Modern private country houses grow like mushrooms, or rather like pines or even sequoias. Today, country houses with two or even three floors are not uncommon. And there are houses with an attic. Not to mention duplex apartments. In order to go upstairs you need stairs or an elevator. The latter, of course, is pampering, although there is a place to be. We will talk about how to make a wooden staircase on your own.

It can be assumed that this is not so difficult, but in reality such work has its own subtleties and requires knowledge of the matter. After all, not just any staircase is needed, but such a structure that will be beautiful, durable and so safe that it can be safely operated for a long time.

Stairs for a country house, dacha or cottage are often made of wood. The right choice of durable wood is a guarantee that the staircase will last for a long time. At the same time, the environmental component is of no small importance.

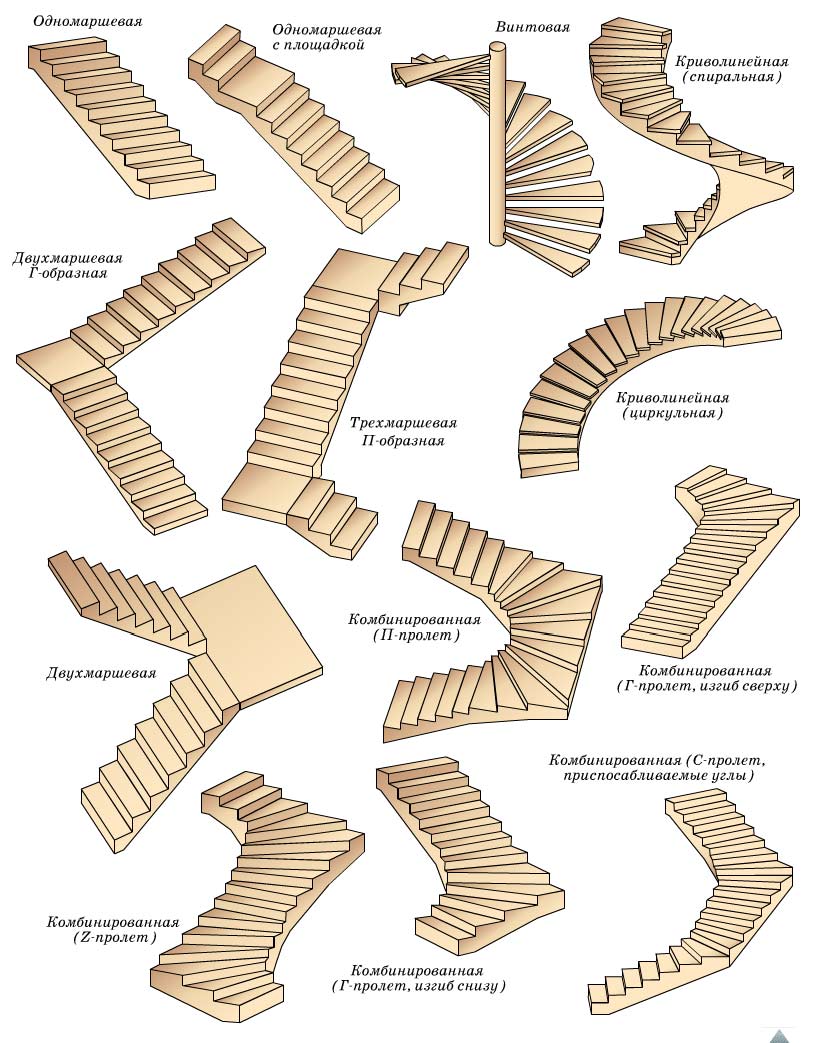

Types and types of staircase designs for a private house

The choice of stairs is often limited by the available space for its device, and of course the budget. But, it is better to be guided by the convenience of location and aesthetic preferences. Among the existing designs of wooden stairs, the most common are mid-flight and spiral.

Spiral stairs

The option is convenient when space is limited. Such a ladder can be placed on a heel of 1.5 meters. True, it can only be used to move up or down one person. It will no longer be possible to lift something large, for example, furniture.

The option is convenient when space is limited. Such a ladder can be placed on a heel of 1.5 meters. True, it can only be used to move up or down one person. It will no longer be possible to lift something large, for example, furniture.

In addition, it has a complex structure, and its construction requires more labor.

At the same time, many nuances have to be taken into account: to check the structure for strength, first of all, the load-bearing racks must be reliable.

The complexity of the design is due to the fact that the main details have to be calculated taking into account all the design features.

This job is best handled by experienced professionals. It is difficult to do it yourself without special skills and tools.

Marching stairs

Wooden stairs for the house can be single-flight, two-flight, three-flight and multi-flight (each of them is used in certain conditions, which depend on the number of storeys and area of the building).

Marching stairs are divided into straight and rotary according to their orientation. They can be located along the wall or as an independent structure in the middle of the room.

It is worth noting that the device of a straight staircase assumes the presence of sufficient free space, as it takes up a lot of space. In general, this type of construction is much simpler in terms of self-implementation compared to the screw version.

