If not so long ago, work on the installation of electrical equipment in residential buildings could only be carried out if there was a project approved by the relevant authorities, but today, thanks to the decree of the Russian government on the abolition of outdated requirements for owners of houses and cottages, everything has become much simpler. Now electrical wiring in a bathhouse can be installed without a design or approvals. But at the same time, the main condition must be fulfilled - the installation is carried out taking into account the requirements of the PUE and other regulations, deviations are prohibited and can serve as a basis for refusing to connect the object to electrical networks.

The latest standards DBN V.2.5-2003 and DNAOP 0.00-1.32-01 prohibit the use of two-core cables for wiring (except for switches); now they must only be three-core with phase, zero working and zero protective copper wires. This applies to single-phase electrical wiring, three-phase ones are almost never used in baths and therefore will not be mentioned in this article.

DBN V.2.5-2003. PDF download

DNAOP 0.00-1.32-01. State regulations on labor protection. PDF download

What are the general requirements for wiring in a bathhouse?

- The placement of lamps, switches and sockets should be carried out by zones, the breakdown is based on the requirements of GOST R 50571.12-96. In the first zone it is strictly prohibited not only to install any electrical equipment, but also lay cable lines. Furnaces for space heating are built here, washbasins, showers, etc. are installed. The second zone is the safest in terms of equipment operation, it has the fewest restrictions and additional requirements. In the third and fourth zones it is allowed to lay cables with an insulation resistance of at least +170°C.

- To install electrical wiring in bathhouses, it is strictly forbidden to use universal flat wires (PUNP).

The fact is that state standards have not yet been developed for these wires; each enterprise has the right to use its own technical specifications(THAT). As an objective market analysis shows, all PUNP wires according to specifications to one degree or another do not meet the requirements of GOST 22483-77, which regulates the electrical resistance of the conductor. The number of fires caused by these cables exceeds 65% of all emergencies caused by electrical equipment.

- , it is also advisable to install the light switch in the vestibule or recreation area.

GOST R 50571.12-96. PDF download

Prices for PUNP cable

PUNP cable

Step-by-step instructions for installing electrical wiring in a bathhouse

For example, we will consider the most difficult option, it can be significantly simplified taking into account the characteristics of baths and the requirements of developers.

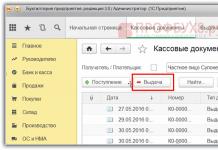

Step 1. Connecting the input cable (power cable). It is fed into the panel from above and connected to the input machine. Cut-off parameters are calculated separately taking into account the total power of consumers. Specific tips are provided later in this article. Blue and gray wires are connected to the input of the machine, yellow-green to the ground bus.

Connecting the power cable. We install gray and blue wires onto the upper terminals of the input difavtomat. And the yellow-green wire goes to the grounding bar.

Step 2. If the shield has additional cut-offs for separate rooms or consumer groups, then supply power to them. Standard position – entry from above, exit from below.

Electrical panel and wires coming from it in plastic boxes

Practical advice. In dry rooms it is better to install wiring in ordinary plastic boxes, in wet areas It is recommended to protect them with polymer pipes. This is not a categorical requirement of the standards, but recommendations from experienced electricians.

Step 3. Wire lighting and outlets in the washroom.

Please keep in mind that the degree of protection of enclosures from moisture and dust must correspond to international standard at least IP 44 in zones 2 and 3. This housing protects against the penetration of solid particles larger than one millimeter in size and does not allow leaks from drops falling on the surface at any angle.

You can do the wiring using a VVGng 3×1.5 cable, stretch it to the junction box.

Connection diagram for VVGng 3×1.5 cable. The cable will be stretched to the junction box. The veins are marked

Place the two-core cable VVGng 2×1.5 into the switch, one core is connected to the upper terminal of the device, and the second to the bottom.

VVG cable ng 2×1.5 lowered to single-key switch. One core is connected from above, the other from below. The cores are marked L and Llight

Thus in one position of the button electrical circuit breaks, and in the second it connects and the light bulb lights up. Before installing the switch, carefully inspect the housing; it indicates the position of the button when closing and opening the contacts. According to the standard, the light should turn on when the switch button is in the upper position. Another nuance is that a phase is always connected to the switch, not zero. This makes it possible to safely change lighting fixtures in case of their failure without turning off the general circuit breaker.

The VVGng 3x1.5 cable is being laid to the installation site of the proposed luminaire. The veins are marked

Step 4. Run the cable from the box to the lamp; drill a hole in the wall and insert a piece of tube into it. It is recommended to fill the free space between the wires and the walls of the pipe with a special non-flammable composition.

A metal sleeve is inserted into the hole

Important. All places where cables pass to other rooms should be made only in a metal pipe; it completely eliminates mechanical damage cables

In the box, connect the ends of the cables of the same color. It is important to know that not all manufacturers can withstand standard colors cables, if you have such a situation, then it is recommended to mark them during installation. This can be done using small stickers or colored markers.

If the lighting has its own circuit breaker, then last stage When installing the wiring, you need to connect it to the power supply and its terminals.

In the distribution board we connect gray vein cable to the lower terminal of the circuit breaker. The blue wire to the zero busbar. Yellow-green to the grounding bus

Keep in mind that installing distribution boxes, switches and sockets in the steam room is strictly prohibited. This fittings are installed at the entrance to the room.

