A device that allows you to search for metal objects located in a neutral environment, for example, soil, due to their conductivity is called a metal detector (metal detector). This device allows you to find metal objects in various environments, including in the human body.

Largely due to the development of microelectronics, metal detectors, which are produced by many enterprises around the world, have high reliability and small overall and weight characteristics.

Not so long ago, such devices could most often be seen with sappers, but now they are used by rescuers, treasure hunters, public utilities workers when searching for pipes, cables, etc. Moreover, many "treasure hunters" use metal detectors that they assemble with their own hands .

The design and principle of operation of the device

Metal detectors on the market operate on different principles. Many believe that they use the principle of pulsed echo or radar. Their difference from locators lies in the fact that the transmitted and received signals operate constantly and simultaneously, in addition, they operate at the same frequencies.

Devices operating on the principle of "reception-transmission" register the signal reflected (re-radiated) from a metal object. This signal appears due to the impact on a metal object of an alternating magnetic field, which is generated by the metal detector coils. That is, the design of devices of this type provides for the presence of two coils, the first is transmitting, the second is receiving.

Devices of this class have the following advantages:

- simplicity of design;

- great ability to detect metallic materials.

At the same time, metal detectors of this class have certain disadvantages:

- metal detectors can be sensitive to the composition of the soil in which they search for metal objects.

- technological difficulties in the production of the product.

In other words, devices of this type must be configured by hand before operation.

Other devices are sometimes referred to as a beat detector. This name comes from the distant past, more precisely from the time when superheterodyne receivers were widely used. Beating is a phenomenon that becomes noticeable when two signals with close frequencies and equal amplitudes are summed. The beating consists in pulsing the amplitude of the summed signal.

The pulse frequency of the signal is equal to the difference in the frequencies of the summed signals. By passing such a signal through a rectifier, it is also called a detector, the so-called difference frequency is isolated.

Such a scheme was used for a long time, but today, it is not used. They were replaced by synchronous detectors, but the term remained in use.

The beat metal detector works using the following principle - it registers the frequency difference from two generator coils. One frequency is stable, the second contains an inductor.

The device is set up by hand so that the generated frequencies match or at least are close. As soon as metal enters the coverage area, the set parameters change and the frequency changes. The frequency difference can be recorded in many ways, ranging from headphones to digital methods.

Devices of this class are characterized by a simple sensor design, low sensitivity to the mineral composition of the soil.

But besides this, during their operation it is necessary to take into account the fact that they have high energy consumption.

Typical design

The structure of the metal detector includes the following components:

- The coil is a box-type design, it houses the receiver and transmitter of the signal. Most often, the coil has an elliptical shape and polymers are used for its manufacture. A wire is connected to it, connecting it to the control unit. This wire transmits the signal from the receiver to the control unit. The transmitter generates a signal when metal is detected, which is transmitted to the receiver. The coil is installed on the lower rod.

- The metal part on which the coil is fixed and its angle of inclination is adjusted is called the lower rod. Thanks to this solution, a more thorough examination of the surface occurs. There are models in which the lower part can adjust the height of the metal detector and provides a telescopic connection with the rod, which is called the middle one.

- The middle shaft is the node located between the lower and upper shafts. Fixing devices are fixed on it, allowing you to adjust the size of the device. on the market you can find models that consist of two rods.

- The top bar, as a rule, has a curved appearance. It resembles the letter S. This form is considered optimal for fixing it on the hand. An armrest, a control unit and a handle are installed on it. The armrest and handle are made of polymeric materials.

- The metal detector control unit is required to process the data received from the coil. After the signal is converted, it is sent to headphones or other means of indication. In addition, the control unit is designed to adjust the operating mode of the device. The wire from the coil is connected using a quick-release device.

All devices included in the metal detector are waterproof.

This is the relative simplicity of the design and allows you to make metal detectors with your own hands.

Varieties of metal detectors

The market offers a wide range of metal detectors used in many areas. Below is a list that shows some of the varieties of these devices:

Most modern metal detectors can find metal objects at a depth of up to 2.5 m, special deep products can detect a product at a depth of up to 6 meters.

Operating frequency

The second parameter is the frequency of operation. The thing is that low frequencies allow the metal detector to see to a fairly large depth, but they are not able to see small details. High frequencies allow you to notice small objects, but do not allow viewing the ground to a great depth.

The simplest (budget) models operate at one frequency, models that are classified as average price levels use 2 or more frequencies in operation. There are models that use 28 frequencies when searching.

Modern metal detectors are equipped with such a function as metal discrimination. It allows you to distinguish the type of material located at depth. At the same time, when ferrous metal is detected, one sound will sound in the searcher's headphones, and another when non-ferrous metal is detected.

Such devices are referred to as pulse-balanced. They use frequencies from 8 to 15 kHz in their work. Batteries of 9 - 12 V are used as a source.