If the number of steps is more than 10, it is recommended to divide the staircase into two parts, connecting them together with an intermediate platform. If necessary and save space (this depends on the characteristics of the room), the staircase can go up from the intermediate platform with a turn, the so-called staircase with turning steps (trapezoidal steps, which are also called winders).

A staircase with a 90 degree turn is called a quarter-turn. The half turn ladder has a 180 degree turn angle.

When the rotation is 360 degrees, then this is already a variant of a circular or spiral staircase. Although, in principle, this is an ordinary marching staircase with winder steps and a turn of * degrees.

Combined stairs

Depending on the layout and design of the house, it is possible to install a combined staircase structure, which will consist of two or more types of stairs. For example, a mid-flight staircase on a certain span is complemented by a screw element supported by bowstrings or stringers. Of course, such a design is very complex and requires precise calculations.

Before choosing one or another design, you should sensibly evaluate your capabilities. It is better to let there be a simpler straight staircase, but reliable and made of quality materials, than an intricate spiral or combined one, for the construction of which there may not be enough money or effort.

And of course, space is of decisive importance, so that later it does not turn out that the stairs will take away more than half of the house.

Start with measurements and calculations. Draw a drawing or order from specialists. You can even create a 3D model of the future staircase and visually see the location in your layout.

Interfloor wooden stairs - selection of components and load-bearing elements

It is possible that the staircase you are creating will be your first experience, then a straight staircase would be the best choice. This option is easy to manufacture, its installation and installation is also not very complicated, and the result will meet all the basic requirements for strength, convenience and durability.

Making wooden stairs with your own hands is possible with the appropriate tools, quality lumber and experience.

Material for the construction of stairs:

- Bars for steps, the thickness of which must be at least 40 mm.

- Boards of approximately the same width and size provided by the project.

- Beams for tread 30-40 mm.

- Beams for risers not less than 30 mm.

- Beam for stringers or bowstrings 50x250 mm.

- Handrails, railings and balusters can be made independently, but it is better to buy ready-made ones.

- Stainless steel screws are used for fastening.

The drawings show drawings of wooden stairs

Do-it-yourself wooden staircase installation:

- As mentioned above, you first need to think over the design, calculate the number of steps and determine the dimensions of the stairs (width, length), you can download a finished drawing on the Internet or make a simple diagram yourself.

- A standard march can be built with the support of the steps on the bowstrings that run from its two sides. Another mounting option involves the support of the steps on the stringers, which are beams located at the bottom of the steps.

- All steps are first connected to the bowstrings, then the structure is reinforced with supporting bars, which are placed under the stairs at an equal distance from each other. With a sufficiently high angle of inclination of the march, there is no need for bars, although it is still desirable to install them to guarantee safety.

- The bottom and top of the string should be attached to the walls, floor or ceiling.

The operational and decorative qualities of a wooden staircase, its ability to withstand moisture and other influences, for example, wood pests, are significantly increased when it is treated with a special varnish, stain. Such a ladder will not lose its original appearance and reliability for a long time.

How to make a wooden staircase with your own hands - video instruction

Photos of wooden stairs for the house

Most private houses in our time have several floors. It is cheaper to build such a house, since you can get more living space with a smaller foundation. After all, it is the foundation that accounts for the main expenses during construction. Yes, and organizing a convenient layout of a two-story house is easier.

But the presence of more floors requires the construction of stairs, which often frightens those involved in the construction of their house or cottage. To them, such work seems to be something complicated, but in fact, everything is quite simple. A good staircase is easy to build with your own hands, just knowing a few features.

What is the staircase made of?

Stair elements

Stair elements First you need, of course, to understand what it is, what are its main elements. The basic design here is so simple that the differences between different types are minimal.

First, everyone knows that it consists of steps. It is on them that the main burden falls. The steps do not hang in the air, they rely on one of two types of supporting structures - bowstrings or stringers.

- Bowstrings are two thick boards in which special grooves are cut for steps and risers. Such grooves are made according to the template. The bowstrings are pulled together with strands of both metal and wood;

- Unlike bowstrings, stringers are not straight boards, but have a sawtooth shape. Horizontal cuts are used as a support for the steps, and vertical cuts are used to fasten the risers. Another difference between the kosour and bowstrings is that during construction, you can use not two boards, but one. In the latter version, the steps rest on the walls.

Kosour marking scheme

Kosour marking scheme Optional, but present almost everywhere, the element is the risers. Their main function is decorative. The risers make it possible to hide the interior space of the stairs.

Railings that increase the level of safety of use are also not required, but highly desirable. Sometimes stairs have elements such as a support step or special platforms.

What are stairs

In most modern houses, one of their three main types is made - marching, on the bolts, screw. At the same time, they choose based on aesthetic preferences, the availability of free space in the house, budget and other parameters.

Marching stairs

The most common marching stairs

The most common marching stairs The simplest and most common design is the marching staircase. Although, having such an important plus - ease of construction, it also has one important drawback - it takes up quite a lot of space. As a result, its construction may not be justified in a small house.

