traditionally, the body is made of 2.5 mm thick ABS plastic. The dimensions of the tester are 80 x 56.5 x 33 mm (excluding legs).

Pic 5. The main parts of the tester.

Pic 5. The main parts of the tester. Before installing the converter in its place in the case, the output voltage was adjusted to +4.5 V.

Pic 6. Before assembly.

Pic 6. Before assembly. Holes are cut in the top cover for the voltmeter indicator, for the contact socket, for the indicator LEDs and for the buttons. The voltmeter indicator hole is closed with a piece of red plexiglass (you can use any suitable one, for example, I have a shade of purple, violet). The holes for the buttons are countersunk so that you can press a button that does not have a pusher.

Pic 7. Assembly and connection of parts of the tester.

Pic 7. Assembly and connection of parts of the tester. The voltmeter and the tester board are mounted on self-tapping screws. The board is attached so that the indicator LEDs, socket and buttons go into the corresponding holes in the top cover.

Pic 8. Before checking the operation of the assembled tester.

Pic 8. Before checking the operation of the assembled tester. A PC111 optocoupler is installed in the socket. A known good DB3 dinistor is inserted into pins 15 and 2 of the socket. It will be used as a pulse generator applied to the input circuit to check the correct operation of the output part of the optocoupler. If you use a simple glow of the LED through the output circuit, then this would be wrong, since if the output transistor of the optocoupler were broken, then the LED would also glow. And this is an ambiguous situation. When using the pulsed operation of the optocoupler, we clearly see the performance of the optocoupler as a whole: both its input and output parts.

Pic 9. Checking the performance of the optocoupler.

Pic 9. Checking the performance of the optocoupler. When you press the component test button, we see a pulsed glow of the first indicator LED (HL1), indicating the health of the dinistor operating as a generator, and at the same time we see the glow of the second indicator LED (HL2), which, by pulsed operation, indicates the health of the optocoupler as a whole.

The voltmeter displays the operation voltage of the generator dinistor, it can be from 28 to 35 V, depending on the individual characteristics of the dinistor.

An optocoupler with four legs is checked in the same way, only it is installed in the corresponding socket contacts: 12, 13, 4, 5.

Socket contacts are numbered in a circle counterclockwise, starting from the bottom left and then to the right.

Pic 10. Before checking the optocoupler with four legs.

Pic 10. Before checking the optocoupler with four legs.  Pic 11. Checking the dinistor DB3.

Pic 11. Checking the dinistor DB3. The tested dinistor is inserted into contacts 16 and 1 of the socket and the test button is pressed. The voltage of the dinistor operation is displayed on the voltmeter, and the first indicator LED pulsed operation indicates the health of the tested dinistor.

Pic 12. Checking the zener diode.

Pic 12. Checking the zener diode. The zener diode under test is installed in the contacts where the dinistors are also checked, only the glow of the first indicator LED will not be pulsed, but constant. The performance of the zener diode is evaluated by a voltmeter, where the stabilization voltage of the zener diode is displayed. If the zener diode is inserted into the socket with the contacts vice versa, then when checking on the voltmeter, the voltage drop at the zener diode junction in the forward direction will be displayed.

Pic 13. Checking another zener diode.

Pic 13. Checking another zener diode. The accuracy of the stabilization voltage readings can be somewhat arbitrary, since a certain current through the zener diode is not set .. So, in this case, the zener diode was checked at 4.7 V, and the readings on the voltmeter were 4.9 V. This can also be influenced by the individual characteristics of a particular component, since zener diodes for a certain stabilization voltage have some variation among themselves. The tester shows the stabilization voltage of a particular zener diode, and not the value of its type.

Pic 14. Testing a bright LED.

Pic 14. Testing a bright LED. To test the LEDs, you can use either pins 16 and 1, where dinistors and zener diodes are checked, then the voltage drop across the working LED will be displayed, or you can use pins 14 and 3, to which the voltage from the storage capacitor C1 is directly output. This method is convenient for checking the glow of more powerful LEDs.

Pic 15. Voltage control on capacitor C1.

Pic 15. Voltage control on capacitor C1. If you do not connect any components for testing, the voltmeter will show the voltage across the storage capacitor C1. For me, it reaches 73.2 V, which makes it possible to check dinistors and zener diodes in a wide range of operating voltages.

Pic 16. Checking the supply voltage of the tester.

Pic 16. Checking the supply voltage of the tester. A nice function of the tester is to control the voltage on the batteries. When two buttons are pressed simultaneously, the voltage of the batteries is displayed on the voltmeter indicator and the first indicator LED (HL1) is lit at the same time.

Pic 17. Different angles on the body of the tester.

Pic 17. Different angles on the body of the tester. The side view shows that the control buttons do not protrude beyond the top side of the lid, so that there is no accidental pressing of the buttons if the tester is put in a pocket.

Pic 18. Different angles on the body of the tester.

Pic 18. Different angles on the body of the tester. The case below has small legs, for a stable position on the surface and so as not to wipe or scratch the bottom cover.

