When you decide to make renovations in your own apartment or house, sooner or later it comes to replacing the doors. In order to do this correctly, the master must have some experience in performing such work, since it requires care and precision at all stages of dismantling and installation.

It is natural that special attention should be paid to the finishing of door slopes and openings. Depends on how high quality the doorway is finished MDF panels, the visual perception of the door and the repair as a whole will depend.

Types of slopes and rules for installing doors

Slopes can be divided into external and internal, according to their location relative to the room. The final stage in the door installation work is finishing the door slopes. The main thing is to solve two main problems in this process: thermal insulation and aesthetic. It is also important to choose the right building material, which will be used for installing doors and mounting slopes.

The issue of choosing a work technology remains important. If you make the right decision, the doors will last for many years and will perform all the necessary functions. Without experience, it is difficult to make slopes with your own hands, but if you strictly follow all the recommendations, the result will not disappoint you, you can see an example in the photo.

Installation of slopes

Rules that will allow you to produce quality products installation work on the formation of slopes on the doorway:

- The slopes should preferably be placed 1.5-2 cm lower than the level of the box;

- the distance from one external slope to another must exceed the distance between two internal slopes;

- In order to install doors correctly and make smooth slopes, you need to accurately measure the dimensions of the doorway.

Various finishes

Today you can use one of the types of finishing of openings or slopes MDF doors DIY panels. The easiest way is to glue a pre-made slope to the door frame. You can see what it looks like in the photo. To create it, MDF panels are used. Naturally, this will significantly reduce the time spent on finishing work and will also facilitate the efforts made. You can even do this work yourself.

The advantage of MDF panels, which are made from compressed wood waste, is that they are not afraid of temperature changes and humidity fluctuations.

If you are looking for additional items from MDF decorative character, the shade of the color of the door leaf must be taken into account.

Central heating in the house involves predominantly “dry” finishing technology. For optimal thermal insulation and increased sound insulation capabilities, the box must be caulked. The joints that remain between the wall and the frame are traditionally sealed with a special solution. The panels used to cover the slopes are fixed using mastic. It is recommended to then paint the outside of the slopes; preference should be given to oil paint.

In houses where it is installed stove heating, predominantly use wet plaster (photo). The solution that is prepared for finishing work will include different components depending on the building material from which the walls are made, the level of moisture content in the air, etc. The main requirement will be that the plaster adheres tightly and reliably to the wall surface.

Metal doors require their own specific actions when installing slopes and finishing work. For slopes in this case it is better to use a cement-sand composition. If the slopes are wooden, then they are filled polyurethane foam. The negative aspect of this option is its reduced insulating properties.

Advantages of different finishing methods

The main criterion when choosing the finish of a doorway, slopes, etc. is the location of the door itself. If installation work is carried out on interior doors, then there is no need to enhance the thermal insulation properties; the main thing is the aesthetic characteristics of the door and finishing work.

Finishing entrance door slopes with MDF panels, on the contrary, requires increased strength, increased protection from temperature effects and increased soundproofing properties. You can see samples of them in these photos. More often, several materials are used for these purposes.

Some of the most popular ones are plaster and MDF panels. This is the most best option, which will provide protection from cold and extraneous sounds, while guaranteeing reliability and safety of external data for a long time even during active use

Do-it-yourself combined MDF panels

- The first step is to get rid of the gaps that have formed between the wall and the door structure. For these purposes, polyurethane foam is preferably chosen. When the cracks are filled with foam, you need to wait a little while it hardens, then use a mounting knife to cut off the excess and smooth out the unevenness as much as possible.

- After this, the installation surface is treated with a primer, this further increases the “adhesion” between the plaster mortar and the wall.

- It is better to apply plaster along beacons, which are metal profiles attached to the wall with dowels. Then the application will be as even and smooth as possible. Plaster is prepared from the following components: cement, sand, lime mortar.

- If you need to save time and are not afraid of additional expenses, then purchase ready-made putty, which is suitable for facade work. External corners are reinforced mounting profile, which is gently pressed into the uncured solution. The last stage is the finishing coat.

- Now you can start finishing using MDF panels. The cement-lime composition serves as the basis for the slopes. When it dries, the surface is thoroughly treated with a primer solution.

- Next, 2 side parts and 1 top part are cut out of the MDF panel. The glue is applied to the upper part of the surface of the slope and the MDF part can be pressed against it. It must be held tightly until it is completely stuck with glue.

- The 2 side panels are glued in the same way. To further ensure secure fixation, you can use spacers. It is recommended to seal the gaps that have formed between the wall and the MDF panels using a decorative plastic corner and glue them with “liquid nails”. When you cut MDF panels, you need to carefully measure all the corners to avoid mismatches during installation work.

- The doors are finished with MDF panels.

You can also view photo and video materials about the technology of finishing doors with MDF panels.

Installing a new door is a joyful event for every owner. However, the work is not limited to just installing the box and the canvas - in the end, it is necessary to design the slopes so that the structure looks beautiful and organic.

Of course, you can invite a specialist to carry out this activity. However, does it make sense to overpay for the services of a third-party master, if such a simple job can be done on your own?

For the design of slopes ( - article), materials such as plaster, polyvinyl chloride-based panels, plasterboard and MDF panels are most often used. Study the presented guides, select the design option that suits your case and get to work.

First step. Seal all gaps between the base and the door frame with foam. Allow the foam to harden and carefully trim off any excess blow-in with a sharp knife. Carefully smooth out any uneven surfaces using sandpaper.

Second step. Start surface treatment for future finishing elements. Apply a coat of primer to ensure better adhesion of the plaster to the surface.

The primer usually has to be applied in several layers. Focus on the situation - as a result, you need to get a perfectly flat and smooth surface. New Layer Start applying primers only after the previous leveling layer has completely dried.

Third step. Proceed with plastering. Buy ready-made facade plaster or prepare the solution yourself from a lime mixture, clean fine sand and cement.

Start plastering from the top door slope. Apply the mixture in a thick layer. Level and remove excess putty using a wooden lath.

To further strengthen the outer corners, install perforated corner profile. It needs to be pressed a little into the still wet plaster mixture.

Allow the starting coat to dry completely and apply a finishing coat of plaster mixture. It should be more subtle. The main task of this layer is to level out minor irregularities. Wait for the finishing plaster to dry completely. Simple door slopes are ready.

Plastering is the most budget option design of slopes. Whether to give preference to this method or choose some other finishing method - each owner has the right to decide independently.

Video - Door slopes

Beautiful and inexpensive slopes can be made from plastic panels. First, the frame is prepared, and then the finishing is done.

Frame

For the frame, prepare a beam with a cross-section of 2x4 cm. They will be attached to the frame plastic panels.

Cut the timber into pieces according to the dimensions of the future slopes. Fix 4 perpendicular strips on each wall part of the doorway. Attach 3 strips to the top. Use nails to secure the elements.

Side elements

Finishing panels should be slightly wider than the surfaces being decorated with them. The finishing elements will need to be bent so that they beautifully “beat” the corners.

The plastic panels have a hollow structure at the end. Voids of regular shape are present along the length of the elements. To give the panel the required shape, make appropriate cuts along the mentioned voids. An ordinary stationery knife will help you with this.

If desired, even the columns can be finished with plastic panels, so there will definitely not be any problems with finishing the corners of the slopes. The joints will be barely noticeable.

Make the cuts exclusively on the back side of the finishing elements.