Depending on the number of storeys of the building, its size, stairs of this type are built single-flight, two-flight, three-flight, etc. Marches are called separate segments, which may consist of a different number of steps, but usually no more than fifteen. The optimal number is considered to be ten steps.

In addition, they are divided into open and closed. In most cases, owners make a choice based on aesthetic preferences, because the only difference between them is the presence or absence of risers. Open marching stairs are chosen by those who want a feeling of lightness in the interior.

They have a similar device. They also differ simply in what kind of support they use for them. They can rely on bowstrings, or they can rely on stringers. At the same time, there is no total preference for one type of support. It all depends on the wishes of the owner or location. For example, for a staircase against a wall, it is quite logical to use a stringer as a supporting beam.

To save space, they are often made with a turn. In this case, trapezoidal rotary steps, called winders, are used. The most common angles of rotation of mid-flight stairs are 90 degrees (quarter-turn stairs) and 180 degrees (half-turn stairs). They also come with a 360-degree rotation, but then they can also be attributed to screw ones.

Bolts stairs

Stairs on the rails have a modern, technological and light look.

Stairs on the rails have a modern, technological and light look. With the growing popularity of high-tech or modern interiors, the popularity of stairs on the rails has increased. They really have a modern, technological and at the same time light look. They got their name from the German word "bolz", which means "bolt" in translation, this is the name of their main structural element - large hinged balusters.

The design feature here is the absence of a frame, which creates the feeling that it is floating in the air. Its role is assumed by the steps and the bolts, mounted to the handrails.

There are several types of designs of stairs on the rails. You can choose either one that involves only the use of balusters, or with one side resting on a wall, bowstring or stringer. Combinations are quite common. The choice depends only on the taste and planning features of the house.

In addition to aesthetics, they have one definite practical plus - high maintainability. Any element, from steps to railings, is very easy to dismantle.

Spiral stairs

Spiral staircases are popular in both modern and classic interiors.

Spiral staircases are popular in both modern and classic interiors. Both in modern and classic interiors, spiral staircases are popular. They are valued primarily for the fact that they take up very little space (example in the photo). If you have a small house, then this is the choice for you. Their compact, space-saving proportions make efficient use of space. On the other hand, it was not without drawbacks - they are not wide and steep, and self-mounting, although not very difficult, requires more work than in the case of marching ones.

There are two main designs in use today:

- The first of them involves the use of bent-glued handrails, on which the steps are attached. This design is quite complex, but it is also distinguished by its special beauty;

- The second, the most common and classic, involves the use of a central support and curved handrails. Steps are attached both to the support and to the handrails. This design is simpler and does not have such strict requirements for the strength of materials as the first one.

The design of the spiral staircase can also provide for the support of the steps on the wall. In this case, special recesses are made in the wall, to which they are attached. It will not necessarily be circular, it may well be polygonal.

Make a ladder: Requirements

You need to design a staircase at the design stage of the whole house. In this case, you need to take into account a few simple conditions and requirements:

- It is necessary to consider where it will be installed;

- How many tenants and how often they will use it, and how old these people will be;

- Will it be necessary to carry something very heavy along it;

- It is required that the slope angle not only does not exceed 42 degrees, but is also constant along its entire length;

- The minimum width should be 80 cm and not less;

- Steps should be installed on the basis of a minimum design load of 200 kilograms per meter. cube;

- The minimum design load for the railing is 100 kg per meter. cube;

- Stair railings should not be too low. Their smallest height can be at least 80 cm;

- Balusters should not be too rare, the clear distance between them should not exceed 15 cm.

Make a ladder: Calculations

Before making a staircase, it is necessary to correctly make calculations

Before making a staircase, it is necessary to correctly make calculations Taking into account all the above requirements and choosing the appropriate type of stairs, you can safely proceed to its construction with your own hands according to the drawing.

The success of independent construction depends on correctly made calculations. Calculating the design parameters of the stairs, you determine those dimensions that best contribute to ensuring convenient and safe movement. Moreover, convenience is supported by a certain ratio between the rise and advancement.

When designing, you need to remember that all steps of one march must have the same dimensions. At the same time, the sum of the double height of the riser and the step should not be less than the length of the average human step, which is 60–66 cm.

To achieve the greatest convenience, it is worth maintaining the difference between the width of the step and the height of the riser at the level of 12 cm, but the greatest safety is achieved when the sum of these parameters is not less than 46 cm.

When calculating the angle of inclination, it is taken into account that the distance from the plane of each step to the ceiling should not be less than two meters.

The optimal angle is considered to be in the range from 23 to 37 degrees.

Naturally, the larger it is, the less space the structure will take, but at an angle of more than 45 degrees, it will simply be inconvenient to climb along it.

In order to determine the total length of a simple flight of stairs, you can use the formula H2 + D2 = L2, where H is the sum of the distance from the floor of the first floor to the ceiling and the thickness of the interfloor ceiling, and D is the size of the projection onto the floor. In order to determine the size of the projection, you must first find out the number of steps required. To do this, divide H by the selected step height. After that, the resulting number of steps is multiplied by their selected width.