Devices of this class are able to detect a gold object at a depth of several tens of centimeters, and ferrous metal products at a depth of about 1 meter or more.

But, of course, these parameters depend on the device model.

How to assemble a homemade metal detector with your own hands

There are many models of devices on the market for searching for metal in the ground, walls, etc. Despite its external complexity, making a metal detector with your own hands is not so difficult and almost anyone can do it. As noted above, any metal detector consists of the following key components - a coil, a decoder and a power supply signaling device.

To assemble such a metal detector with your own hands, you need the following set of elements:

- controller;

- resonator;

- capacitors of various types, including film ones;

- resistors;

- sound emitter;

- Voltage regulator.

The simplest do-it-yourself metal detector

The metal detector circuit is not complicated, and you can find it either in the vastness of the global network, or in specialized literature. Above is a list of radio elements that are useful for assembling a metal detector with your own hands at home. A simple metal detector can be assembled with your own hands using a soldering iron or another available method. The main thing at the same time, the parts should not touch the body of the device. To ensure the operation of the assembled metal detector, power supplies of 9-12 volts are used.

To wind the coil, a wire with a cross-sectional diameter of 0.3 mm is used, of course, this will depend on the selected circuit. By the way, the wound coil must be protected from the effects of extraneous radiation. To do this, it is screened with your own hands using ordinary food foil.

To flash the controller, special programs are used, which can also be found on the Internet.

Metal detector without chips

If a novice "treasure hunter" has no desire to get involved with microcircuits, there are schemes without them.

There are simpler circuits based on the use of traditional transistors. Such a device can find metal at a depth of several tens of centimeters.

Deep metal detectors are used to search for metals at great depths. But it is worth noting that they are not cheap and therefore it is quite possible to assemble it with your own hands. But before you start making it, you need to understand how a typical circuit works.

The scheme of a deep metal detector is not the simplest and there are several options for its execution. Before assembling it, it is necessary to prepare the following set of parts and elements:

- capacitors of various types - film, ceramic, etc .;

- resistors of different ratings;

- semiconductors - transistors and diodes.

Nominal parameters, quantity depend on the selected circuit diagram of the device. To assemble the above elements, you will need a soldering iron, a set of tools (screwdriver, pliers, wire cutters, etc.), material for making the board.

The process of assembling a deep metal detector is approximately as follows. First, a control unit is assembled, the basis of which is a printed circuit board. It is made from textolite. Then the assembly scheme is transferred directly to the surface of the finished board. After the drawing has been transferred, the board must be etched. To do this, use a solution that includes hydrogen peroxide, salt, electrolyte.

After the board is etched, holes must be made in it to install the circuit components. After the board has been tinned. The most important step is coming. Do-it-yourself installation and soldering of parts on a prepared board.

To wind the coil with your own hands, use a wire of the PEV brand with a diameter of 0.5 mm. The number of turns and the diameter of the coil depend on the chosen scheme of the deep metal detector.

A little about smartphones

There is an opinion that it is quite possible to make a metal detector from a smartphone. This is wrong! Yes, there are applications that install under the Android OS.

But in fact, after installing such an application, he will really be able to find metal objects, but only pre-magnetized ones. He will not be able to search and, moreover, discriminate against metals.

No one needs to explain what a metal detector is. This device is expensive, and some models are very decent.

However, you can make a metal detector with your own hands at home. Moreover, you can not only save thousands of rubles on its acquisition, but also enrich yourself by finding a treasure. Let's talk about the device itself and try to figure out what's in it and how.

Step-by-step instructions for assembling a simple metal detector

In this detailed instruction, we will show how you can assemble the simplest metal detector from improvised means with your own hands. We will need: an ordinary plastic CD box, a portable AM or AM / FM radio receiver, a calculator, a VELCRO-type contact tape (Velcro). So let's get started!

Step 1. Disassemble CD box case. Carefully disassemble the case of the plastic CD case by removing the insert that holds the disc in place.

STEP 1. Removing the plastic insert from the sidyboxStep 2 Cut off 2 Velcro strips. Measure the area at the center of the back of your radio. Then cut out 2 pieces of Velcro the same size.

STEP 2.1. We measure approximately in the middle of the area on the back of the radio (highlighted in red)

STEP 2.1. We measure approximately in the middle of the area on the back of the radio (highlighted in red)  STEP 2.2. Cut out 2 Velcro of the appropriate size, measured in step 2.1

STEP 2.2. Cut out 2 Velcro of the appropriate size, measured in step 2.1 Step 3 Fasten the radio. Attach one sticky side of Velcro to the back of the radio and a second to one of the inside sides of the CD case. Then attach the radio to the body of the plastic CD box with Velcro to Velcro.

Step 4 Clip the calculator. Repeat steps 2 and 3 with the calculator, but apply Velcro to the other side of the CD case. Then attach the calculator to that side of the box using the standard Velcro to Velcro method.

Step 5 Setting the radio band. Turn on the radio and make sure it is tuned to the AM band. Now tune it to the end of the AM band, but not to the radio station itself. Turn up the volume. You should hear only one interference.

Clue:

If there is a radio station that is at the very end of the AM band, then try to get as close to it as possible. In this case, you should hear only one interference!

Step 6 Roll up the CD box. Turn on the calculator. Start rolling the side of the calculator box towards the radio until you hear a loud beep. This beep signals to us that the radio has picked up an electromagnetic wave from the calculator's electrical circuit.

STEP 6. We turn the sides of the CD box towards each other until a characteristic loud signal is heard

STEP 6. We turn the sides of the CD box towards each other until a characteristic loud signal is heard Step 7 Bring the assembled device to a metal object. Open the plastic box flaps again so that the sound we heard in step 6 is barely audible. Then start moving the box with your radio and calculator close to the metal object and you will hear the loud sound again. This indicates the correct operation of our simplest metal detector.

Instructions for assembling a sensitive metal detector based on a two-circuit oscillator circuit

Operating principle:

In this project, we will build a metal detector based on a double oscillator circuit. One oscillator is fixed and the other varies depending on the proximity of metallic objects. The beat frequency between these two oscillator frequencies is in the audio range. As the detector passes over a metal object, you will hear this beat frequency change. Different types of metals will cause a positive or negative shift, raising or lowering the audio frequency.

We will need materials and electrical components:

| Copper multilayer PCB, single-sided 114.3 mm x 155.6 mm | 1 PC. |

| Resistor 0.125W | 1 PC. |

| Capacitor, 0.1μF | 5 pieces. |

| Capacitor, 0.01μF | 5 pieces. |

| Capacitor, electrolytic 220μF | 2 pcs. |

| PEL winding wire (26 AWG or 0.4 mm in diameter) | 1 unit |

| Audio jack, 1/8', mono, panel mount, optional | 1 PC. |

| Headphones, 1/8' plug, mono or stereo | 1 PC. |

| Battery, 9 V | 1 PC. |

| 9V battery binding connector | 1 PC. |

| Potentiometer, 5 kOhm, audio taper, optional | 1 PC. |

| Switch, single pole switching | 1 PC. |

| Transistor, NPN, 2N3904 | 6 pcs. |

| Sensor wire (22 AWG or 0.3250 mm2) | 1 unit |

| Wired speaker 4′ | 1 PC. |

| Speaker, small 8 ohm | 1 PC. |

| Locknut, brass, 1/2′ | 1 PC. |

| Threaded PVC pipe connector (1/2' hole) | 1 PC. |

| 1/4′ wooden dowel | 1 PC. |

| 3/4′ wooden dowel | 1 PC. |

| 1/2′ wooden dowel | 1 PC. |

| Epoxy resin | 1 PC. |

| 1/4' plywood | 1 PC. |

| Wood glue | 1 PC. |

We need tools:

So let's get started!

Step 1: Make a PCB. To do this, download the board design. Then print it out and etch it onto the copper board using the toner-to-board transfer method. With the toner transfer method, you print a mirror image of the board design with a conventional laser printer, and then transfer the pattern onto the copper cladding with an iron. During the etching stage, the toner acts as a mask, keeping the copper tracks, while like the rest copper dissolves in chemical bath.

Step 2: Will fill the board with transistors and electrolytic capacitors . Start by soldering 6 NPN transistors. Pay attention to the orientation of the collector, emitter and base legs of the transistors. The base leg (B) is almost always in the middle. Next add two 220μF electrolytic capacitors.

Step 2.2. Add 2 electrolytic capacitors

Step 2.2. Add 2 electrolytic capacitors Step 3: Fill the board with polyester capacitors and resistors. Now we need to add 5 0.1μF polyester capacitors in the places shown below. Next, add 5 0.01μF capacitors. These capacitors are not polarized and can be soldered onto the board with the pins pointing in any direction. Next, add 6 resistors of 10 kΩ (brown, black, orange, gold).

Step 3.2. Add 5 0.01μF Capacitors

Step 3.2. Add 5 0.01μF Capacitors  Step 3.3. Add 6 resistors 10 kOhm

Step 3.3. Add 6 resistors 10 kOhm Step 4: We continue to fill the electrical board with elements. Now we need to add one 2.2 mΩ resistor (red, red, green, gold) and two 39 kΩ resistors (orange, white, orange, gold). And then solder the last 1 kΩ resistor (brown, black, red, gold). Next, add pairs of wires for power (red/black), audio output (green/green), reference coil (black/black), and detector coil (yellow/yellow).

Step 4.1. Add 3 resistors (one for 2 mΩ and two for 39 kΩ)

Step 4.1. Add 3 resistors (one for 2 mΩ and two for 39 kΩ)  Step 4.2. Add 1 1 kΩ resistor (far right)

Step 4.2. Add 1 1 kΩ resistor (far right)  Step 4.3. Adding wires

Step 4.3. Adding wires Step 5: We wind the coils on the coil. The next step is winding turns on 2 coils, which are part of the LC generator circuit. The first is the reference coil. I used wire 0.4mm in diameter for this. Cut off a piece of dowel (about 13 mm in diameter and 50 mm in length).

Drill three holes in the dowel to pass the wires through: one lengthwise through the middle of the dowel, and two perpendicularly at each end.

Slowly and carefully wind as many turns of wire as you can around the dowel in one layer. Leave 3-4 mm of bare wood at each end. Resist the temptation to "twist" the wire - this is the most intuitive way to wind, but it's the wrong way. You must rotate the dowel and pull the wire along with you. Thus, he winds the wire around himself.

Pull each end of the wire through the perpendicular holes in the dowel, and then one of them through the slotted hole. Secure the wire with tape once you're done. Finally, use sandpaper to remove the coating on the two open ends of the spool.

Step 6: We make a receiving (search) coil. It is necessary to cut the spool holder from 6-7mm plywood. Using the same wire 0.4 mm in diameter, wind 10 turns around the groove. My reel has a diameter of 152mm. Using a 6-7 mm wooden peg, attach the handle to the holder. Do not use a metal bolt (or something similar) for this - otherwise the metal detector will constantly detect treasure for you. Again, using sandpaper, remove the coating from the ends of the wire.

Step 6.1. Cut out the spool holder

Step 6.1. Cut out the spool holder  Step 6.2 We wind 10 turns around the groove with a wire 0.4 mm in diameter

Step 6.2 We wind 10 turns around the groove with a wire 0.4 mm in diameter

Step 7: Setting up the reference coil. Now we need to tune the frequency of the reference coil in our circuit to 100 kHz. For this I used an oscilloscope. You can also use a multimeter with a frequency counter for these purposes. Start by connecting the coil to the circuit. Next, turn on the power. Connect the probe from an oscilloscope or multimeter to both ends of the coil and measure its frequency. It must be less than 100 kHz. You can, if necessary, shorten the coil - this will reduce its inductance and increase the frequency. Then new and new dimensions. Once I got below 100kHz, my coil was 31mm long.

Metal detector on a transformer with Ш-shaped plates

The simplest metal detector circuit. We will need: a transformer with W-shaped plates, a 4.5 V battery, a resistor, a transistor, a capacitor, headphones. Leave only the W-shaped plates in the transformer. Wind 1000 turns of the first winding, and after the first 500 turns make a tap with PEL-0.1 wire. Wind the second winding 200 turns with PEL-0.2 wire.

Attach the transformer to the end of the rod. Seal it from water ingress. Turn on and close to the ground. Since the magnetic circuit is not closed, when approaching the metal, the parameters of our circuit will change, and the tone of the signal will change in the headphones.

A simple scheme on common elements. You need transistors of the K315B or K3102 series, resistors, capacitors, headphones, a battery. The ratings are shown in the diagram.

Video: How to make a metal detector (metal detector) with your own hands

A master oscillator with a frequency of 100 Hz is assembled on the first transistor, and a search oscillator with the same frequency is assembled on the second. As a search coil, I took an old plastic bucket with a diameter of 250 mm, cut it off and wound a copper wire with a cross section of 0.4 mm2 with 50 turns. I placed the assembled circuit in a small box, sealed it and fixed everything on the bar with adhesive tape.

Scheme with two generators of the same frequency. There is no signal in standby mode. If a metal object appears in the field of the coil, then the frequency of one of the generators changes and sound appears in the headphones. The device is quite versatile and has good sensitivity.

A simple scheme on simple elements. You need a microcircuit, capacitors, resistors, headphones, power supply. It is advisable to first assemble the L2 coil, as shown in the photo:

A master oscillator with an L1 coil is assembled on one element of the microcircuit, and the L2 coil is used in the search oscillator circuit. When metal objects enter the sensitivity zone, the frequency of the search circuit changes and the sound in the headphones changes. With the knob of the capacitor C6, you can rebuild unnecessary noise. A 9V battery is used as a battery.

In conclusion, I can say that every person who is familiar with the basics of electrical engineering and has enough patience to complete the work he has begun can assemble the device.

Principle of operation

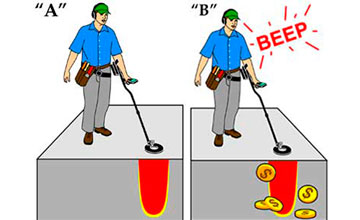

So, a metal detector is an electronic device, where there is a primary sensor and a secondary device. The role of the primary sensor is performed, as a rule, by a coil with a wound wire. The work of the metal detector is based on the principle of changing the electromagnetic field of the sensor with any metal object.

The electromagnetic field created by the metal detector sensor causes eddy currents in such objects. These currents cause their own electromagnetic field, which changes the field created by our device. The secondary device of the metal detector registers these signals and signals us about the discovery of a metal object.

The simplest metal detectors change the sound of the signaling device when a desired object is detected. More modern and expensive samples are equipped with a microprocessor and a liquid crystal display. The most advanced firms equip their models with two sensors, which allows you to search more efficiently.

Metal detectors can be divided into several categories:

- public devices;

- middle class devices;

- devices for professionals.

The first category includes the cheapest models with a minimum set of functions, but their price is very attractive. The most popular brands in Russia: IMPERIAL - 500A, FISHER 1212-X, CLASSIC I SL. Devices of this segment use the “receiver-transmitter” scheme, operating at an ultra-low frequency and require constant movement of the search sensor.

The second category, these are more expensive units, have several interchangeable sensors and several control knobs. They can work in different modes. The most common models: FISHER 1225-X, FISHER 1235-X, GOLDEN SABER II, CLASSIC III SL.

Photo: general view of a typical metal detector

Photo: general view of a typical metal detector All other devices should be classified as professional. They are equipped with a microprocessor, can work in dynamic and static modes. Allow to determine the composition of the metal (object) and the depth of its occurrence. Settings can be automatic, or you can adjust them manually.

To assemble a homemade metal detector, you need to prepare several items in advance: a sensor (a coil with a wound wire), a holding rod, an electronic control unit. The sensitivity of our device depends on its quality and size. The bar-holder is selected according to the height of the person so that it is convenient to work. All structural elements are fixed on it.

Among amateur radio designs, developments that help detect metal objects hidden in the ground are of particular interest. Especially if the latter are small in size, lie at a considerable depth and are, moreover, non-ferromagnets.

Good-quality electrical circuits of such devices, called metal detectors by analogy with well-known military developments, and descriptions of fully functional designs have been published in various technical

Editions, but they are often designed for trained, experienced do-it-yourselfers who have a good material base, scarce parts.

But the design we propose can be completely repeated, made even by a beginner. Moreover, the necessary parts (including a 1 MHz quartz resonator) will be quite affordable to purchase. Well, as for the sensitivity of the assembled metal detector... It can be judged at least by the fact that with the help of the proposed device it is easy to find, for example, a copper coin with a diameter of 20 mm and a thickness of 1.5 mm at a depth of 0.9 m.

Operating principle

It is based on comparing two frequencies. One of them is standard, and the other is changing. Moreover, its deviations depend on the appearance of metal objects in the field of a highly sensitive search coil. In modern metal detectors, to which the design under consideration can be quite reasonably attributed, the reference generator operates at a frequency that differs by an order of magnitude from that which occurs in the field of the search coil. In our case, the reference generator (see circuit diagram) is implemented on two logic elements ZI-NOT integrated DD2. Its frequency is stabilized and is determined by a ZQ1 quartz resonator (1 MHz). The generator with a variable frequency is made on the first two elements of the IC DD1. The oscillatory circuit here is formed by the search coil L1, capacitors C2 and C3, as well as the varicap VD1. And for tuning to a frequency of 100 kHz, the potentiometer R2 is used, which sets the required voltage to the varicap VD1.

Fig.1. Schematic diagram of a highly sensitive homemade metal detector.

As buffer signal amplifiers, logic elements DD1.3 and DD2.3 are used, working on a mixer DD1.4. The indicator is a high-resistance telephone capsule BF1. And the capacitor C10 is used as a shunt for the high-frequency component coming from the mixer.

The printed circuit board configuration is shown in the corresponding illustration. And the layout of the radio elements on the side opposite to the printed conductors is given here in a different color.

Fig.2. The printed circuit board of a homemade metal detector, indicating the location of the elements.

The metal detector is powered by a 9 V DC source. And since high stabilization is not required here, a Krona battery is used. Capacitors C8 and C9 successfully work as a filter.

The search coil requires special precision and attention in manufacturing. It is wound on a vinyl tube with an outer diameter of 15 mm and an inner diameter of 10 mm, bent in the shape of a circle 0 200 mm. The coil contains 100 turns of PEV-0.27 wire. When the winding is done, it is wrapped with aluminum foil to create an electrostatic shield (reducing the effect of capacitance between the coil and ground). It is important to prevent electrical contact between the winding wire and the sharp edges of the foil. In particular, “twisting obliquely” will help here. And to protect the aluminum coating itself from mechanical damage, the coil is additionally wrapped with an insulating bandage tape.

The diameter of the coil may be different. But the smaller it is, the higher the sensitivity of the entire device, but the search area for hidden metal objects narrows. With an increase in the diameter of the coil, the effect is reversed.

Work with a metal detector as follows. Having placed the search coil in close proximity to the earth's surface, tune the generator with potentiometer R2. And so that the sound is not heard in the telephone capsule. When the coil moves above the surface of the earth (almost close to the latter), the cherished place is found - by the appearance of sound in the telephone capsule.

When using the device discussed above to find objects hidden in the ground of archaeological and national cultural value, prior permission is required from the relevant authorities.

Attention!!! The information contained on this page was added from unverified sources, may be out of date and contain errors. Therefore, it is provided for informational purposes only.

N. Kochetov, based on the materials of "Mlad Constructor"

The dream of finding a treasure is increasingly being replaced in our time by a more realistic program for searching for precious metals in a natural or artificial environment.

In modern conditions it is very important to find and extract valuable materials, turned out to be among the waste, or in another uncontrolled environment.

Hardware is an important component of such a search technology.

The search and extraction of gold and valuable metals from waste, garbage, in a natural setting is part of the recycling strategy, the technology for the efficient processing of used materials, including.

Searching for them in the ground or in a mass of industrial and other wastes not only requires the use of equipment, but also stimulates its improvement. Are being created devices of different levels and specializations. There is an interest in such equipment among amateurs and enthusiasts in the search for valuable metals.

A metal detector is the most important tool for manually searching for metals in a chaotic natural or artificial environment.

A metal detector is the most important tool for manually searching for metals in a chaotic natural or artificial environment.

With the help of such a device, you can search not only, but also, silver, and other precious metals.

Device principle any metal detector based on electromagnetic effects.

Here is how a typical metal detecting technology works:

- device creates an electromagnetic field.

- Metal an object, secretly located in a foreign environment, affects such a field when falls within his sphere of influence..

- device captures the effect of the object on the electromagnetic field and signals it.

Most metal detector models work on this principle.

Technical differences of such equipment allow obtaining more complete information about the fact of detection of a metal object, for example:

- estimate the mass of the find;

- get data about the shape, size and configuration of the object;

- specify the location, including depth.

There is a lot of information on the Web about metal detectors of varying complexity and design. There you can brush up on the electromagnetic field theory, studied at school.

The simplest, primitive metal detectors (usually these are self-made designs for searching for gold, silver and other metals by amateur enthusiasts) assembled from finished devices and products working with the use of electromagnetic effects.

Many are familiar with the primitive, but quite workable metal detector circuit, in which the electromagnetic field creates a pulsed element of a conventional calculator.

reaction created field on the detected metal objects picks up the simplest household radio. The signal about such a find is audible, quite distinct and understandable.

reaction created field on the detected metal objects picks up the simplest household radio. The signal about such a find is audible, quite distinct and understandable.

More complex amateur and professional metal detecting devices preserve the logical basis of technology in the form of three components:

- electromagnetic field generator;

- a sensor for changes in this field;

- equipment for evaluating detected anomalies, signaling this.

Devices of different levels of complexity and functional potential can be conditionally divided into groups. Classification based on professionalism and specialization of users - one of the generally recognized:

- amateur equipment assembled by oneself and used as a hobby tool or by beginners in the search for metals;

- semi-professional equipment necessary for enthusiastic amateurs and fanatics;

- professional metal detectors for permanent workers in this field;

- special devices for metal searchers in difficult conditions - at depth, under water, with the release of precious metals.

The distribution of search equipment is such that many devices of this type can be purchased at garden and country equipment stores.

An apparatus for searching and detecting metal is needed not only in the recycling business, in the search for artifacts and treasures. Numerous security systems, all well-known frames - one of the versions of the technology metal search. The settings of these frames are focused on the search for weapons and similar dangerous items.

Coil

Very important node metal search equipment - coil or frame. This is most often a winding of a special configuration, the task of which is to form an electromagnetic field and catch its reaction to the detection of a metal body foreign to the search environment.

In most designs the coil is placed on a long rod– a handle to move it near the search area.

For amateur manufacturing of coils, frames of the most popular types are sold. The easiest way to make such a purchase is in an online store.

Many lovers make coil frames yourself. This is done for reasons of cost savings or in the hope of obtaining a higher quality instrument of the author's design.

Many lovers make coil frames yourself. This is done for reasons of cost savings or in the hope of obtaining a higher quality instrument of the author's design.

For this, improvised means are used.- plastic products, plywood and even filling the assembled winding with mounting construction foam.

The search operator or treasure hunter seeks to find the most effective technique for working with a metal detector, choosing the right electronics operating modes and the correct methods of manipulating the coil.

Electronic circuit

The logical element of the metal detector is an electronic circuit. She performs many functions:

- The first task of this component is in creating an electromagnetic signal of the desired format, which is converted into a field by means of a coil.

- The second task of the electronic circuit is analysis of field changes caught by the frame, their processing.

- The third task is giving an informing signal to the operator- sound, light, readings of indicators and instruments.

It is best if a person who wants to assemble an electronic circuit independently has knowledge of amateur radio or electronic technology. Such a master can not only assemble the desired circuit, but also change and improve the design.

Many electronic devices are quite simple, even a beginner can assemble them. The resulting device will be operational without configuration if the assembler exactly followed the recommendations of the developer of such a scheme.

How to make "Pirate" yourself?

One of the most popular models of metal detectors designed for DIY amateur production is the Pirate.

One of the most popular models of metal detectors designed for DIY amateur production is the Pirate.

Abbreviated for his device and developer's website, this name wittily captures the romance of finding precious metals.

Here main advantages of this model:

- simplicity of device and assembly;

- low cost of parts and materials;

- sufficient operating parameters;

- recognized convenience for beginners.

The electronic circuit of this model does not require programming. In "Pirate" parts available to everyone are used, correctly assembled circuit is fully functional.

Design and principle of operation

The design scheme and layout of the "Pirate" metal detector is traditional for equipment of this kind. It is a rod, at the lower end of which is installed coil, and at the top - electronic unit with battery.

The location of the electronic unit should leave room for convenient holding of the rod by hand.

Some masters prefer that the sound signal of the device is given not by a speaker, but by headphones. In this case, the headphone cable leaves the electronic unit.

The technology of the device is pulsed. This makes it possible to provide very good sensitivity indicators for this class of equipment. Below is a diagram of an electronic unit on microcircuits.

A similar circuit can be assembled using transistors instead of microcircuits. This version may require additional settings available only to experienced radio masters. That is why the transistor circuit is used less frequently.

Materials, parts and blanks

In addition to the details and precisely indicated on the circuit diagram of the electronic unit, for assembly metal detector for gold and other metals you need to prepare some materials and blanks:

- a ready-made board for assembling an electronic circuit or foil material for its self-production;

- power source in the form of any combination of accumulators or batteries with a total voltage of 12V;

- enamel wire with a cross section of 0.5 - 0.6 mm for the manufacture of a coil;

- stranded copper wire for connections with a cross section of at least 0.75 sq. mm;

- housing for the electronic unit - a plastic container of a suitable size;

- Sufficiently strong plastic pipe for the rod;

- frame for winding the coil;

- consumables - solder, heat-shrinkable cambric, electrical tape, screws and self-tapping screws, adhesives and sealants.

A printed circuit board for assembling an electronic circuit is best done according to the model of developments presented on the Internet.

Below is one of these samples suitable for the assembly of electronics on microcircuits.

Fans of home-made electronics are engaged in the manufacture of the board, and even then not all. Most people who want to create a metal detector on their own prefer to buy such a part.

For coil assembly frame or frame required containing no metallic elements. An amateur craftsman can make such a frame from plywood, plastic, or pick up a similar one in terms of parameters from finished plastic products, for example, dishes. The frame can be purchased ready-made or made independently.

Recommended coil parameters- 25 turns of enamel wire with a diameter of 0.5 mm along a mandrel with a diameter of 190-200 mm. Increasing the diameter by 30% will lead to an increase in the sensitivity of the device, provided that the number of turns is reduced to 20-21.

A plastic frame for a coil is one of the most common metal detector parts on sale.

The coil manipulation technology is such that this very fragile assembly can suffer from impacts on uneven ground, stones, and sharp objects. To avoid this the coil on the frame is covered from below with a plastic plate. Such a dish not only protects the coil, but also provides a sliding mode on tall grass. The search becomes more intense.

Assembly order and design

For a successful metal detector assembly it is best to follow this procedure:

For a successful metal detector assembly it is best to follow this procedure:

- PCB manufacturing and electronic circuit assembly;

- selection of a suitable plastic container for it and completion of the assembly of the electronic unit;

- coil manufacturing;

- manufacturing a conveniently shaped rod and attaching an electronic unit and coil to it, making connections to the electronic circuit.

Although the order of assembly is not fundamental. For those who manufacture an apparatus for continuous long-term work in the field of non-ferrous metal search and subsequent recycling (recycling for reuse), ease of use is an important factor.

In this case, the study of the shape of the rod and the layout of the main elements of the apparatus becomes a key factor. Thus, a serious design phase appears in the creation of the device.

The best way to do this step is to use life size simulation. Such modeling can be done using wooden parts of a suitable shape, for example:

- shank for a shovel;

- plywood pieces of the desired shape;

- scraps from;

- temporary fasteners from pieces of wire, nails and ropes.

After making sure that the assembled model of the device will be functional and convenient enough, you can proceed to the final assembly. Finished apparatus, usually, does not require configuration, it is completely ready to work. You can start searching for metal by choosing the desired level of sensitivity and the correct tactics for manipulating the coil.

Assemblers who need to assemble their apparatus as quickly as possible, can use ready-made kits.

Assemblers who need to assemble their apparatus as quickly as possible, can use ready-made kits.

The purchase of such a kit allows you to greatly simplify the manufacture of "Pirate". There is one of the proposals.

Users of the Pirate metal detector, who have skills in amateur radio, modify the design of this device. That's just several directions such improvements:

- Manufacturing coils with unusual parameters- by size, from special materials, for example - twisted-pair cable.