Step 5. It is better to use low-voltage lighting in the steam room, although this is not a mandatory requirement. 220 V lighting devices must have a special protected housing.

For low-voltage lighting, you need to install a step-down transformer and supply power to the light bulbs from it. The technical parameters of transformers should be selected taking into account the required output voltage and the total power of all consumers.

To reduce the voltage, a step-down transformer is used, which is selected in accordance with the required output voltage and the power of the connected lighting devices

Remember that it is very difficult for a transformer to operate at the limit; under such operating conditions it quickly fails. Always buy equipment with a power reserve; this approach increases the reliability and duration of operation of the devices.

Run a two-core cable from the transformer to the box, and insert the cables from the light bulbs and switch into it.

Laying a two-core cable to the junction box

Wire connection diagram in the junction box. The veins are stripped and marked. Next, the cable is lowered to the switch

Important. Lighting into the steam room is carried out only using a special heat-resistant cable; such requirements are specified in the current regulations.

Laying a heat-resistant PRKS cable to the intended installation location of the luminaire. The sleeve must be filled with a fireproof compound

Step 6. Installation of sockets. For them, you can also provide a separate machine in the distribution panel. It is allowed to install sockets only in zones 2 and 3; the housings must have protection of at least IP 44.

Installation of sockets and distribution boxes in the washing room is allowed only in zones 2 and 3

A VVG 3×1.5 cable is laid from the distribution panel to the first distribution box.

Further from it, the wire is fed to all the others; each room must have its own distribution box (Berman box). From the box, the wires are laid to the sockets, their ends are stripped and connected to the appropriate terminals.

After connecting, cover the outlet with the front panel.

Step 7 All cable ends are the same color or have the same markings in distribution boxes connect using terminal blocks.

Using terminal blocks instead of twisting is safer and more convenient

Important. If there are powerful electrical appliances in the bathhouse, their technical parameters may affect the cable cross-section. Carefully check the developed tables of the dependence of cable cross-section on current strength.

If the wires are located near electric furnaces, they must be protected with a metal pipe. But at the first opportunity, use other, more safe ways connecting powerful thermal appliances.

Some modern heating elements have an automatic control and protection system, the connection of these devices should be made taking into account the attached manufacturer’s instructions.

Connecting the controller for the oven (temperature sensor)

Thermostat connection diagram. Terminals 1 and 2

Thermostat connection diagram. Terminals 3 and 4

Temperature sensor connection diagram. Terminals 6 and 7

The cores of the VVGng 4x1.5 cable are connected to the corresponding screw terminals. Lived brown to the terminal marked L. Blue to terminal N. Gray - A1. Black - A2.

The lower terminals of the difavtomat are connected to two wires per terminal. One pair of wires is used to connect to the starter. The second pair is used to connect to screw terminals L and N. Cores with gray and blue colors A three-core cable VVGng, intended for powering the electric heater, is connected to the starter, and the yellow-green core is connected to the ground bus

Wiring diagram in the steam room and dressing room

After completing the installation, you need to charmingly ring the wiring and check the correctness and reliability of all connections

Prices for electrical panels

electrical panels

What electrical equipment can be in the bathhouse?

Energy networks issue, according to a simplified scheme, permission to connect no more than 15 kW per section; it is advisable to provide for the total power of consumers electrical energy bathhouses and residential buildings so that it does not exceed the specified limit. Otherwise, you will have to obtain special permission, but it is not always given. IN mandatory you will have to order a project from specialized organizations that takes into account the existing reserve capacities of transformers, the parameters of installed lines, etc. Such work takes a lot of time and money, and the results are often unpredictable. As for single-phase or three-phase wiring, things are still much more complicated. Before making a final decision, it is recommended to visit the distribution zone and consult with responsible representatives of the organization.

What cables to use for wiring in the bathhouse

The diameter of the cables is selected based on the possible maximum power; there are special tables for this. For single-phase input, wiring is done with a 2×16 SIP cable, for a three-phase SIP 4×16. Experienced electricians advise not to skimp on the cross-section conductors, the difference in cost is insignificant, but there can be many problems.

- No one can ever accurately predict the total power of current consumers over the long term. Such situations cause overloading of the wiring and can cause fires.

- Cables should only be from well-known and trusted manufacturers. Non-certified products do not withstand the same cross-section of wires along the entire length; it fluctuates between 20–30% and only downwards. This means that if the cross-section is indicated, for example, 10 mm 2, then in fact you should focus on 8 mm 2.

Prices for SIP cable

SIP cable

Video - About cables for baths

How many machines are required for a bathhouse?

A very complex and very simple question at the same time. From an electrician's point of view, the more the merrier. This is their profit, they are trying by every possible means to increase it. The craftsmen will assure developers that protective electrical fittings are required for each room in the bathhouse, separately for sockets and all powerful consumers. From large quantity There is no harm in RAM, just as there is no benefit. In practice, it is enough to install one circuit breaker at the input; it is triggered when the rated load is exceeded or when a short circuit occurs. There is no need to protect each room and outlet separately. It should be understood that each connection also has its negative sides - due to poor-quality connection of the ends, the connection points heat up. And this can cause wiring malfunctions or fires in the bathhouse.

What is the best way to connect a bathhouse: underground or overhead cable?