Make a ladder according to the instructions: a ladder with bowstrings

There are many types of stairs, now we will talk about the stairs on bowstrings.

Staircase to the second floor on bowstrings

Staircase to the second floor on bowstrings How to make a string

It is necessary to start building a staircase on bowstrings from their manufacture. Why choose either a solid solid and fairly thick board or a durable glued laminated timber. The length of the boards is selected based on the length of the stairs or march. You also need to prepare the strands with which you fasten the beams so that they do not part in different directions during operation.

The markup is done even before the bowstrings are installed. This stage plays an important role, since its incorrect execution often leads to a banal distortion of the steps. In order for the cutouts of the grooves to be completely identical, located equidistant from each other, a self-made template is used when marking. A thin sheet of plywood is used as a template.

On the inside of the board, you need to draw a boundary line, stepping back 5 cm from the edge, otherwise the bowstring has a chance to turn into a string.

It is these lines that will act as the border of the steps. Then they take a template, apply and outline the places for future grooves, moving to the end. The location of the grooves on the beams of the bowstrings should be mirrored.

Mounting the bowstring

Mounting bowstrings does not require any special skills and a lot of time. The whole procedure consists in the fact that the bowstring is fastened with screws to the floor and the ceiling of the floors. Sometimes, if a very large load is expected, support beams are used. But such a design is rarely found in interiors, due to its bulkiness and lack of practical necessity.

Cutting elements

For cutting grooves, a conventional milling machine is used. This requires two or three approaches, no more. They almost always start with side cuts, after which they make additional ones that make work easier with a chisel. The optimal depth is 1.5–2 cm. At the end, the grooves are cleaned and the edges are smeared with glue before mounting the steps.

How to make steps and mount them

The manufacture of steps is one of the simplest procedures among all installation work. A dry board is taken. Its thickness should be at least 3.5 cm. The width must correspond to that which was chosen for the steps in the calculations. The board is cut based on the width of the stairs, including the railing. Grind after cutting. The procedure for making risers looks almost the same. Unless you can use a less thick board - up to 2 cm.

When assembling a flight of stairs, the steps are first of all attached, for which self-tapping screws are used. The best option is 6x90 self-tapping screws, of which there should be six pieces.

It is also possible to mount without the use of additional devices, but only with glue. But its strength depends on how tightly the step fits into the groove.

Sometimes the steps are attached to the bowstrings without using grooves. Then, surfs or bars are attached to the inside of the boards with the help of metal holders, on which the steps are placed. Risers can be attached to bowstrings with or without screws.

How to make railings and mount them

Railings can be either made independently or bought ready-made. Although they may differ from each other in appearance, they have the same design - the railing consists of handrails and balusters. Handrails are usually made from boards, and balusters are usually made from square bars. Moreover, the latter can be both very simple and carved.

The number of balusters should usually correspond to the number of steps. Two of them, installed at the beginning of the stairs and at its end, play the role of support. All the rest are decorative.

They also help the safe use of the design. Self-tapping screws act as fasteners, which can be hidden with a decorative plug. After fixing the balusters, handrails are attached to them. For this, self-tapping screws are also needed.

Staircase on stringers

Staircase to the second floor on stringers

Staircase to the second floor on stringers The manufacture of a stringer is in many ways similar to the manufacture of bowstrings, although these two types of support structures use a slightly different principle for holding steps.

Using this technology, temporary, outdoor (street) home-made stairs are made in houses.

You need to choose a solid board of solid durable wood. The board must be dry.

After that, a marking template is made, similar to the one used to make the bowstring. The template imitating the protrusions must correspond to the calculated dimensions of the steps. This time you do not need to draw an indent line, since it will not be necessary to cut out the grooves.

For sawing out protrusions, it is most convenient to use an electric jigsaw. After they are sawn, they need to be sanded.

Self-made stairs at first glance may seem like a rather complicated task, requiring calculations, the right choice of material and certain skills. But this is only at first glance. It is enough to get acquainted with how everything is done to understand that there is nothing complicated here.

Making your home comfortable does not require too much time, or too much effort, or a significant financial outlay.

There are also types of stairs for limited space - folding, retractable, cabinet stairs. They are temporary and are made mainly of iron.

Video

Watch a YouTube video on how to make a ladder with your own hands.

Stairs- this is one of the main elements of the interior design of the room, therefore, when designing it, attention should be paid not only to reliability and functionality, but also to the appearance. Before taking on making a wooden staircase with your own hands, it is necessary to take into account a large number of factors on which not only its design, but also its dimensions will depend.

These factors include:

- available space,

- height,

- maximum load for which the ladder is designed,

- ease of use for people living in the house.

To date, there are a huge number of options for the execution of interfloor stairs, so choosing the right design is a rather difficult task.

Choosing which staircase to build

Stairs marching and spiral. The design of a flight staircase is quite simple and is the best choice if you plan to make it yourself, however, in order to provide an acceptable slope and height of the steps, a considerable area is required. This ladder is very easy to use and can withstand heavy loads. It can easily lift furniture and other large items to the second floor, in addition, it is safer, so it will be the best choice if children or the elderly live in the house.

