The technology of design and construction of buildings made from light steel frames, which is constantly gaining popularity today, is being introduced into almost all areas of activity. Many residential buildings and premises for commercial use have already been built from light metal frames. The popularity of this construction method is directly related to the many benefits that the customer receives. In particular, using LSTK technology, buildings are built that are inexpensive, prefabricated and pay for themselves in the shortest possible time.

General information about construction technology from LSTK

The considered method of constructing buildings refers to frame construction. The key material is light steel profiles, manufactured by rolling on special equipment. The raw material for this production is galvanized thin-walled steel with an average thickness of 2-4 millimeters. Solid and perforated profiles of various sections and configurations are made from it.

In accordance with a pre-developed project, such factories produce ready-made sets of materials for assembling the frame of a building. The material is then delivered in packages directly to the construction site. It is worth noting that due to the lightness of the structural elements, transportation costs are significantly lower than during the construction of permanent buildings - brick, concrete, wood, and so on.

In accordance with a pre-developed project, such factories produce ready-made sets of materials for assembling the frame of a building. The material is then delivered in packages directly to the construction site. It is worth noting that due to the lightness of the structural elements, transportation costs are significantly lower than during the construction of permanent buildings - brick, concrete, wood, and so on.

A spatial steel frame is assembled from the above profiles at the construction site. It consists of wall studs or panels, as well as roof trusses. Typically, the panel wall configuration is used for the construction of buildings intended for residential use. In the commercial sphere, the frame is based on load-bearing posts made of a U-shaped profile, reinforced with spacers and other cohesive elements.

To form a roof from LGSF, the simplest, cheapest and most reliable configuration is most often used - a triangle. Trusses are assembled from the same thin-walled profiles, which are then installed on the wall frame with a certain pitch. The variability of construction from LSTK does not end there. Ease of processing and installation allows you to create almost any architectural shape, including semicircular, oval and others.

Next, the metal frame is sheathed with barrier structures. These include roofing and wall pie. In the commercial sphere, in this regard, as a rule, the simplest solutions are used - corrugated sheets or ready-made sandwich panels are used for cladding walls and roofs. The choice depends on whether the building will be heated or cold during operation.

Next, the metal frame is sheathed with barrier structures. These include roofing and wall pie. In the commercial sphere, in this regard, as a rule, the simplest solutions are used - corrugated sheets or ready-made sandwich panels are used for cladding walls and roofs. The choice depends on whether the building will be heated or cold during operation.

In the field of metal-frame housing construction, the following enclosing structures are used. The roof, if it is in an unheated attic, is protected by waterproofing and covered with any roofing material available today - metal tiles, corrugated sheets and even flexible tiles. In attic attics, the ceiling is additionally insulated and lined with finishing materials from the inside.

The following layers are laid into the wall cake (from the inside out), such as: finishing cladding, plasterboard, vapor barrier, insulation, wind protection and facade cladding. The most important component in this cake is the insulation. The thermal insulation characteristics of finished housing almost completely depend on it. By adjusting its thickness at the design stage, you can achieve the required level of heat loss for any climatic zone.

Communications for a building made of LGTS are laid similarly to other construction technologies. In the commercial sphere, premises must be equipped with lighting fixtures, as well as fire and security alarms. Residential buildings are additionally equipped with water supply, sewerage, heating and ventilation systems.

Areas of application of construction technology from LSTK

Today in our country the following buildings are being built from light steel thin-walled structures:

Today in our country the following buildings are being built from light steel thin-walled structures:

- residential buildings;

- office rooms;

- administrative buildings;

- hangars;

- private garages;

- commercial service stations;

- car washes;

- gas stations;

- warehouses;

- agricultural buildings;

- shopping pavilions;

- exhibition centers;

- car dealerships;

- multi-story houses;

- manufacturing enterprises.

The scope of application of construction technology based on light steel frames is far from limited to the above points. Cheapness, speed of assembly and variability of architectural solutions make it possible to build metal-frame buildings in almost any area. In many industries, this technology has completely replaced outdated traditional construction methods.

