Anton Tsugunov

Reading time: 4 minutes

Drywall is one of the most common materials for interior finishing works. It allows you to quickly and efficiently level any surface; moreover, this type of finishing is cheap, affordable, and much easier to work with than plaster. If you have no experience working with this material, but would like to use it to decorate your apartment, the first question that will arise is how to attach drywall to the wall? Depending on the degree of curvature of the walls and the characteristics of the room, you can choose one of two methods, described in detail below.

Mounting methods

Attaching drywall to the wall is done in two ways:

- demon frame method;

- framed.

The frameless method is considered the simplest, since for its implementation there is no need to construct a sheathing: the drywall is attached with gypsum glue. But in order to use this method, the height of the ceiling must correspond to the size of the sheet. Using the frame fastening method, you can finish a wall up to 10 meters high.

Installation of gypsum boards using both methods is carried out in the process interior decoration before installation flooring. Work on laying electrical wiring, heating systems, water supply and sewage systems must be completed by the time the walls are covered with plasterboard.

Features of frameless fastening

How to properly attach drywall to a wall using an adhesive (frameless) method? To avoid problems in the future, the following conditions must be observed:

- absence of fungal infections and areas that may crumble;

- sufficient strength of the base;

- the wall should not freeze, it must be protected from the formation of dampness;

- the surface must be completely free of paint, oils and dust.

Frameless method used for wall curvatures not exceeding 4 cm.

Installation instructions

Step-by-step instructions will help you understand how to attach drywall to a wall.

- Stage 1. Wall measurements and placement planning are carried out plasterboard sheets.

Avoid cross-shaped joints; sheets should be placed offset.

- Stage 2. Prepare the surface. If the wall is porous, it must be treated with a primer.

- Stage 3. GCR is cut out. In addition to solid sheets, pre-prepared inserts are also useful.

Straight cuts are best made with a sharp construction knife, and a jigsaw will help when making curves and radius lines.

- Stage 4. Glue is prepared. Acceptable use gypsum mixtures that harden slowly, such as starting putty.

In order to extend the hardening time of the mixtures, you can add wallpaper glue or PVA.

- Stage 5. Plasterboard sheets are glued to the wall.

If you are worried about how to securely fasten drywall, then know that this type of fastening does not require any additional actions.

It is important that seams 5–7 mm wide and gaps of 7–10 mm from the floor and 3–5 mm from the ceiling are left between the sheets. For this purpose, pre-prepared wooden wedges are used.

Fastening gypsum boards using the frame method

A more common method of fastening gypsum boards is to install sheets on a frame made of metal profiles installed along the wall.

Work order:

- Stage 1. First of all, measurements and markings are carried out for the installation of profiles and hangers. Marking for the guides begins from the top profile, the required distance is set aside from the wall, a line is drawn, and transferred to the floor using a plumb line. Vertical load-bearing profiles should be located at a distance of 60 cm from each other, and so that each sheet of plasterboard fixed to the wall rests on three posts. Suspensions should be installed at a distance of 60–80 cm.

- Stage 2. Installation is in progress. It is necessary to install around the perimeter: using a hammer drill, dowels and screws, the top one must be screwed to the ceiling, the bottom one to the floor. Suspensions are attached to the marked points, and carriers are inserted into the guide profiles. They must be secured with hangers.

No renovation nowadays is complete without drywall. Walls are constantly lined with this material, and they are used to make various designs and they decorate the ceilings. As a rule, to install plasterboard sheets, a frame is pre-installed on which the material is fixed. However, more and more often people are trying to attach drywall to the wall without a profile. What is this connected with? First of all, with the desire to save time, money and labor resources.

But is it possible to attach drywall directly to the wall? The question is ambiguous. Experienced craftsmen It is recommended to mount metal or and then attach gypsum sheets to it. However, when correct installation, you can install drywall on walls without a frame. However, it is better to think everything over several times and unless the decision has no alternatives, proceed to the matter, since fastening gypsum boards without a frame just for the sake of saving can result in high costs in the future. fasten gypsum board this way You can, for example, if you are renovating small rooms, such as bathrooms, toilets, balconies, then the frame will steal precious space.

One of the exotic ways to attach gypsum board without a profile is.