The spiral staircase has a more complex device. It is used in conditions of limited space, when, due to lack of space, it is not possible to provide a safe slope for an ordinary staircase. The main disadvantages include a not very convenient design, which makes it difficult to lift and does not allow you to carry large items. At the same time, a skillfully executed spiral staircase has sufficient strength and can be the main element of the interior.

Safety above all!

Before proceeding to making stairs with your own hands need to take care of its safety. Firstly, it must be strong and easily withstand a load several times greater than the weight of a person of average build. Secondly, the ladder should be comfortable and ergonomic. In this case, it is necessary to pay great attention to such factors as the height of the steps, the slope of the stairs, as well as the location and shape of the railing. The steps should have a non-slip coating, and the gaps between the balusters should be chosen so that the child cannot squeeze through them and fall.

Design features of stairs

Depending on the method of fastening the steps, marching stairs can be on bowstrings, stringers or bolts.

- Ladders on bowstrings have two side beams to which steps are attached. Such squirrels (strings) can be made of metal or wood. They can be attached to the wall or special supports, providing high strength of the entire structure.

- The steps of the stairs on the stringers are attached to the beams, which are located below and repeat the geometry of the entire structure. Such beams (kosoura) can be straight or curved. Straight stringers, as a rule, have a jagged shape, while the steps are superimposed on the teeth.

- Stairs with a bolt connection of steps are highly durable, so this design does not require additional supports and can be held at two points. The steps are attached to each other with metal rods - bolts, which completely eliminates the creaking caused by the friction of two wooden surfaces.

How to make a staircase with your own hands. Choosing materials

For the manufacture of stairs, softwood is most often used, since it is affordable and easy to process. An oak staircase will be more durable, but the cost of such a design will increase several times, moreover, the processing of this type of wood is a rather laborious task and requires certain skills.

The main steps in the manufacture of stairs

Consider the basic principles of making stairs using the example of a wooden structure on stringers. Before starting the design, it is necessary to understand that any, even minor errors and inaccuracies in the calculations can lead to serious problems that will arise during installation, so each step should be taken very carefully. Our future staircase will consist of three main elements: steps, handrails and stringers. At the initial stage of design, it is necessary to perform all the necessary design calculations.

Calculation of the width and height of steps

To calculate the size of steps, the formula 2A + B = 64cm is usually used, where A is the width and B is the height. Typical step heights range from 140 to 170mm. We measure the height of the future stairs and divide by the estimated value of the height of the steps.

Suppose it is 240cm, and the desired height of the steps is 17cm. We divide the resulting value by the height of the steps 240/16=15 and round the result to the nearest integer, therefore, our future staircase will consist of 15 steps. Now we determine the exact height of the steps, for this we divide the height of the entire staircase by the number of steps: 240/15 \u003d 16cm. We find the width by the formula, using the height value, we get 24cm. You can also use a table.

The protrusion (part of the step hanging over the riser) should be no more than 3-4 cm. The greater the height of the riser, the narrower the step itself, but its width should not be less than the height. The most optimal step width should correspond to the forty-second shoe size (29-30cm.)

When calculating the stairs, it is also necessary to take into account the distance between the steps and the objects located above them (ceiling, beams, balconies, etc.). It should be at least 1.9-2 meters.

The horizontal size of the stairs is determined as follows: the width of the steps is multiplied by their number, while it should be taken into account that the floor surface serves as the first step, so in our case the calculation will look like this: 13x24=312cm.

If the height of the stairs is large enough, you can make a platform. Such platforms are recommended to be done in 7-8 steps. In the case when it is necessary to design a staircase with a certain number of steps, you can reduce their height in order to make a platform.

Manufacturing of stringers

As a material for the manufacture of stringers, you can use a 40mm wide pine board. Make a pattern that exactly repeats the dimensions of the profile of the steps and mark the prepared boards. Then cut the teeth with a hacksaw or electric jigsaw. In those places where the riser joins the step, it is necessary to cut off the corner. Having made one kosour, you can use it as a template for the rest. Since the strength, safety and durability of the stairs depend on the stringers, you should not save on their quantity, as well as on the quality of the material from which they are made. Boards should be free of knots and any signs of insect activity. Consider a way to attach stringers. To achieve the required strength, as a rule, 3-4 stringers are enough.

Installation of steps and railings making wooden stairs with your own hands

Steps can be attached directly to the stringers, or with the help of additional wooden elements - filly. Measure and cut out the required number of steps and risers from wood, and do not forget to take into account the ledge. Steps are fastened with nails or self-tapping screws.

The design using triangular fillies is more reliable. The fillies are fastened using dowels, for which grooves are previously made. The most durable construction is obtained using complex-shaped fillies, while a special cutout is made on the stringers. The connection of the elements of the stairs is carried out with the help of glue and self-tapping screws.