Advantages of construction of LSTK buildings

The construction technology under consideration has quite a lot of advantages and benefits. Not all methods of building construction can boast such a set of advantages. In particular, experts highlight the following advantages of light steel thin-walled structures:

The construction technology under consideration has quite a lot of advantages and benefits. Not all methods of building construction can boast such a set of advantages. In particular, experts highlight the following advantages of light steel thin-walled structures:

- Economic benefit. Attractive tariffs are available both at the stage of purchasing a set of building materials and during the assembly process. On average, if we take the construction of a residential building from LSTK, then its final cost is almost always 30% cheaper than frame wooden houses, and if we take brick ones, then the budgets are generally cut in half.

- Short time. Again, using the example of an ordinary private house made of light steel thin-walled structures, the installation time beats all currently known records. Thus, housing with a total area of 50 to 150 square meters is built in just 3-5 working days. At the same time, only a small team of three people, not necessarily with the highest qualifications, is involved in the work.

- Long service life. Developer companies engaged in dense construction using this technology guarantee a service life of galvanized metal frames of at least 70 years. In practice, not a single one of these buildings has rotted yet. With the exception, of course, of buildings assembled from low-quality handicraft materials.

- Strength. A properly designed metal frame can easily withstand not only strong gusts of wind, but also long-term static loads, the weight of snow, and even seismic activity of the soil.

- Light weight. Due to the fact that thin-walled perforated profiles are used to assemble buildings, the weight of the finished building is relatively small. This allows you to significantly save money on the foundation being laid, as well as expand the construction area, regardless of the condition of the soil and groundwater level.

- Fire resistance. The basis of the building is a metal frame that is not subject to combustion. Mineral heat insulators (mineral wool, fiberglass and analogues) are used as insulation, which are also not prone to fire.

- Invulnerability to corrosion. High-quality profile elements for assembling a metal frame must be made of pre-galvanized steel. The zinc layer protects the metal from corrosion and rotting for many years, which was typical for buildings made from traditional rolled metal.

- High levels of thermal insulation. They are adjusted due to the thickness of the insulation and can be increased to the required level without adding weight to the supporting structure.

- Easy to use. Finished buildings require virtually no maintenance during use. There is no need to regularly paint the metal frame, and modern types of finishing retain their original appearance for many years without any additional effort or costly measures.

When you need more detailed information about the design and construction of LSTK buildings, contact our company. Answers to any questions on this topic can be obtained by calling the specified phone number, or by asking them to a consultant through a convenient online feedback form directly on the website.

Comprehensive information on the technology of construction from light steel thin-walled structures, as well as the visit of a measuring specialist to your site, are provided absolutely free of charge. Other details are discussed individually over the phone.

The cost of building a turnkey house from light steel thin-walled structures includes a budget for the frame, a set of finishing and other materials, as well as a fee for installation work. This technology is characterized by short implementation times, as well as a favorable price for finished projects.

A residential building using LSTK technology is built according to the following principle:

- Design.

- Laying the foundation.

- Assembly and installation of wall panels.

- Assembly and installation of roof trusses.

- Roofing.

- Arrangement of communications.

- Interior and exterior finishing works.

At the design stage, the main attention is paid to calculating the rigidity and strength of the supporting frame. The foundation for a lightweight LSTC building can be absolutely anything. Wall panels and roof trusses are assembled from ready-made perforated profiles manufactured in production from galvanized steel. To cover the roof, traditional materials are used - corrugated sheets, metal tiles, etc.

The basis of the wall pie is insulation. From the outside it is covered with wind protection and facade cladding, from the inside - with a vapor barrier, plasterboard and finishing.

Benefits of LSTK technology

By giving preference to LSTK technology in housing construction, the user receives the following benefits:

By giving preference to LSTK technology in housing construction, the user receives the following benefits:

- low cost of materials;

- compressed construction lines;

- the most favorable price when ordering turnkey construction;

- flexibility in choosing and individually finalizing projects;

- can be built in any season;

- The house has been in service for more than 70 years without renovation.