Attach the cut modules to the frame. For fixation, you can use self-tapping screws or small nails. Fix the bent elements to the wall surface. Work in this order:

- determine the border of the finishing element;

- make five holes in the wall so that in the future they will be covered by the edge of the panel;

- drive wooden plugs into the prepared recesses;

- screw the panel to the wooden plugs using self-tapping screws (nail).

- Install all panels according to this algorithm.

Excellent door slopes can be made from plasterboard.

Video - Installation of a plasterboard slope on entrance doors, part 1

Video - Installation of a plasterboard slope on entrance doors, part 2

First step. Drill holes around the entire perimeter of the opening at a distance of about 200 mm. Hammer the dowels into the holes and screw the screws into the dowels, not tightening the ends a little.

Second step. Determine the appropriate dimensions for the starting guide rail. To do this, you need to measure three sides of the opening. Cut the guide according to your measurements.

You can make the upper guide according to the width of the opening, since in the future the side sheets will rest against the upper slope. You can make the side guides a little shorter.

Third step. Screw the starter rail to the wall using self-tapping screws. The long side should be placed outside the door slope, and the short side should be placed inside.

Fourth step. Mark strips of the required size on a sheet of drywall. Cut the drywall according to the markings.

It is very important to follow the cutting technology. Otherwise, the cut edges will be unsightly.

To cut, attach some long, flat object to the marking line, for example, a piece of a fastening profile. Cut through the top layer of paper. By carefully tapping the cut strip on the back of the sheet, break through the plaster, and then cut through the second layer of paper.

Fifth step. Prepare the adhesive mixture. Follow the instructions specifically for your adhesive.

Sixth step. Apply a uniform adhesive mixture to the back of the drywall strips. You also need to coat the pre-installed dowels with glue.

Seventh step. Proceed directly to finishing. Place the edge of the strip into the starting guide. Align the trim piece and then press it into the base. Secure the side slopes in the same way. Remove excess glue immediately, otherwise it will lead to deformation of the drywall in the future.

The slopes must be supported with spacers while the glue dries.

You can fill the gaps between the base and the drywall with removed excess glue.

Give the slopes 12-24 hours to dry and you can begin finishing: puttying, painting or other finishing of your choice.

Such slopes will serve for many years without any complaints.

Beautiful door slopes can be made from MDF.

First step. Prepare the basis for future door slopes. To do this, treat the base with a simple lime-cement mixture. Let the mixture dry and apply a primer over it.

Second step. Cut the MDF into three slopes of the required sizes. Before you start cutting, carefully measure the joining angles of the sides of the opening. Next, you need to cut the ends of the trim pieces according to the measured angles.

Before you begin installing the panels, make sure the joints are correct. To do this, attach the elements to be connected to each other. Try not to have any gaps - they will ruin appearance finishing.

Third step. Apply the required amount of adhesive mixture to the top of the doorway. Press the corresponding trim element onto the glue and support it until the glue dries completely. Fix the side elements in the same way.

For maximum quality fixation of the elements, place spacers between them.

Hide the gaps between the base and the fixed slopes using plastic corners. To attach the corners, use liquid nails or other suitable glue.

Try to select panels for making slopes whose appearance would be as close as possible to the appearance of the door leaf. This finish will look as complete and beautiful as possible.

Thus, a wide variety of materials can be used to arrange door slopes. Select suitable option, follow the instructions given, and you will be able to cope with the tasks as well as any specialist.

Good luck!

Video - Do-it-yourself door slopes

If the width of the slope does not exceed 20-25 cm, the laminated panel can be installed using liquid nails and polyurethane foam. The method requires a minimum of time, and the result is good.

Preparing the slope elements

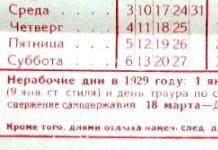

Laminate door slopes consist of three parts: two side parts and one top part. If the slopes are made at an angle, then one edge of the sidewalls will be beveled.

This is what the “pattern” for a slope made of MDF or laminated chipboard looks like:

Measure the distances from door jamb to the corner in several places, cut off the strip to the required width and height. The cut out sides should be a couple of centimeters higher than the required length - just in case they missed the dimensions. You can cut it off, but you can’t build it up.

You try on the sides, insert the top. If the edge is flush with the main wall, and the gaps are near door frame minimal - everything is done correctly. If there are mistakes, we correct them.

After cutting off the parts, try them on on the spot.

Then the outer edge of the chipboard or MDF is trimmed - a trim film is glued on: you do not nail the platbands to the very edge, so that some part will be visible. That's why it needs to be decorated. You can do without trimming if you trim the edge with a matching decorative corner. But it is made of plastic, and how good it will look is the question.

Applying the trim film is easy. She is on adhesive based. Only the edge must be smooth and clean - free from dust and dirt. Glue the trim strip evenly onto it, then take a dry cotton fabric that does not fade, and iron the end through it with an iron (at medium power). Then it sticks tightly, but all the irregularities are visible, so saw off evenly.

If you can choose a plastic corner to match, it looks good, and there is less work: it is glued with liquid nails or silicone

If a telescopic platband is used at the final stage of finishing the slope, a groove is made under it using a milling cutter in the laminated end. The width is exactly for the tenon of the platband, the depth is a little more than required so that it “fits” well. For a regular MDF trim, you don’t need anything. It simply sticks onto liquid nails.

Installation of slopes

Having completed all the preparations, we begin to install MDF slopes ( laminated chipboard). The end facing the door is coated with liquid nails. It is better to take a transparent composition - it will not be visible. The jamb to which the MDF is glued is degreased. Having pressed the sidewall, it is placed in the desired position, checking the verticality and maintaining the same indentation. Then peel it off and wait until the glue dries a little. After 5-7 minutes, the fragment is installed in place, checking the position relative to the walls.

The second side panel is installed in the same way, and then upper part. The top expands additionally: spacer wedges are installed above the place where it joins the sidewalls. This will prevent the trim from bending and additionally “pinches” the sidewalls.

Having installed all parts of the MDF slope, place wedges at the top

Fixation

After the wedges are inserted, check whether everything is aligned correctly and evenly. If everything is fine, take the foam and place “patches” in the gap between the panel and the wall - apply a small amount of foam in islands. They should be full depth, but not wide. There is no need to fill the entire volume: a lot of foam will be required, and it may bend. Therefore, make islands.

After polymerization of the applied foam, the slope fragments are held rigidly. Now you can start filling the empty space. It is also more convenient to seal it with foam, but not to the full depth, but only in front.

The procedure for fixing slopes made of laminated fiberboard

After the foam has hardened, its excess is cut off with a knife. You can start finishing.

Installation of platbands

This part of the work is carried out in a standard way: first, one side panel is measured and cut, then the top one, then the second side panel. After trying on everything folded and checking the accuracy of the joining, the platbands are installed on foam or liquid nails - depending on the situation.

Alternative methods for installing plasterboard slopes

Installing a plasterboard slope on a window

Installing a plasterboard slope on a window

You can bring the slopes into perfect evenness using drywall. The plasterboard material is selected to be moisture-resistant, since fogging of windows and condensation will quickly destroy the gypsum material. Regular sheets of drywall are used, but then a primer is used, as well as protective agents and paint. In some cases, a window block with profiles on the sides is used, which is the basis of the entire slope.