After the steps are ready, you can screw the railing balusters to them. In order to protect the tree from the influence of destructive factors (dampness, mold of harmful insects), it is necessary to apply a paint and varnish coating on it.

Making a wooden staircase with your own hands, in principle, is not so difficult. All you need for this is quality wood, the necessary tools and a little patience. Before starting work, carefully consider all the nuances of the future design and check the preliminary calculations several times.

One of the serious stages of the internal arrangement of a two-story private house is the construction of a flight of stairs designed to climb up. Here the homeowner is faced with a choice: hire experienced craftsmen for this work or take up the manufacture himself. The second option is supported by cost savings and conscientiousness with which the owner will get down to business in his own home. It remains only to fill the gap in knowledge and understand how to make a staircase to the second floor with your own hands, having carefully studied our recommendations.

Schemes of stairs for climbing to the second floor

To independently build an interfloor passage, you need to choose a suitable design that will fit in the allocated area and at the same time be safe to use. But first, you should understand the names of the elements and details of the stairs:

- bowstring (otherwise - kosour) - a longitudinal beam that serves as a support for the steps;

- tread - the upper plane of the step;

- riser - an opening between two treads;

- a support post is used in some designs for mounting stringers or steps;

- baluster - a vertical support for the railing.

Straight staircase 1 flight

To organize the ascent to the upper floor of a private house, it is customary to build 4 types of stairs:

- Direct march with or without a transition platform.

- Swivel 90 or 180° with winder steps.

- Screw.

- Compact ladder "goose step".

Reference. For the sake of saving usable space and building materials, the listed structures are placed along the walls. An exception is a screw structure, located in any convenient place, even in the middle of a hallway or hall.

A simple staircase to the second floor consists of one flight with a railing. It is not difficult to make it, but with a ceiling height of more than 2.5 m, the building will take up a significant area. To save space, it would be more correct to make an ascent according to the scheme with two marches and a transitional platform, as shown in the photo above.

The device of rotary (winder) steps allows you to effectively use the entire length of the stairs and thus reduce the size of the span. The assembly of such a structure is somewhat complicated due to the installation of a support column and the manufacture of figured wedge-shaped steps.

Turning staircase drawing

If there is very little space in the house or in the country, then it makes sense to build a spiral staircase or a goose step structure shown in the photo. In the first case, all the steps are winders and are attached at one end to the support post, and in the second they are cut in width so that you can put your foot on only one side. It is quite difficult to make a screw structure from scratch, but the goose step ladder is built using the same technology as conventional marching climbs.

Note. Typically, homeowners buy metal, wood, and glass spiral staircases as prefabricated kits that are assembled on site. Now on sale it is not difficult to find beautiful products that are in harmony with any interior, but you cannot call such a pleasure cheap.

This is what a steep goose step staircase looks like

To finally choose a suitable staircase scheme to the second floor, you should calculate the size and number of steps.

Calculation of interfloor stairs

For calculations, you need to know the height difference between the clean floors of the first and second floors, as well as the size of the area that you are ready to allocate for a conditional staircase. The calculation method does not depend on the chosen design and is based on the following requirements that ensure convenience and safety during its operation:

- tread width - at least 26 cm;

- step height - no more than 20 cm;

- the slope of the flight of stairs should be in the range from 27 to 42 °;

- railing height - from 900 mm;

- the minimum span width is 90 cm.

Advice. In order to correctly calculate the parameters of a flight of stairs and decide on its design, it is recommended to solve the problem graphically. Make your own mini-project by drawing freehand or computer drawings of the stairs in plan and side views.

The essence of the calculation is to determine the number of steps and the total length of the lift, taking into account the slope of the homemade ladder. The order of calculations is proposed to be considered on the example of a country cottage with a height difference of 3 m:

- So that the rise does not come out steep, we take the most convenient height of the riser - 15 cm. The number of steps is calculated by dividing the total height by this value: 300 cm / 15 cm = 20 pcs.

- Taking the width of the tread equal to 30 cm, we calculate the span length: 30 cm x 20 \u003d 600 cm or 6 m.

- Having drawn a sketch of such a staircase made of wood with a side view, we will determine the slope angle - 27 °.

Calculation scheme of a straight march with a slight slope

The 6 m long structure shown in the picture will not fit into every house, so its design will have to be adjusted. Option one: break the rise into 2 marches of the same length and make a transition platform. Given its size, equal to the minimum span width, the length of the ladder will be 3.9 m, which is also a lot. To some extent, sacrificing amenities, the dimensions of the stairs can be optimized as follows:

- reduce the step width to 26 cm;

- increase the height to 18 cm;

- push the tread forward 3 cm.

Schematic of an optimized staircase

Using the instructions above, we calculate the new parameters of the flight of stairs and get the number of steps 17 pieces, the angle of inclination is 37 °, and the total length is 3.7 m. can be reduced to 3 m, and this is quite acceptable. You will receive more visual information about the calculation of flights of stairs by watching the video:

An important point. All home buildings, including interfloor stairs, must be safe for small children. Provide gaps between the balusters according to the age of the child, so that he cannot squeeze between them and fall.