What is this article about?

Conditions for fastening without profiles

In order to attach gypsum plasterboard or gypsum fiber board directly to the wall, you need to follow a series of necessary conditions, without which this procedure is simply impossible.

The wall must be vertical and perfectly level, that is, not have even the slightest slope. There are situations when the wall is not level enough and in such cases the frame is partially installed. Metal profiles in this installation option serve only as a leveler for the wall.

The height of the room should not exceed the length plasterboard leaf. The problem here is that when installing plasterboard sheets, it is assumed that the joints of different pieces of plasterboard will be located along the transverse metal profiles. If you attach the sheets directly to the wall, then you should not have transverse joints at all, since there will be nothing to attach them to.

If the wall has minor unevenness from two millimeters to two centimeters, then there is an option to level it with starting putty, to which ten to fifteen percent of gypsum must first be added. To attach drywall, it is recommended to use ready-made adhesive mixtures. The mixture must be applied around the perimeter of the entire sheet, as well as in one continuous stripe in its center.

If the unevenness is much greater, then instead of frame profiles you can use plasterboard beacons. They are plasterboard, cut into squares or rectangles of ten to twenty centimeters and serve to level the wall plasterboard sheets without frame.

After the adhesive mixture has dried, the plasterboard sheets are again secured with dowels in the corners and in the center. The dowels are attached so that they extend into the wall by at least forty millimeters.

After the final installation of the sheets has been carried out, it is necessary to putty the connecting seams, and also glue the mesh.

Video on the topic to help

Required Tools

For finishing you will need some non-standard tools. It's better to prepare them in advance.

- Knife with replaceable blades for cutting plasterboard sheets;

- Electric jigsaw or saw for working with drywall;

- Strong thread. It will be useful to create a plane level;

- Nails or screws;

- Construction level;

- Simple pencil;

- Plumb;

- Scraper to clean up edges plasterboard leaf;

- Drill, whisk and bucket to dilute and stir the solution;

- Spatula. It is better to take two spatulas - wide and narrow;

- Rubber hammer;

- Regular hammer;

- Pliers;

- Phillips screwdriver.

Let's also consider the materials that will be used during the work.

- Plasterboard sheets;

- Glue, for working with plasterboard sheets. You can also use starting putty if you add ten percent gypsum or PVA glue to it;

- Water;

- Primer;

- Dowels. The size of each dowel should be from eighty to one hundred and twenty millimeters;

- Serpyanka;

- Glue.

Preparation for installation

If you are going to finish a brick or concrete wall with plasterboard, you must first clean it and spray it with a solution. Then the surface needs to be primed. The soil must be diluted strictly in accordance with the instructions provided by the manufacturer. If it says on the package that the primer is ready for use, then there is no need to dilute anything. You can immediately begin processing the wall.

If there is old plaster on the wall, you need to carefully examine it to identify weak points and treat them with a solution and then with a primer.

It is strictly forbidden to attach plasterboard sheets to walls in rooms where there is constant dampness. And also, this type of repair cannot be carried out if condensation remains on the walls of the room. This will seriously damage the fastening of the sheets. In such rooms it is necessary to use special moisture-resistant plasterboard and attach it only to the frame.

Before attaching drywall, it is necessary to inspect using a level and plumb line for deviations from the vertical and in the alignment. If this is possible, then all convex areas must be knocked down and the depressions covered with mortar in order to perfectly level the surface before installation.

After priming, markings are applied to the wall using a pencil or chalk. If you do this before priming, then all the drawings will simply be washed away. Drywall sheets on the side attached to the wall also need to be coated with a primer before fastening. Beacons need to be cut out of waste plasterboard sheets and coated with primer on both sides.

If this is necessary, the next stage of installation is the installation of electrical wiring. In cases where the wire must run on wall projections, it must be buried in drywall. To do this, you will have to make special grooves in the sheet.

Mounts on flat and curved surfaces

If the wall surface is relatively flat, then you will not have to use beacons. Use a mixer to dilute the dry powder in water and make glue. If you don't have a mixer, you can make glue by hand, but then the process will take much more time and effort.