There is no specific advice for all cases; each method has its own strengths and weaknesses.

| Connection type | Technical and operational features |

|---|---|

| Cables are used for aerial connection; the protection is made of special plastics resistant to hard ultraviolet radiation. Can withstand significant temperature changes, differ high performance physical strength. The cheapest and simplest type of connecting a bathhouse to the network, its reliability fully complies with existing requirements. The only drawback is that not all developers like electrical wires hanging over the site. | |

| A very expensive and complex method. For installation you need to purchase a special underground cable with an armored shell, a layer of sand is provided in the trenches to compensate for seasonal swelling of the soil during freezing/unfreezing. Digging trenches often has to be done by hand, which is difficult and time-consuming. In addition, if the site has already completed landscape design, then after filling the trenches it will be necessary to restore its original condition. |

As can be seen from the table, many individual factors influence decisions, all of which should be taken into account.

A bathhouse is a functional building with special operating conditions that requires reliable and safe power supply. For this reason, the wiring in the bathhouse is laid in accordance with the basic requirements of the Electrical Installation Rules designed for wet rooms. Any violation established standards can have dire consequences for the owner of the building.

Electrical wiring safety requirements

Installation of electrical wiring in a bathhouse must comply with the following safety requirements:

- Organization of a power supply circuit from a distribution unit with an automatic input device and installation of an individual grounding loop. All protective devices are installed in the electrical panel.

- Using wires for interior spaces, capable of withstanding heating temperatures up to 165 degrees.

- The organization of wiring in the steam room of a bath made of brick and cinder block is carried out in a closed way. An open installation method is possible in a wooden structure.

- The installation diagram must provide for the mandatory use of protective electrical equipment - automatic circuit breakers and RCDs from 5 to 10 mA.

- The wires are connected using terminal blocks.

- Electrical cables require additional insulation from wooden surfaces and elements. Optimal solution– closed cable channel or heat-resistant route.

- All main electrical fittings are installed outside the steam room and washing room. In the bathhouse it is allowed to use sockets, switches and dimmers with a maximum load of up to 16A in a splash-proof housing with protection class IP44.

- Electrical wiring in the steam room should not pass over heating equipment.

- Lighting devices must have a protective housing and ceramic sockets; metal auxiliary elements require additional grounding.

Electrical wiring diagram for the bathhouse

You can prepare a working diagram of the electrics in the bathhouse yourself, taking into account the total number and power of energy consumers, as well as the type of connection - single-phase or three-phase.

- Connecting to one phase requires the presence of two wires at the input: phase - supplying electricity to end consumers– instruments, equipment and electrical accessories; zero – current return. The maximum permissible power threshold is 15 kW.

- Connection for three phases: four wires at the input - three per phase and zero. The electricity supply chain is similar to the previous diagram. The maximum permissible power is 43 kW.

As a rule, a single-phase connection is used for a standard bath; three-phase is important if powerful electrical appliances and equipment are installed in the premises.

It is better to schematically determine the installation locations and the number of electrical appliances, calculate the maximum load on the electrical wiring, select the type and number of wires, and also take into account other technical parameters.

When organizing electrical wiring in a private bath, it is important to remember that the main equipment for a bath uses voltage in the range from 12 to 36 volts. To ensure safe supply and distribution of electricity, it is recommended to install a step-down transformer.

The finished project for the electrification of a bathhouse must contain data on the installation locations of protective devices - automatic devices and RCDs.

Selection of wires and electrical appliances for the bath

When choosing wires for electrical wiring, you should take into account the cross-sectional size and material of the conductor.

Important! In the bathhouse it is allowed to install wires only with copper conductors.

Steam room and washing room

For these premises, cables or wires are intended, the insulation of which can withstand maximum heating temperatures of up to 200 degrees. Only heat-resistant wire with a copper core can be used here:

- Stranded (flexible) – up to 185 degrees.

- Single and multi-wire (flexible) - up to 205 degrees.

- Imported (flexible) – up to 200 degrees.

Dressing room, locker room, rest room

In others functional areas baths, the use of non-flammable power cables VVGng is allowed.

Important! For organization internal wiring In bathhouses, universal flat wires (PUNP) are not used, which can become the main cause of a fire hazard.

When choosing circuit breakers for protection against power surges in the network, first of all it is worth determining their operating power. The main machine must have maximum power, auxiliary devices this figure has been significantly reduced.

To set the limit value of the machine for disconnecting from the network, the current strength in the circuit and in its specific section is taken into account. For example, if the current strength in a section of the circuit is 18A, then the maximum permissible threshold of the main circuit breaker is 20A.

No less important for the protection of electrical appliances is the device protective shutdown(RCD). According to the PUE, the RCD response threshold should be from 25 to 30 mA.

Methods for conducting electricity in a bathhouse

To conduct electricity to bathhouse building, it is necessary to ensure its delivery from the central shield through the incoming power cable. You can lay the cable to the bathhouse in one of two ways: underground or over the air.

Underground installation method

The safest and most labor-intensive method of laying power cables, requiring preliminary preparation an earthen trench - from the source of electricity to the bathhouse.

For underground input, a VBBShV cable with copper conductors with a cross-section of 10 to 16 kV is used. mm. It has increased strength, safety and durability. Protection from mechanical damage and biological effects is provided by heat-resistant insulation and steel braiding.