Construction materials

The best material for making stairs with your own hands is wood. It is not only easy to process, but also fits well into any interior. Metal structures are more durable, but also heavier and more difficult to assemble, not to mention the cost of iron elements. Dried wood of the following species is suitable for construction:

- ash;

- aspen;

- conifers: spruce, pine, larch.

Advice. For building inside the house, you should not use birch, as it quickly dries out and loses its appearance.

For the manufacture of stringers, you will need a board with a thickness of 40 mm or more of the required length (it is unacceptable to splice a bowstring from pieces). The width of the board should be 25-30% more than the calculated tread width. A wooden bar with a section of 10 x 10 cm or more will fit on the extreme and intermediate posts for the railing, depending on the length of the supporting part and the weight of the structure.

The appearance of a wooden staircase largely depends on the design of the balusters. In order to beautifully decorate the railing, it is better to order the manufacture of balusters somewhere in the production, where according to your drawing they will be machined on a lathe. If you own wood carving, then you can do the design of the racks yourself. Also, do not forget to purchase fasteners - self-tapping screws, metal studs or dowels for installing balusters, nails.

Installation guide

Recently, wooden stairs to the second floor, equipped with turning steps, have gained popularity. They take up little room space and are relatively easy to assemble, so we will give step-by-step instructions for installing such a structure. First of all, prepare the necessary tools and a ladder or a simple ladder for temporary access to the second floor. Then proceed in this order:

- Mark the blanks according to your drawing. For convenience, you can make a wooden template to draw cut lines along the stringers one by one. Cut out the pieces with an electric jigsaw.

- Install the support post and attach as shown in the picture below. Make grooves in it for attaching winder steps and bowstrings.

- Fasten both stringers - screw the first to the wall, and the second to the vertical pole and the end of the interfloor ceiling.

- To support the winder steps, install horizontal bars on the wall. Mount 2 bowstrings for a short march - the entrance to the stairs.

- Mount all the steps, moving from the bottom up. Mark on them the attachment points of the balusters.

- Fasten the balusters on the dowels or studs, put the railing.

The scheme of fastening the central support and the assembly of the flight of stairs

Advice. Do not cut 3 turn steps from one array. It turns out that the fibers of the first of them will be located across the length of the tread, which is why the step will break at the slightest load.

It makes sense to make the risers of a homemade staircase closed if you plan to sew up the space under the march (for example, for a pantry). In other cases, the openings between the steps do not have to be sealed. To extend the service life, finish the flight of stairs - treat the wood with an antiseptic composition and varnish it. How to properly assemble the turning ladder yourself is described in the next video:

Conclusion

When building a wooden staircase, pay special attention to the preliminary stages - calculation, marking and cutting out parts. If you make a mistake here, then it can be difficult to eliminate it during assembly, up to the alteration of the stringers. Think about the design of balusters and railings, study the existing options from photographs and choose the most interesting and suitable for the interior of your home.

Related posts:

Wooden stairs are gaining more and more popularity every year. This is due, first of all, to the fact that people more often began to purchase country houses with several floors. When arranging the room, the correct choice of steps plays an important role. Stairs made of natural wood have many positive aspects. This type of product can be both bought and made independently. To do this, you need to collect a certain set of tools, buy good wood and be patient.

How to calculate correctly?

Before starting work, special attention should be paid to the choice of the main material. Wooden stairs to the second floor can be made from different types of trees, but pine is best suited. This type of raw material is characterized by softness and low price. With such material it will be easy to work even for a beginner.

Before starting work, special attention should be paid to the choice of the main material. Wooden stairs to the second floor can be made from different types of trees, but pine is best suited. This type of raw material is characterized by softness and low price. With such material it will be easy to work even for a beginner.

A staircase made of solid pine will not darken if, before starting work, the raw materials are treated with a high-quality special agent.

In order for the design to be reliable and last for many years, it is recommended to buy wood of more expensive varieties. These include beech, oak, larch. They have a denser structure, but have a high price.

The main types of stairs:

- screw;

- marching.

For the manufacture of the first option, in addition to wooden materials, metal ones are also used. Such ladders are intended only for the movement of a person. It is almost impossible to lift furniture or other dimensional elements along them. Often, screw structures are chosen in rooms of a small area. Popular types of wooden stairs are shown in the photo below:

Marching are the most practical and easy to manufacture. Such structures are divided into many types. They can be either single-march or consist of several parts. In the second option, a platform is often used that separates these elements and is used to create a turn.

Before you start work, you need to calculate the wooden stairs:

- The product should not have an inclination angle greater than 45 0 .

- Tread depth - not less than 25 cm.

- The dimensions of the riser should be in the range of 16-20 cm.

- Opening width from 1000 mm.

- The height of the railing is from 1 meter. For children - 60 cm.

- The opening is vertical - at least 2 meters.

In order to determine the number of steps, it is necessary to divide the height of the future staircase by the height of the riser. The resulting number should be rounded up to an integer. This indicator will be the number of steps.