In addition, it is also worth noting the resistance of the galvanized metal frame to corrosion, fire, gusts of wind and seismic loads.

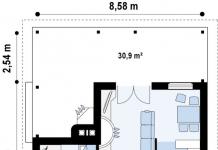

Housing made of LSTK: cost of standard projects

Below is a table with approximate prices for housing construction using LSTK technology. In particular, it provides an opportunity to clearly understand what main components make up the budget for the implementation of standard turnkey projects.

You can learn more about the construction of housing from light steel thin-walled structures from the specialists of our company by contacting them at the specified phone number or using the feedback form on the website.

Estimated prices for the construction of standard housing from LSTK |

||||

| Total area of the finished house | Housing Features | Cost of metal frame | Cost of the entire set of materials | Turnkey construction cost |

| 90 m2 | A one-story country house with four living rooms, a bathroom and a boiler room. | 250 thousand rubles | 1000 thousand rubles. | 1500 thousand rubles. |

| 120 m2 | A two-story cottage with a terrace, two living rooms and a bathroom on the first floor, three rooms and a bathroom on the second. | 500 thousand rubles. | 1300 thousand rubles. | 2000 thousand rubles. |

| 130 m2 | A compact two-story house, on the first level there are two full rooms, a bathroom and a toilet, on the second level there is a living room, a bedroom and a children's room, as well as an additional bathroom. | 460 thousand rubles. | 1400 thousand rubles. | 2200 thousand rubles. |

| 140 m2 | A two-story country house, on the first floor there are three rooms plus a bathroom, on the second there are the same number of rooms plus a balcony. | 450 thousand rubles. | 1600 thousand rubles. | 2500 thousand rubles. |

| 160 m2 | A one-story residential building with an attic, the first floor is divided into four full rooms plus a bathroom, the attic floor is divided into two rooms. | 600 thousand rubles. | 1800 thousand rubles. | 2800 thousand rubles. |

| The prices provided in the table are purely indicative; please ask our managers for more specific information. | ||||

LSTK represent a modern solution for the construction of buildings for any purpose in various climatic conditions. LSTK technology appeared in the 50s of the 20th century and today is rapidly gaining popularity due to its efficiency, excellent thermal insulation properties and speed of construction.

This technology is perfect for mass construction of low-budget residential buildings and industrial buildings. Light Steel Thin-Wall Structures (LSTC) successfully compete with traditional technologies. Steel metal structures are often used in countries with cold and temperate climates. In Russia, the production of buildings made from light-weight reinforced concrete materials has not yet reached a serious scale.

The main area of use of prefabricated metal structures is prefabricated commercial and industrial buildings: hangars, industrial and commercial warehouses, storage facilities for grain and other agricultural products, exhibition and shopping centers, parking lots for special equipment. The private sector has not been left without attention: LSTK frame-panel houses are gradually appearing in Russian regions with temperate, cold and warm climates.

Lightweight steel thin-walled structures: technology and capabilities

LSTK consist of thermoprofiles and galvanized steel beams. The latest equipment of our plant allows us to produce profiles and ceilings for standard and non-standard projects.

The main advantage of LSTK is its ability to retain heat excellently. This is facilitated by the use of thermal profiles equipped with perforations in the form of longitudinal “grooves”.

Galvanized thin-walled profiles and thermal profiles are delivered directly to the Customer’s site, where metal structures are assembled from them according to the principle of a children’s construction set. The LSTK frame is assembled very quickly - using standard fasteners (bolts, self-drilling screws, screws, stamping rivets, etc.).

External and internal cladding can be of any kind: plasterboard, rolled steel, DSP, gypsum fiber, etc. The cladding created with these materials is durable and reliable, and after insulation with mineral wool, monolithic concrete or ecowool, the characteristics of the building will be superior to those made of wood, brick or concrete.

Advantages of lightweight metal structures

- Design of an object in an extremely short time frame.

The development of an average project takes five to seven days, and a large project of a prefabricated building made of LGSF requires no more than ten days.

- Light weight.