For underground cable laying, polypropylene pipes are used that are resistant to corrosion and freezing; metal pipes can be used when installing cables on poles or wall structures no more than 180 cm in height.

The technology for laying cables underground is as follows:

- Preparing an earthen trench up to 70 cm deep. Filling the bottom (10 cm) sand layer. Cable laying and re-filling with sand.

- The introduction of the cable into the building through a metal input sleeve, which is used to protect against damage to the insulation during shrinkage of the walls of the bathhouse.

- The cable is stripped of insulation before connecting to the machine in the input panel. Next, grounding and protection against lightning strikes are performed.

Important! Wavy laying of the cable in the trench will prevent its mechanical damage as a result of soil movements or shrinkage of the building.

Air installation method

Over-the-air installation is more accessible and cheaper in terms of labor and financial costs, but at the same time it is characterized by fragility due to susceptibility to damage and deformation.

If you need to connect a wire from a house to a bathhouse, then you need to correctly calculate the maximum permissible distance between objects. When buildings are located at a significant distance from each other, aerial laying is irrational, since the risk of cable damage increases under unfavorable climatic conditions.

It is also important to observe the regulated height of cable laying: above the road - at a height of up to 6 meters, above pedestrian paths - up to 3.5 meters, on the site - up to 2.75 meters.

If the distance between buildings does not exceed 21 meters, then cable entry by air is carried out according to the following scheme:

- Entrance holes are made in the walls in accordance with the diameter of the cable. Plastic or metal adapters are installed in the holes to protect the cable from damage.

- Brackets are installed near the holes for fixing the insulators.

- A metal cable is stretched between the insulators.

- The cable is fixed to the cable with plastic clamps, after which it is inserted into the holes and connected in the panel to the input machine.

All cable entry points through the walls are carefully sealed, and the space in the adapters is filled with foam or mineral wool. The metal cable should have a slight slack to ensure reliable fixation of the cable.

The best option for overhead laying - insulated self-supporting heat-resistant wire (SIP).

Step-by-step instructions for installing internal wiring

The wiring in the bathhouse and steam room will be powered from the input distribution panel. The main thing in this matter is to comply with the installation technology and requirements in accordance with the PUE.

Internal wiring

To properly install indoor wiring, a general bathhouse electrification diagram is used.

When installing cables, the following requirements must be observed:

- The cable is led from the shield in one piece.

- Wiring is laid on wooden surfaces open method, so-called retro wiring. The use of plastic and metal pipes as insulation is prohibited.

- Wiring is carried out on brick and cinder block surfaces in a hidden way with the application of a plaster layer.

- The wires are fixed in horizontal and vertical lines, without bending or twisting.

- The wires should not be located opposite entrance doors, heating equipment and electrical appliances.

- To connect current-carrying conductors, a welding or soldering connection is used.

Connecting electrical accessories

Saunas and baths are buildings with special temperature conditions, so sockets and switches are optimally located in the dressing room, relaxation room and locker room at a height of up to 95 cm from the floor level.

The use of electrical accessories and mounting boxes in wet areas is prohibited. This is because over time, excess moisture condenses on the surface of the device and can cause a short circuit.

Features of installation of the distribution panel and calculations of working loads

All electrics in the bathhouse are carried out from the entrance panel. When deciding where to install it, you must adhere to some rules:

- Availability free access to the switchboard.

- Ensuring sufficient lighting and regular ventilation in the room with a shield.

- The panel is equipped with an incoming circuit breaker, RCD and outgoing circuit breakers for each energy consumer.

To calculate the power of the introductory machine, it is necessary to take into account the maximum load that is created by the electrical appliances, equipment and lighting devices installed in the bathhouse. The total power of consumers is divided by the voltage indicator.

For example, the total power was 4000 VA, the network voltage was 220V. Power of the input machine: 4000/220 = 18.18 A. For maximum protection, you should choose a device with a small power reserve, for example, 20 A. Using a similar scheme, the power for each outgoing machine is calculated.

Choosing lighting equipment for a bath

To organize it safely and practically, it is recommended to use reliable lighting devices with protection class IP44.

High demands are placed on lamps installed in the steam room and washing room. These are premises with special operating conditions, which are characterized by high humidity and temperature changes. The best option for them is waterproof lamp for wall mounting.

A good option for a steam room is fiber optic lighting equipment that is resistant to negative impacts and providing soft diffused light.

Since the main material for wall cladding is lining, it is recommended to use special built-in lamps that can be easily sewn into a wooden surface.

Important! According to the regulations, the body of the lamps can be metal, and the lampshade can be glass. Equipment with a plastic base is susceptible to overheating and deformation, and therefore is not suitable for a bathhouse.

In the remaining rooms of the bathhouse, you can use halogen light bulbs or LED lamps.

Features of connecting an electric furnace

The electric furnace is connected using a three-phase machine and a magnetic starter. Circuit breaker provides protection against short circuits and voltage surges in the network, the starter provides automatic control of the heating circuit.

You will also need heat-resistant cables of the PVKV, PMTK, PRKS, RKGM brands with copper conductors with a cross-section of 3×2.5 mm, capable of withstanding loads up to 4 kW.