If you decide to add PVA glue to the putty, then first you need to dilute the glue in water, and only then add the dry powder. If you do the opposite, the putty will very quickly harden and turn into stone. Naturally, after this, it will no longer be able to be used for its intended purpose.

Apply glue to plasterboard sheets in one continuous strip around the entire perimeter on all edges. You also need to apply several cakes of the solution in a checkerboard pattern in the center of the sheet. The distance between the cakes should be about forty centimeters. To make the fastening sufficiently reliable, you need to coat more than a tenth of the surface with glue. plasterboard leaf.

Attach the sheet to the wall strictly vertically. It must be applied and pressed against the wall. It is best if someone helps you with this, since it is problematic to complete this process alone. Check how firmly the sheet is attached. If you have any doubts, press it harder in those places where the lag occurs. It is to take into account such subsequent adjustment that enough solution is applied to the sheet. If the solution is not enough, then theoretically the sheet can be peeled off, but it is better to avoid such situations, since during the peeling process the plasterboard sheet may simply break.

If the wall is tilted or rotated, you will have to use beacons. Use strong thread to create a net that indicates the desired verticality and plane. Next, the beacons are installed in the right places. They need to be installed so that they touch the thread frame. Then the drywall sheets are attached in the same way as in the first option. After this, secure the problem areas with dowels, and seal the seams with putty and sickle.

If you are attaching plasterboard sheets to a wooden wall or ceiling, then everything is much simpler. To install such sheathing, it is enough to screw the sheets to the wall with self-tapping screws or self-tapping screws. If wooden wall If it is not level, this can be corrected by applying additional wooden overlays, and all bulges can be removed with a regular plane.

As you can see, there are different ways installation of plasterboard sheets, however, the most reliable way installation of gypsum boards - installation on metal frame. This is the only way the sheets will hold firmly enough.

To level walls during repairs, plasterboards are often used. There are two ways to install them - with and without a frame. The first method is more reliable, but it is not suitable for small rooms, since the thickness of the structure reduces the already small size rooms. In this case, attaching drywall to walls without a frame is suitable, as a method that is simpler and less expensive.

The essence of the method is to attach plasterboard sheets to the wall using special adhesive compositions, but provided that the height of the ceilings does not exceed 3 m, that is, not higher than the length of the sheet. It is performed after complete completion of work that uses water - putty or plaster, as well as when the walls are completely dry.

Preparing the wall

To carry out the work you will need the following equipment and materials:

- Rulers, tape measures and markers for taking measurements;

- Construction or stationery knife for cutting slabs and chamfering;

- Construction level, usually a level lath, rubber hammer;

- A container for mixing glue and a drill with an attachment;

- Primer and construction adhesive.

The complexity of surface preparation depends on the material from which it is made. A convenient option is brickwork, which just needs to be coated with a primer. If you attach it to old plaster, it will eventually begin to fall off and deform the slab from the inside. To eliminate this, all old coatings are removed to a solid base, including whitewash, wallpaper, painting and non-wettable stains, after which the surface is treated with an appropriate primer. If the old base is solid, the preparation procedure will be as follows:

- “Tapping” the wall with a trowel to identify places where part of the layer may fall off.

- Removal of old coatings, wallpaper, and weak areas of the coating.

- Plastering the damaged areas.

- Cleaning the wall from dust.

- Primer with deep penetrating compounds.

Before the main work begins, all necessary communications are carried out. Lines with high voltage must be hidden in grooves and a fire hazard hose. Low voltage wires are attached directly to the wall.

Glue mounting

Before direct installation, the main walls are measured to ensure correct cutting of the sheets. The fragments are arranged so as to prevent cross-shaped joints. An adhesive mass is prepared using gypsum putty, mixed to the consistency of sour cream. The mixture is applied to the pre-primed drywall. Based on the degree of unevenness on the wall, the glue is applied as follows:

- If the height difference is less than 4 mm, fixation is carried out with Funenfüller putty, which is applied in a small layer over the entire perimeter;

- With a difference of up to 2 cm the slabs are fixed with Perflix, applied in separate spots with an interval of up to 35 cm;

- With a difference of up to 40 mm in such places, strips of plasterboard 10 cm wide are attached, and the main sheets are attached to them.