- The device of additional functional systems, for example - indication of the degree of discharge of the battery.

- Manufacturing underwater models.

- Add-ons electronic circuit, to distinguish between metals(creating a discrimination function).

A simple, inexpensive and reliable metal detector "Pirate" works properly in a variety of conditions.

Homemade metal detector - pros and cons

Cheapness, base advantage self-manufacturing of any products is relevant for a metal detector. Here are some more dignity on a homemade device:

- the most relevant search technology for beginners;

- the possibility of creating a device of a completely individual shape, design and configuration;

- the pleasure of making an efficient, workable device on your own.

Like any device made by an amateur, a metal detector not without some shortcomings.

Here are the features of the Pirate model that users note:

Here are the features of the Pirate model that users note:

- vigorous charge consumption batteries;

- no discrimination, that is, accurate sensitivity to ferrous, non-ferrous and precious metals;

- limited compared to expensive models sensitivity.

Despite the shortcomings, the Pirate model is very popular. This is due to the simplicity of home-made manufacturing and the high performance of an inexpensive device.

Recycling professionals believe that the discrimination capabilities of a metal detector are not of great importance. All found metals are so valuable that their processing is always justified. Orientation to the search for gold requires not only equipment, but also considerable experience, accompanying knowledge and of course Good luck.

Related videos

The video provides a detailed guide to the manufacture and assembly of the Pirate metal detector with your own hands:

Conclusion

When the metal detector is ready, you can start working. You need to be aware that not a single most advanced apparatus will allow you to find only golden hidden objects.

A metal detector will help you find valuable metal, and it is very likely that it will be gold. It is best if the future metal and gold prospector has a real understanding of the search technique.

Many features of the operation of finished equipment are very important for those who develop and assemble their own models. You need to have an idea about the technology of work in advance with such equipment - this is the basis of its high-quality design.

The effectiveness of the search for gold increases with experience. Here the most important elements such experience:

- the right choice of metal detector design and its high-quality do-it-yourself manufacturing;

- the ability to correctly select the search site;

- the ability to use the full potential of the metal detector;

- choosing the right search technology in different conditions;

- metal detector upgrade.

Properly assembled and debugged equipment will always help in the search for gold, and this valuable metal will definitely be found.

In contact with

Device search is just huge popularity. Looking for adults and children, and amateurs and professionals. They are looking for treasures, coins, lost things and buried scrap metal. And the main search tool is metal detector.

There is a great variety of different metal detectors for every “taste and color”. But for many people, buying a ready-made branded metal detector is simply financially expensive. And someone wants to assemble a metal detector with their own hands, and someone even builds their own small business on assembling them.

Homemade metal detectors

In this section of our site about homemade metal detectors, will be collected: best metal detector circuits, their descriptions, programs and other data for manufacturing DIY metal detector. There are no metal detector circuits from the USSR and circuits on two transistors here. Since such metal detectors are only suitable for a visual demonstration of the principles of metal detection, they are not at all suitable for real use.

All metal detectors in this section will be quite technologically advanced. They will have good search characteristics. And a well-assembled home-made metal detector will be a little inferior to factory counterparts. Basically, there are different schemes. pulse metal detectors And metal detector circuits with metal discrimination.

But for the manufacture of these metal detectors, you will need not only desire, but also certain skills and abilities. We tried to break down the schemes of the given metal detectors according to the level of complexity.

In addition to the basic data required to assemble a metal detector, there will also be information on the required minimum level of knowledge and equipment for self-manufacturing of a metal detector.

To assemble a metal detector with your own hands, you will definitely need:

This list will provide the necessary tools, materials and equipment for self-assembly of all metal detectors without exception. For many circuits, you will also need various additional equipment and materials, here are just the basic ones for all circuits.

- Soldering iron, solder, tin and other soldering accessories.

- Screwdrivers, pliers, wire cutters and other tools.

- Materials and skills for the manufacture of printed circuit boards.

- Minimum experience and knowledge in electronics and electrical engineering as well.

- As well as straight arms - they will be very useful when assembling a metal detector with your own hands.

Here you can find schemes for self-assembly of the following models of metal detectors:

|

Principle of operation | IB |

| Metal Discrimination | There is | |

| Maximum search depth | ||

| There is | ||

| Operating frequency | 4 - 17 kHz | |

| Difficulty level | Average | |

|

Principle of operation | IB |

| Metal Discrimination | There is | |

| Maximum search depth | 1-1.5 meters (Depends on coil size) | |

| Programmable microcontrollers | There is | |

| Operating frequency | 4 - 16 kHz | |

| Difficulty level | Average | |

|

Principle of operation | IB |

| Metal Discrimination | There is | |

| Maximum search depth | 1 - 2 meters (Depends on the size of the coil) | |

| Programmable microcontrollers | There is | |

| Operating frequency | 4.5 - 19.5 kHz | |

| Difficulty level | High | |