To connect the cable, a mounting box is used, installed in the neutral zone, followed by entry into the distribution panel. Thus, the electric oven is not connected to a regular outlet, but directly to the panel.

If operating power the furnace is less than 4 kW, then it is enough to organize a single-phase connection.

Common mistakes when organizing wiring

Often, novice craftsmen make serious mistakes when electrifying a bathhouse, which are associated with violation of technical requirements or incorrect calculations.

Common mistakes:

- Incorrect choice of electrical wire type and incorrectly calculated cross-section.

- Wrong choice protective equipment– automatic machines and RCDs.

- Poor insulation of wires in fire hazardous areas.

- Violation of safety rules when laying electrical wiring.

Electrification of a bathhouse is a complex and responsible process that requires wise choice. consumables, compliance with the technology and installation diagram, proper commissioning of the system. This is the key to a safe and comfortable stay in the bathhouse throughout the entire period of operation.

In the 21st century, electrics in a bathhouse are an integral part of it. And lighting is only one of the reasons for conducting electricity into a building. Modern comfortable sauna unthinkable without energy-dependent appliances: gas furnaces, boilers, water pumping stations etc. Not to mention the recreation room, where there are televisions and stereo systems.

Connecting the bathhouse to the general electrical network

This building rarely has its own electric meter installed. As a rule, do-it-yourself electrical wiring in a bathhouse involves connecting energy from the home distribution board. There are two ways to conduct electricity: underground and overhead. The last option is the most common.

The reliability of an overhead power line will be higher if certain rules are followed:

- When pulling a sauna cable through the air, provide additional supports if its length exceeds 25 meters;

- The external electrical main is connected to the building at a level of 2.75 m.

SNIPs give several more interesting requirements: the line must be higher highway 6 meters and 3.5 meters above the pedestrian crossing. On private territory It's hard to imagine a freeway. Therefore, these requirements are of no practical use.

When connecting the building to an external power supply, pay attention to the type of power cable. For an aerial connection, a self-supporting insulated wire (SIP) is used. The safety of electrical wiring in a bathhouse depends on many factors. And the quality of the cable is not in last place.

Overhead and underground power lines - features of electrical wires

When connecting a bathhouse to the general electrical network by air, the cross-section of the SIP starts from 1.6 cm. This cable allows you to connect 3 phases with a total power of 43 kW or one of 14 kW. This is more than enough. Using self-supporting insulated wires, you will encounter the following difficulties:

- A cable of this thickness does not bend well, so it will not be easy.

- SIPs are made of aluminum, which imposes some restrictions. Such a cable cannot be run into the attic - you will have to switch to a wire with a different filling.

- Connection equipment different wires and getting through wooden walls is not cheap.

However, there are also positive qualities. The official service life of such a cable is 15 years. But in fact it lasts much longer - the coating is resistant to exposure environment. Laying a power line underground involves a lot of labor, but this only increases the reliability. The trench under the underground highway is dug to a depth of at least 0.7 m. A sand cushion ten centimeters thick is created at its bottom. The wiring laid on it is again covered with sand. Additional protection, if necessary, is provided by brickwork.

The power line enters the bathhouse through a metal tube (sleeve), which protects against shrinkage of the building and potential movement of the walls. When connecting the cable to the shield, remove from it surface layer. Having finished with the main work, provide grounding and lightning protection. Remember that the underground pipeline cannot be protected with metal structures - they attract moisture, which shortens its service life. Metal pipes are used only when installing the cable vertically on a wall or pole.

When laying power lines underground, VBBShV wire is used. The abbreviation stands for:

- The presence of an insulating layer of polyvinyl chloride ("B");

- Additional layer of armor ("B");

- Index "b" warns of the absence of an additional cushion under the armor layer;

- “Shv” indicates hose protection for the cable made of polyvinyl chloride.

The absence of the "A" index means that the cable is made of copper conductors. The cable cross-section for underground cable wiring to the bathhouse starts from 10 mm.

Such a power line will not be to the taste of mice and other chewers. The only drawback of such wiring is the price. But the electric highway is not built for one year. Therefore, it is better to suffer financial losses, but get a reliable power line that will last for decades.

Protection and installation of bath electrical equipment: technical regulations

When deciding how to install wiring in a bathhouse, take care of safety. Install a distribution board equipped with the necessary devices (RCD, input, differential circuit breakers). Blocks must be protected from humid atmosphere and high temperatures. The machines are triggered when the current drops below 10–30 mA.

In a hot room with high humidity, several types of cables are used. For example, NYM or VVG wires 2.5 mm thick are used to connect sockets. Lighting of the building is provided by cables with a diameter of 1.5 mm.

The wiring in the steam room is resistant to its microclimate, which cannot be said about sockets and switches. Therefore, professional electricians recommend installing such electrical appliances in a room with a normal microclimate (dressing room, rest room).

In hot, humid buildings, IP-44 is the minimum level of protection for electrical appliances. But for lighting, use devices rated IP-54. Sockets (switches) of this level of protection are equipped with special covers. Do not allow the sauna cable to pass directly above the sauna stove.

Electrical equipment for a bath should not be purchased in the markets. It is better to contact stores of the relevant subject. When purchasing equipment, reputable organizations will provide technical documentation, warranty obligations. By the way, the body of bath electrical appliances must provide comprehensive protection.