Pic 19. Finished view.

Pic 19. Finished view. The photo shows the finished view of the tester. Its dimensions can be represented by a standard box of matches placed next to it. In millimeters, the dimensions of the tester are 80 x 56.5 x 33 mm (excluding legs), as indicated above.

Pic 20. Digital voltmeter.

Pic 20. Digital voltmeter. The tester uses a purchased digital voltmeter. I used a meter from 0 to 200 V, but it can also be from 0 to 100 V. It is inexpensive, within 60 ... 120 P.

To quickly check the performance of optocouplers, radio amateurs make various tester circuits that immediately show whether this optocoupler is working or not, today I will propose to solder the simplest tester for testing optocouplers. This probe can test optocouplers in both a four-pin package and six, and using it is as easy as shelling pears, insert an optocoupler and immediately see the result!

Necessary parts for optocoupler tester:

- Capacitor 220uF x 10V;

- Socket for the microcircuit;

- Resistor from 3 kOhm to 5.6 kOhm;

- Resistor from 1 kOhm;

- Light-emitting diode;

- 5V power supply.

How to make a device for testing optocouplers, instructions:

The optocoupler tester works from 5 volts, if less then not all types of optocouplers can work correctly, any charger for a mobile phone can serve as a power supply. When correctly inserted into the tester panel of the working optocoupler, the LED will flash, which means that everything is in order with it, the frequency of flashes depends on the capacitance of the electrolytic capacitor. If the optocoupler is burnt out or inserted on the wrong side, the LED will not light up, or if there is a breakdown of the transistor inside the optocoupler, the LED will simply glow but not blink.

The socket for checking optocouplers is made from a socket for a microcircuit and 4 pins are left at one end to check the optocoupler in a 4-pin package, and 5 pins for a 6-pin package are left at the second end of the socket. I soldered the remaining parts of the device for checking optocouplers by surface mounting on the contacts of the socket, but if desired, you can etch the board.

It remains to choose a suitable case and a simple optocoupler tester is ready!

Answer

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five http://jquery2dotnet.com/ centuries , but also the leap into electronic typesetting, remaining essentially unchanged.

Do-it-yourself opto-relay test device

The other day I needed to check the opto-relay in large quantities. By assembling this solid state relay tester in half an hour, from a minimum of parts, I saved a lot of time testing optocouplers.

Many novice radio amateurs are interested in how to check an optocoupler. Such a question may arise from ignorance of the device of this radio component. If we consider the surface, then a solid-state optoelectronic relay consists of an input element - an LED and an optical isolation that switches the circuit.

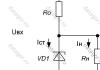

This circuit for checking an optocoupler is simple to the elementary. It consists of two LEDs and a 3V power supply - a CR2025 battery. The red LED acts as a voltage limiter and, at the same time, is an indicator of the operation of the optocoupler LED. The green LED is used to indicate the operation of the optocoupler output element. Those. if both LEDs are lit, the optocoupler test was successful.

The process of checking the opto-relay comes down to installing it in the corresponding part of the socket. This solid state relay tester can test DIP-4, DIP-6 optocouplers and DIP-8 dual relays.

Below I give the positions of the opto-relay in the sockets of the tester and the glow of the LEDs corresponding to their performance.

Using the proposed probe, you can check the NE555 (1006VI1) microcircuits and various optodevices: optotransistors, optothyristors, optotriacs, optoresistors. And it is with these radio elements that simple methods do not work, since it is simply impossible to ring out such a detail. But in the simplest case, you can test an optocoupler using this technology:

With a digital multimeter:

Here, 570 is the millivolts that fall on the open junction of the optotransistor. In diode continuity mode, the drop voltage is measured. In the "diode" mode, the multimeter outputs a voltage of 2 volts pulsed, rectangular to the probes, through an additional resistor, and when the P-N junction is connected, the multimeter's ADC measures the voltage falling on it.

Tester of optocouplers and microcircuits 555

We advise you to spend a little time and make this tester, as optocouplers are increasingly used in various amateur radio designs. And I’m generally silent about the famous KR1006VI1 - they put it almost everywhere. Actually, on the tested microcircuit 555, a pulse generator is assembled, the operability of which is evidenced by the blinking of the LEDs HL1, HL2. Next comes the optocoupler probe.

It works like this. The signal from the 3rd leg 555 through resistor R9 enters one input of the VDS1 diode bridge, if a working optocoupler radiating element is connected to contacts A (anode) and K (cathode), then current will flow through the bridge, causing the HL3 LED to blink. If the receiving element of the optocoupler is also working, then it will conduct current to the VT1 base by opening it at the moment of ignition of HL3, which will conduct current and HL4 will also blink.

P.S. Some 555s do not start with a capacitor in the fifth leg, but this does not mean they are malfunctioning, so if HL1, HL2 did not blink, short-circuit c2, but if after that the indicated LEDs did not blink, then the NE555 chip is definitely faulty. Good luck. Sincerely, Andrey Zhdanov (Master665).