The thickness of the steel used for the manufacture of profiles and polymetals is no more than 3.5 mm. A square meter of a supporting frame made of lightweight metal structures weighs from twenty kilograms. This allows you to do without a deep foundation.

- Low cost of construction work.

Construction of houses using LSTK technology is an excellent opportunity to save on the foundation and reduce costs through the use of metal profiles, the cost of which is lower than wood or brick. On average in Russia, the market value of a square meter of a turnkey building does not exceed 20,000 rubles.

- Construction of metal building structures in the shortest possible time. The construction of lightweight steel frames from ready-made elements can significantly speed up the building construction process. The manufacture and installation of metal structures for any project takes no more than seven to ten working days, and for the installation of a large hangar of a large shopping complex it will take three to five months.

- All-season installation.

When constructing a building, no building mixtures or cement mortars are required, which allows installation at any temperature.

- Durability.

Prefabricated metal structures are able to withstand the influence of destructive biological and atmospheric processes. American credit companies have determined that the service life of LMK can be 70 years. If simple operating rules are followed, the building can be used indefinitely.

- Reliability.

The metal frame can withstand seismic loads of six to seven on the Richter scale, which is why it is very popular in Japan.

- The ability to implement any architectural solutions. With LSTK technology, even the most unusual design ideas can be easily realized.

- Excellent heat retention.

Due to the use of a thermal profile and additional insulation (mineral wool, monolithic foam concrete or ecowool), heat loss is 50-60% less than that of wooden or brick walls of the same thickness.

- Environmental friendliness of LMK.

The composition of lightweight structures is absolutely safe for health and does not harm the environment.

Scope of application

LSTK are widely used in many areas of construction - in the commercial, industrial and private sectors.

In the industrial and commercial sector

Light steel frames are widely used for the construction of the following facilities:

- production premises:

- workshops;

- agricultural buildings:

- granaries;

- garages for special equipment;

- exhibition and shopping centers;

- entertainment centers;

- sports facilities:

- hockey rinks;

- football fields;

- tennis courts;

- basketball courts.

Lightweight steel structures are also used to construct modular buildings, which are assembled from prefabricated containers on site. Typically, cafes and canteens, dormitories, hotels, kindergartens and schools, checkpoints and security posts are built using a modular principle. The LSTK panel can be used as a hanging element of ventilated facades.

In the private sector

In low-rise construction, LSTK are used in the construction of buildings up to three floors high, townhouses, cottages and country houses.

For this purpose, frame-panel technology is used. A frame is mounted on the basis of light steel structures, which is then covered with sandwich panels or other cladding materials: tiles, decorative bricks, natural or artificial stone, siding, lining and others.

LSTK is the best option for the construction and reconstruction of rafter systems, attics and attics.

The production and sale of LSTK is a priority activity of one of the largest manufacturers of LSTK - the StalProfilGroup light steel structures plant, therefore we guarantee the high quality and reliability of our products.

We invite everyone who wants to buy LSTK to familiarize themselves with the products of our company. You can consult our employees regarding the cost of standard LSTK projects; prices for LSTK profiles can be found in the price list.

The technology of building houses from light steel thin-walled structures has been actively developing since 1950. Not so long ago, the first construction standards and regulations appeared in our countries, from which the popularity of prefabricated frame buildings made of metal structures began to grow at a moderate, unabated pace. Everyone should know the pros and cons of frame houses made of LSTK, because this technology is the future.

Thin-walled steel structures made of light galvanized profiles (LGSK) up to 4 mm thick are used in the construction of prefabricated frame buildings. The metal frame consists of profiled sheets and thin-walled P-S-Z-PSh-shaped profiles.

Frame of a low-rise building made of LSTKOrigin of technology

The technology for constructing frame buildings and structures from LSTK originated in Canada in 1950. In those days, the middle strata of the population needed high-quality and inexpensive housing. The possibility of mass production of LGSC elements and the availability of material solved this problem and, since then, construction using LGST technology has been actively distributed in the United States of America, Scandinavia and Japan.