Lighting lamps are connected to a network with reduced voltage (12–36 V). This will avoid installing a transformer. The RCD requires maintenance - press the "TEST" button monthly.

A building of this class is characterized by the use of wires, at least double insulated. They are connected to switches (sockets) on the floor side. This prevents moisture from getting inside the devices. The steam room with its high temperatures requires the use of wiring that is resistant to high temperatures. For example, the heat-resistant SILFLEX cable can withstand 180 degrees.

Electrical distribution equipment is not recommended to be installed in a furnace or steam room. Best option, this is a rest room, a dressing room. For safety, place the cables in metal, plastic channels or corrugated non-flammable pipes. In the event of a fire, the melting mass will flood the wiring, preventing the spread of the fire.

Calculation of electric current power - examples of calculations

Compliance with the rules fire safety- the main condition for doing it yourself. Electrification of the bathhouse begins with preliminary calculations. It is necessary to find out the power required for the operation of the sauna electrical system. This data will be needed to calculate the current power according to the cross-section of the wires.

Note that for lighting devices, a power of 1–2 kW is sufficient with a margin. However, when it is planned to install additional energy-intensive appliances (boilers, electric heaters), it is better to increase the power to 8 kW. An electric sauna stove typically consumes about 7 kW. Considering that other devices will also consume electricity, the estimated current power can increase to 20 kW.

Despite the apparent complexity, working with electrical wiring does not require any special knowledge, but care. We come across many definitions in everyday life. For example, on a light bulb the voltage is indicated in Volts and the power in Watts. Almost all electric household appliances operate from a network with a voltage of 220 Volts, only some devices require a voltage of 380 Volts (electric heater or oven).

A single-phase connection of 220 Volts is considered classic. But when installing an electric furnace, preliminary calculations will need to be adjusted. Let's give a clear example:

The calculation takes into account all appliances in the building that consume electricity. Eight 10 volt light bulbs require 800 W power, normal washing machine will need 2,000 watts, a hairdryer needs 2,000 watts. IN winter time a break room heater is added, consuming another 2,000 watts. Electric heater/oven – 4,000 W. That is, the total power of all devices will be 10,800 W. The power reserve is necessary measure precautions. Therefore, increasing the calculated parameters by 20%, we get 12960 W.

When buying a machine, you need to know the current strength, but these are simple calculations. The total power of electrical appliances is divided by voltage: 12,960/220 ≈ 58 A. By the way, the current for the furnace, calculated according to the same principle, will be 22 amperes. The cross-section of the wire for connecting the bathhouse to the home power system is selected taking into account the data obtained.

A three-phase oven is connected with a cable with 4–5 cores, and the load will need to be distributed evenly. That is, the current strength of one phase will be divided by 3. For heating device with a power of 22 A, the current per wire will be approximately 7 A.

Features of maintenance of “open” and “closed” electrical networks

When starting work on electrifying a bathhouse, study the “Rules for the construction of electrical installations.” Of course, this will not make you a professional electrician, but it will allow you to avoid gross mistakes. Electrical wiring is installed in an open or hidden way. Of course, the latter option looks more preferable from an aesthetic point of view. However, open wiring is considered more practical.

If necessary, it will be easier to repair a damaged section of an uncovered highway. Co hidden option you will have to dismantle the walls or ceiling. An open power line is fixed using porcelain insulators, staples or special trays.

In fact, the definition of “open wiring” is quite arbitrary. Special channels, corrugated pipes, European baseboards, etc. are provided for cables. This makes the power line not only more attractive, but also provides additional protection.

Important point. Any equipment must undergo regular maintenance. The sauna electrical network is no exception. An audit must be carried out every four years - this is a guarantee of long-term and safe work. The official service life of aluminum wires is 15 years, their copper counterparts are 20. This applies to rooms with a normal microclimate. The bathhouse atmosphere will reduce this period.

Even if you decide to turn to the services of specialists, you need to master the basics of electrical wiring installation. There are “professionals” whose services will lead to dire consequences. Moreover, a burned-out bathhouse is not the worst thing. Electric shock in 100% humidity can kill a person.

Almost all work on electrifying a bathhouse can be done independently. Yes, it’s not easy to do, but it’s quite possible for anyone who knows how to work with electrical and hand tools. Having studied all the nuances, it will not be necessary to hire an electrician, whose services cost a lot of money.

Electrical wiring in saunas and baths is one of the the most important stages construction of this irreplaceable structure, since the safety of the people receiving the procedures depends on the quality of the work and the materials used. To avoid mistakes when laying electrical wiring, select optimal materials and options for their use should be considered in detail the nuances and features of the work. In the article we will tell you which wire to use for baths and saunas, and consider the installation features.

Selecting materials for wiring in the bathhouse

The main condition when selecting a cable for a bath or sauna should be called it thermal resistance. It is also important to understand that installing sockets of any type in steam rooms is prohibited. A condition for laying wiring is that a grounding loop must be installed.

When selecting electrical wiring, you should understand what rooms are usually available in the bathhouse and their main categories. The bathhouses are divided into two groups:

- rooms with normal temperature conditions, in which it is allowed to lay electrical wiring similar to that found in residential premises;

- rooms in which only heat-resistant cables are allowed, since the temperature in them often reaches 170°C.