The sheet is applied to the wall quickly and carefully. First, the gaskets are installed from the bottom edge, and after it is installed in accordance with the marks on the floor, the rest of the part is pressed.

Using a rule or a long level, bulging areas are corrected, which are leveled by light tapping. It is not recommended to knock on the instrument. It is removed, the place is leveled, and checked again. After leveling, the sheet is supported for several hours with a wooden board.

Instead of glue, the fastening compound can be polyurethane foam, which has a low expansion coefficient. But at the same time the sheet is securely fixed. If this is not done, due to the expansion of the foam, bumps will appear that cannot be removed.

If the wall deviations are significant (up to 4 cm), during installation, guides are used, which are attached in places of maximum deviation. Large differences are compensated by a higher amount of glue. In this case, leveling the slab is carried out more carefully, since excessive force can cause the surface to bend. For ease of positioning, you need to mark the floor and walls; this measure will help to avoid mistakes and rework of inaccuracies.

After installation is completed, the joints are glued with sickle tape, and as they dry, putty is applied on top. Irregularities are sanded after drying sandpaper, and the surface is cleaned of dust and coated with a primer.

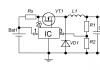

Self-tapping installation

The method is more complex than the previous one, but the fastening is reliable, and the method is successfully used on walls with a large curvature. For this you will additionally need:

- Electric drill and screwdriver;

- Glue and polyurethane foam;

- A set of self-tapping screws and screws with washers with a diameter of more than 1 cm;

- Thick foam.

At frameless method When installing plasterboard slabs, the ceiling height should not be higher than 3 m, since the technology does not provide for the installation of horizontal joints.

After priming the wall surface with all prepared sheets, the following actions are carried out:

- The plate is applied to the wall, and holes are drilled in it at a uniform distance from each other at 8-10 points, which are marks;

- The sheet is removed, and on the marks in drilled holes hammer in dowels;

- Foam rubber is glued onto the drywall 10-12 cm from the holes, which will act as a shock absorber during installation;

- The sheet is applied to the wall and secured with screws with washers on them;

- Using a level, the sheet is installed in a strictly vertical position by screwing or unscrewing the screws;

- The actions described above are carried out with all plasterboard boards;

- A hole with a diameter of up to 7 mm is made near each screw for injection polyurethane foam for the purpose of fixation. Its supply is carried out blindly, and you first need to experiment with the dosage to get a spot with a diameter of up to 15 cm;

- All slabs are fixed with simultaneous control of their position using the building level;

- The screws are removed after the foam has hardened, and the remaining holes are filled with putty;

- The work is completed by standard puttying of the seams and then sanding them with sandpaper after drying.

Frameless leveling of walls with plasterboard slabs is a complex technology that requires knowledge of the properties of the materials used and skill in working in this area. You need to be able to choose putties and glue based on the conditions of the work and the characteristics of the surface on which installation will be carried out. take on self-execution This task requires confidence in your abilities. Otherwise, it is faster and cheaper to entrust the repair to professionals.

Repair and decoration of any room is not complete without drywall. The material is a layer of gypsum covered on both sides with cardboard. Used for installing partitions, finishing wall surfaces. It can be used to create complex multi-level suspended structures ceilings, arches complex configuration, finish niches in the walls and make built-in wardrobes with open shelves.

Drywall is classified as a universal construction and finishing materials, which are used in all structural planes of the building. For ceiling works use thinner sheets of plasterboard, 9 mm thick, their size is 1.2 x 2.5 m. Wall sheets are 12 mm thick, 1.2 x 3.0 m in size.

For work under normal conditions, standard plasterboard is used. beige color, for the installation of moisture-resistant partitions, green sheets are used, and the implementation of structures in fire hazardous rooms will require gray shade surface of the material.

Sometimes attaching plasterboard to a frame is not possible due to the small size of the room, for example, on a balcony, loggia, in utility rooms, or when reconstructing plumbing units in an apartment. If the structure of the frame “steals” such necessary centimeters, then it is allowed to attach sheets of material directly to the wall.

Features of fastening drywall without a profile

What you need to prepare for work

Tools

- Drywall knife, spare blade block.

- Drywall saw or electric jigsaw.

- Strong thread to create a level plane, nails or screws to secure to the wall.

- Construction level, plumb line, pencil, scraper for cleaning the edges of the sheet.

- Drill and whisk for solution, bucket for mixing.

- Spatula, hammer, rubber mallet, pliers, Phillips screwdriver.

Materials for work

- Sheets of wall plasterboard.

- Dry glue for working on drywall. It is allowed to use starting putty with the addition of building gypsum or PVA glue in an amount of 10%.

- Water and primer for surface adhesion.

- Dowels ranging in size from 80 to 120 mm.

- Mesh for gluing serpyanka seams and glue.

How to attach drywall to a wall without profiles

Surface preparation

If the wall is made of brick or concrete, then preparatory work include cleaning the surface from deposits and splashes of solution. Next, the surface is primed with an impregnating composition. The impregnation should be diluted according to the instructions on the package, since each manufacturer makes a different composition of soil concentration. If it is written that the soil is ready for use, then there is no need to dilute it.

If the wall is made of brick or concrete, then preparatory work include cleaning the surface from deposits and splashes of solution. Next, the surface is primed with an impregnating composition. The impregnation should be diluted according to the instructions on the package, since each manufacturer makes a different composition of soil concentration. If it is written that the soil is ready for use, then there is no need to dilute it.

If available on the wall old plaster you need to inspect it and identify weak, lagging areas, which can be knocked down and repaired with mortar. Then treat with primer.

Drywall should not be attached to walls in rooms where the walls are constantly damp, moisture is transferred from an uninsulated foundation or enters from the roof. Frameless mounting is not allowed on walls that are subject to constant condensation due to non-compliance with the wall thickness according to thermal engineering calculations.

Before fixing drywall, inspect it using a level and plumb line to identify the greatest deviations from the vertical and in alignment. If possible, the bulging areas are knocked down, and large depressions are reduced by applying a layer of solution.

All markings with a pencil or chalk are applied to the walls after priming, otherwise the impregnation will blur the marks and everything will have to be repeated again. Drywall sheets are also covered with primer on the side where they are attached to the wall. Cut beacons from sheet waste are primed on both sides and left to dry.

If necessary, install electrical wiring, which will be hidden by reinforced sheets on top. If the wire runs on protruding sections of the wall, then make a groove to recess the wire.

Fastening drywall without beacons to a relatively flat surface

Dilute dry glue with water in a container using a mixer. Stirring by hand is also allowed, but it will require more effort and time. First, water is poured, and then the dry mixture is poured into it.

If there is a need to add PVA glue to the putty mixture, first mix it in water and then pour the putty. It will not be possible to add polyvinyl acetate glue to the ready-mixed putty, since the solution will quickly harden and turn into stone.

The glue is applied to the edges of the sheet along the entire perimeter in a continuous strip. In the center, cakes are made from the solution at a distance of 0.4 m in a checkerboard pattern. Total area glue or putty applied to the surface must be more than 1/10 of the sheet area for reliable fastening.

The sheet is installed vertically and pressed over the entire area. It's better to do this with a helper. After this, the level of fastening is checked. If it does not meet expectations, then the material is pressed harder in certain places. For this purpose, enough solution is applied to the sheet to account for such adjustment. It is possible to remove an already rooted sheet from the wall to apply mortar, but it risks compromising its integrity, in other words, it may break if it comes off.

Some installers hold the sheet in the correct position for about 20 minutes to allow the solution to set, others grab it in this position with dowels, trying not to disturb the level.

Fastening drywall to a curved wall using beacons

If the wall is inclined or has a rotation in the plane, then to attach the drywall you need to make a special layer in the largest depressions. First, the curvature of the wall is measured. A sheet of material is placed against the wall and drilled through with self-tapping screws in the depressions, so that they make a mark on the wall. The sheet is removed and the screws are unscrewed.

If the wall is inclined or has a rotation in the plane, then to attach the drywall you need to make a special layer in the largest depressions. First, the curvature of the wall is measured. A sheet of material is placed against the wall and drilled through with self-tapping screws in the depressions, so that they make a mark on the wall. The sheet is removed and the screws are unscrewed.