For installation, a profile is used, which is installed on the window frame, resulting in a frame. The profile must be coated with acrylic sealant, and then the window must be covered. The space between the wall and the plasterboard material is filled insulating materials. Next, everything is fixed with self-tapping screws. You can also glue drywall with glue. The mixture is applied to the drywall, after which it is pressed against the wall and held for several seconds, everything is set to the level.

Important! It is convenient to use a metal frame if severe deformation occurred during window replacement and the design cannot be corrected in any other way. Installation is carried out using self-tapping screws directly to the profile, the cracks must be sealed with polyurethane sealant

Next, a primer is applied, plaster and putty are applied in 2-3 layers. After drying, everything should be painted with colored or white paint. It is recommended to cover the slope angle using a decorative corner.

The surface can be designed in any way you like, desired interior. They also make arches on the window or a standard U-shaped window slope.

Installation of PVC slopes (video)

How to choose a finishing method

Cladding can be done in different ways. The standard method includes attaching a ready-made slope directly to the box itself. In this case, there is a great saving of time, since it is not necessary to make the slopes for the entrance doors themselves.

There is a finishing option using plasterboard or plaster. This method is considered no less popular, however, not everyone can carry out such finishing, since this requires some knowledge in the construction field.

In order to decide on the method, you need to know the type installed box. If door slopes are installed on interior design, insulation in this case is not required. Here, the best option would be cladding with decorative materials.

As for entrance doors, they require more careful and attentive work. Here, the best option would be MDF panels (fibreboard). Their popularity is quite high, since this material is not affected by temperature and dampness. The color of the panels in this case is selected in accordance with the color of the door itself. TO high-quality finishing This includes the combined use of MDF with plaster.

Why do you need window treatments?

The interior decoration of plastic windows carries not only decorative function, but also protective. The installation seam must be reliably protected from the influences exerted on it so that the window system as a whole functions correctly: the glass does not fog up or freeze, and condensation does not accumulate on the slopes.

The installation seam on the outside must also be reliably protected from the effects of precipitation, wind and sun rays, under the influence of which expanded polystyrene is destroyed. You can effectively protect it by installing metal slopes and trims on plastic windows for exterior finishing, which will give the window a neat, finished look.

For the interior decoration of a window opening in a house, different types of material are used. This could be decorative plaster, do-it-yourself installation of PVC panels or drywall on the slopes of plastic windows. The decoration of internal slopes with decorative looks impressive artificial stone. To understand which of these methods is better, it is worth considering each of them separately.

Why laminate

The use of slopes was previously used to strengthen the doorway, but today it has become more of a decorative part, which is why laminate is used. So why laminate and not another type of material.

Laminated slope

Laminated slope

First, let's look at the features of laminate to understand why this material is often used for decorating slopes.

The laminate is a four-layer lamella. The base of the lamella is MDF, impregnated with resins and having a protective layer on each side. On the front side of the lamellas, under a protective film, there is paper with a pattern that imitates the surface of a stone or the texture of wood. Therefore, laminate is popular due to the variety of shapes and structures.

These statements are supported by the following characteristics of the laminate:

- affordable price. Laminate is also popular because of its affordable price, and since the slopes do not require the use of high-strength lamellas, you won’t have to spend money like you would on flooring.

- aesthetics. As already mentioned, the lamella can imitate wood or stone. In addition, it has many colors and shades, thanks to which you can choose the material both for a certain material and for the design of the room.

- easy installation. The panels are easy to install. Locking mechanisms are used to connect two lamellas, so that the joints are smooth and there are no gaps between them.

- wear resistance. Laminate endures abrasion and other loads, and when used for finishing slopes, it does not experience such effects, so it will last a long time.

- lasting. Capable of withstanding heavy weight and impact.

- moisture resistance. Regarding this indicator, we can say that it depends on the class of the material, but even low-quality laminates can withstand exposure to moisture.

Against the background of these positive properties laminate we can say that this material is beneficial for decorating slopes.

Opening design options

The opening after installing a metal door looks unpresentable and requires finishing work.

The most common types of decoration are:

- plastering the opening with ordinary cement mortar;

- forming edges using drywall sheets;

- finishing doorways MDF panels;

- plastic linings;

- wooden extensions;

- an opening trimmed with decorative stone.

The most common are considered plastering work on the design of openings.

These elements have their own characteristics that need to be taken into account when choosing an installation option.

Entrance door slopes must meet the following requirements:

- should serve as a beautiful detail that matches not only the entrance area, but also the entire interior;

- must have good thermal insulation properties, preventing cold air from entering the apartment;

- must be strong enough not to be accidentally broken;

- Such a characteristic as resistance to scratches and mechanical stress is also valued, because they often cling to the slopes and touch them with objects brought in and out through the door.

Plaster

The plaster solution is applied in several stages and rubbed in well.

The most labor-intensive option is considered to be plastering the opening with cement mortar. But it also has its advantages. Such slopes are monolithic and completely cut off the possibility of cold air penetrating through them.

The plastering process is carried out in several stages and can take 3-4 days, since it is necessary to wait for the previous one to dry before applying the next layer. After finishing the plastering, you can paint the surface or stick any material on it.

Important. If you already have metal doors installed with MDF finishing, then take care of their safety during the plastering work

Drywall

The photo shows the process of applying glue to the back side of drywall blanks.

This option is used quite often when there is no time or desire to do plastering work.

There are two options for working with plasterboard sheets:

- glue installation;

- installation on guides.

For doorways, adhesive installation is more often used. Special glue is diluted thickly and distributed in cakes in the form of beacons across back side plasterboard blanks. The strips are then glued into place, leveling is done by pressing the sheets until the glue dries.

Important. The disadvantage of this method is that there is free space under the plasterboard strips, and the plasterboard can be accidentally punctured during operation.

The process of finishing MDF door slopes consists of several stages:

- Preparation and insulation of the opening.

- Plastering.

- Preparation of MDF fragments for finishing.

- Installation of panels.

- Installation of platbands.

Preparation and insulation of the doorway

The initial stage of arranging a doorway consists of from door preparation and the entire adjacent space for finishing work.

To do this you need:

- remove from the door all elements that will interfere with installation (handles, chains, locks);

- cover thoroughly plastic film door leaf and adjacent walls (in case there is no general repairs). You can lay out sheets of cardboard on the floor so as not to damage its surface;

- clean slopes of dirt, dust and old plaster. The surface can be treated with a primer (antiseptic impregnation);

- Use polyurethane foam to treat the gaps between the door frame and the opening (to improve thermal and sound insulation). Upon completion of work, excess foam will need to be cut off with a sharp knife;

- styling electrical wires(cable) for installing lighting above the door opening.

To prevent the cold from outside from penetrating into the room, along the door slope lay a layer of insulation from:

- mineral wool;

- isolona;

- polyurethane foam;

- padding polyester;

- foamed polystyrene.

It is also possible to spray insulation, which will cost more.

Plastering slopes

To facilitate further cladding, as well as to eliminate remaining gaps, you should carefully plaster the slopes. Applying a small amount of plaster on them will be sufficient, and it is not necessary that the surface be plastered perfectly evenly. At the corners of the slopes you need to install special profiles that will not only help make them even, but also strengthen the corner segments.

Preparation of MDF fragments for slopes

Before finishing the opening slopes with facing panels, it is necessary to take measurements and then cut the material into fragments of the required size. In order to take measurements correctly, you will need:

- roulette;

- square;

- templates for creating patterns.

- Correct “cutting” of the material suggests that you need to start with the strip that will be secured first.

- When marking, you will definitely have to take into account that the edges of the corners of the door slope have a certain angle of inclination.

- All subsequent panels prepared for installation will be installed after the initial one has already been secured.

- When starting to work with the side panels, be sure to take into account the presence of a threshold (to ensure free movement of the door).

- It is best to cut the material with an electric jigsaw. Its cutting element allows you to get an even cut, without burrs or chips.

Panel installation

Installation of facing material is performed in the following order:

- Panels that do not have a locking connection are attached to the frame. It is constructed from aluminum profiles or wooden planks (the more preferable option).

- Determining the level of finishing placement. First of all, you need to take into account the thickness of the panels, because their protruding edges can interfere with the free movement of the door leaf.

- Fastening the frame to the wall with bolts (the wooden plank is attached directly to the door frame using a drill).

- Installation of MDF panels on the frame. First, the top crossbar is fixed to the frame, then they begin to finish the side parts of the slopes, while the protruding excess parts of the panel are cut off. It is quite possible to reverse the order of installation of the panels, i.e. start with finishing the sides of the door slopes.

The cladding can be nailed to wooden planks using small nails without heads or glue with liquid nails .

To complete the finishing, the protruding foam is cleaned off with a painting knife. If necessary, it will need to be puttied to prevent destructive effects. external factors(temperature and humidity). At the same time, the new door slopes must remain clean, and therefore they will have to be carefully covered with masking tape.

Installation of platbands

The doorway becomes ideal in appearance after the final finishing stage. This includes:

- installation of platbands (they are installed in the upper part of the door opening);

- masking material joints on door slopes. The nail heads are carefully covered with mastic, matched to the tone of the finishing material (for this you can use furniture stickers).

The simple technology of covering door slopes with MDF panels will especially appeal to those who try to carry out repair work with their own hands.

Why should you choose laminated slopes for PVC windows?

Plastic is the basis of modern double-glazed windows. For this reason, plastic finishing of openings looks most harmonious and appropriate. PVC panels are manufactured both in standard white color and, after applying a special laminating film, in the most various shades. Laminated slopes for wood-effect windows are especially in demand, completely imitating the color and texture of natural wood.

The undoubted advantages of sandwich panels are:

- Reliability and practicality. Slopes made of plaster, plasterboard or natural wood, subject to conditions high humidity, may crack, delaminate, grow mold or mildew. All components of PVC panels are resistant to moisture and microorganisms, so the flawless appearance of the windows is maintained for a long time;

- Tightness and sound insulation;

- Resistance to ultraviolet radiation, moisture, low temperatures and mechanical damage. Thanks to this, laminated slopes can be installed both indoors and outdoors. A window opening decorated in this way on both sides looks simply luxurious;

- Easy to install and cost effective.

Main types of finishing panels

Various types of panel material can be used to finish window slopes.

MDF products

This option is not so common, but has its own characteristics:

- MDF slopes require more careful finishing. Due to the fact that the window opening is located on walls that are in contact with the street, there is a high probability of moisture penetration through cracks and crevices. Therefore, there is a need to completely seal the surface and assembly seams.

- MDF has a specific material size that limits its use in some areas. Although there are wide options, they have a narrow selection of textures and colors.

- Plastic windows are not always compatible with such products. Difficult to pick required option, which would look good against the background of white plastic.

- MDF looks most successful on doorways or balcony blocks.

Finishing window slopes with MDF panels

Finishing window slopes with MDF panels

In reality, such material will great solution m, if you think about it correctly overall design premises. The combination that imitates a cut of natural wood looks especially advantageous.

Plastic wall panels

Plastic panels for slopes are the most popular option and are used everywhere. There are many factors that contribute to this:

- Cheap material. These products have a lower price than other options. Naturally, you should beware of purchasing panels that are unreasonably cheap.

- Easy to install. Installing panels yourself is an event that does not require professional skills or the use of special devices.

- Variety of options. Modern technologies make it possible to produce many variations of textures and colors. This means that the products are excellent for decorating various types of interiors.

Plastic panels are often used for finishing slopes, due to the low cost of the material and ease of installation.

Plastic panels are often used for finishing slopes, due to the low cost of the material and ease of installation.

Of course, there are certain difficulties that arise during work.

- So, if you plan to sheathe areas more than twenty-five centimeters wide, then it is necessary to install additional support points. Otherwise, the coating will literally begin to “walk.”

- We must not forget that it is advisable to perform additional insulation. If you do not do this, then when you come into contact with the surface of the plastic slopes, you will feel cold.

- The material is not very resistant to mechanical damage. It's easy enough to ruin.

Slopes made of PVC panels are rightfully considered the most a good option. After all, even insulation work will not be required special costs.

Slopes made of PVC panels look very impressive, but require additional insulation

Slopes made of PVC panels look very impressive, but require additional insulation

PVC sandwich panels

This option is a type of plastic panels that has better characteristics. Naturally, this component affects the price of the material. Such products have the following features:

- The material consists of two sheets of plastic, between which there is a layer of heat-insulating material. This feature allows you to avoid additional work on slope insulation.

- Installation of the product is carried out without special costs. Naturally, care and accuracy of preliminary calculations are required.

Sandwich panels contribute additional insulation window openings

Sandwich panels contribute additional insulation window openings

It must be borne in mind that the sandwich has one negative feature. So, if the window opening is sealed incorrectly, moisture penetration can cause damage to the material. That is, its delamination will occur.

Of course, there are other panel options for finishing slopes:

- Products made from natural wood. This option is different at a high price and high installation requirements.

- Gypsum-based material lined with PVC.

- Metal options. This is a more exclusive modification that requires special conditions.

Slopes made of natural wood

Thus, there are many options that differ in their technical characteristics, but have practically the same installation technology.

Method two

MDF slope finishing

Installation of panels on the finished surface. Making such slopes is somewhat more difficult, but since cold zones most often form in the area of the front door, this method additionally insulates and insulates the wall.

For such finishing of slopes, you will need a more extensive set of tools and materials, as well as a certain skill in plastering.

Tool

- Rule.

- Spatula or trowel.

- Gun for liquid nails.

Materials

- Plaster mixture.

- Liquid nails.

- Lighthouses, two per slope.

- MDF panels and decorative corners.

Installation

As in the first option, we first prime the wall; this will never be superfluous. Next, we install beacons along which the coating will be leveled. This can be done using liquid nails or alabaster solution.

We cover the space between the beacons and the beacons themselves with a solution of plaster mixture, and remove the excess using the rule to create a flat surface.

Important! The layer of plaster should be approximately 7 mm less than the frame of the front door. This will allow the panel to be installed flush with the frame.

Door slope in the apartment

Now, the plaster needs to be allowed to dry thoroughly and only after that can you proceed to the installation of the panels.

The panels are fastened using liquid nails, which are applied both to the panel itself and to the walls. The panel is pressed tightly against the surface and held in this position for some time, usually only a few minutes.

The slopes are ready, and you can install the corners. The same liquid nails or any other glue capable of connecting the plastic to the paper surface of the panel will do.

Marking and cutting

No less important stage in the process of finishing door slopes than preparation and installation itself is cutting the necessary fragments. In order to take measurements as accurately as possible, one tape measure will not be enough. Use a square and templates to create unique patterns.

You need to start with the bar that you plan to secure first. This is usually the top panel. Please note that in most cases the edges of the slopes are not evenly cut, but run slightly at an angle. All this should be displayed on MDF. Subsequent elements must be applied after installing the initial panel. That is why the process of marking and cutting is combined with installation.

Cutting MDF panels should start from the top strip

You can cut MDF using a hacksaw or saw, but the best option is a jigsaw. Thanks to its cutting element, it is possible to obtain a perfect cut without chips or burrs. Plus, you won't have to put in any effort.

When working with sidewalls, be sure to take into account the presence of a threshold. This important point, as it can significantly affect the height of the side bars

Types of window slopes and their advantages

How to make slopes on windows with your own hands depends on the location of such an opening. The slope can be external, internal and external. When installing the inside of the window, there is no functional role from the design, except for the tightness of the system. The cladding serves to hide the joints between windows and walls. An external slope is necessary to absorb extraneous noise from the street, as well as to preserve heat.

Why do you need slopes on windows?

Why do you need slopes on windows?

The finishing of window slopes inside can be different, based on the material:

- Plastering.

- Wooden.

- Plasterboard.

- Plastic.

- Sandwich panel.

A description of each type with pros and cons is presented in the table:

| View: | Description: |

|---|---|

| Plastering: | The classic way to design a window opening using cement or plaster. Installing a window made of plaster material will take a lot of time, at least a couple of days, due to the duration of drying of the solution at each stage. Working with putty and plaster is labor-intensive and requires certain skills, but you can use it anywhere. The material is the cheapest, after application to the walls, it requires smoothing and painting. |

| Wooden: | Wood is more often used if the window is also made of wood. In this case, the appearance will be exquisite and expensive. For work, it is better to select only high-quality wood species that are well dried and processed. High-quality wood will last over time, just like plastic. The main advantage is environmental friendliness, the disadvantage is cost. |

| Plasterboard: | Installing a slope for a gypsum plasterboard window is simple, better than using putty. Drywall is used if the damage to the window opening is severe and cannot be covered. Used for internal slopes; if desired, insulation can be carried out by filling the space between the wall and drywall. Any material is suitable as insulation, especially mineral wool. Such a slope must be puttied and painted. The disadvantage is that the material swells after a while. |

| Plastic: | Lining is more expensive than drywall, but has many advantages. The plastic slope is easy to install, in just a day, it does not require any maintenance, just rinsing. An ideal frame for a plastic window, since the expansion due to temperature is the same. Used inside and outside, on the facade. The width of the window opening should be up to 25 cm, otherwise additional measures must be taken to fix the material. |

| Sandwich panel: | One of the types of plastic slope. The panels differ from plastic in their layering, because they have three layers. A couple of layers of plastic and insulation between them. Great for installation, no need to use additional materials. The most expensive material for window decoration. |

There are also other materials for slopes, for example, siding or aluminum profiles; such materials are often used to decorate the outer part of the window, from the street. The slope turns out to be voluminous and looks beautiful on the house.

Slopes made of MDF panels

Slopes made of MDF panels

Beautiful door slopes can be made from MDF.

First step. Prepare the basis for future door slopes. To do this, treat the base with a simple lime-cement mixture. Let the mixture dry and apply a primer over it.

Second step. Cut the MDF into three slopes of the required sizes. Before you start cutting, carefully measure the joining angles of the sides of the opening. Next, you need to cut the ends of the trim pieces according to the measured angles.

Slopes made of MDF panels

Before you begin installing the panels, make sure the joints are correct. To do this, attach the elements to be connected to each other. Try to avoid any gaps - they will ruin the appearance of the finish.

Third step. Apply the required amount of adhesive mixture to the top of the doorway. Press the corresponding trim element onto the glue and support it until the glue dries completely. Fix the side elements in the same way.

For maximum quality fixation of the elements, place spacers between them.

Hide the gaps between the base and the fixed slopes using plastic corners. To attach the corners, use liquid nails or other suitable glue.

Try to select panels for making slopes whose appearance would be as close as possible to the appearance of the door leaf. This finish will look as complete and beautiful as possible.

Thus, a wide variety of materials can be used to arrange door slopes. Choose the appropriate option, follow the instructions provided, and you will be able to cope with the tasks as well as any specialist.

Good luck!

Video - Do-it-yourself door slopes

Method one

Slope for MDF doors

Installation on the lathing. For this we need:

- Drill and screwdriver.

- Self-tapping screws and dowels.

- Wooden beam.

- Tape measure and pencil.

- A sharp knife or jigsaw.

- MDF panels and decorative components in the form of corners matching the color.

- Primer for walls and impregnation for wooden beams.

First, we prepare the walls and bars, treating them with impregnations and primer, respectively. Of course, this stage can be skipped, but there is a possibility that moisture, hated by builders, will begin to accumulate under the slopes, which will eventually eat the wood and the panels themselves.

Advice! Before buying a block, you need to measure the distance from the door frame to the wall. You need to subtract 7 mm from this size, this will be the required thickness of the bar. With this installation, the “tenon” of the panel can be placed behind the box, it will look good and there is no need to glue it, an additional corner is needed.

Finishing a door slope in an apartment

On each slope, two bars are enough. They are attached to dowels directly to the wall in increments of about 50 cm. The first beam is adjacent to the door frame, and the second is installed flush with the corner of the wall. The space between the guides can be additionally insulated or filled with foam.

In order to make slopes, you may have to cut the panel lengthwise, the main thing is that it is not narrower than the slope.

The MDF is sawn off to height and attached to the guide bars using self-tapping screws with countersunk heads, which will “sink” into the panel and then be covered with a decorative corner.

Interesting! The second block, flush with the wall, may be thinner than the first. In this case, the panel will go at an angle and create visual extension opening.

MDF panels

Facade option for entrance doors made of MDF.

The benefits that come from finishing a door with MDF panels and designing an opening from them can be felt at the installation stage. The opening does not require preliminary preparation or plastering. The registration process is accelerated, and doing it yourself becomes quite possible.

Interestingly, even with an old metal door that you would not want to replace, it is also possible to decorate the doors with MDF panels yourself. You can choose sheets in the form of door facades and similar sheets to decorate the opening.

Installation of facades

More recently, it was difficult to imagine a different finish for a metal entrance door than upholstering it in leatherette. Today, manufacturers provide us with a wide selection of different materials.

The most interesting of them are products made from MDF. The price of such facades is slightly higher than the price of leatherette, but the result exceeds all expectations. And this applies not only to the appearance of the doors as a result of finishing, but also to their acquisition of excellent performance qualities.

It is not at all difficult to decorate the front door with MDF panels yourself.

You just need to perform the actions in a certain sequence:

- first of all, thoroughly clean the door of the old coating;

- remove the lock and other fittings;

- metal sheets must be treated with products designed to combat corrosion;

- carefully mark and cut out holes for the lock on the MDF panel;

- we attach the panels with glue, securing them in several places with self-tapping screws; we choose the screws of such a length that they do not damage door panel on the reverse side;

- install locks and fittings;

- The finishing of the MDF entrance door from the inside is complete, let's move on to the design of the opening.

Installation of slopes

Opening design diagram.

Before you start sealing the opening with panels, you need to completely seal all the holes and cracks and cut off the excess foam around it.

The sequence of work on finishing the slopes of the front door is described by the following step-by-step instructions:

- We fill wooden guide strips on the edges of the openings according to the level;

- we apply the platband on the outside of the slope and measure the distances to determine the width of the workpiece;

- when measuring the distance, take into account that it will be necessary to install a decorative finishing corner on the edge under the casing;

- Use a jigsaw to cut along the workpiece for the upper slope;

- We fasten the workpiece to the top bar with self-tapping screws;

- proceed in the same way with the side blanks;

- glue a decorative corner along the top and sides of the opening;

- we close the corner with platband;

- in the places where the slopes join the door frame we also glue thin decorative corners;

- small gaps between the slopes themselves can be sealed using a special wood putty.

Advice. To make it easier to complete the opening design work, you can use cardboard templates. Before turning on the jigsaw and sawing off the workpieces, try on cardboard templates on the slopes. And then cut out the parts using them, so you will protect yourself from damage to the material.

In the video presented in this article you will find additional information on this topic.

Installation of entrance door slopes, preparatory stage

Whatever finishing method you choose, the preparatory work will be the same. First you need to protect the door leaf and frame with masking tape, or better yet, cover the entire surface with film. And only then proceed to leveling the base - if separate areas protrude too much, they need to be trimmed down, and also get rid of all loose materials that are held too loosely.

Using a broom or brush with fairly coarse bristles, sweep away dust from all cracks and cracks, thoroughly sweep every centimeter of the base, especially if you decide to finish with mortar - the adhesion strength of the materials depends on this. Next, the surface is primed with deep penetration compounds. However, foam concrete or similar loose material should be primed with a regular surface primer.

At this stage, you can lay the electrical wiring under the switch or provide a through hole for the cable - for this purpose, you can fix it at the very bottom of the baseboard aluminum tube slightly larger in diameter than the diameter of the cable through which it can subsequently be laid. If you plan to make do with forming a frame, then you will have to tinker with the wire after it is created.

Slopes.MOSCOW on Instagram

61 likes

The secret to a warm and beautiful window is proper preparation of the rough surfaces of the opening. See for yourself: I foamed the seams, removed all the unevenness of the blocks so that the gap between the sandwich panels and the blocks was minimal, after installation...

57 likes

How to create a respectable #interior at home or in the office? #Designers advise starting with window decoration. #Laminated slopes in golden oak color will make the decoration look solid and status. Like️ and find out details about the design...

48 likes

Place for indoor flowers or little things that are pleasant to the eye - a beautiful #windowsill. Have you already decided where you will order an integral part of the window structure? @otkosymoskva has a great offer for you! ⠀ Subscribe...

336 likes

LIFE HACK: 4 WAYS TO CARE FOR PLASTIC WINDOW SILLS ⠀ Deadline PVC operation window sill ranges from 25 to 70 years. Agree: impressive numbers! However, this does not mean at all that the canvas does not require care and even your…

Technology for finishing work on slopes

The technological process is similar to the installation of plastic slopes and begins with the installation and screwing of profiles, which are attached to the frame using self-tapping screws.

On preliminary stage the necessary markings are made for the metal frame, so that the upper part of the profile rests on the side frames.

Next, using a construction stapler, the panels are carefully fastened, for which a sufficiently large number of staples are used to ensure reliable fixation due to the flexibility of the material.

In order for the polyurethane foam to adhere better, it is recommended to spray the areas with a little ordinary water from a spray bottle.

After the foam has dried, it is carefully trimmed. At the final stage, the slopes are plastered or painted with a special durable paint.

To decorate finished slopes, you can use corners, which are also made from MDF and are selected in color that best matches the shade of the finishing panels themselves. Typically they are sold in construction stores included with the plates.

This finishing method gives completeness to the work and the aesthetic appearance of the window as a whole. A special colored sealant or silicone is used to treat gaps and cracks.

Types of panels

Today, manufacturers offer the following types of panels.

Whole pressed. The main technical characteristics of this tile material are average strength and smoothness on both sides of the slab. Produced by hot pressing wood material, which is mixed with special binders. Features include reasonable price, attractive appearance and simple installation method.

Laminated. They are manufactured using the same technology as pressed boards, but at the final stage of production they undergo a lamination process. Applying a special protective film allows you to preserve the properties and quality of the material, as well as produce them in a wide range of colors.

Moisture resistant. The main difference from other boards is their increased strength and resistance to moisture, which allows them to be used for finishing window slopes with MDF panels. Produced without adding special chemicals under the influence of temperature to give increased strength to the slabs.

Installation of slopes using the adhesive method

Plastering a door slope

Plastering a door slope

If preference is given to the glue method, then you should familiarize yourself with the tips for installing the front door and MDF slopes. Work algorithm:

- First of all, for the glue method, you need to plaster the slopes .

- It is recommended to treat the prepared surface with a primer. After priming, the surface must be waited until completely dry.

- Install beacon profiles according to level. To install profiles on slopes, apply a solution and level the beacons in all directions. Give the solution time to set.

- The solution is applied to the slopes and leveled along the beacons with a spatula. After the manipulations, the slopes should be left for 2 days until the solution completely sets.

- The inside of the part is coated with glue and pressed to the surface.

- When all the elements are installed, the resulting joints are sealed or covered with overlays.

Important! After completing all the manipulations, you can proceed to the exterior finishing. door design. For this purpose, it is possible to cover the surface with platbands or level the surface using putty

In the vastness of the Runet there are photos, videos and reviews that describe in detail the whole step by step process frame and glue method.

Purpose of slopes

A finished door jamb is necessary to give the doorway a finished look. If new doors are installed, then leaving the old slopes will not be presentable. Therefore, they emphasize the novelty of the doors and redo the slopes with laminate.

The slopes undergo changes when the old door frame is dismantled. The plaster is crumbling, so they are either re-plastered or sealed in some other way. When a new door is inserted, the seams are foamed to seal, so this foam is closed.

The use of plaster to seal the resulting holes does not seem to be decorative and in an effective way. Therefore, the use of laminate has become something of a novelty, which provides many opportunities in choosing the design of the opening.

Finishing slopes with plaster with insulation

Window plastering is different; it is possible to use insulation, or not to use it. The step-by-step process for decorating a window with plaster and insulation is as follows:

- The insulation is being installed, in this case it is better to use polystyrene foam or polystyrene foam. It is glued to an adhesive solution on a primed wall, which is pre-leveled if there is a large flaw. Good insulation should not exceed 1.5 cm in thickness, you need to look in the store when choosing the material.

- The material is fastened with glue or foam. The solution is applied directly to the insulation.

- First, the material is glued to the side walls of the window, after which the upper part is sealed. If the work is carried out outdoors, then you need to start at low tide. If necessary, the joint of materials is foamed.

Plastering external slopes

Plastering external slopes

- Large window openings can be aligned using a similar scheme, but insulating material with fungus is additionally used. For such fastening you need to punch a hole in the wall, through the insulation and install a dowel into the finished hole.

- For the finishing material to serve long time, mesh is used for reinforcement. External corners need to be finished with corners that are glued directly to the putty or other solution.

- The mesh is pressed into the putty and excess material is removed.

- The solution is applied standard method in several stages, usually 2-3 times is enough to level the window.

- At the end, the finishing layer is applied and painting is carried out.

Such a slope will be washable, since paint is applied over the plaster, which protects the window from water.

Advantages of building materials

Finishing a door opening is a labor-intensive process that requires precision and following advice. Therefore, it is possible to make this kind of cladding yourself. Slopes can be finished with panel materials, the variety of which can satisfy any request. Often finishing work is done with plastic, wood panels, plasterboard, but MDF panels are considered the most successful.

Advantages of MDF panels

Advantages of MDF panels

Since this finishing building material has numerous advantages:

- Availability of material.

- Easy to install.

- Aesthetic appearance.

- The density of the material creates additional sound and heat insulation.

- Environmental friendliness. Fiberboard It is made by pressing wood chips under the influence of temperature and pressure. The core binders of the fibrous material use carbide resins, which are harmless to humans. Consequently, MDF is an environmentally friendly building material that can be safely used for cladding both exterior and interior structures.

- The color palette allows you to satisfy any request. You can choose the colors of the panels from wenge to bright shades.

Doorway lined with MDF slopes

Doorway lined with MDF slopes

But like any building material, MDF panels are not without disadvantages:

- Weak resistance to mechanical damage. If the MDF panel is deformed, the damage cannot be restored.

- Does not withstand significant levels of humidity.

Therefore, finishing door slopes with MDF panels should not be done in conditions of high humidity.

DIY entrance door slope made of MDF (video)

Installation of PVC slopes

Attaching the profile to window slopes

Attaching the profile to window slopes

Installing plastic panels for window slopes is quite simple, following the rules for performing the work:

- Initially, you need to make guides, securing them around the perimeter of the window. For this, a starting profile is used, which is mounted on the slope wall. Fastening is carried out with self-tapping screws; they should go quite deep into the wall.

- If the walls are made of brick, then use a drill to drill holes, and then attach the profile with dowels. To make the panel slope level, a level is constantly used during the work.

- Next, the size of the window is taken and transferred to the finishing material. Measurements must be taken accurately so that everything falls into place and the opening is reliable. It is necessary to saw or cut the panel according to the transferred dimensions.

Measuring the window slope

Measuring the window slope

- The cut out elements are tried on in depth. If the opening is deep and the sandwich panel does not fit, then it is trimmed.

- The cracks must be sealed with polyurethane foam or sealant applied if the internal slope has minimal holes.

- After the material has dried, you can complete the window with special decorative elements. A corner is mounted on the joints, due to which each corner of the window will be of the correct shape. Manufacturers make them from plastic and are simply used to mask seams.

- All dirt and dust are removed, foam or sealant is cut off. If the joints are not perfectly smooth, then white sealant is used to seal the imperfections.

- Next, the panel is mounted into the starting profile at the required length, and the space can be filled with insulation. There is no need to finish the window additionally, except to install corners.

Installation of PVC slopes

Installation of PVC slopes

The slope on the balcony from plastic panels is carried out by analogy; the façade slope of windows, attic, interior, if we are talking about the front door, is also made. You can put a platband on the door, choosing it by color or finishing it with other materials.

Photos on the Internet will allow you to get acquainted with the finishing and composite. Each stove has different technical characteristics, depending on the country of manufacture. The Alt-profile company, which produces panels, has a good reputation; reviews about it are only positive, and there is a large selection, you can even buy matte material. Finally, you can watch a video tutorial on how to assemble a plastic window assembly:

Finishing slopes with panels

Finishing of slopes is carried out using several methods, each of which is used for panel materials.

The following set of tools is required:

- Spatula.

- Level.

- Drill.

- Construction pistol.

- Construction knife.

There may be some differences depending on the cladding option.

Method one - cladding using profiles

This method allows you to complete the work most quickly. The technology consists in initially installing profiles that will serve as the basis for installing the material. General procedure the work is as follows:

- The starting profile is attached. This is done directly along the edge window frame. Fixation is carried out using self-tapping screws.

Attaching the starting profile

- On the other edge of the window - mounted wooden slats, which form a complete contour.

- A panel prepared to size is installed. It is inserted into the profile and secured to a wooden strip.

- Next, an F-profile is used, which acts as a platband.

This technology allows work to be done very quickly. But it must be taken into account that it is additionally required to provide for the laying of the resulting voids.

Method two - gluing

The option is to glue the material onto the slopes. For this, special glue or polyurethane foam is used. The instructions are as follows:

- The window needs to be well prepared. Excess foam is removed. The surface is puttied and leveled.

- Each area is measured. The facing product is cut.

- Each element is coated with glue (spray foam is applied). For some time, the fragment is pressed to the surface and torn off. After a couple of minutes, final fixation is carried out.

- The internal corners are coated with sealant, and the external corners are closed with a plastic corner.

Installation of window slopes with glue

Installation of window slopes with glue

This method is convenient for installing PVC slopes. There are other finishing variations, but they require more time-consuming work.

Advantages and disadvantages of the material

- This is a simple procedure that requires only a certain accuracy and compliance with some nuances. Different materials can be used in the work, but MDF panels are considered the most successful. Their popularity is due to numerous advantages:

- Availability. Indeed, it exists now great variety of these products that are affordable. You can purchase all the necessary components for them.

- Easy to install. Naturally, if you have no experience, then any finishing work may seem complicated. But once you practice a little and understand the essence, the work will seem quite easy.

- Great looks. There is a certain rule, which is that all elements must be combined with each other. Therefore, the slopes on the front door must be made of suitable products. MDF will be an excellent solution in such a situation.

- Additional sound and heat insulation. This is an important point that many initially do not take into account.

- Safety. The panels are completely environmentally friendly.

MDF panels allow you to create spectacular decorative coating and insulate slopes

MDF panels allow you to create spectacular decorative coating and insulate slopes

We must not forget that there are no completely ideal materials. Therefore, the disadvantages should also be taken into account:

- Average resistance to damage. This product perfectly withstands various impacts due to its high density, but is very unstable to scratches, as well as other similar impacts.

- MDF is a bad option for rooms that have high humidity.

- Sometimes difficulties arise with the selection of additional elements. The fact is that overhead MDF corners, which have a limited decorative range, can be used for finishing. Therefore, you should think through the overall design in advance.

Note! Many people mistakenly confuse finishing MDF doorways with installing extensions on door frames. These are completely different procedures in technology. It should be taken into account that extensions are excellent for narrow (up to 11-12 cm) and straight openings that are found in interior structures.

Covering entrance door slopes with MDF panels

Covering entrance door slopes with MDF panels

Samples of films for lamination RENOLIT STANDARD

| PVC profile lamination color | Image | Catalog number |

|---|---|---|

| Dark brown - 851805 |  |

RENOLIT 851805 |

| Bog oak – 2052089 |  |

RENOLIT 2052089 |

| Mahogany - 2065021 |  |

RENOLIT 2065021 |

| Mahogany KBE - 2097013 |  |

RENOLIT 2097013 |

| Golden nut - 2178007 |  |

RENOLIT 2178007 |

| Rustic oak – 3149008 |  |

RENOLIT 3149008 |

| Light oak – 2052090 |  |

RENOLIT 2052090 |

| Mountain pine – 3069041 |  |

RENOLIT 3069041 |

| Golden Oak - 2178001 |  |

RENOLIT 2178001 |

| Striped Douglas - 3152009 |  |

RENOLIT 3152009 |

| Oregon - 1192001 |  |

RENOLIT 1192001 |

| Natural oak – 3118076 |  |

RENOLIT 3118076 |

| Light red - 305405 |  |

RENOLIT 305405 |

| Green moss – 600505 |  |

RENOLIT 600505 |

| Emerald green - 611005 |  |

RENOLIT 611005 |

| Dark blue - 515005 |  |

RENOLIT 515005 |

| Blue – 503005 |  |

RENOLIT 503005 |

| Gray - 715505 |  |

RENOLIT 715505 |

All we use decorative films and coatings have passed the necessary quality certification.

Do you want stylish windows your dream? Finishing wood-look slopes with laminated sandwich panels according to German quality standards!

Features of installation work

We prepare the surface

We prepare the surface

Now, if you have a prepared hand, you can start making the slats yourself and fixing them on your window. Then you can follow the given diagram or watch video or photo instructions from experienced finishers on the Internet.

- From the panel you need to cut 2 vertical parts and 1 horizontal.

- The prepared parts are applied to the window opening to carry out trimming, which is carried out strictly along the window.

- Then liquid nails are applied to the back of the panel and the material is fixed to the wooden frame.

- After this, you need to adjust the panel as much as possible so that the gaps disappear or become minimal.

- It also wouldn’t hurt to further strengthen the fixation of the panels with self-tapping screws, which can be hidden in drilled recesses and buried with caps to match the panel.

- All gaps are filled with putty to match the panels or colorless sealant.

As can be seen from the instructions given, the work is labor-intensive. But, despite the complexity of installation, it is possible to master the technique.

Stages of sealing slopes with MDF panels

When everything is ready, you can begin installation. The work is carried out in the following stages:

- It all starts from the top bar. First, foam patches are applied to the wall at the top of the opening. Their diameter is 5-8 cm, and their height depends on the distance of the wall from the beginning of the dimensions of the box. Ideally, you need to make a slope for an MDF entrance door so that the panel is flush with the frame or even slightly lower.

- The cut overlay is placed in place on the desired height. There will be a gap between it and the wall. It is tied up with masking tape and then the position is adjusted according to the level. The bar is supported from below with a T-shaped wooden spacer.

- Now you can put the nose of the gun inward and give more foam for better fixation, but you must act carefully so as not to squeeze the material out.

- Using the same principle, the side panels are installed on tubercles with foam, only they will need to be pushed apart with pieces of timber tied with tape to the box in order to eliminate the curved shape of the MDF.

After closing the inner wall of the opening, you need to create a beautiful transition to outside. For this, a second set of cut strips 7 cm wide is used. But before fixing, you will need to cut the end of the panel at 45 degrees to get the correct joint with the top jumper. For such cutting, measure 7 cm in length from the edge and draw a solid line to the corner, along which the cut is made. This is done on the right and left panels in a mirror image. The trimmed edge is sanded for a neat look, but you should not overlap the outer surface too much, so as not to remove the decorative layer.

The panels are mounted on mounting foam and secured with masking tape to the wall and door leaf. At the bottom, their length extends to the plinth, if it already exists, or to the floor itself, and the plinth extends from the overlay. Installation of MDF slopes on the front door ends with a sticker plastic corner with a 15 mm shelf at the corner of the wall around the perimeter, which is permitted only after the foam holding the main structure has dried and the tape has been removed. The color of the element covering the joint is selected identical to MDF, which will look holistic and beautiful.

The online store “The Right Choice” offers not only to correctly install metal door, but also to seal the slopes with MDF panels, which will completely relieve the owners from the final finishing work. Installation of extensions starts from 800 rubles. and available large selection by color and thickness of panels. It is possible to install an entire portal. It is convenient to find out deadlines and finishing options through feedback.

Finishing the door slope with MDF panels

To finish door slopes with MDF panels you will not need special tools or special efforts. The following stages of work are distinguished:

- surface preparation;

- insulation of the opening;

- plastering of slopes;

- marking and cutting MDF;

- installation of panels;

- installation of platbands.

Everything can be done with your own hands. To do this you will need the following tools and materials:

- spatula;

- hammer;

- dowels;

- self-tapping screws;

- drill;

- screwdriver;

- ruler and pencil;

- plumb line;

- building level;

- polyurethane foam;

- cement mortar;

- wooden slats.

Preparation and insulation of the doorway

At the preparation stage, the surface is cleaned of dirt and dust, all protruding objects are removed, and cracks and crevices are sealed. If there is major damage, the coating must be removed to the base. When making slopes for entrance doors, you should be careful not to damage the wires, which are often run near the door.

If the old coating is being dismantled, the surface is plastered. For this, a cement-sand mixture is used. They proceed to the next stage only after the solution has completely hardened. Lay on top heat insulating material. This completes the preparation of the opening for installation of slopes.

Plastering slopes

If the old coating has not been removed, the surface should be leveled and slopes made at the required angle. It is necessary to do the work efficiently, because otherwise drafts may occur in the room, heat loss may occur, etc. For this, a cement-sand mixture is made. Level the surface using a wooden strip or rule.

Preparation of MDF fragments for slopes

First, take all dimensions and transfer them to paper. Based on the received data, each slope element is marked. The following should be taken into account:

- presence or absence of a threshold;

- in what order are the parts arranged?

- opening width and angles of inclination.

Panel installation

Now you can begin installing the panels. This can be done in two ways. When the opening width is small and solid parts are attached, the fragments are fixed with glue. Often used materials in this case are liquid nails and polyurethane foam. When the sheathing needs to be joined, a sheathing is installed. Each element is attached to it using self-tapping screws.

The second option is inconvenient because it requires hammering into the wall wooden blocks. This creates additional stress and destroys the surface. Therefore, it is better to choose MDF in sheets, since fragments of any size can be cut.

Installation of platbands

After installing the slopes, they proceed to the installation of platbands. They are the final and easiest stage of the work. The easiest way to attach trim is with flat head nails. This way you can achieve high quality fixation, and if necessary, you can also easily dismantle all elements.

Nails about 4 cm long are driven in every 40-45 cm. Holes of the appropriate diameter are pre-drilled so as not to damage the material.

Installation of panels

In order to install door slopes into the opening with your own hands, you need to complete several stages of work:

- First you need to decide on the mounting method. If the panels do not have a locking connection, the easiest way is to secure them to the frame. As a last resort you can use aluminum profiles or wooden planks, which is more preferable.

- Determine the level at which the trim will be placed. In this case, it is important to take into account the thickness of the panels themselves, since if the material protrudes excessively in the opening, the movement of the door leaf may be difficult.

- The frame is fixed to the wall using bolts. You will also need a drill for this. From the inside, you can attach the strip to the door frame itself. There is also an alternative to a wooden frame - special guides that are installed at the corners of the opening. This option is suitable for installing L-shaped panels.

- After the frame is fixed, MDF panels are applied to it and all excess is cut off. You can first secure the top crossbar and then proceed to the sides, or do the opposite. MDF can be glued to wooden planks using liquid nails or nailed. In the latter case, small nails without heads are used.

Examples of finishing entrance door slopes with MDF panels

In order to eliminate drafts, additionally insulate slopes and provide stronger adhesion, polyurethane foam is used

It is important not to smear the MDF during the foaming process, as it will not be easy to clean.

Plaster slopes for metal-plastic windows

Plastering slopes is inexpensive; the method is old and considered standard. Today there are a lot of putties and any composition can be used. The materials are prepared in water according to the proportions indicated on the package, after which the mixture will be ready. Gypsum mixtures can be replaced with cement-sand mortar.

Before starting work, you need to treat the window area, remove dirt and dust, excess concrete and foam. Additionally, the seams in the corners are enlarged so that the putty adheres better to the wall. Initially, you need to plaster the wall, and only then proceed to the slope.