The advantages of LSTK outweigh all the disadvantages, making this innovative construction technology popular and accessible to everyone who wants to build a building of any level of complexity.

The construction of light steel structures in Russia appeared in 1990, but active use began only in the 2000s, when the Central Research and Design Institute of Building Metal Structures issued recommendations for the design of buildings and structures. State standards exist for metal structures with a profile thickness of 4 millimeters or more, but in practice it is customary to use European or international practices and construction regulations, which have more stringent requirements in contrast to Russian ones.

Foundation structure

Construction of a frame house begins with. This is an important stage of work, because correcting mistakes that were made during the construction of the foundation is very difficult. The consequences of mistakes are a skewed porch or veranda, doors and windows that begin to open poorly, and damaged thermal and sound insulation of walls and partitions.

The most common type of foundation, which is most often installed for LSTC houses of prefabricated panel construction, is a columnar foundation. The pillars are laid in each corner of the building, at the intersection of adjacent walls and under the piers, under the supports of especially loaded purlins at a distance of 1.5 m to 2.5 m from each other. Pillars can be stone, brick, concrete and reinforced concrete. Strip foundations can also be installed under frame LSTC houses. They are laid under all external and internal walls.

Composition of LSTK

All elements of light steel thin-walled structures are produced by specialized factories that guarantee the quality and accuracy of the geometric shape of each part. LSTK consists of smooth galvanized high-strength profiles and perforated (so-called thermal profiles): racks, guides and lintels.

The connection of LSTC profiles is carried out:

- Bolts of different diameters (5-16 mm.)

- Self-tapping regular and self-drilling screws

- Blind rivets

- Mounting dowels (powder and pneumatic)

- Puklyovka

Finished frame of a house (cottage) made of LSTK.

Finished frame of a house (cottage) made of LSTK. Scope of application of LSTK technology

The advantages significantly outweigh the minor disadvantages that the LSTC technology has, therefore the use of prefabricated structures is widespread in civil and industrial areas.

LSTK is used:

- Construction of low-rise residential buildings and cottages.

- Commercial construction of industrial and industrial buildings. It is used for the construction of hangars and warehouses, garages and parking lots, car services and parking lots, shopping centers, pavilions and shops.

- Construction of attic floors.

- It is used as enclosing structures for multi-storey buildings.

Pros and cons of LSTK

The advantages of lightweight steel thin-walled structures are presented in a long list, and the disadvantages are ambiguous. Let's look at all the pros and cons of this construction technology.

Construction of a complex lightweight steel frame structure.

Construction of a complex lightweight steel frame structure. Pros of LSTK

- Frame buildings do not harm the environment.

- LSTK costs quickly. For quick construction you will need 3-4 people. The average frame assembly time is 2-3 months.

- Easy installation according to factory instructions. You can assemble a building from LSTK yourself.

- Does not shrink on the foundation either during construction or during operation.

- High strength characteristics. Without a doubt, one of the main advantages of LSTK.

- Possibility of assembly in any weather.

- Seismic stability of the structure. An undoubted plus that made LSTC structures popular in Japan, a country with a high level of seismic activity.

- Low cost.

- Accuracy of profile dimensions.

- Factory quality.

- High thermal insulation characteristics.

- Long service life. The declared service life of the building is 70-120 years.

All the advantages of LSTK are before you; it is these advantages that have made frame construction from thin-walled steel profiles in demand and popular. Even despite the advantages of LSTK technology, it is a modern and innovative solution.

Cons of LSTK

It's time to determine the disadvantages and disadvantages that the LSTK frame construction technology has. There are few of them; they occur only in our countries.

The disadvantages of LSTK are as follows:

- Thin wall or low rigidity and strength of the structure. The controversial opinion of most people is that LSTC can be bent or punched. This disadvantage can be refuted by the fact that the strength of the structure is determined by the design in a finished, assembled form, when the building is put into operation, and not in individual cases of each detail.

- Low service life. This minus also disappears if all the raw materials were of high quality and a zinc coating of 25 microns was used.