An accurate calculation can be made using a special computer program. Using simple rules and recommendations, you can make a comfortable, and most importantly, reliable staircase.

Product design

Before you make a wooden staircase, you need to know what it consists of. This will help you quickly create the option that will best fit into the chosen interior of the room.

Before you make a wooden staircase, you need to know what it consists of. This will help you quickly create the option that will best fit into the chosen interior of the room.

For ease of movement, the number of steps should be odd.

The design of the flight of stairs includes the following parts:

- Bowstring. This element acts as a carrier beam and is an additional fastener for the steps.

- Kosoura. They are cuts that are created in the main parallel beams. They are needed to accommodate the treads.

- Riser. They are designed to cover the visible part between the steps. Riser mounted vertically. These elements are optional.

- Tread. This type of element is the upper part of the steps.

- Balusters. With this part, maximum rigidity and strength of the product is achieved. Elements are attached to the steps and railings.

- Columns. They are also often referred to as support rods. This is the main part of screw structures.

- Handrails. Mounted on top of balusters.

- Radius risers. They are presented in the form of a rounded shape. Installed at the bottom of the stairs.

- Decorative pieces. They are mounted on poles. They are often referred to as stubs.

- Running step. It is mounted at the very beginning of the flight of stairs. Its distinctive feature is its unusual shape.

The complexity of the structure depends not only on the type of structure, but also on the method of manufacture. A wooden staircase to the second floor with your own hands for a private house can be made both on bowstrings and on stringers.

Bowstrings are mounted from the end of the tread. For this, corners, grooves and construction glue are used. They can also be fixed using bars. All elements are fixed with bolts or self-tapping screws.

As for the kosour, they are placed under the steps themselves. For their installation, special fasteners are used.

For the manufacture of bowstrings and stringers, it is best to use oak or ash. Also masters prefer larch. Such tree species will make the structure more reliable.

Markup and creation of elements

The manufacture of wooden stairs should be started only after a full calculation has been made. You also need to finally decide on the place where the product will be installed.

Sequencing:

If the steps will be laid on stringers, then their length should be 10-20 mm longer, and the width should be 20-30 mm.

Particular attention should be paid to wooden railings for stairs. Sanding them should be in several stages, reducing the graininess of the paper. Thus, the handrails will turn out perfectly smooth.

Also, do not forget about the connector to the second floor. If it is not there, then the dismantling method will require removing part of the floor.

Installation of a wooden ladder

Mounting the structure is the main part of the work. A lot depends on the correct assembly of the elements.

Mounting the structure is the main part of the work. A lot depends on the correct assembly of the elements.

The installation of a wooden staircase must begin with the fastening of the support beam. It is fixed to the floor where the stairs will begin. Then a kosour is attached to the beam. This can be done in two ways: washed down in a beam or washed down in a stringer.

After that, the product is fixed on the support beam, to the side wall and ceiling opening. As soon as the first kosour is well fixed, you can proceed to the second. The second element is set according to the length of the prepared steps.

After that, the product is fixed on the support beam, to the side wall and ceiling opening. As soon as the first kosour is well fixed, you can proceed to the second. The second element is set according to the length of the prepared steps.

The top step should be on the same level with the floor of the second floor.

Depending on the width of the stairs and the expected loads, you can use not two stringers, but three or more. The use of several elements gives the structure rigidity.

In order for the steps not to be tilted in different directions, the stringers should be installed as evenly as possible.

After the main parts are attached, you can proceed with the installation of the risers, and then to the steps. The treads are fastened with wood screws to the stringers and risers. It is important to ensure that the fasteners are well deepened into the wood.

The installation of balusters and pillars must begin from the markup where they will be located. The hole for the dowel should be located in the middle of the baluster. Fasteners are fixed into the connector with glue. They should protrude 10-15 cm up. Under the size of the dowel, a hole is drilled in the baluster.

Then the columns are attached. On a single-march structure, they are mounted at the beginning and end. At first, only the upper elements should be attached, the lower ones will be installed at the very last moment.

After that, you need to fix one or two balusters. This is necessary in order to determine the angle of the surface. To do this, you need to attach a handrail. Cut off the unnecessary part from all elements.

Then the base and holes of the prepared balusters are carefully treated with glue and connected to the dowels.

The railings are cut at the required angle. Holes are made on the sections to connect them with the posts, using a dowel. The slats are attached to the balusters after the glue has completely dried. They are also fixed with adhesive and self-tapping screws. For reliable fastening we use.

The bottom column is installed last. It is also fixed to the railing with a dowel. After the glue has completely dried, the handmade wooden staircase is considered ready.

To prevent the material from infecting fungus and insects, the wood must be painted with an antiseptic. The stairs should be varnished or other paints and varnishes after the primer dries well. This will require you to wait at least 24 hours. If this is not done, then the paint will not lay down evenly and will begin to peel off over time.

It is not difficult to make a staircase out of wood. By following the sequence of actions and recommendations, you can make a beautiful, strong and durable structure that will decorate the room for many years.