A net is made with a strong thread that will show the desired verticality and plane. Next, in the places of the marks on the wall from the self-tapping screws, one or several layers of rectangles from drywall waste are attached with glue. All of them must be pre-primed with impregnation. These overlays are placed so that on top they touch the thread frame.

An adhesive mixture is applied to the sheet, placing it, as in the previous version, around the perimeter and in the middle of the sheet, only special attention paid attention to placing the cakes in place from drilling screws that will coincide with the pads on the wall.

The sheet is lifted into a vertical position and pressed against the wall, combining everything assigned places. Fix for setting and move on to the next sheet. The thread frame and overlays are made simultaneously on the entire wall, and not on each sheet separately.

After fixing the problem areas with dowels, seal the seams between the sheets using putty and sickle.

Installation of drywall without frame on a wooden wall

To perform this type of work, the use of putty or glue is not required; sheets of material are attached to wooden surface without gluing with simple screws or wood screws, made with countersunk heads. Places from drilled heads in drywall are sealed with putty.

To perform this type of work, the use of putty or glue is not required; sheets of material are attached to wooden surface without gluing with simple screws or wood screws, made with countersunk heads. Places from drilled heads in drywall are sealed with putty.

If there is curvature and unevenness of the wall, then it is leveled using additional wooden overlays different thicknesses. The bulges of the tree are cut with a plane or saw.

Certainly, the best option is to fasten drywall with a frame, but, having understood the intricacies, they attach the material directly to the wall, trying to withstand set level. There are many videos that show the mount without a profile. If you miscalculate and the curvature still appears, separate places can be corrected by applying small layers of putty through a putty mesh.

Options for fastening gypsum board without profiles

Drywall – universal material, which is used in various types repair work. It gives the opportunity to short terms change the state of space. But the budget will be quite optimistic. That’s why drywall is so popular; virtually anyone can learn to work with it.

IN in this case it all depends on the type of drywall - the smaller the distance between the supports, the more durable the sheet will be. In this case the best option there will be sticking. This method is not always suitable, so a metal profile is used.

There are building regulations that require:

- For wall gypsum, support strips must be installed at least every 40 cm;

- Moisture-resistant plasterboard requires an interval every 60 cm;

- Ceiling plasterboard - for it you need to assemble a mesh from a profile, the cell size of which is no more than 40 by 40 cm.

But it is not enough that you install the planks with a reference step.

It is very important to correctly make holes for the screws. If you screw them in very often, then the integrity of the sheet will be compromised, it will crumble and fall out. If there are few fasteners, then the consequences will be the same.

How and how to properly attach drywall with your own hands

All installation work It is recommended to use appropriate types of screws. And there are only two of them - metal screws and drywall screws. The first type of screws is divided into two subtypes: metal-to-metal and metal-to-wood. Metal-to-metal is needed to connect profiles. The screw at the end is equipped with a special drill, which easily allows you to connect the elements to each other.

Black phosphated coated screws are suitable for fastening drywall. It reduces friction, firstly, and secondly, it protects against corrosion. When cutting through drywall, the seam will not destroy the structure of the plaster.

Installation process: how to attach drywall, step-by-step instructions

Installation of drywall will consist of four stages - these are measurements and drawings, assembly of the frame, installation of insulation and soundproofing material, installation of the drywall itself.

Taking measurements and drawing a plan of how you see the future structure is very important.

If you plan to fix the drywall only on the wall, it is enough to show the frame on the plan.

Frame assembly:

- First, guides are installed - a wide U-shaped profile, it is attached to the bottom and top of the wall, or along the perimeter of the ceiling. They need to be installed perfectly straight.

- If a gap forms between the profile and the wall, you need to insert thick cardboard or wood into it.

- Depending on the frame, the guides need to be secured with dowels at intervals of 30 cm from each other. After installing the guides, the frame is installed.

First, one corner sheet is installed, which is secured with one screw. Then comes the level check and fixing the second self-tapping screw to the cross. Then the sheet is “squeezed” around the perimeter. Then the sheet is screwed to the supporting strips. This procedure requires sequential execution.

What you need to attach drywall to the ceiling

Examples: how to attach drywall (video)

Fastening drywall – simple technology, if you do not engage in amateur performances. Correct fastenings, good frame, tools, parts, and the work will not seem difficult to you.

Happy renovation!