- Quality of designs. Unfortunately, in Russia there are many unscrupulous enterprises that deceive customers. The declared quality does not correspond to reality. Deliberately, in pursuit of profit, enterprises reduce the thickness of the profile and reduce the thickness of the zinc layer, which affects the quality and safety of the entire structure. Trust manufacturing and construction to reliable developers.

These are all the disadvantages of LSTK technology. In order for the structure to serve for a long time, it is important to entrust the design and construction to professionals with a high qualification level.

Let's look at how construction occurs and what the house is made of.

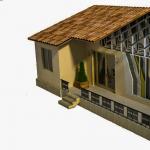

Graphic design of a finished house made of LSTK

Graphic design of a finished house made of LSTK Construction of a frame house from LSTK

- Design. Construction begins with ordering a design for the future structure. Without design documentation, it is impossible to begin the assembly and installation of the structure. The architect draws up a project taking into account the requirements and wishes of the customer, as well as taking into account the climatic characteristics of the region. The design documentation contains information on possible and critical loads, type of foundation and building materials. After the project is ready, it is sent to the factory, where a ready-made set of profiles with all fasteners and assembly documentation is formed from metal structures.

Construction structure and features.

- Base structure. The construction of the plinth is part of the work during the construction of a frame house from light thin-walled steel structures. The basement is the above-ground part of the foundation that limits the underground space. When installing a columnar foundation, the structural elements of the base are a grillage and a fence that fills the space between the foundation pillars. The fence can be made of base slabs, brick or monolithic concrete. Ventilation holes must be provided in the basement to prevent dampness in the basement.

- LSTK frame house floors. The installation of the basement floor and floor is carried out in the following sequence: waterproofing from one layer of roofing material or uniflex is installed along the grillage. Then the purlins are laid from LGSF, and the logs are laid along the purlins. OSB boards or moisture-resistant plywood are sewn onto them, waterproofing is installed, additional logs are installed, insulation boards are laid, a vapor barrier is installed, another layer of OSB is sewn on top and the flooring is laid.

- Walls. Sequence of wall construction: the LSTK frame is mounted along the purlins. An insulation of three layers of mineral wool boards is laid “staggered” between the frame posts. A layer of vapor barrier is made on the inside of the wall and sheathed with sheet material. The outer side is sheathed with sheet material and prepared for finishing.

- Roof. The installation of the roof begins with the installation of the rafter system. The pitch of the rafter legs should be 0.6 or 0.35 meters. Depending on the type of roof, sheathing is laid along the rafters, which can be made of profiled galvanized sheet. Any type of roof must provide reliable protection for the house from precipitation and withstand snow and wind loads.

- Facade finishing. The construction of the frame house is completed by finishing the facade. Not only the appearance of the home, but also the improvement of comfort conditions such as heat and sound insulation depends on the choice of material for finishing the facade. It is possible to use materials made of wood - lining and block house. Vinyl or polyvinyl chloride siding has gained wide popularity. In some cases, facades are plastered using sheets of expanded polystyrene, previously glued to the outside of the wall. Sometimes facades are finished with various tile materials and fiber cement siding, facing bricks, natural or artificial stone.

Video:

Building structures made from thin-walled metal profiles have a number of advantages and positive features, but despite the large list of advantages, LGST technology sometimes encounters significant disadvantages associated with unscrupulous manufacturers. In Russia, the shortcomings of LSTK can be for several reasons.

Disadvantages of LSTK

Thin walls.

The first drawback can be characterized by the words “thin wall”. In our country, since the times of the USSR, people have become accustomed to quality, the characteristically high quality of manufactured products. Thus, there is an ambiguous opinion, which is that structures made of light steel fiber reinforced concrete are not strong enough and can be easily broken or damaged.

This is unfounded information that is devoid of evidence, since when designing a structure, information is included with calculations of possible and critical operational loads, taking into account the climatic characteristics of the region. Yes, individual elements (for example, a cold-formed LSTC profile) can be deformed by applying force, but in its finished form the LSTC structure is a strong and rigid frame!

Low service life.