A heat-resistant cable must also be used to connect an electric furnace (if one is installed in a bathhouse). Read also the article: → "".

Wiring for standard premises

AVVG cable is suitable for electrical wiring in rooms with normal humidity

AVVG cable is suitable for electrical wiring in rooms with normal humidity In rooms with normal temperature conditions it is recommended to use cables following types:

- AVVG;

Any of the above types of cables can be laid during installation either in a hidden way or on top of walls. The main and only condition for their use should be the increased requirements for wire insulation, since most often the construction of a bathhouse or sauna is made of wood. For cable insulation, cross-linked polyethylene, PVC and other polymer materials with the required properties are used.

The following cable brands are suitable for installing and connecting lighting devices:

- PPGng-HF 3x1.5;

- VVGng-LS 3x1.5;

- NYM 3x1.5.

To install sockets, the wire must be selected with a cross-sectional area of at least 2.3 mm2.

Wiring in steam rooms

In the steam room, it is allowed to use only heat-resistant cables that have a sufficient level of resistance to high temperatures. This is due to the fact that even with the slightest deformation of the insulation there is a high risk of fire.

The following types of cables are available on the modern market, suitable for use in steam rooms:

- RKGM 1x2.5;

- PVKV 1x2.5;

- PRKS 3x2.5;

- PMTK 3x2.5.

Tip #1. If we consider foreign-made cables, then for electrical wiring in the steam room you can use Olflex Heat 3x2.5. However, the cost of such a wire is significantly higher than its domestic counterparts.

Wire connections should only be made in boxes protected from moisture.

Wire connections should only be made in boxes protected from moisture. Requirements for wiring in the bathhouse

Before proceeding with installation, it is necessary to study and strictly follow the rules for laying electrical wiring in baths and saunas:

- cables must be laid only vertically or horizontally;

- if rotation is necessary, it must be arranged strictly at an angle of 90°;

- horizontal wiring lines should be placed at a distance of 10-20 cm from the ceiling and run parallel to it;

- the distance from the laid cable or switches to the window or door must be at least 10 cm;

- from heating radiators and other metal devices the cable must be located at a distance of at least 0.5 m;

- switches are placed from the floor at a distance of at least 1 m, sockets - 0.3 m;

- sockets and switches are located from the shower stall at a distance exceeding 0.6 m;

- the line from the distribution panel to the electricity consumers should be laid only with a single piece of wire - any connections are prohibited;

- Wiring connections may only be made in junction boxes that have high level protection from moisture;

- The electrical panel is placed as close as possible to the point of entry of the supply cable into the bathhouse building. Read also the article: → "".

Cable connection methods

The VVG cable is suitable for supplying power to the bathhouse building without restrictions

The VVG cable is suitable for supplying power to the bathhouse building without restrictions Before installing internal electrical wiring, you need to connect the power cable to the building. Eyeliner is carried out in two ways:

- underground;

- air.

The advantages of the air method are obvious: low cost and labor-intensive work, high installation speed. Most often, SIP-4 cable is used for these purposes. It is important to know that laying SIP cable is not allowed in attic spaces, and therefore for a bath it is better to choose wires of the VVG or NG brands.

When attached to external wall The cable should be placed in a plastic box or corrugated. At the entry point into the room you need to place a box with circuit breakers. Laying the cable below ground level is an expensive and time-consuming method, but at the same time it provides more reliable protection of the cable from damage. When choosing an underground connection, it is recommended to use VB6Shv cable.

Cable brand VB6Shv - great choice for underground installation to a bathhouse

Cable brand VB6Shv - great choice for underground installation to a bathhouse

Installation of wiring and devices in a bathhouse or sauna

Before installing a heat-resistant cable, you should calculate the power required for normal functioning each of the appliances that consume electricity. In accordance with the calculations, a cross-section of a heat-resistant cable is selected that can withstand the design load.

To operate lighting in a bathhouse, a power of 1-2 kW is sufficient, but it should be taken into account that when installing additional electrical appliances, the power will increase. Baths heated by an electric furnace require a power of at least 10 kW for normal operation.

When installing any electricity consumer in a sauna or bathhouse, you should remember the electrical safety rules and turn off the circuit breakers in the distribution panel. The purchase of sockets, switches, lighting devices and the cables themselves must be done only in specialized supermarkets or stores. Thus, the likelihood of purchasing defective or counterfeit products is significantly reduced.

Salespeople and consultants from large stores can also provide assistance in choosing a cable and draw up an approximate installation diagram, taking into account the features of building a sauna or bathhouse. Read also the article: → "".

Installation of wiring in the sauna

As mentioned above, in a bathhouse or sauna the cable can be laid in both open and closed ways and covered with various protective elements. Even though closed method is considered more preferable; there are some nuances in its implementation.

According to the requirements of the PUE and SNiP, laying electrical wiring in metal corrugations and tubes is not allowed. Also, wires sheathed with metal-containing materials should not be used. This ban is due to the fact that a bathhouse is a place with high humidity, and metal, like no other material, is susceptible to corrosion processes.

Installation of switches and sockets

Upon completion of the cable laying work, you can begin installing switches and sockets. These electrical network elements can be installed in any room except the steam room itself.

Also, switchboards should not be placed in rooms with high humidity. In addition to steam rooms, this ban also applies to showers. All other premises are allowed to be equipped with electrical elements without any serious restrictions.

Sockets in the bathhouse, regardless of the installation location, must be installed in a waterproof design

Sockets in the bathhouse, regardless of the installation location, must be installed in a waterproof design Lighting system installation

After laying the heat-resistant cable, in addition to sockets and switches, you can install lighting fixtures. Standard light bulbs and lamp shades are not suitable for a bathhouse due to high temperatures and humidity. Therefore, in order to avoid rapid failure and possible fire, you should select heat-resistant lamps.

The lighting devices installed must be sufficiently sealed so that steam and splashes of water entering the housing cannot lead to a short circuit and subsequent fire. Also, if steam gets on the lampshade, the device may heat up unevenly, become deformed and even burst, which will lead to serious injuries to people taking bath procedures. When installing the lighting system, it should be taken into account that the light in the steam room should not be too bright. Most often, matte lampshades with light bulbs up to 60 W are used.

Electrical voltage in the sauna

Also, the owner of the bathhouse must select the voltage to provide the structure with electricity. The reason for this is the fact that heat-resistant cables for baths and saunas can be laid together with a home network with a voltage of 220 V. To make a connection, a number of PUE conditions must be met:

- the electrical wiring line must be reliably protected by placing automatic blockers or automatic machines;

- the power supply to the bathhouse must be carried out with the mandatory installation of grounding type TN-C-S;

- The sauna electrical system should not operate without a potential equalization system.

Automatic box for turning off the power supply to separate rooms baths

Automatic box for turning off the power supply to separate rooms baths If it is not possible to fulfill the three conditions described above, the supply of electricity to the bathhouse building should be carried out through a voltage-reducing transformer, for example, YaTP-0.25 220/36V. The placement of such a device should be provided outside the building.

Mistakes when choosing a cable for a bath

- A common mistake is placing control equipment in the steam room that is not built into the electric heater. If such a mistake has already been made, then the PUE requires the installation of a limiter that turns off all equipment when it reaches a temperature of 140°C. In this case, the electric furnace will automatically turn off.

- Also a serious mistake should be the presence of connections, breaks and twists in the cable in the steam room or shower. This is very dangerous, since the presence of deformed and damaged insulation is fraught with a short circuit and a high probability of subsequent fire.

This is a non-standard room, so the electrical system for it is also created non-standard. There are special rules for installing wiring for the premises similar type. After all, bathhouses are characterized by stable high temperatures and high humidity. And also the presence of flammable material, namely wood. Therefore, correctly installed electrical wiring in a bathhouse is a matter of vital importance. We offer you step-by-step instructions, supported by a diagram, which will help you install the wiring with your own hands in a high-quality manner.

We follow safety precautions

We deliberately highlighted the point regarding safety rules when working with wiring, primarily because of the specifics bath room. A bathhouse is a source of a large amount of steam, and steam, as you know, is particles of water in a gaseous state. If sockets/switches are installed in places where steam accumulates, there is a high probability that it will settle on the elements in the form of condensation. And this can be fraught with a short circuit or worse, a fire in all the wiring.

Therefore, the first thing you need to do is carefully calculate and draw up a competent diagram of the future electrical wiring, which is very difficult to do without the appropriate knowledge. The best solution will invite a specialist. If you are determined to do all the work yourself, follow the appropriate rules established specifically for wet rooms.

Requirements for electrical wiring in the bathhouse

In order for the result of your work in the bathhouse to be a high-quality and reliable electrical system, adhere to the following principles when installing wiring in wet wooden rooms such as a bathhouse:

- The cable is installed using the open method, in rooms with high content pair - the shortest path to electrical elements;

- We attach all electrical accessories (sockets, switches) outside the steam room;

- We do not run cables over the stove;

- We provide grounding and lightning protection in the premises;

- connecting the wires only using terminals;

- choose non-combustible insulation;

- We use metal protection only for lines passing through the wall.

Advice. Choose wires with copper conductors for the bath: they pass a stronger current and are less susceptible to mechanical damage.

Installing wiring in a bathhouse: step-by-step instructions

Wiring in a bathhouse is usually installed in two ways: hidden and open. The first is used in bathhouses made of brick or cinder block (in grooved channels), the second - in wooden buildings(right along the wall). Let's consider the main stages of installing an electrical system in a bathhouse:

Advice. Place the fittings only in the dressing room. According to the rules, the bath and shower rooms are not intended for such electrical elements. Protect the lamps with special shades with sealed connections.

Finally, we suggest you take note of a few tips from specialists involved in installing electrical systems of various types:

- Place fire-resistant material under the cable ducts, for example, a thin strip of asbestos sheet.

- When working indoors, use thermally insulated elements.

- Lay the cables in a corrugated material made of non-flammable material. This will help prevent the spread of fire if the wiring spontaneously ignites.

- Be sure to install a metal plate between the wooden wall and the switches/sockets - it will serve as excellent protection.

- Since in modern baths Powerful electrical appliances are often used, choose for street work conductors with a cross section of at least 16 millimeters square.

We have schematically examined the process of laying electrical wiring with our own hands. Now you know that this is a rather labor-intensive process that requires certain skills and compliance with a number of rules. Before starting work, be sure to read the PUE. Be careful! Good luck!

Electrical wiring in the bathhouse: video