The second disadvantage is the service life. This is both an advantage and a disadvantage, everyone knows how modern permanent structures are built, what kind of “quality” residents have to deal with, so the disadvantage that determines the fragility of the structure also applies to all buildings made of brick and concrete. Is it possible to know for sure whether a house made of brick, stone and concrete will last 70 or 120 years? - No one can answer this question with certainty. The same situation occurs in prefabricated frame construction, where the service life of a structure made of light steel frames with professional assembly is 50-120 years or more.

Inconsistency of product quality.

Basically, all the shortcomings of LSTK, which are common and known, exist exclusively in Russia. Do not trust dubious factories and enterprises to produce a set of prefabricated buildings from LSTK. Often, for the purpose of additional enrichment, “enterprising” owners of metal structures factories violate quality standards for manufactured products, underestimating the actual characteristics of products in pursuit of low cost. This quality will not correspond to the stated characteristics. A standard, typical case is a reduction in the thickness of the profile and zinc layer, which negatively affects the quality and reliability of the future structure. This drawback can be avoided by entrusting the design, construction and production of products to proven enterprises with a positive reputation in the LSTK services market.

Dependence of the buyer on the manufacturer.

This is the second disadvantage of LSTK, which relates to the previous, production disadvantage. If any element was produced with a violation of the geometric shape or an important design detail was lost in the kit, then problems may arise during installation. At any stage of construction, a situation may arise when the parts do not fit together or there is not enough fastening element.

Electromagnetic safety of LSTK.

In the Russian Federation, unfortunately, there are still no conclusions on the electromagnetic safety of living in houses made of light steel thin-walled frames. There is no information on possible threats to human life in a house made of metal profiles. This drawback also occurs only in our country; many enterprises that monitor quality and their image adopt and use international standards in the construction of prefabricated LSTK structures. Structures made from light reinforced steel reinforced concrete, built according to international and European standards, are safe for living.

Human factor.

The construction of any structure made of light steel thin-walled profiles and profiled sheets must be carried out by highly qualified professional workers. The safety of the structure depends on the level of the specialist.

Furniture installation.

This disadvantage can be attributed to low-rise residential buildings where it is necessary to furnish the interior. The furniture is mounted on a solid surface (walls), so you need to think in advance about the places where the cabinet or picture, shelves or any other objects will be installed. In places where furniture will be attached, the walls of the house made of LSTK are additionally reinforced with transverse platforms made of boards or timber.

High level of fire hazard.

LSTC technology has disadvantages that appear when a fire occurs inside the room. When exposed to high temperatures, steel profiles begin to deform, lose rigidity and sag under higher loads. The design takes into account all these shortcomings, so take the time to additionally protect the structure from fire and fire with special fire-retardant compounds (impregnations).

Low load-bearing strength.

Many people believe that a structure made of LSTC cannot cope with the weight load on the frame. This opinion is erroneous and cannot be considered a shortcoming. Each project is unique; the possible permissible load and the critical load that the building can withstand are always calculated. Another refutation of this shortcoming is the high popularity of frame construction from LSTK in Japan, the land of the rising sun, where there is a high level of seismic activity.

Pros and cons of LSTK:

Construction from light steel thin-walled structures (LSTC) has its disadvantages and advantages. The benefits have been tested by numerous experiments of reputable Western organizations. For example, Japanese scientists conducted a test that confirms the high service life of LSFC. During the experiment, LSTC elements were placed in the highly aggressive environment of sea water and remained unharmed. Disadvantages of LSTK have mixed opinions, certain news agencies, frame construction is safe and economically profitable.

Advantages of LSTK:

- Environmental friendliness.

- Low cost.

- Fast construction time.

- Easy installation.

- Long service life.

- Seismic resistance.

- All-season installation.

- No shrinkage on .

- Excellent heat saving.

- Accuracy of parts geometry.

- Factory quality.

- Compact for transportation.

The advantages clearly outweigh all the disadvantages of LSTK. Metal frame buildings are widely in demand and popular all over the world. Trust construction and design to professionals.

Video about the LSTK house: